BUILDING THE BASIC SHED

STEP A: BUILD THE FOUNDATION & FLOOR FRAME

-

Excavate the building site and add a 4" layer of compactible gravel. If desired, add an extension to the base for the optional wood ramp. Tamp the gravel thoroughly, making sure it is flat and level.

-

Cut three 4 × 4 treated timber skids at 144". Arrange and level the skids on the gravel bed, following the FLOOR FRAMINGPLAN.

-

Cut two 2 × 6 rim joists at 144" and ten joists at 93". Mark the joist layout onto the rim joists, following the plan. Assemble frame with 16d galv. common nails; be sure to check each joist for crowning and install it with the crowned edge up.

-

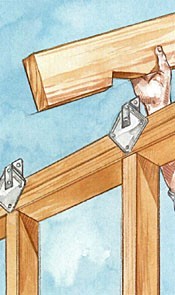

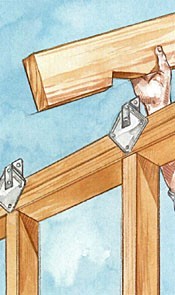

Set the floor frame on top of the skids and measure the diagonals to make sure it's square. Install metal clip angles ateach joist along the two outer skids, using 1 1/2" joist hanger nails and 16d galv. common nails, and toenail each joist to the center skid with 16d galv. nails.

-

Install the tongue-and-groove floor sheathing, starting with a full sheet at one corner of the frame. Use 8d galv. nails driven every 6" along the edges and every 12" in the field.

Secure the joists to the outer skids with angles. Drive hanger nails into the joists and 16d nails into the skids.

Frame and raise the walls, then fasten adjacent walls together at the corner studs.

STEP B: FRAME THE WALLS

-

Snap chalk lines on the floor for the wall plates.

-

Cut the 2 × 4 wall plates: four at 144" for the side walls and four at 89" for the front and back walls.

-

Mark the stud layouts onto the plates following the FLOORPLAN.

-

Cut twenty-seven studs at 92 5/8", and cut six at 81 1/2" to serve as jack studs.

-

Build three headers with 2 × 6s and 1/2" plywood: one at 65" for the door opening, one at 67" for the right side window, and one at 35" for the rear window.

-

Assemble, raise, and brace the walls one at a time, then add the double top plates.

STEP C: FRAME THE ROOF

-

Cut two pattern rafters, following the RAFTER TEMPLATE. Test-fit the rafters using a 2 × 8 spacer block, then cut the remaining twelve common rafters. Cut eight rafters for the gable end overhangs—these do not have bird's mouth cuts.

-

Cut the 2 × 8 ridge board at 156". Draw the rafter layout onto the top plates and ridge board, using 16" on-center spacing. The outsides of the outer common rafters should be 6" from the endsof the ridge board.

-

Install the rafters. Reinforce the rafter-wall connection with metal anchors—install them on all but the outer common rafters.

-

Cut three 2 × 4 rafter ties at 96", and clip the top outer corners so they won't project above the rafters. Position each tie next to a pair of rafters as shown in the FRAMING ELEVATIONS. Facenail each tie end to the rafter with three 10d nails, then toenail each tie end to the top wall plate with two 8d nails.

-

Cut the gable-wall plates to reach from the ridge to the wall plates. Install the plates with their outside edges flush with the outer common rafters. Cut and install the gable studs, following the FRAMING ELEVATIONS.

Fasten the bottom ends of the common rafters to the wall plates with metal anchors.

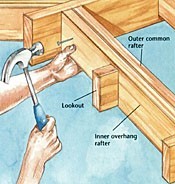

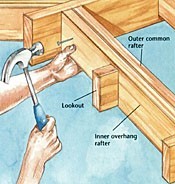

Attach lookouts to four of the overhang rafters, then nail the overhang rafters to the outer common rafters.

STEP D: BUILD THE GABLE OVERHANGS

-

Cut twelve 2 × 6 lookouts at 3". Endnail the lookouts to eachof the inner overhang rafters, using 16" on-center spacing (see the GABLE OVERHANG DETAIL).

-

Facenail the inner overhang rafters to the outer common rafters with 10d nails.

-

Fasten the outer overhang rafters to the ridge and lookouts, using 16d nails.

STEP E: INSTALL THE FASCIA, SHEATHING & ROOFING

-

Cut and install the 2 × 6 subfascia along the eaves (see the EAVE DETAIL). Keep the ends flush with the outsides of the overhang rafters, and the bottom edges flush with the bottom rafter edges; use 16d nails.

-

Install the 1 × 8 fascia along the gable overhangs, then along the eaves, holding it 1/2" above the rafters so it will be flush with the sheathing; use 6d galv. finish nails.

-

Install the 1/2" plywood sheathing, starting at a lower corner of the roof; use 8d box nails driven every 6" along the edges and every 12" in the field of the sheets.

-

Attach metal drip edge along the eaves, then apply 15# building paper over the sheathing. Add dripedge along the gable ends, over the paper.

-

Install the asphalt shingles, starting at the eave edge. If desired, install roof vents.

Install the plywood roof sheathing after installing the fascia. Nail every 6" at the edges and every 12" in the field.

Rip the soffit panels to fit between the wall plates and fascia. Fasten the panels to the nailers, rafters, and subfascia.

STEP F: INSTALL THE SOFFITS & SIDING

-

Cut twelve 2 × 2 nailers to fit between the rafters, as shown in the EAVE DETAIL. Fasten the nailers between the rafters with 10d facenails or 8d toenails.

-

Rip the 3/8" plywood soffit panels to fit between the wall framing and the fascia. Fasten the soffits to the rafters with 3d galv. box nails.

-

Cut holes for four soffit vents: locate one vent in each of thetwo outer rafter bays, along the eave, on both sides of the building. Install the soffit vents.

-

Install the plywood siding, using 8d galv. finish nails. Butt the top edges of the siding against the soffits. Don't nail the siding to the rear-window and door headers in this step. At the gable ends, install Z-flashing along the top edge of siding, then continue the siding up to the soffits.

Note: Along the side walls, 8-ft. siding will cover the floor plywood by about 1/2" (this is necessary); if you want the siding to cover the floor framing, use 4 × 9-ft. sheets.

STEP G: BUILD & INSTALL THE DOORS

1. Cut out the bottom plate from the door opening.

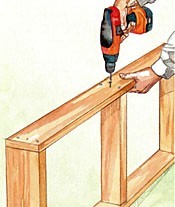

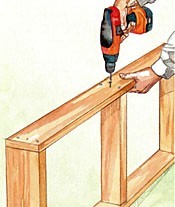

2. Cut the door frame pieces from 3/4" × 4 1/2" (actual dimension) cedar: cut the head jamb at 61 1/4" and the side jambs at 81 7/8". Assemble the frame by screwing through the head jamb and into the side jambs with 2 1/2" deck screws.

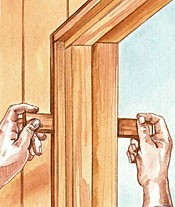

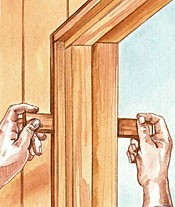

3. Cut 1 × 2 stops and install them inside the jambs with 11/4" deck screws or 3d galv. finish nails. If the doors will swing out, install the stops 2 1/4" from the outside edges of the frame; if they'll swing in, install the stops 2 1/4" from the inside edges.

4. Install the door frame in the rough opening, using shims and 10d galv. casing nails. Make sure the frame is square and plumb.

5. Cut twelve pieces of 1 × 6 tongue-&-groove boards at 81 3/4". For each door, fit together six boards with their ends flush, then mark the two end boards for trimming so that the total width is 30". Trim the end boards.

6. Cut the Z-brace boards following the DOOR ELEVATIONS. Lay the doors on a flat surface and attach the brace boards using construction adhesive and l 1/4" wood screws.

7. Install the hinges and hang the door, using shims to set the gaps at the bottom and top of each door.

8. Install flashing above the door, nail-off the siding, then install the 1 × 4 door trim, using 8d galv. finish nails.

Use pairs of tapered shims to plumb and level the door frame in the rough opening.

Assemble the window frames with screws. Add a 2 × 4 mullion in the center of the side window frame.

STEP H: BUILD & INSTALL THE WINDOWS & TRIM

Note: If you've bought prehung windows for the shed, install them following the manufacturer's directions. To build homemade windows, use the following directions.

1. For each window, cut the 3/4" × 4 1/4" frame stock to form a rectangular frame with outer dimensions that are 1/2" shorterand narrower than the rough opening. Assemble the frame with 2 1/2" deck screws. Cut and install a 2 × 4 mullion in the center of the frame for the side-wall window.

2. Install each window frame in its rough opening, using shims and a level to make sure the frame is plumb and level and the jambs are straight. Fasten the frame with 10d galv. casingnails.

3. Cut the 1 × 2 stops. Bevel the outer sill stops as shown in the WINDOW JAMB DETAIL. Attach the inner stops with 6d galv. finish nails. Order the glass to fit.

4. Install the glass and outer stops, applying glazing tape to the stops on both sides of the glass. Install the 1 × 4 window trim.

5. Install the horizontal 1 × 4 trim as shown in the ELEVATIONS. Fasten the trim with 8d galv. finish nails.

6. Install the 1 × 4 corner trim so that it butts against the horizontal trim and extends to the bottom edges of the siding.

7. Caulk along all trim joints, where trim meets siding, and around the door and window trim.

STEP I: BUILD THE RAMP (OPTIONAL)

Determining the width and length (and thus the slope) of the ramp is up to you, but here is the basic constructionprocedure:

1. Determine the best slope for the ramp using boards or plywood set on the ground and the shed floor. Mark the ground to represent the end of the ramp.

2. Cut two 2 × 8 pads to the full width of the ramp.

3. Measure the distance from the ground to the shed floor; subtract 2" from that dimension to get the height of the tapered stringers.

4. Use the ground marking to determine the length of the stringers—be sure to account for the 1 1/2" thickness of the decking. Cut the tapered stringers from 2 × 8 lumber: cut one for each end and one for every 16" to 24" in between.

Attach the pads to the stringers with 16d galv. nails driven through the bottom faces of the pads and into the stringers

5. Cut 2 × 4s for the ramp decking—the number needed depends on the length of the sloping sides of the stringers. Allow for a 1/8" gap between decking boards when calculating the number needed.

6. Attach the decking boards to the supports with 16d galv. nails or 3" deck screws, maintaining a 1/8" gap between boards.

7. Set the ramp in place against the shed and fasten it by toenailing through the end stringers and top decking board with 3 1/2" deck screws.

Build the ramp with pressure-treated 2 × 8s and 2 × 4s, following the plan's size or building it to a custom size.