Called as Nodular Iron.

In this alloy, as the Graphite nodules are separate & unconnected, the metallic

Matrix dictates the properties that are achievable. This material has good

Machinability & some amount of Vibration Dampening properties because

of presence of Graphite

It’s properties have been discussed ( in Ferrous Foundry Practice )

Compacted Graphitic iron. In Grey Iron ,the flakes of Graphite have Sharp

Edges & as there is absolutely NO connection between Metal & Graphite, it is

As good as hole being present (INCOHERENCY). These sharp edges act as

stress raisers leading to premature Fracture propagation.

In case C,G iron, sharp edges are ABSENT, as a result C.G. Irons do show

some amount of ductility.

An undertreated S.G. Iron or faded S.G .Iron would behave like C.G. Iron.

CARBON EQUIVALENT ( C.E.) = % C + 0.31 x % Si + 0.33 x %P +

0.05 x % Ni + 0.075 x % Cu—0.06 x % Cr –0.03 x % Mn --0.1 x % V

--0.11 x % Mo

C.E. value tells you as to how far are you from 4.3.

There is another problem which we need to understand.

Let us take an alloy with 1.2 % C & 12 % Cr.

C.E. = 1.2 % ( C)—0.06 x 12% Cr

= 1.2 –0.72 = 0.48. THIS MUST BE DEFENITELY STEEL.

BUT IT IS A CAST IRON.

THIS IS BECAUSE Cr IS A FERRITE STABILIZER. So IT SHRINKS

AUSTENITIC AREA. So Our idea of up to 2.0 C.E is STEEL does not hold

good any more.

Cast iron starts at a C level much lesser than 2.0.( if Ferrite stabilizers are

present. Except Ni, Mn, N all alloying elements are Ferrite stabilizers )

This is not a hearsay, but my practical Experience.

In Grey cast iron, the type of Graphite present decides the properties that can be

103

Achieved.

The Graphite, can be in several forms.

1) Type “ A “ Graphite flake ( Normal & desirable )

2)Type “ B “ Graphite flake ( Rosette )

3) Type “ C “ Graphite flake—which occurs in Hypereutectic Grey Irons.

4) Type “ D “ Graphite flake—Under cooled

5) Type “ E “ Graphite flake – inter dendritic

In a Good Grey Iron casting, only “ A “ type Graphite is preferred .It gives the

Best of Properties. Type A Graphite is achieved by Good Inoculation.

Alloy Cast Irons:

Austenitic Irons:

1) Corrosion Resistance--- Ni- Resist type.

2) Low Expansion ---Minover type.

3) Non Magnetic--------- No-mag type.

4) High temperature Resistance—Nicrosilal type.

1) Corrosion Resistance type of cast iron has a composition of :

% C 2.2 to 3.0.

% Si 1.0 to 4.0.

% Mn 0.4 to 1.5

% Ni 13.00 to 32.00

% Cr 1.0 to 4.5.

2) Low Expansion Type:

All though normal Austenitic Steels & Cast Irons have a Coefficient of

Thermal Expansion of 18 x 10 -6 per degree, a group of High Nickel

Irons with 35 to 36 % Ni have a Thermal Expansion varying from

4 to 8 x 10 -6 per degree.

3) Non magnetic cast irons :

% C 3.5

% Si 2.2

% Mn 5.0

% Ni 10 to 11

These alloys have a Ms temperature of --166 degrees.

4)High Temperature Resistance cast irons have a composition of

% C 1.6 to 2.2

%Si 4.0 to 4.5

%Mn 0.6 to 1.2

% Ni 18 to 22

% Cr 2.0 to 4.0

104

These alloys retain high strength & oxidation resistance up to 900 degrees.

Martensitic White Cast irons:

1) %C 2.7 to 2.9

%Si 0.3 to 0.6

% Mn 0.6 to 0.9

% Ni 4.0 to 6.0

% Cr 8.0 to 10.00

As cast Hardness could vary from 320 to 550 BHN depending on section

thickness .These alloys are Heat treated at 1040 to 1070 degrees for a period of

One Hour per Inch ( 25 mm), air cooled & Stress relieved at 200 to 240 degrees.

This will give hardness of 600 BHN.

2) % C 2.5 to 3.0

% Si 0.8 to 1.5

% Mn 1.5 to 3.0

% Cr 15 to 28

% Ni 1.5 to 3.0

% Mo 0.2 to 0.8

3) % C 2.9 to 3.1

% Mn 0.65 to 0.85

% Si 0.55 to 0.75

% Cr 19 to 21

% Ni 0.9 to 1.10

% Mo 1.60 to 1.75

4) %C 1.25 to 1.35

%Mn 0.50 to 0.70

%Si 0.40 to 0.60

%Cr 11.5 to 12.00

% Mo 0.45 to 0.55

High Silicon Cast Irons:

These are Acid Resistant Cast Irons.

% C 0.35 to 1.0

% Si 14 to 15

% Mn 1.0 max

These alloys have very low strength ,highly brittle & highly prone to cracking.

A special care is taken while making these castings.

As soon as the liquid metal has solidified, mould is broken, feeders, gates,

runners& sprue are knocked out while the castings are still bright red in colour.

Immediately the castings are put in a furnace whose temperature is about 850

105

Degrees. Castings are allowed to cool to room temperature over a period of

30 to 40 hrs.

This material is very hard. Hence the machining allowance is minimal.

Machining should be done with special carbide tips or grind it.

While transporting the casting in a TRUCK, extra care is taken to see that

Castings do not experience any jolt. So a bed of hay ( dry grass) is spread on the

Truck & castings are so placed in such a way that one casting does not even hit

An other casting while the truck is in motion ( like carrying damageable fruits

in a truck)

IS STANDARDS FOR FERROUS CASTINGS.

Iron Castings:

210

Grey Iron Castings.

1865

S.G. Iron Castings.

4729

Austenitic Iron Castings.

4771

Abrasion Resistant Iron Castings.

5788

S.G. Iron Castings, for Pressure containing

parts suitable for elevated temperature

5789

Austenitic S.G. Iron castings, for Pressure

containing parts suitable for low

temperature applications

6331

Automotive Grey iron castings.

Steel Castings :

276 Austenitic Manganese Steel Castings.

1030 Steel Castings for General engineering

purposes.

2644 High Tensile Steel Castings.

Carbon Steel Castings for Surface

2707 Hardening.

2708 1.5 % Mn Steel Castings.

2856 Carbon Steel Castings suitable for High

temperature service.

3038 Alloy Steel Castings for Pressure containing

parts suitable for high temperature service

106

3444 Corrosion Resistant Steel Castings.

4522 Heat Resistant Alloy Steel Castings.

4898 Steel Casting For Case Carburizing.

3896 Comparison of Indian & Overseas Standards

for Iron Castings.

4331 Comparison of Indian & Overseas

Standards For Steel Castings.

ASTM Steel Casting Specification :

Carbon & low alloy Steels:

A27

Mild to Medium Strength-Steel Castings for General Application.

A148 High Strength Steel Castings.

A216 Carbon Steel Castings For Fusion Welding For High-Temperature

Services.

A217 Alloy Steel Castings For Pressure Containing Parts Suitable For

High Temperature Services.

A352 Ferritic Steel Castings For Pressure containing parts Suitable For

Low Temperature Services.

A389 Alloy Steel Castings Specially Heat Treated For Pressure

Containing Parts

High Alloy Steel Castings:

A128 A 128--- Austenitic Manganese Steel Castings.

A296 A 296---Corrosion Resistant Iron-Chromium and Iron-Chromium-

Nickel Alloy Castings ( Stainless Steel Castings CA-15,CF-8,CF-8M

etc )

A297 A 297---Heat-Resistant Iron-Chromium and Iron-Chromium-Nickel

Alloy Castings ( HA, HF etc )

Here there is a problem lurking in the corner, i.e. IS 2644 & ASTM A-148

Alloys are HIGH STRENGTH STEEL CASTINGS , But their Composition

is Left to YOUR choice (excepting S & P)

A word of advice, even if you get the similar Mechanical Properties in Wrought

Steels, you can NEVER get the Properties sought by A-148 at the S & P levels

mentioned.

For instance, ASTM A-148-1965, wants 124 Kg / mm2( UTS ), 102 Kg / mm2

(YS), % E 0f 6.0, % RA of 12 ( All Minimum Values ) at a Specified S 0f

107

0.06% max & P of 0.05 max. You will not get these values, if you operate

at a S of 0.059 % & a P of 0.049 %. Ensure that you operate at a S of 0.030 %

& a P of 0.03 %.

REMEMBER THAT % S & % P ARE ENEMIES OF % E , % RA &

IMPACT STRENGTH IN STEELS.

SO OPERATE AT AS LOW A S & P VALUE AS POSSIBLE.

An attempt is made to give you the nearest composition which will satisfy

both IS-2644 & ASTM A-148.

IS-2644.

UTS YS %E %RA BHN

(MPa) (MPa)

Min Min Min Min Min

640 390 15 35 190

700 580 14 30 207

840 700 12 28 248

1030 850 8 20 305

1230 1000 5 12 355

ASTM A-148

UTS YS %E %RA BHN

(MPa) (MPa)

Min Min Min Min Min

550 276 18 35 160

550 345 22 35 160

620 415 20 35 180

725 590 17 35 210

830 660 14 30 240

1035 870 9 22 300

1210 1000 6 12 350

The values of ASTM A-148 have been converted to MPa.

The values given under are extracted from STEEL CASTINGS HAND

BOOK.

1) % C-0.25, % Mn- 1.37, % Si- 0.51-------Normalizing.

UTS-662 MPa,YS-448 MPa, %E-25, %RA- 49, BHN-192.

2) %C-0.28, %Mn- 1.43, %Si- 0.49-----Water Quench & Temper at 430 degree

Celsius.

UTS-897 MPa, YS-760 MPa, %E- 20, %RA -41, BHN-260.

108

3) %C- 0.34, %Mn -1.28, % Si-0.25-------Water Quench & Temper at 530

degree Celsius.

UTS- 1040 MPa, YS-945 MPa, %E-12.5, %RA-23,BHN-300.

4) %C -0.40, %Ni- 0.63, %Cr- 0.70, %Mo- 0.26—Water Quench & Temper at

480 degree Celsius.

UTS-1300 MPa, YS-1035 MPa, %E-8, %RA-12, BHN-388.

The above Compositions cover the ENTIRE GAMUT OF IS-2644 &

ASTM A-148 Specifications.

PROBLEMS TO BE LOOKED INTO

1) Make Grey Iron with less than 2.0 % C.

Make a melt of Iron with the following composition.

% C 1.55 to 1.85 , % Si 2.20 to 2.60 , % Mn 0.30 to 0.80, % S 0.05 to 0.2,

% P 0.05 max , % B 0.01.

Boron can be added in the form of FeB. Pass Nitrogen gas through the melt,

BN forms. It has a lattice coherency with Graphite , hence it results in Grey

2

2

Iron of Strength as high as 50 Kg / mm as against 20 to 30 Kg / mm in

Conventional Grey iron .

2) Try to make Spheroidal Carbidic Iron. In high Cr cast irons of say % C 2.0,

% Cr 12, Chromium Carbide formed is M7C3 type. From HAND BOOK OF

CRYSTALLOGRAPHY , find out any other any other Compound, with same

Lattice parameters as M7C3. This compound should be obtainable in-situ in

Liquid melt.

3) Take AISI D2 Steel, the word Steel is a misnomer. Because D2 is a White

Cast Iron. Hold it at 1050 to 1080 degrees for a prolonged period, sharp edges

in Carbide will disappear. ( I have done it.) Check the properties.

4) Make P treated Al- 13 % Si & Al – 8 % Si alloys, so that you get Primary

Silicon. Compare the properties.

5) Hold P treated Al – 8 % Si alloy at 490 to 500 degrees , to remove sharpness

of Si . Check the properties. ( I have done it with P treated Al-12 % Si ,

the sharpness of Si had gone. Si looked like a LUMP rather than a Cuboid.)

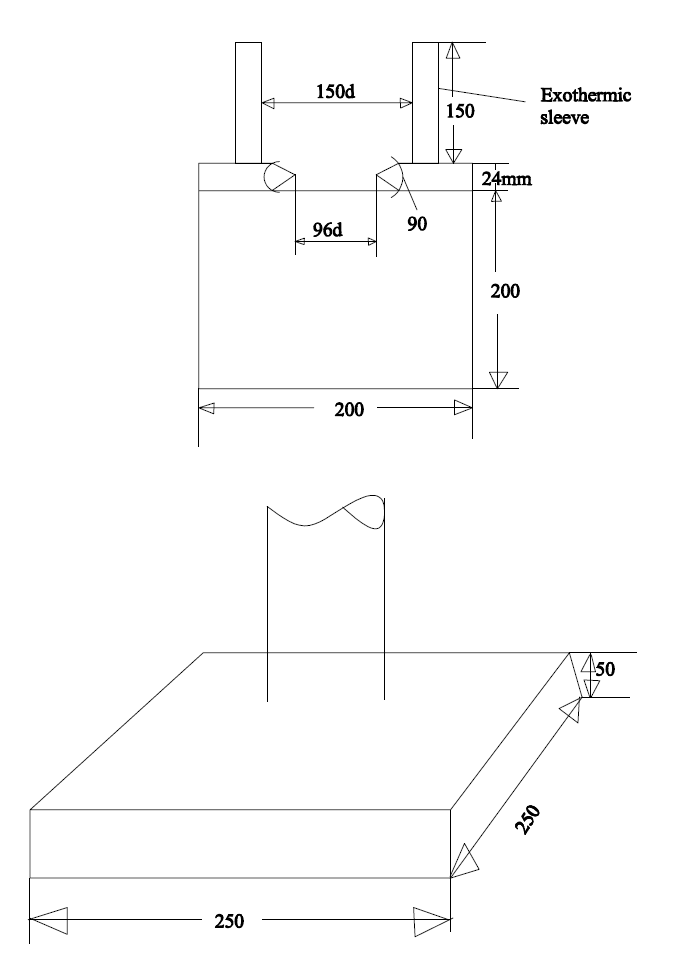

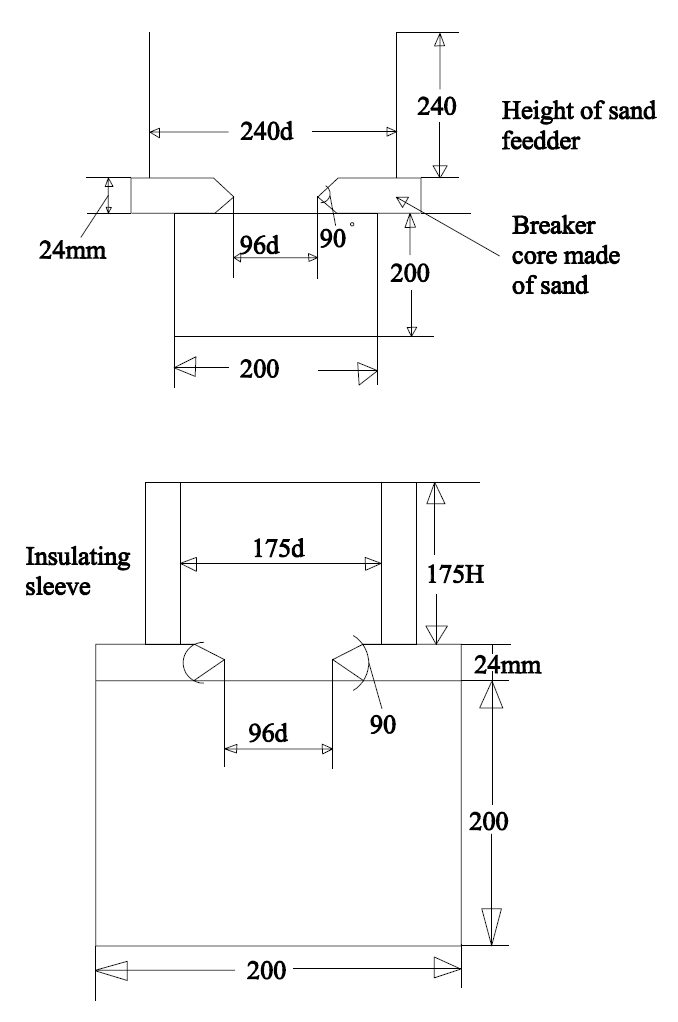

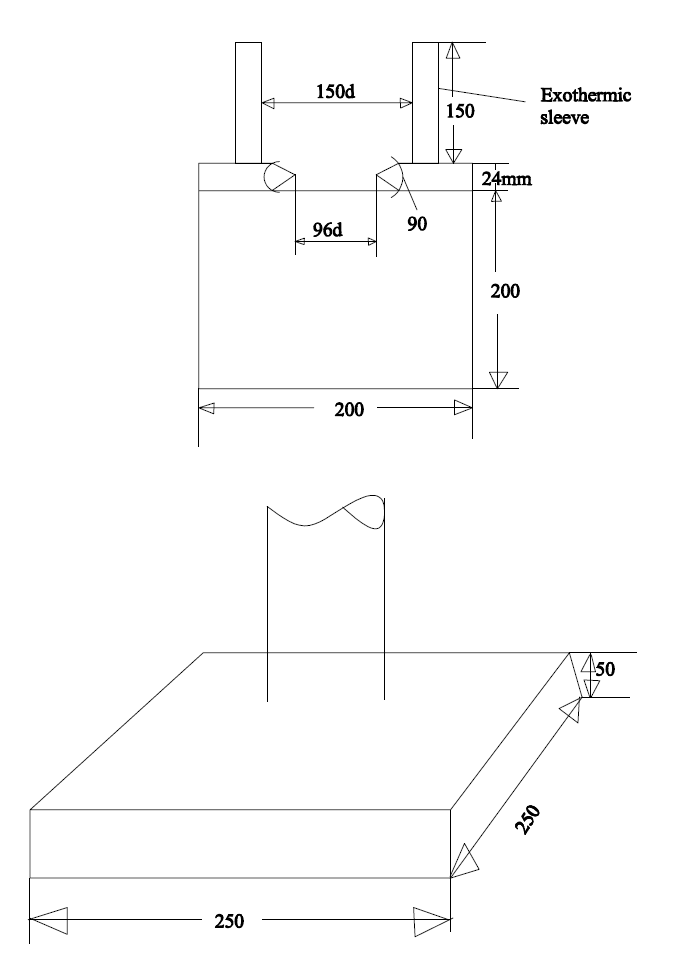

6) Make an Insulating Sleeve & an Exothermic Sleeves ( with the details

given) & Do the Cost- Benefit analysis.

109

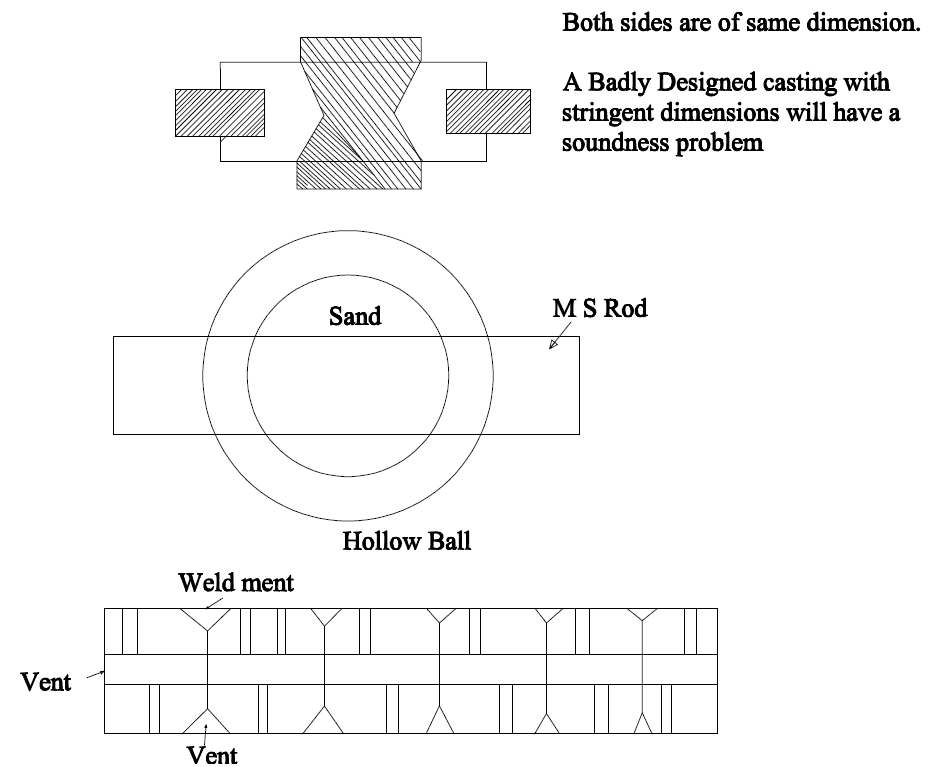

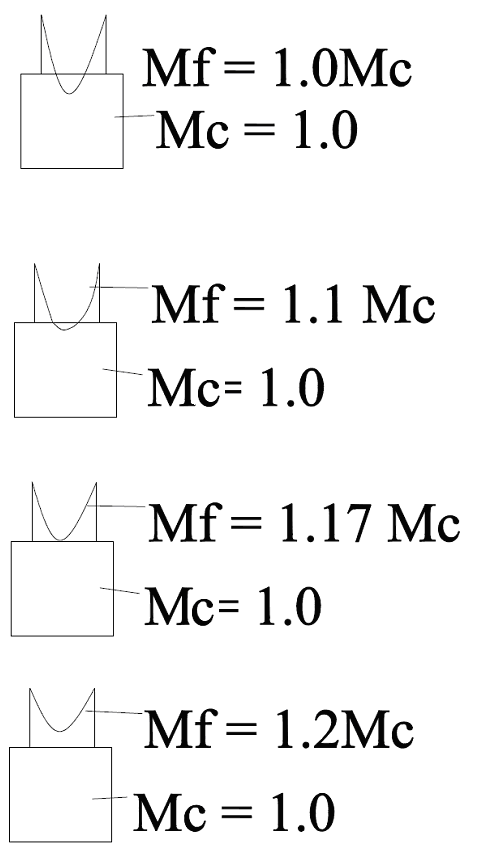

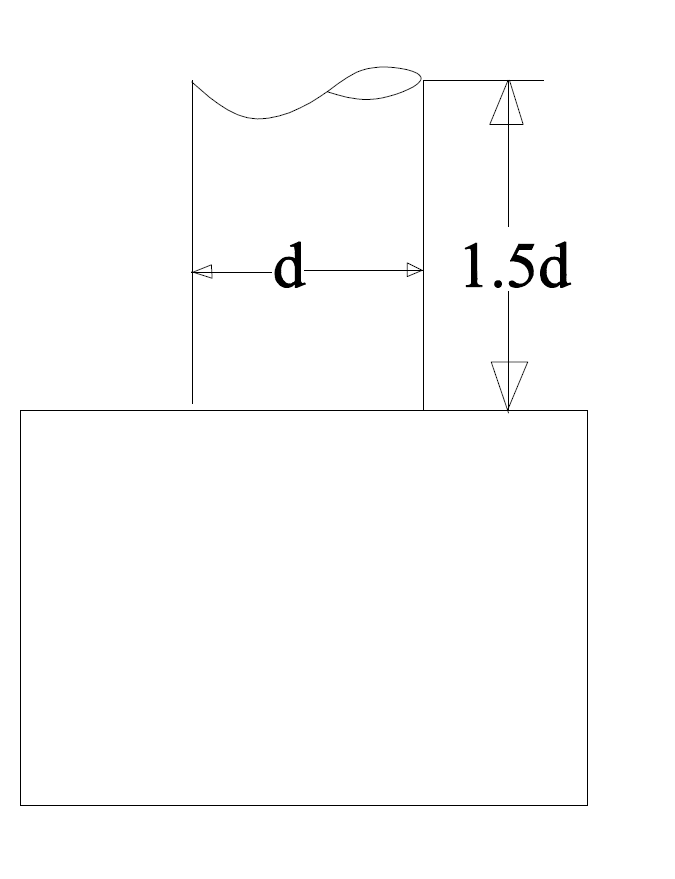

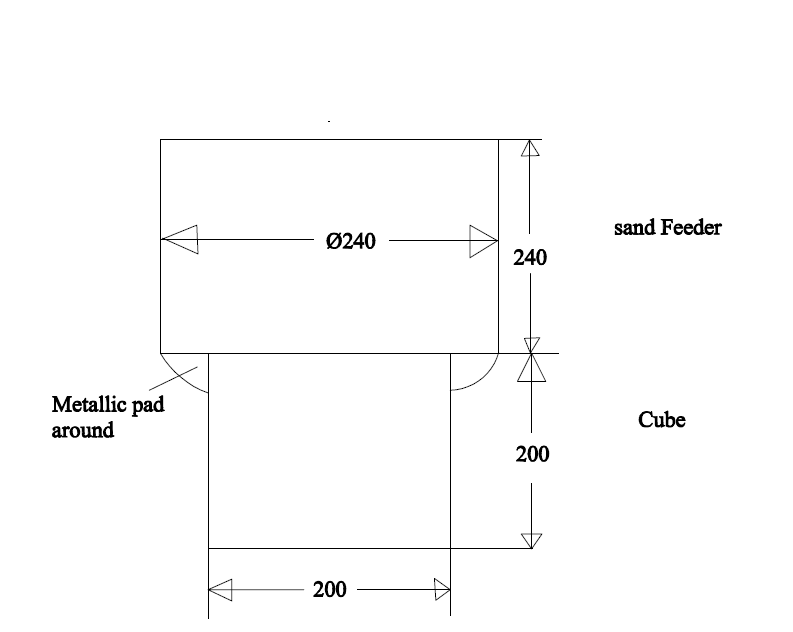

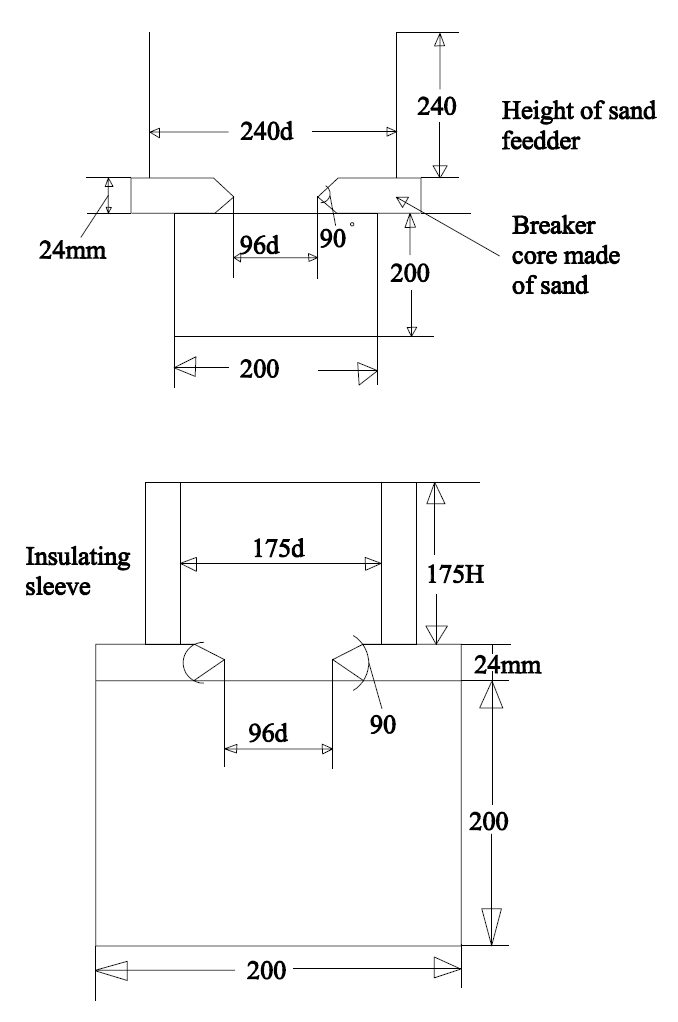

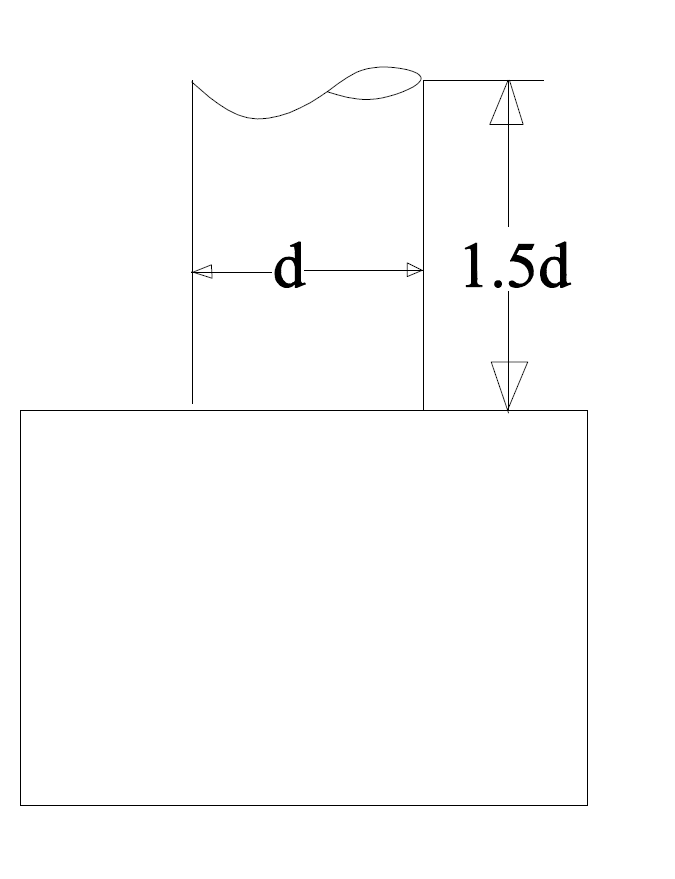

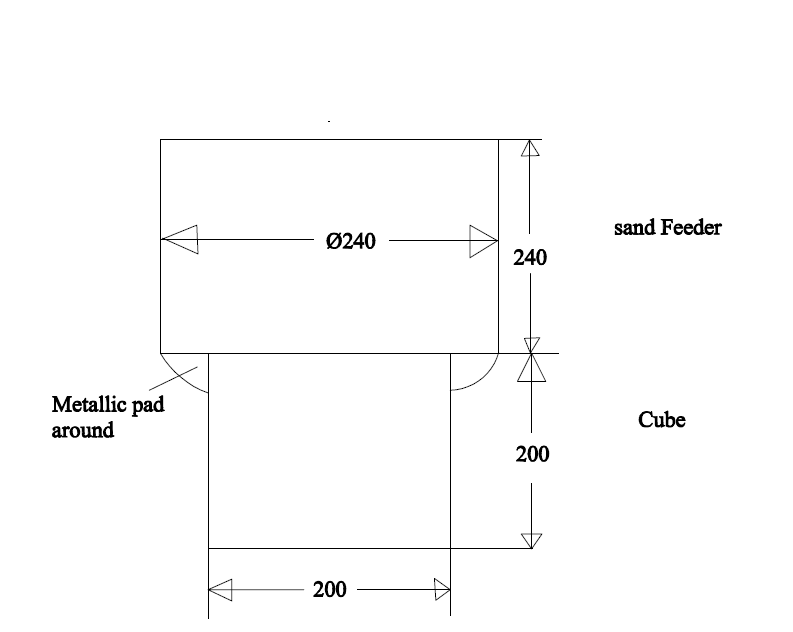

7) A Cube of 100 needs a Sand Feeder of 120 dia x 120 ht.

It needs 10.3 Kgs of Steel.( For FEEDER ONLY)

A Sand Sleeve with an OUTER ANNULAR SPACE was made.

(Shown in the SKETCHES )

The Feeder proper is 95 dia x 95 ht. The outer annular space has a dimension

of 135 OD x 115 ID x 85 ht. We got a SOUND CUBE Casting.

Let us do some calculation.

1) 0.785 x ( 1.35 + 1.15 ) ( 1.35 – 1.15 ) 0.85 x 7.6 = 2.54 Kgs.

Molten Steel requirement of annular space.

3

2) 0.785 x ( 0.95) x 7.6 = 5.11 Kgs ( Feeder Proper)

1+2 = 2.54 + 5.11 = 7.65 Kgs.

Savings in LIQUID STEEL is 10.3 Kgs – 7.65 Kgs = 2.65 Kgs.

Savings % 2.65 / 10.3 = 0.257 x 100 = 25.7 %

MEF = 120 dia / 95 dia = 1.26

The whole Purpose behind doing this Experiment was to make temperature

Gradient FLAT IN THE SAND ADJACENT TO LIQUID METAL IN

FEEDER FOR A WHILE.

If this experiment is repeated with INSULATING SLEEVE & EXOTHERMIC

SLEEVE. It would result in greater benefit.

TRY DOING IT. These kind of Sleeves are not available in the market & hence

You will have to make your own Sleeves.

8) Make a Sodium Silicate Core & pass a combination of CO2 gas and HOT

AIR. See the difference between this core & Conventional core. Do the Cost-

Benefit analysis.

9) Find out as to why Core made out of Sodium Silicate Sand & Bentonite

does not become FRIABLE.

10) Use dry BAMBOO Powder for making Insulating or Exothermic Sleeves.

11) Treat Al – 3 % Fe melt with SULPHUR to see if Fe can be removed as

FeS.

12) Find out how effective is PADDY HUSK as APC & also the Effectiveness

of Mixture of Paddy husk & dry BAMBOO powder.

13) Try Dry wood waste as an APC & also try to use Coconut shell powder as

APC. The Calorific Values of these have given in the text.

14) Check up the Effectiveness of Powdered COW DUNG CAKE as APC

110

15) Check up the effectiveness of a Sleeve made out of COW DUNG CAKE

POWDER.

16) Along with the stream of Steel or Grey Iron melt, add 1,2,3,4,5% Fine

STEEL SHOTS & Evaluate the Microstructure , Mechanical Properties &

Shrinkage pattern

17) For those of you , who want to work on Al –Si & get Primary Silicon ,

you need to add P-Cu ( 8 % P ) as Al2P3 is the nuclei for Primary Silicon.

For P to be available in the alloy, alloy must be free from Na, Ca , K & Ba

( Alkalis ) The cheapest Silicon available is CHINESE SILICON. But it

has alkaline elements. P being acidic, alkalines have to be removed before

adding P- Cu. Alkaline elements can be removed by TREATING the LIQUID

metal of Al-Si with ALUMINUM CHLORIDE ( Commercial Grade ).

This material, has a SUBLIMATION POINT of 190 degrees.

This material can be had from M/ s Kanoria Chemicals, Renukot, UP.

This material is Hygroscopic in nature , Heat the material to remove all

the moisture before use. This material does the TWIN work of removing

Alkaline elements & acts as a DEGASSER too.

THE PURPOSE BEHIND THIS LIST OF THINGS THAT CAN BE TRIED

OUT, IS ONLY TO IGNITE NEW IDEAS IN YOU

Books Referred to :

1) STEELS------R.W.K. Honeycombe.

2) THE PHYSICAL METALLURGY OF STEELS----Leslie.

3) THE APPLIED SCIENCE IN CASTING OF METALS—K. Strauss.

4) STEEL CASTINGS HAND BOOK--- Steel Founders’ Society Of America,

1970.

5) CAST IRON : PHYSICAL AND ENGINEERING PROPERTIES---

H. T. Angus.

6) THE DIRECTIONAL SOLIDIFICATION OF STEEL CASTINGS—

R.Wlodawer.

7) STRUCTURE OF METALS --- Barret & Masslaski.

8) INDIAN FOUNDRY JOURNAL--- April ,1986—Institute of Indian

Foundrymen.

9) P.R.Beeley----Foundry Technology.

111

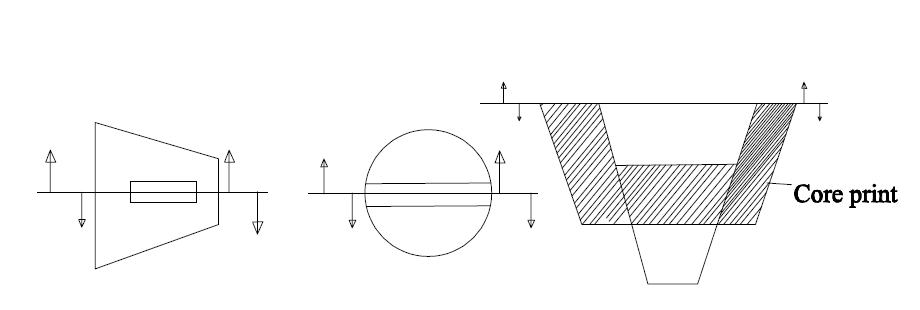

PATTERN

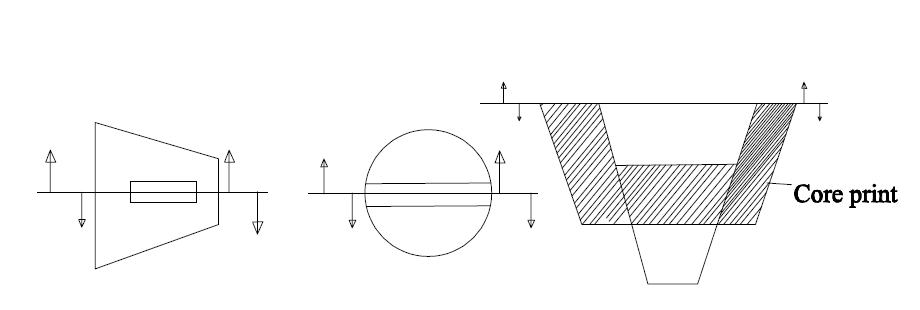

Parting line, taken, should not lead to any casting problem. In the

First case a SHIFT in casting can occur, resulting in Casting rejection.

No such problem exists in second case.

112

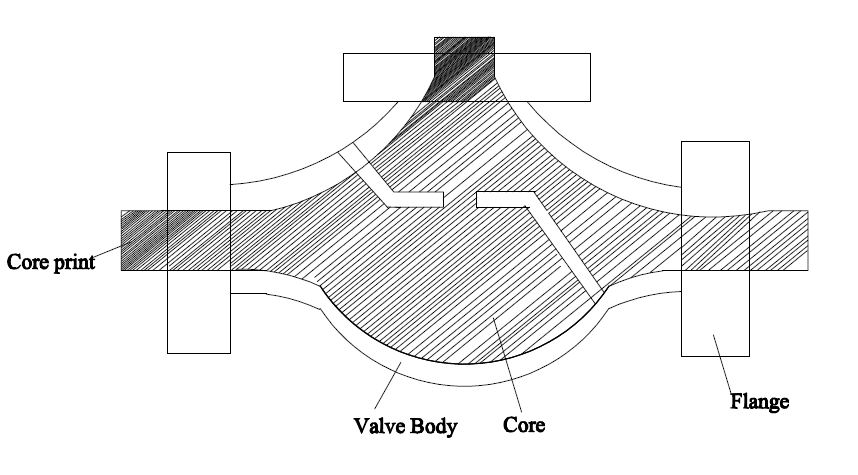

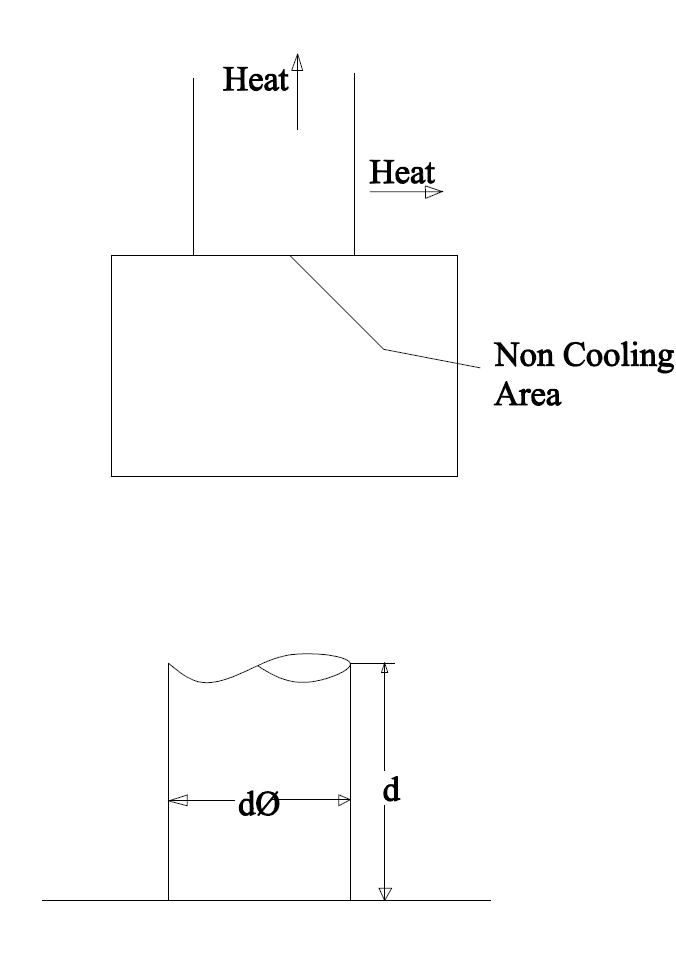

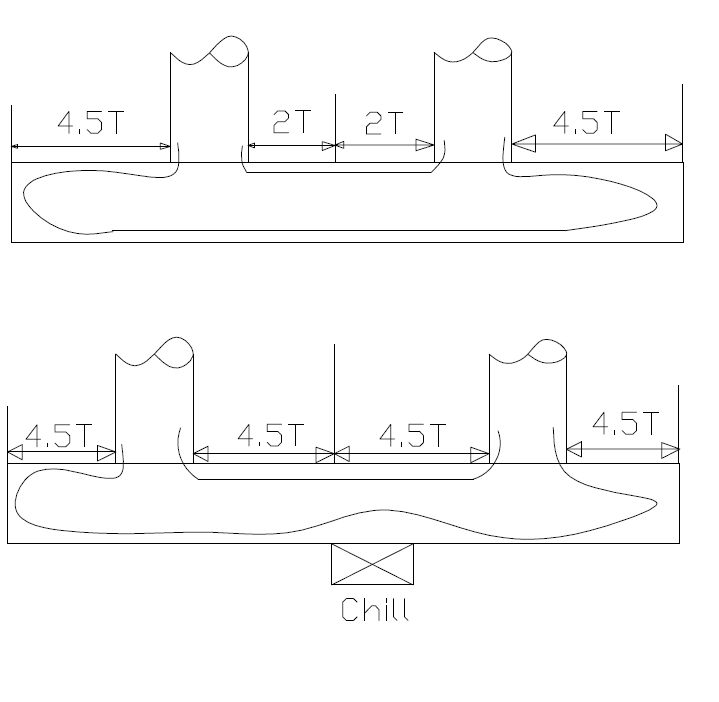

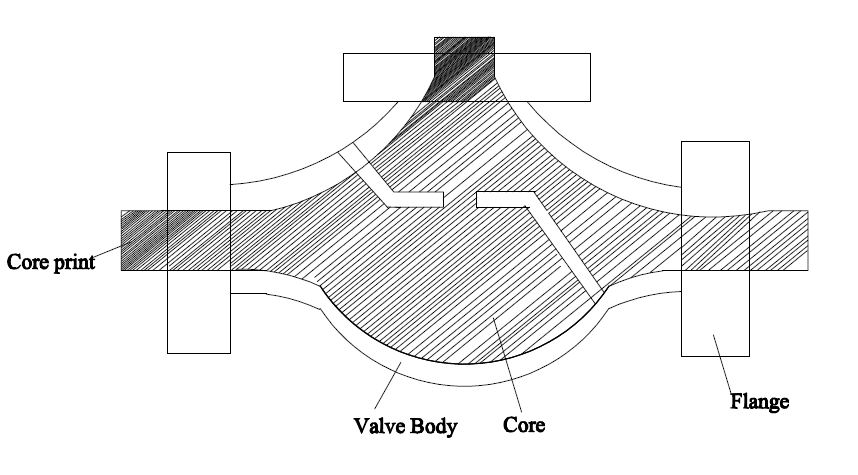

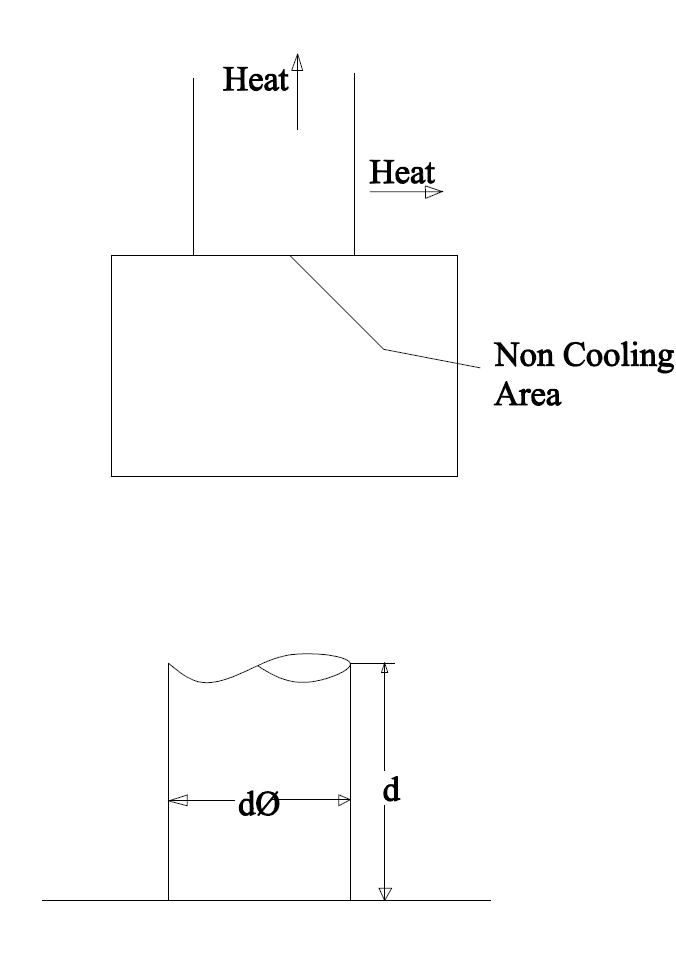

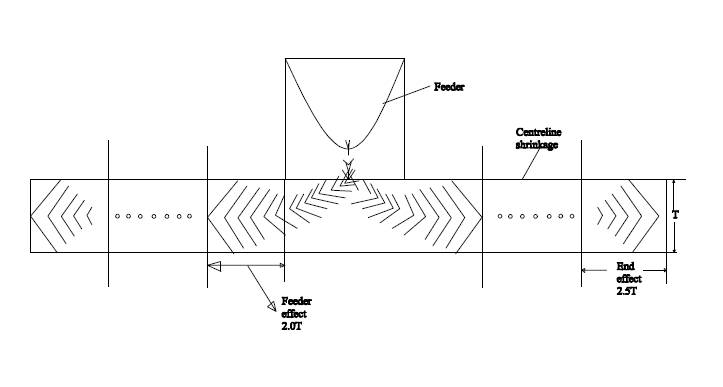

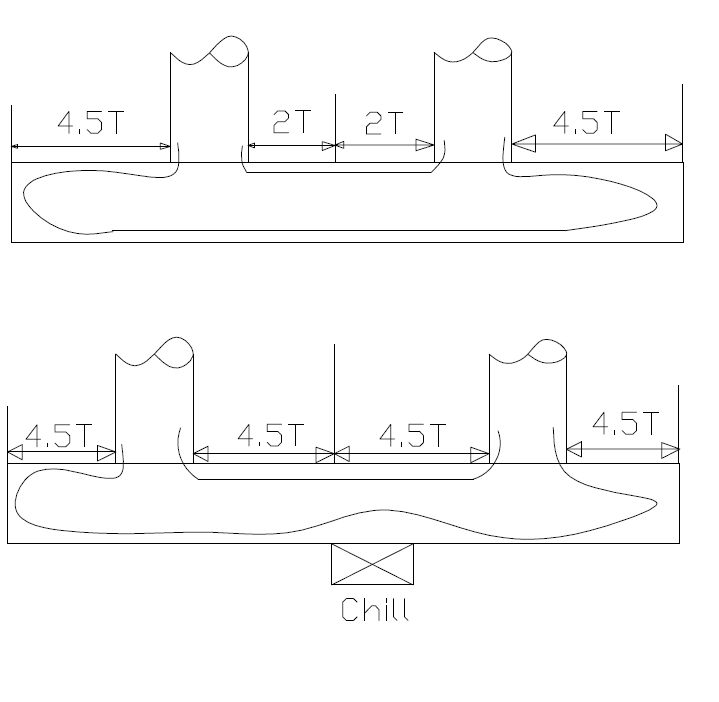

While designing a Casting, the Designer should always bear in MIND that

There are NO ISOLATED HOT SPOTS WHICH can not be FED.

113

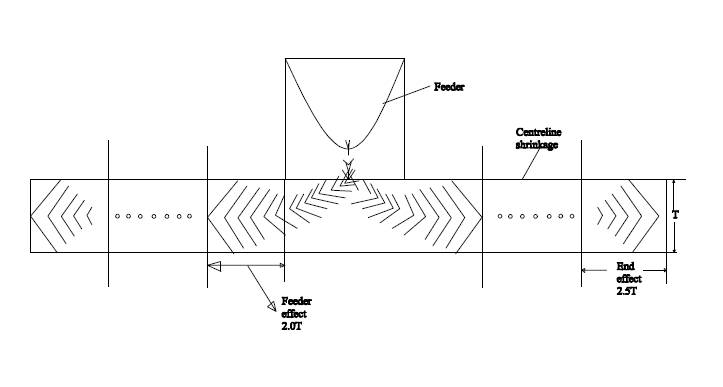

A TAPERED BAR IS AN IDEAL CASTING TO FEED FROM THE

POINT OF DIRECTIONAL SOLIDIFICATION.

METHODING

114

115

116

117

118

119

120

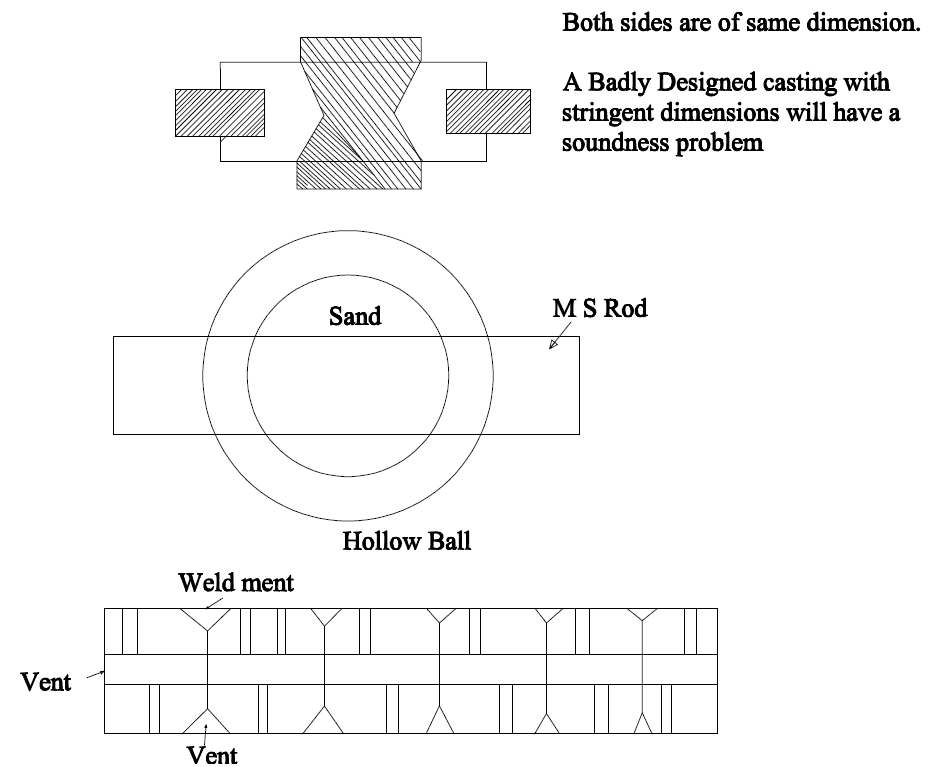

Centreline shrinkage is not acceptable in Radiography. Feeding system

Should be so designed that Centreline defect does not occur.

121