pressure. Blue: simulation without optimization, red: Simulation with optimization.

4.4 Neural network controller

Optimization previously done "off line", would be directly unexploited "on-line" by a

controlling processor seen the enormous computation time that is necessary to resolve the

optimization problem. In order to integrate the results of this optimization’s procedure in a

closed loop controller (ref fig. 3), and to be able to use it in real time engine applications, we

suggest to use a black box model based on neurons. Neural network is a powerful tool

capable of simulating the engine’s optimal control variables with good precision and almost

instantly.

The neural network inputs are the fuel mass flow rate and the resistant torque, and its

output variables are the optimal values of the air mass flow rate and the intake pressure.

However in real time engine applications, the injected fuel flow rate is measurable, while the

resistant torque is not. Consequently, we suggest substituting this variable by the crankshaft

angular speed which can be easily measured and which is widely used in passenger cars

controlling systems.

Firstly, we need to create a large database which will be used to train the neural model, and

which covers all the functioning area of the engine in order to have a good precision and a

highly engine performance. The database is created using the optimization process as

explained in subsection 4.3.

Then we have to judicially choose the number of the inputs time sequence to be used, in

order to capture the inputs dynamic effects and accurately predict the output variables.

With intensive simulations and by trial and error, we find out that a neural network with

inputs the fuel mass flow rate and the crankshaft angular speed at instant (i), (i-1) and (i-2) is

capable of precisely predicting the optimal values of the air mass flow rate and the intake

Optimized Method for Real Time Nonlinear Control

183

pressure at current instant (i). Fig. 12 describes the neural network. The network is built

using one hidden layer and one output layer, the activation functions of the hidden layer are

sigmoid; the ones at the output layer are linear.

. m f ( i)

.

.

f

m ( i)

1

mc ( i)

.

f

m ( i )

2

.

.

(

w i)

p ( i)

.

c

(

w i )

1

.

.

(

w i 2)

Fig. 12. The structural design of the neural network adopted in this paper for predicting the

optimal control of the in-air filling and the intake pressure in real time applications.

The number of neurons in the hidden layer is determined by referring to the errors

percentage of the points which are under a certain reference value wisely chosen; the

errors percentage (table 3) are the results of the difference between the outputs of the

network after the training process is completed, and the desired values used in the training

database.

Table 3 shows the results of the neural networks with different number of neurons in their

hidden layer, these networks are trained with the same database until a mean relative error

equal to 10-8 is reached or maximum training time is consumed. The values in the table

represent the percentage of the neural network results respecting the specified error

percentage computed with respect to the reference values.

Error percentage

Number of neurons of the

Relative

hidden layer

< 10

< 1 % < 5 %

error

%

110 57.71

88.85 96.71 3.6 10-5

120 98.428

100

100

10-8

130 98.734

100

100

10-8

140 99

100

100

10-8

Table 3. Results of four neural networks trained using different neurons number in their

hidden layer and the same database.

The neural network adopted in this paper includes one hidden layer with 140 neurons and

one output layer with 2 neurons. Fig. 13 and 14 show a comparison between the air mass

flow rate and the intake pressure calculated using the theoretical optimization procedure,

and the ones computed using the neural network. The results are almost identical; the mean

relative error is 10-6.

184

Applications of Nonlinear Control

0.42

Optimization Process

Neural Model

0.4

2.46

2.44

0.38

ar]B 2.42

0.36

g/s]

re [

K [

2.4

C

ressu

m'

0.34

P

2.38

takeIn

0.32

2.36

0.3

Optimization Process

2.34

Neural Model

0.28

2.32

0

1

2

3

0

1

2

3

t [s]

t [s]

0.45

2.5

Optimization Process

Optimization Process

Neural Model

Neural Model

0.4

2.4

2.3

0.35

ar]B 2.2

0.3

/s]

[Kg

2.1

C

ressure [

m'

0.25

ke P

2

taIn

0.2

1.9

0.15

1.8

0.1

1.7

0

1

2

3

0

1

2

3

t [s]

t [s]

Fig. 13. & 14. Comparison between the neural network outputs and the optimal values of the

air mass flow rate and the intake pressure.

5. General conclusions

We successfully developed and validated a mean value physical model that describes the

gas states evolution and the opacity of a diesel engine with a variable geometry

turbocharger. Then we proposed a dynamic control based on the optimal “in-air cylinders

filling” in order to minimize the pollutants emissions while enhancing the engine

performance. The optimization process is described in detail and the simulation results (fig.

8-11) prove to be very promising. In addition, the control principle as described here with

the opacity criterion can be easily applied to other pollutants which have available physical

model. This will be the object of future publications.

Optimized Method for Real Time Nonlinear Control

185

Also, in order to overcome on line computation difficulties, a real time dynamic control based

on the neural network is suggested; therefore the optimal static maps of the fig. 2 can be

successfully replaced by dynamic maps simulated in real time engine functioning (fig. 15).

Xp

m'

GV

Opacity

C, ref

Neural

Network Pref

P.I

Engine

EGR

m’

P

C

Fig. 15. Proposed control in closed loop

Finally, we should note that, in this chapter, while we did find, in theory, the optimal air mass

flow rate and intake pressure necessary to minimize the opacity, but we didn’t discuss the

mechanical equipments required to provide the optimal intake pressure and intake air flow

rate in real time engine applications. The practical implementation of the dynamic control is an

important question to be studied thereafter. The use of a turbo-compressor with variable

geometry and/or with Waste-Gate, and/or electric compressor is to be considered.

6. References

Arnold, J.F. (2007). Proposition d’une stratégie de commande à base de logique floue pour la commande

du circuit d’air d’un moteur Diesel. PHD thesis, Rouen University, (March 2007), France.

Bai, L. & Yang, M. (2002). Coordinated control of EGR and VNT in turbocharged Diesel engine

based on intake air mass observer, SAE Technical paper 2002-01-1292, (March 2002).

Bartoloni, G. (1989). Chattering Phenomena in Discontinuous Control Systems. International

Journal on Systems Sciences, Vol. 20, Issue 12, (February 1989), ISSN 0020-7721.

Bellman, R. (1975). Dynamic programming. Princeton University Press, (1957), Princeton, NJ.

Doyle, J.C. (1979). Robustness of multiloop linear feedback systems” Proceedings of the 1978

IEEE Conference on Decision and Control, pages 12–18, Orlando, December 1979.

Dreyfus, S.E. (1962). Variational Problems with Inequality Constraints. Journal of

Mathematical Analysis and Applications, Vol. 4, Issue 2, (July 1962), ISSN 0022-247X.

Friedland, B. (1996). Advanced Control System Design. Prentice-Hall, Englewood Cliffs, ISBN

978-0130140104, NJ, 1996.

Hafner, M. (2000). A Neuro-Fuzzy Based Method for the Design of Combustion Engine

Dynamometer Experiments. SAE Technical Paper 2000-01-1262, (March 2000).

Hafner, M. (2001). Model based determination of dynamic engine control function

parameters. SAE Technical Paper 2001-01-1981, (May 2001).

Hahn, W. (1967). Stability of Motion, Springer-Verlag, ISBN 978-3540038290, New York, 1967.

Hassenfolder, M. & Gissinger, G.L. (1993). Graphical eider for modelling with bound graphs

in processes ». ICBGM’93, pp. 188-192, Californie, January 1993.

Jung, M. (2003). Mean value modelling and robust control of the airpath of a turbocharged diesel

engine. Thesis for doctor of philosophy, University of Cambridge, 2003.

Kao, M. & Moskwa, J.J. (1995). Turbocharger Diesel engine modelling for non linear engine

control and state estimation. Trans ASME, Journal of Dynamic Systems Measurement

and Control, Vol. 117, Issue 1, pp. 20-30, (March 1995), ISSN 0022-0434.

186

Applications of Nonlinear Control

Li, D.; Lu, D.; Kong X. & Wu G. (2005). Implicit curves and surfaces based on BP neural

network. Journal of Information & Computational Science, Vol. 2, No 2, pp. 259-271,

(2005), ISSN 1746-7659.

Minoux, M. (1983). Programmation Mathématique, Théorie et Algorithmes. tome 1 & 2, editions

dunod, ISBN 978-2743010003, Paris 1983.

Omran, R.; Younes, R. & Champoussin, J.C. (2008a). Optimization of the In-Air Cylinders

Filling for Emissions Reduction in Diesel engines, SAE Technical Paper 2008-01-1732,

(June 2008).

Omran, R. ; Younes, R. & Champoussin, J.C. (2008b). Neural Networks for Real Time non

linear Control of a Variable Geometry Turbocharged Diesel Engine , International

Journal of Robust and non Linear Control, Vol. 18, Issue 12, pp. 1209-1229, (August

2008), ISSN 1099-1239.

Ouenou-Gamo, S. (2001). Modélisation d’un moteur Diesel suralimenté, PHD Thesis, Picardie

Jules Vernes University, (2001), France.

Ouladssine, M.; Blosh, G. & Dovifazz X. (2004). Neural Modeling and Control of a Diesel

Engine with Pollution Constraints . Journal of Intelligent and Robotic Systems; Theory

and Application, Vol. 41, Issue 2-3, (January 2005), ISSN 0921-0296.

Outbib, R. & Vivalda, J.C. (1999). A note on Feedback stabilization of smooth nonlinear

systems. IEEE Transactions on Automatic Control. Vol. 44, No 1, pp. 200-203, (August

1999), ISSN 0018-9286.

Outbib, R. & Richard, E. (2000). State Feedback Stabilization of an Electropneumatic System.

ASME Journal of Dynamic Systems Measurement and Control. Vol. 122, pp 410-415,

(September 2000), ISSN 0022-0434.

Outbib, R. & Zasadzinski, M. (2009). Sliding Modes Control, In: Control Methods for Electrical

Machines, René Husson Editor, Ch. 6, pp. 169-204, 2009. Wiley, ISBN 978-1-84821-

093-6, USA.

Pontryagin, L.S.; Boltyanskii, V.; Gamkrelidze, R.V & Mishchenko, E.F. (1962). The

Mathematical Theory of Optimal Processes. 1962, John Wiley & Sons, USA

Rivals, I. (1995). Modélisation et commande de processus par réseaux de neurones ; application au

pilotage d’un véhicule autonome, PHD Thesis, Paris 6 University, (1995), France.

Sira-Ramirez, H. (1987). Differential Geometric Methods in Variable-Structure Control.

International Journal of Control, Vol. 48, Issue 2, (March 1987), pp. 1359-1390, ISSN

0020-7179.

Slotine, J-J.E. (1984). Sliding Controller Design for Non-linear System. International Journal of

Control, Vol. 40, Issue 2, pp. 421-434, (March 1984), ISSN 0020-7179.

Utkin, V.I. (1992). Sliding Modes in Control and Optimization, Springer-Verlag, ISBN 978-

0387535166, Berlin 1992.

Winterbonne, D.E. & Horlock, J.H. (1984). The thermodynamics and gas dynamics internal

combustion engines. Oxford Science Publication, ISBN 978-0198562122, London 1984.

Younes, R. (1993). Elaboration d’un modèle de connaissance du moteur diesel avec

turbocompresseur à géométrie variable en vue de l’optimisation de ses émissions. PHD

Thesis, Ecole Centrale de Lyon, (November 1993), France.

Zames, G. (1981). Feedback and optimal sensitivity: Model reference transformations,

multiplicative seminorms, and approximative inverse” IEEE Transcations on

Automatic Control, Vol. 26, Issue 2, pp. 301–320, (June 1981), ISSN 0018-9286.

Zweiri Y.H. (2006). Diesel engine indicated torque estimation based on artificial neural

networks. International Journal of Intelligent Technology, Vol. 1, No 1, pp. 233-239,

(July 2006), ISSN 1305-6417.

0

11

Nonlinear Phenomena and Stability Analysis for

Discrete Control Systems

Yoshifumi Okuyama

Tottori University, Emeritus

Japan

1. Introduction

Almost all feedback control systems are realized using discretized (discrete-time and

discrete-value, i.e., digital) signals.

However, the analysis and design method of

discretized/quantized (nonlinear) control systems has not been established (Desoer et al.,

1975; Elia et al., 2001; Harris et al., 1983; Kalman, 1956; Katz, 1981). This article analyzes

the nonlinear phenomena and stability of discretized control systems in a frequency domain1

(Okuyama, 2006; 2007; 2008).

In these studies, it is assumed that the discretization is

executed on the input and output sides of a nonlinear element at equal spaces, and the

sampling period is chosen of such a size suitable for the discretization in the space. Based

on the premise, the discretized (point-to-point) nonlinear characteristic is examined from two

viewpoints, i.e., global and local. By partitioning the discretized nonlinear characteristic into

two sections and by defining a sectorial area over a specified threshold, the concept of the

robust stability condition for nonlinear discrete-time systems is applied to the discretized

(hereafter, simply wrriten as discrete) nonlinear control system in question. As a result, the

nonlinear phenomena of discrete control systems are clarified, and the stability of discrete

nonlinear feedback systems is elucidated.

h

r† ✲+ ❣ e ✲

†

v

N( e†)

✟❆❯

DH

✻

−

S1

h

y†

u

❄+ d

DH

❍

✁☛

G( s)

✛

❣✛+

S2

Fig. 1. Nonlinear sampled-data control system.

2. Discrete nonlinear control system

The discrete nonlinear control system to be considered here is represented by a sampled-data

control system with two samplers, S1, S2 and the continuous nonlinear characteristic N( ·) as

1 In the time domain analysis (e.g., Lyapunov function method), it is difficult to find a Lyapunov function

for the discretized (severe nonlinear characteristic) feedback system. The frequency domain analysis

will be important in cases where physical systems with uncertainty in the system-order are considered.

188

2

Nonlinear Control

Applications of Nonlinear Control

Nd( e)

r ✲+ ❣ e ✲ D ✲

e†

✲

v†

v

1

N( e†)

D 2

✻

−

y

u†

❄+ d†

G( z)

✛

❣✛+

Fig. 2. Discrete nonlinear control system.

(a)

(b)

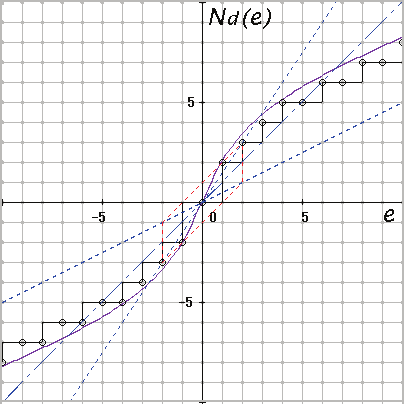

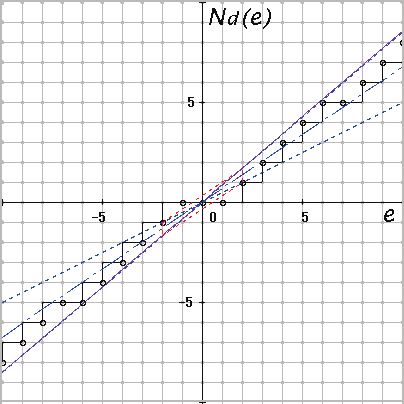

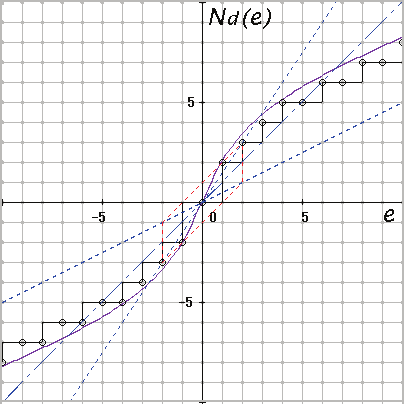

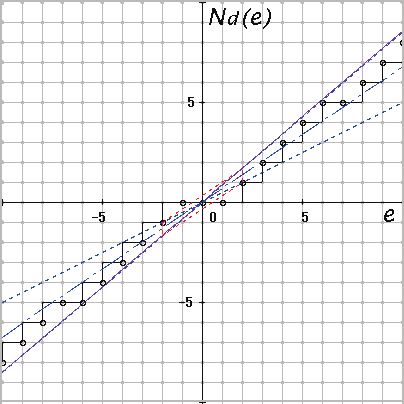

Fig. 3. Discretized nonlinear characteristics.

shown in Fig. 1. Here, DH denotes the discretization and zero-order-hold, which are usually

performed in A/D(D/A) conversion, and G( s) is the transfer function of the linear controlled

system. It is assumed that the two samplers with a sampling period h operate synchronously.

The sampled-data control system can be equivalently transformed into a discrete control

system as shown in Fig. 2. Here, G( z) is the z-transform of G( s) together with zero-order-hold, and D 1 and D 2 are the discretizing units on the input and output sides of the nonlinear

element, respectively. The relationship between e and v† = Nd( e) in the figure becomes a

stepwise nonlinear characteristic on integer grid coordinates as shown in Fig. 3 (a). Here, a

round-down discretization, which is usually executed on a computer, is applied. Therefore,

the relationship between e† and u† is indicated by small circles (i.e. a point-to-point transition)

on the stepwise nonlinear characteristic. Even if continuous characteristic N( ·) is linear, the

discretized characteristic v† becomes nonlinear on integer grid coordinates as shown in Fig. 3

(b) (Okuyama, 2009).

In Fig. 2, each symbol e, u, y, · · · indicates the sequence e( k), u( k), y( k), · · · , ( k = 0, 1, 2, · · · ) in discrete time, but for continuous value. On the other hand, each symbol e†, u†, · · · indicates a

Nonlinear Phenomena and Stability Analysis for Discrete Control Systems

189

Nonlinear Phenomena and Stability Analysis for Discrete Control Systems

3

discrete value that can be assigned to an integer number, e.g.,

e† ∈ {· · · , − 3 γ, − 2 γ, −γ, 0, γ, 2 γ, 3 γ, · · · }, u† ∈ {· · · , − 3 γ, − 2 γ, −γ, 0, γ, 2 γ, 3 γ, · · · }, where γ is the resolution of each variable. Here, it is assumed that the input and output signals

of the nonlinear characteristic have the same resolution in the discretization. In the figure,

e† and u† also represent the sequence e†( k) and u†( k). Without loss of generality, hereafter, γ = 1.0 is assumed. Thus, the input and output variables of the nonlinear element can be

considered in the set of integer numbers, i.e.,

e†( k), u†( k) ∈ Z

def

Z = {· · · , − 3, − 2, − 1, 0, 1, 2, 3, · · · }.

3. Equivalent discrete-time system

In this study, the stepwise and point-to-point nonlinear characteristic is partitioned into the

following two sections:

Nd( e) = K( e + ν( e)), 0 < K < ∞,

|ν( e) | ≤ ¯ ν < ∞,

(1)

for |e| < ε, and

Nd( e) = K( e + n( e)), 0 < K < ∞,

|n( e) | ≤ α|e|, 0 < α ≤ 1,

(2)

for |e| ≥ ε, where ν( e) and n( e) are nonlinear terms relative to nominal line