CHAPTER 11

BY-PRODUCTS AND VALUE-ADDED PRODUCTS

1. Vermiwash

In the vermicomposting process, the bed filled with organic wastes, bedding materials and earthworms is fitted with a drainage and collection system. Vermicomposting produces a leachate as a result of addition of moisture contents through the column of worm action. Draining of this water or leachate is important to prevent saturation of the vermicomposting unit and attraction of pests. The leachate so obtained is termed as vermiwash(Fig.14) It is beneficial in the sense that when collected it can be used as a liquid fertilizer as it contains large amounts of plant nutrients. It is a collection of excretory products and mucous secretion of the earthworms, along with the micronutrients from the organic molecules. This liquid partially comes from the body of earthworms (as worm’s body contain plenty of water) and is rich in amino acids, vitamins, nutrients like nitrogen, potassium, magnesium, zinc, calcium, iron and copper and some growth hormones like auxins, cytokinins. It also contains plenty of nitrogen fixing and phosphate solubilizing bacteria (Nitrosomonas, Nitrobacter and Actinomycetes). Vermiwash, if collected properly, is clear and transparent, honey brown colored fluid. It should be noted; however, that plant bioassay test of vermiwash should be done prior to its use as foliar spray in order to explore the presence of pathogens and phytotoxic compounds. If used as fertilizer, the vermiwash is better diluted to avoid plant damage, but this automatically decreases its nutrient content so it has to be combined with other mineral fertilizers. Commercial formulations of liquid fertilizers are sometimes complemented with certain chemical compounds, such as polyoxyethylene tridecyl alcohol as dispersant and polyethylene nonylphenol as adherent, to increase nutrient availability for plants.

Vermiwash has great growth promoting (Suthar,S.,2010) as well as pest killing properties. Study by Giraddi, R.S.(2003) reported that weekly application of vermiwash increased radish yield by 7.3%. Another study also reported that both growth and yield of paddy increased with the application of vermiwash and vermicast extracts (Thangavel, P et al, 2003)

Fig.14 :Vermiwash-concentrated and diluted

Ansari, A.A. and Sukhraj, K. (2010) reported the effect of vermiwash and Vermicomposton soil parameters and productivity of okra (Abelmoschus esculentus). Recently Rekha G.S., et al (2013) studied the influence of vermicompost and vermiwash on the growth and productivity of Black Gram (Vigna mungo).

Farmers from Bihar in North India reported growth promoting and pesticidal properties of this liquid. They used it on brinjal and tomato with excellent results. The plants were healthy and bore bigger fruits with unique shine over it. Spray of vermiwash effectively controlled all incidences of pests and diseases significantly reduced the use of chemical pesticides and insecticides on vegetable crops and the products were significantly different from others with high market value. In order to evaluate its efficacy against thripsand mites for the management of ‘thrips’ (Scirtothrips dorsalis) and ‘Mites’ (Polyphagotarsonemus latus) on chilli vermiwash was used in three different dilutions e.g. 1:1, 1:2 and 1:4 by mixing with water both as ‘seedling dip’ treatment and ‘foliar spray’ (Saumaya, G et al,2007). Giraddi, R.S.(2003) also reported significantly lower pest population in chilli applied with vermiwash (soil drench 30 days after transplanting, and foliar spray at 60 and 75 days after transplanting) as compared to untreated crops. Suthar (2010) has reported hormone like substances in vermiwash. He studied its impact on seed germination, root and shoot length in Cyamopsis tertagonoloba and compared with urea solution (0.05%). Maximum germination was 90% on 50% vermiwash as compared to 61.7% in urea solution. Maximum root and shoot length was 8.65 cm & 12.42 cm on 100% vermiwash as compared to 5.87 and 7.73 on urea.

Preparation steps

The preparation of vermiwash involves the following steps:

1. Take a plastic container of about 50 liters capacity.

2. Make a hole at the bottom and fix a tap using a safety gauge.

3. Put a layer of broken bricks, pieces of stones having thickness of 10-15 cm in the container.

4. Over this layer put another layer of sand having thickness of 10-15 cm.

5. Then put a layer of partially decomposed cow dung having 30-45 cm thickness over it.

6. Then put another layer of soil having 2-3 thicknesses.

7. Then introduce 100-200 nos. of earthworms.

8. After that, a layer of paddy straw having 6 cm thickness is given.

9. Spray water regularly for a period of 7-8 days.

10. After 10 days the liquid vermiwash will be produced.

11. Hang one pot with a bottom hole over the container in such a way so that water falls drop by drop.

12. Every day 4-5 litres of water is to be poured in the hanging pot.

13. Keep another pot under the tap to collect the vermiwash.

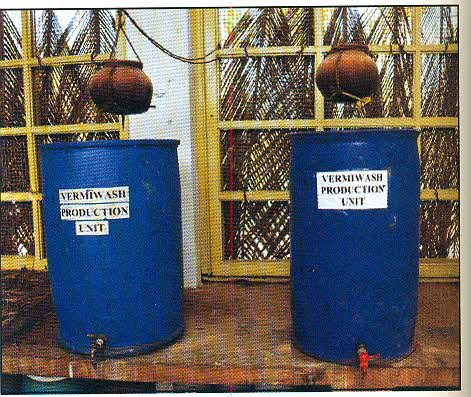

A typical model for vermiwash collection is shown in Fig.15

(Courtesy: CPCRI, Kasaragod, Kerala)

Fig.15: Vermiwash collection

2. Vermicompost tea or Liquid Vermicompost Vermicompost tea is a type of compost tea derived from soaking vermicompost in water. It contains beneficial microbes that may also reduce or control diseases and improve soil health. Studies also indicate that the tea has a positive effect on suppressing plant-parasitic nematodes and arthropod pests (Edwards, C.A, et al, 2007). Vermicompost tea nutrients will vary based on the vermicompost source materials and the brewing techniques. Liquid Vermicompost can contain the three basic plant nutrients: nitrogen in the form of nitrate or ammonium (N03 and NH4); phosphorus (P); and potassium (K). One analysis of this product brewed at a 1:10 ratio showed on average: nitrate (NO3) at 77 ppm (parts per million); ammonium (NH4) at 3.7 ppm; P at 18 ppm; and K at 186 ppm.

Preparation

Methods of producing aqueous extracts include:

- Passing water through vermicomposts

- Standing vermicomposts in water (1-7 days)

- Modifications of these methods

-Aeration

-Addition of other materials

-Addition of organic substrates

3.Vermimeal

Vermimeal or earthworm meal is a feed preparation consisting of processed earthworm biomass. It is a rich source of animal protein as well as essential amino acids, fats, vitamins, and minerals for livestock, birds and fish. About 5.5 kg of fresh earthworm biomass (18% dry matter) is needed to produce 1 kg of vermimeal. It can be packed in plastic bags and stored in a cool dry place out of direct sun for up to 3 months. Proximate analysis of an earthworm vermimeal in dry and pulverized form revealed the following composition; 68% crude protein, 9.57% fat, 11.05% nitrogen-free extract, and 9.07% ash. Numerous studies on different livestock animals, birds and fishes have shown excellent results of feeding the animals with vermimeal or earthworm meal. This is not surprising, considering that earthworms are a natural source of nutrition for birds and other animals in the wild.

4. Enriched Vermicompost

The enhancement of nutrients and beneficial microbial population in the vermicompost is yet another important evolving trend where the vermicompost is value added with nutrients and or microorganisms resulting in improved growth and yield of crop plants. “Enriched vermicompost” is a mixture of vermicompost, natural minerals and microorganisms. Not only does it contain additional nutrients, it also takes less time to produce than conventional vermicompost. Another benefit of the new compost is the ability to exchange ingredients and vary the concentrations of nutrients depending on the specific requirements of different plants and soils. To produce the fertilizer, vermicompost made from raw materials like farm manure and legume residues is mixed with natural minerals such as rock phosphate and mica powder. In 2011, a study on enriching vermicompost using iron and zinc and its effect on the growth and nutritional status of peach trees was reported by Hashemimajd, K and Jamaati-e-Somarin, S. Also included are microorganisms, such as Aspergillus awamori and Trichoderma viride, which are effective at providing and protecting fertilizers and help mineralize elements that are used by the crops. In 2012, Rajasekar,K. et al reported the possibility of enrichment of vermicompost with microbial inoculants (i.e.,biofertilizer organisms), Azospirillum brasilense and Rhizobium leguminosarum, optimization of inoculum level and time of inoculation during vermicomposting.

5. Pelleted Vermicompost

Vermicompost is an effective material for improving the physical and chemical conditions of soil. However, there are two factors that limit the application of this composted manure. The first problem is that vermicompost usually has high moisture content and a high volume per unit of weight. As a result, it is difficult and costly to transport. The second problem is that the quality of the vermicompost and its nutrient content are not constant. This also limits the efficient use of compost. The molding technology to manufacture compost in the easy-to-use pellet form is an effective solution to these problems.

A pellet making machine can be used to make composted manure into pellets of 0.5-1 cm in diameter. The machine designed in 2007 by Nitin K Tyagi of Meerut, Uttar Pradesh, India is manually operated, and consists of a hopper, flat moving belt, a die to form pellets and power transmission system. A single person can operate the machine. The principle used here involves mixing the vermicompost with suitable binder (molasses), putting the mixture in the hopper, carrying the compost using the conveyor belt on a flat bed in the form of a sheet and passing through pellet making die to generate a stream of pellets. Though the use of conveyor and die system to make conventional compost-pellets is well known (Zafari and Kianmehr, 2012) and in chemical and pharmaceutical industries, the deployment of this concept to create "vermicompost pellets" is novel in application. If pelleting is to be done without adding any other materials, it is important to control the moisture content of the compost and the rate at which the compost is supplied to the die part of the pelleting machine.

The dried pellets retain their form during storage and distribution, and have a volume only 60-90% of the raw compost. The pellets produced need less space to store and can be spread uniformly to the fields. In pellet form the release of the nutrients to the plants is slow and for a longer period(Fig.16).

Fig.16:Vermicompost: Pellets