4. DESIGN AND FABRICATION

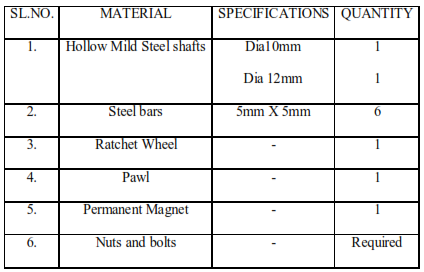

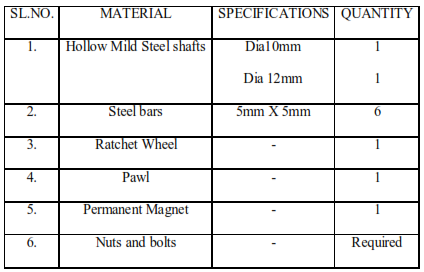

4.1. MATERIALS REQUIRED

4.2. EQUIPMENTS USED

• Arc welding equipment

• Portable Grinding Machine

• Drilling machine

• Hacksaw Blade

• Ball peen hammer, etc.,

4.3. FABRICATION PROCESS

• Materials required to do the project are purchased.

• Then a reconnaissance was carried out about the methods through which the project was to be done.

• Finally a most efficient and economical method was selected for the experimentation.

• As Ratchet and pawl mechanism is the major equipment used in our project. It is essential to have a study over the mechanism. It is explained below:

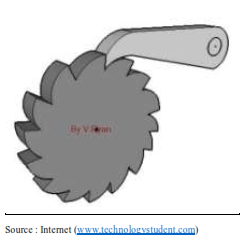

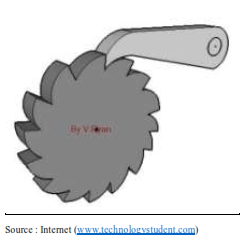

RATCHET AND PAWL MECHANISM

A ratchet is nothing but a mechanical device that allows continuous linear or rotary motion in only one direction while preventing motion in the opposite direction. Ratchets are widely used in machinery and tools. We utilised this mechanism in arresting the unexpected reverse motion of an automobile in mountain roads and sloppy areas.

• The ratchet wheel was first welded with one of the metal wheels at its centre.

• The 10mm shaft was inserted into the 12mm shaft. The inner shaft acts as the interconnector between two wheels while the outer shaft acts as a support to the rectangular frame.

• The wheels are welded together to the both the ends of the inner shaft form anaxle like structure.

• The steel bars of above mentioned specifications are cut into equal lengths to design a frame which supports the pawl and the lever mechanism.

• Then the steel bars are welded with the outer shaft forms a rectangular frame.

• A stand to place the entire equipment was fabricated using four iron bars which are welded with the frame.

• Then the lever mechanism to engage and disengage the pawl from ratchet wheel was to be designed.

• Here we used a permanent magnet to attach and detach the pawl.

• A lever mechanism in the form of an L was welded with the rectangular frame and a permanent magnet was attached to it.

• When the lever was pushed the pawl gets engaged with the ratchet and arrest the further movement of it and when it is pulled away from the wheel it allows the free motion without any interruption.

• So, a driver can use this attachment whenever required and it has no impact on vehicle design and overall weight.

• The finishing works are carried out like grinding the extra projections, painting, etc.,

• The design and fabrication of our project was thus completed.