chAPter 15 Preventing and lessening CoMPaCtion

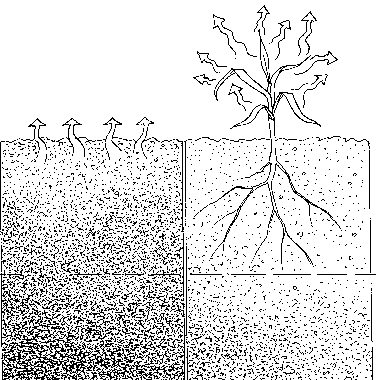

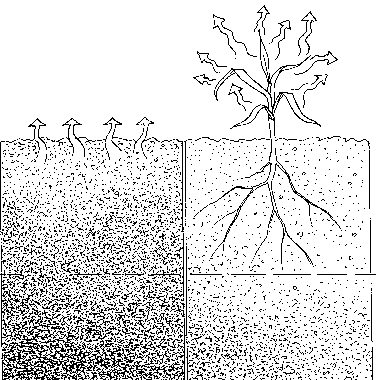

Figure 15.7. Reduction of soil compaction by increased distribution of equipment loads. Left: Tracks on a tractor. Middle: Dual wheels on a tractor that also increase traction. Right: Multiple axles and flotation tires on a liquid manure spreader this scenario, emphasis should be placed on improving

wheels similarly reduces compaction by increasing the

the harvesting operations. In another scenario, a high-

footprint, although this load distribution is less effective

plasticity clay loam soil is often spring-plowed when still

for reducing subsoil compaction, because the pressure

too wet. Much of the compaction damage may occur at

cones from neighboring tires (see figure 6.10, p. 64)

that time, and alternative approaches to tillage and tim-

merge at shallow depths. Dual wheels are very effective

ing should be a priority.

at increasing traction but, again, pose a danger because

Better load distribution. Improving the

of the temptation (and ability) to do fieldwork under

design of field equipment may help reduce compac-

relatively wet conditions. Duals are not recommended

tion problems by better distributing vehicle loads. The

on tractors for performing seeding and planting opera-

best example of distributing loads is through the use of

tions because of the larger footprint (see also discussion

tracks (figure 15.7), which greatly reduce the potential

on controlled traffic below).

for subsoil compaction. But beware! Tracked vehicles

Improved soil drainage. Fields that do not drain

may provide a temptation to traffic the land when the

in a timely manner often have more severe compaction

soil is still too wet. Tracked vehicles have better flota-

problems. Wet conditions persist in these fields, and

tion and traction, but they can still cause compaction

traffic or tillage operations often have to be performed

damage, especially through smearing under the tracks.

when the soil is too wet. Improving drainage may go

Plow layer compaction may also be reduced by lowering

a long way toward preventing and reducing compac-

the inflation pressure of tires. A rule of thumb: Cutting

tion problems on poorly drained soils. Subsurface (tile)

tire inflation pressure in half doubles the size of the tire

drainage improves timeliness of field operations, helps

footprint to carry an equivalent equipment load and cuts

dry the subsoil, and, thereby, reduces compaction in

the contact pressure on the soil in half.

deeper layers. On heavy clay soils where the need for

The use of multiple axles reduces the load carried

close drain spacing is very expensive, surface shap-

by the tires. Even though the soil receives more tire

ing and mole drains are effective methods. Drainage is

passes by having a larger number of tires, the result-

discussed in more detail in chapter 17.

ing compaction is significantly reduced. Using large,

Clay soils often pose an additional challenge with

wide tires with low inflation pressures also helps reduce

respect to drainage and compaction, because they

potential soil compaction by distributing the equip-

remain in the plastic state for extended periods after

ment load over a larger soil surface area. Use of dual

drying from wet conditions. Once the upper inch of the

167

Building SoilS for Better CropS: SuStainaBle Soil ManageMent