7.2 The Pringles Can

At the Portland Summit last June, Andrew Clapp presented a novel yagi antenna design. It used a bolt, metal tubing, washers, and PVC tubing to make an inexpensive "shotgun" yagi, either 18" or 36" long. While his antenna shows between 12 and 15dBi gain (which is impressive for such a simple design), it's also quite large. When we returned from Portland, some members of our local group and I realized that, if we were careful, we could fit a full wavelength inside a Pringles can, as shown in Figure 7-1. This would show a reduced total gain, but it would also make the entire antenna much more compact.

Figure 7-1. The complete antenna—it's just a can!

7.2.1 Parts List

7.2.1 Parts List

Here are the items you'll need to make a Pringles can antenna:

Part

All-thread, 5 5/8" long, 1/8" OD

two nylon lock nuts

five 1" washers, 1/8" ID

6" aluminum tubing, 1/4" ID

A connector to match your radio pigtail (we used a female N connector)

1 1/2" piece of 12-gauge solid copper wire (we used ground wire from house electrical wiring)

A tall Pringles can (any flavor, Ridges are optional)

Scrap plastic disc, 3" across (like another Pringles can lid)

TOTAL

Approximate cost

$1.00

$0.10

$0.10

$0.75

$3.00

negligible

$1.50

negligible

$6.45

Of course, buying in bulk helps a lot. You probably won't be able to find a 6-inch piece of allthread; buy the standard size (usually one or two feet) and a 10-pack of washers and nuts while you're at it. Then you'll have more than enough parts to make two, all for about $10.

7.2.2 Required Tools

You'll need the following tools to make your antenna:

• Ruler

• Scissors

• Pipe cutter (or hacksaw or Dremel tool, in a pinch)

• Heavy-duty cutters (or Dremel again, to cut the all-thread)

• Something sharp to pierce the plastic (like an awl or a drill bit)

• Hot glue gun (unless you have a screw-down type connector)

• Soldering iron

Construction time should be about an hour.

7.2.3 Front Collector Construction

Mark and cut four pieces of tubing, about 1.2 inches (1 15/64 inches). Where did I get this number? First. figure out the wavelength at the bottom of the frequency range we're using (2.412 GHz, or channel 1). This will be the longest that the pipe should be:

W = 3.0 x 108 x (1 / 2.412) x 10-9 W = (3.0 / 2.412) x 10-1

W = 0.124 meters

W = 4.88 inches

We'll be cutting the pipe to quarter wavelength, so:

1/4 W = 4.88 / 4 1/4 W = 1.22 inches

Now figure out what the shortest length we'll ever use is (2.462GHz, or channel 11 in the United States):

W = 3.0 x 108 x (1 / 2.462) x 10-9 W = (3.0 / 2.462) x 10-1

W = 0.122 meters

W = 4.80 inches

1/4 W = 1.20 inches

Practically speaking, what's the difference between the shortest pipe and the longest pipe length? About 0.02 inches, or less than 1/32 inch. That's probably about the size of the pipe cutter blade you're using. So, just shoot for 1.2 inches, and you'll get it close enough.

Cut the all-thread to exactly 5

5/

8 inches. The washers we used are about

1/

16 inch thick, so that should leave just enough room for the pipe, washers, and nuts.

Pierce a hole in the center of the Pringles can lid big enough for the all-thread to pass through. Now is probably a good time to start eating Pringles (we found it better for all concerned to just toss the things; the salt and vinegar-flavor chips are almost caustic after the first fifteen or so).

Cut a 3-inch plastic disc just big enough to fit snugly inside the can. We found that another Pringles lid, with the outer ridge trimmed off, works just fine. Poke a hole in the center of it, and slip it over one of the lengths of pipe.

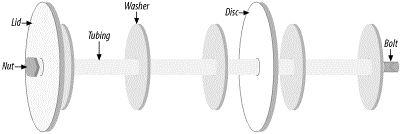

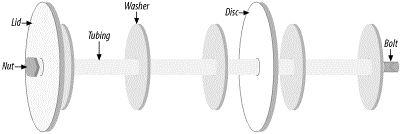

Now, assemble the pipe. You might have to use a file or Dremel tool to shave the tips of the thread if you have trouble getting the nuts on. The pipe is a sandwich that goes on the allthread as shown in Figure 7-2.

Figure 7-2. Nut, lid, washer, pipe, washer, pipe, washer, pipe-with-plastic, washer, pipe, washer, nut

Tighten down the nuts to be snug, but don't overtighten (I bent the tubing on our first try; aluminum bends very easily). Just get it snug. Congratulations, you now you have the front collector, just like the one shown in Figure 7-2.

7.2.4 Preparing the Can

By now you should have eaten (or tossed) the actual chips. Wipe out the can, and measure 3 3/8 inches up from the bottom of the can. Cut a hole just big enough for the connector to pass through. We found through trial and error that this seems to be the "sweet spot" of the can. On our Pringles Salt & Vinegar can, the N connector sat directly between "Sodium" and "Protein."

7.2.5 Element Construction

Straighten the heavy copper wire and solder it to the connector. When inside the can, the wire should be just below the midpoint of the can (ours turned out to be about 1 1/16 inches). You lose a few dB by going longer, so cut it just shy of the middle of the can.

We were in a hurry, so we used hot glue to hold the connector in place on our first antenna. If you have a connector that uses a nut and washer, and you're really careful about cutting the hole, these work very well (and aren't nearly as messy as hot glue). Just remember that you're screwing into cardboard when you connect your pigtail. It's very easy to forget and accidentally tear the wall of the can.

Now, insert the collector assembly into the can and close the lid. The inside end of the pipe should not touch the copper element; it should be just forward of it. If it touches, your allthread is probably too long. Figure 7-3 shows a completed antenna.

Figure 7-3. The completed antenna

How can one estimate gain without access to high-end radio analysis gear? Using the Link Test software that comes with the Orinoco Silver cards, you can see the signal and noise readings (in dB) of a received signal and your test partner's reception of your signal. As I happen to live 0.6 mile (with clean line of sight) from O'Reilly headquarters, we had a fairly controlled testbed to experiment with. We shot at the omni on the roof and used the access point at O'Reilly as our link test partner.

To estimate antenna performance, we started by connecting commercial antennas of known gain and taking readings. Then we connected our test antennas and compared the results. We had the following at our disposal:

• Two 10dBi, 180-degree sector panel antennas

• One 11dBi, 120-degree sector panel antenna

• One 24dBi parabolic dish

• A couple of Pringles cans and some hardware

Here were the average received signal and noise readings from each, in approximately the same physical position:

Antenna Signal Noise

10dBi A -83db -92db

10dBi B -83db -92db

11dBi -82db -95db

24dBi -67db -102db Pringles can -81db -98db

The test partner (AP side) signal results were virtually the same. Interestingly, even at only

0.6 mile, we saw some thermal fade effect; as the evening turned into night, we saw about

3dB gain across the board. (It had been a particularly hot day, almost 100 degrees. I don't know what the relative humidity was, but it felt fairly dry.)

Yagis and dishes are much more directional than sectors and omnis. This bore out in the numbers, as the perceived noise level was consistently lower with the more directional antennas. This can help a lot on long distance shots, because not only will your perceived signal be greater, the competing noise will seem to be less. More directional antennas also help keep noise down for your neighbors trying to share the spectrum as well. Be a good neighbor and use the most directional antennas that will work for your application (yes, noise is everybody's problem).

The Pringles can seemed to have large side lobes that extend about 45 degrees from the center of the can. Don't point the can directly at where you're trying to go; aim slightly to the left or the right. We also found that elevating the antenna helped a bit as well. When aiming the antenna, hold it behind the connector, and slowly sweep from left to right, with the Link Test program running. When you get the maximum signal, slowly raise the end of the can to see if it makes a difference. Go slowly, changing only one variable at a time.

Remember that the can is polarized, so match the phase of the antenna you're talking to. For example, if shooting at an omni, be sure the element is on the bottom or the top of the can, or you won't be able to see it! See the earlier discussion on antenna polarization for more information on how you can use this effect to your advantage.

We were fortunate enough to have a member of our community group bring a return loss meter to one of our meetings, and we were able to get some actual measurements of how much signal was returning to the radio. The results weren't as good as I had hoped, but they showed that the antenna was usable, particularly at lower frequencies. Most likely, failing to take into account the thickness of the washers has made the entire front element a little too long. There isn't nearly enough power leaving the radio to cause damage due to high return loss, but it does point out that the antenna isn't as well tuned as it could be.

We haven't looked into weatherproof housing for the can; sinking the whole thing into some

3-inch PVC should do the trick. Over a clear line of sight, with short antenna cable runs, a

12dB to 12dB can-to-can shot should be able to carry an 11Mbps link well over ten miles. You can check out our progress with the can online at http://nocat.net/.