Chapter 7

Smart Sensor and Industrial IoT- a Driver for Industry Growth

Internet of Things (IoT) applications — regardless of whether for city foundations, processing plants, or wearable gadgets — utilize huge varieties of sensors gathering information for transmission over the Internet to a center, cloud-based computational resource. Software analytics on the cloud PCs decreases the volumes of produced information into noteworthy data for clients, and orders to actuators back out in the field.

Sensors are one key factor in IoT achievement, but these are not customary types that simply convert actual factors into electrical signals. They have expected to advance into something more complex to play out an in fact and financially feasible job inside the IoT climate.

This chapter dedicatedly surveys the IoT's applications for its sensors — how it should deal with accomplishments of the enormous sensor cluster's attribute of the IoT. When it tends to how producers have reacted with enhancements to creation, more reconciliation, and inherent insight, coming full circle in the idea of the smart sensors now in wide use.

It will become clear that sensor insight, aside from working with IoT networks, also makes a lot more advantages identified with prescient support, more adaptable assembling, and improved efficiency.

What Does The IoT Expect Of Its Sensors?

Sensors have been functioning as direct gadgets that change actual data into electrical signals or changes in electrical properties. While this usefulness is at a beginning stage, sensors need to add the accompanying properties to proceed as IoT segments:

Low cost, so they can be financially conveyed in huge numbers

Low cost, so they can be financially conveyed in huge numbers

Physically little, to "vanish" subtly into any climate

Physically little, to "vanish" subtly into any climate

Wireless, as a wired association is practically unrealistic

Wireless, as a wired association is practically unrealistic

Self-distinguishing proof and self-approval

Self-distinguishing proof and self-approval

Very low force, so it can get by for quite a long time without a battery change, or deal with energy collecting

Very low force, so it can get by for quite a long time without a battery change, or deal with energy collecting

Robust, to limit or take out support

Robust, to limit or take out support

Self-symptomatic and self-recuperating

Self-symptomatic and self-recuperating

Self-aligning, or acknowledges adjustment orders through remote connection

Self-aligning, or acknowledges adjustment orders through remote connection

Data pre-preparing, to diminish the load on gateways, PLCs, and cloud resources

Data pre-preparing, to diminish the load on gateways, PLCs, and cloud resources

Data from various sensors can be combined and associated to make informed decisions about inactive issues; for instance, temperature sensor and vibration sensor information can be utilized to recognize the beginning of mechanical failure. Sometimes, the two sensor capacities are accessible in one gadget; in others, the capacities are combined in programming to make a 'delicate' sensor.

The Manufacturers' Response: Smart Sensor Solutions

This part takes a look at the smart sensors that have been produced for IoT applications as far as both their structure blocks and their manufacturing and afterward surveys a portion of the benefits that build from the sensors' in- assembled knowledge, particularly the opportunities for self-diagnostics and fix.

What's in a Smart Sensor and what is it capable of?

We've explored the IoT's assumptions for a smart sensor, however, how has the business reacted? What's incorporated into a cutting-edge smart sensor and what is it prepared to do?

Smart sensors are worked as IoT segments that convert this present reality variable that they're estimating into an advanced information stream for transmission to a gateway. The application calculations are performed by a built-in microprocessor unit (MPU). These can run sifting, remuneration, and some other process explicit sign molding assignments.

The MPU's knowledge can be utilized for some different capacities also to decrease the load on the IoT's more focal assets; for instance, alignment information can be shipped off the MPU so the sensor is naturally set up for any creative changes. The MPU can also detect any creation boundaries that begin to float past adequate standards and produce alerts in like manner; administrators would then be able to make a precaution move before a disastrous disappointment happens.

The sensor could properly work in "report by special case" mode, where it possibly communicates information if the deliberate variable worth changes altogether from past sample value. This diminishes both the heap on the focal registering asset and the smart sensor's power requirements — typically a basic advantage, as the sensor should depend on a battery or energy collecting without associated power.

If the smart sensor remembers two components for the test, sensors’ self- diagnostics can be implicit. Any developing float in one of the sensor component outputs can be distinguished right away. Furthermore, if a sensor is completely damaged— for instance, because of a short circuit or any other reasons— the process can proceed with the second estimating component. Then again, a test can contain two sensors that turn out together for improved checking input.

IoT sensors are vital for the new industrial age?

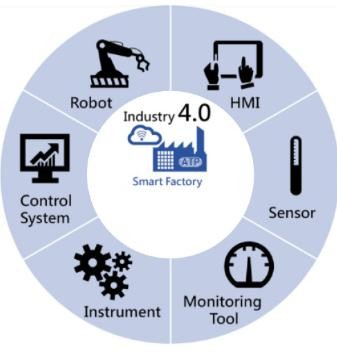

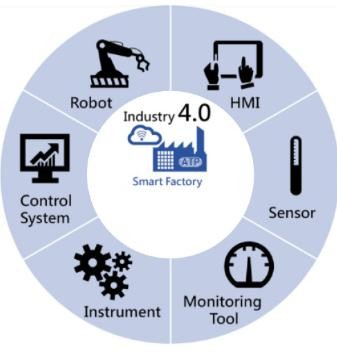

While there is no single standard that could be applied to help the case that a sensor is "smart", Smart Sensors are primarily described by ready knowledge and the capacity to convey through an advanced organization. With the development of both the Internet of Things (IoT) and the Industrial IoT (IIoT), new sensors and related applications are coming up every day. Progressively, these sensors are "brilliant", a necessity for IoT sensors just as for some mechanical applications.

Sensors are all over, both in industry and in our regular daily existences in day-to- day life. In modern offices, they measure factors like temperature, pressure, level, stream, pH, and turbidity; electrical factors like the voltage, flow, and frequency; and mechanical factors like turn, number of processes, position, course of movement, static and dynamic pressing factors, vicinity; natural factors like dampness, vibration, wind speed and heading, etc.

In our regular daily life, sensors measure as well as show the temperatures inside and outside our homes, workplaces, or plants; road lighting levels and traffic streams; how quick we're driving our vehicles and whether another vehicle is in our vulnerable side; regardless of whether the vehicle door is shut and if travelers have affixed their safety belts; our actual area; the structure floor that the lift has reached; the temperatures inside our fridge and ACs, the cost of a container of cereal or container of milk; where our bags have meandered to in an airport, etc.

The particular applications for sensors or estimation systems shift across businesses. The compound, oil, and gas, and atomic force age businesses need sensors to oversee the basic process. The electric power industry also expects sensors to oversee topographically huge power transmission and dispersion systems.

In these kinds of basic foundations, guidelines have been created to address correspondence, interoperability, unwavering quality, alignment, security, and precision for smart sensors. Different enterprises have done as such also. Sensor principles vary generally across these and different businesses like logistics, clinical gadgets, drugs, mash and paper, food and drink, agribusiness, building energy the board, smart urban cities, rail and traffic light, self-ruling vehicles and robots, military, airport regulation, research, climate checking, transporting, etc.

Smart Sensors in the Process Industries

In the process businesses, sensors were utilized before automated correspondences or even power were accessible. The simply mechanical sensor and actuator work to choke a steam valve to adequately direct motor speed.

Afterward, pneumatic sensors communicated simple (3-15 psi) signals as pressing factors to pneumatic regulators, regularly fusing round graph recorders for information obtaining. These regulators, thus, controlled pneumatic control valves to close the control circle. (Air conditioning systems in most enormous structures utilize comparable pneumatic techniques for zone control.)

Electronic simple controls embraced the 4-20 mA standards for conveying between sensors, regulators, and actuators. 4-20 mA signals are generally invulnerable to the electrical commotion and with per-point wiring; correspondence is dependable and simple to investigate. Simple signs, regardless of whether pneumatic or electronic, additionally oppose hacking, as this would require actual admittance to wires or tubing and, probably, could just affect a solitary sensor reading. Electronic simple guidelines are still broadly utilized today in DCS and PLC systems utilized for measure control in numerous ventures, just as for various other mechanical and business systems requiring control and additionally observing. A shockingly huge number of more established plants additionally still utilize probably some pneumatic sensors and controls.

With the coming of automation technologies, the industry created proper principles for measure control and computerized or "smart" sensor organizations, both wired and remote. These empowered a vast variety of gadget status, ID, demonstrative, time stamp, and other information to be imparted alongside the computerized estimation signal.

Sensors in the Discrete Manufacturing Processes

To meet the particular necessities of the discrete assembling ventures, CANbus, DeviceNet, Sercos, EtherCAT, and another high velocity, yet less information-rich sensor organizations and conventions arose to help computerized correspondences between smart sensors and PLCs, HMIs, information securing systems, etc. These incorporate both wired and remote organizations.

Smart Sensors and IT/OT Convergence

Today, with the expanding union of operational innovation (OT) and information technology (IT), Ethernet-based interchanges are unavoidably moving further down in the computerization chain of command. Ethernet-based conventions offer the possibility to kill the presentation and transfer speed impediments of FOUNDATION Fieldbus and Profibus. In any case, along with the goals to remain consistent with the IT world's Ethernet standard, a wide range of "flavors" of these Ethernet-based conventions will in general go astray fairly from the first Ethernet, hampering interoperability and making disarray inside the commercial center. Arising norms like OPC UA TSN (time-touchy systems management) could ultimately answer here in both the cycle and discrete assembling ventures, especially for non-wellbeing related or comparable applications.

The Industrial IoT additionally offers the guarantee of using recently abandoned resource information from the minimal expense, web-connected smart sensors mounted directly on gear and machines related to cutting-edge investigation programming to recognize, distinguish, and stay away from execution debasement or resource disappointments. Eventually, this could enhance modern resource accessibility, use, and execution to improve return on resources and backing operational greatness.

Manufacturing

To understand the maximum capacity of the IoT, sensor manufacturing strategies should keep on reducing the size, weight, force, and cost (SWaP-C) of the sensor part and system. A similar pattern needs to apply to sensor bundling, which at present records for as much as 80% of the general expense and structure factor.

Smart sensors structure when miniature electromechanical system (MEMS) sensor components are firmly incorporated with CMOS integrated circuits (ICs). These ICs give gadget predisposition, signal intensification, and other signal preparing capacities. Initially, the wafer- level vacuum package (WLVP) innovation utilized included just discrete sensor gadgets, and smart sensors were acknowledged by interfacing discrete MEMS chips to IC chips through the bundle or board substrate in a methodology called multi-chip reconciliation. An improved methodology interconnects the CMOS IC and sensor components directly, without the utilization of directing layers in the bundle or board, in a development known as a system-on-chip (SoC). When contrasted with the discrete multi-chip bundling approach, SoC is commonly more perplexing however prompts decreased parasitic, little footprints, higher interconnect densities, and lower bundle costs.

Different Advantages of Smart Sensor Intelligence

Brilliant photoelectric sensors can identify designs in an object structure and any progressions in them. This happens autonomously in the sensor, in no outside processing component. This expands preparation throughout and decreases the focal processor — or neighborhood PLC's — handling load.

Assembling adaptability is improved — an essential benefit in the present cutthroat climate. Smart sensors can be distantly modified with appropriate boundaries each time an item change is required. Creation, investigation, bundling, and dispatch can be set for even single-unit clump sizes at large scale manufacturing costs, so every buyer can get a customized, one-off item.

Input from straight position sensors has generally been hampered by issues identifying with system commotion, signal lessening, and reaction elements. Every sensor required tuning to defeat these issues. Honeywell offers an answer with their SPS-L075-HALS Smart Position Sensors. These can self-adjust by utilizing a protected blend of an ASIC and a variety of MR (magnetoresistive) sensors. This precisely and dependably decides the situation of a magnet appended to moving articles like lifts, valves, or hardware.

The MR cluster estimates the output of the MR sensors mounted along the magnet's course of movement. The output and the MR sensor succession decide the closest pair of sensors to the focal point of the magnet area. The output from this pair is then used to decide the situation of the magnet between them. This non-reaching innovation can furnish upgraded item life and sturdiness with less vacation. A self- diagnostics highlight can additionally lessen vacation levels.

These sensors compensate for the other sensors requirements. Their little size permits establishment where space is at a higher cost than expected, while IP67 and IP69K fixing alternatives permit arrangements in unforgiving conditions. They are smart enough to supplant a few sensors and switch segments along with the additional wiring, outside parts, and associations also recently required. The sensors are utilized in aviation, clinical, and modern applications

Smart Sensors with Self-Diagnostics and Repair Capabilities

Smart sensors can also be appropriate to security basic applications like the location of dangerous gas, fire, or interlopers. The situation in these conditions can be brutal, and the sensors can be hard to access for support or battery substitution, but high dependability is basic. A group at the Lab-STICC Research Center, University of South-Brittany, has been looking for an answer that improves unwavering quality by utilizing double tests and equipment that can self-analyze and fix itself.

A definitive objective of their undertaking is to incorporate every one of the components portrayed into a solitary discrete gadget, appropriate for applications, for example, dangerous gas recognition in regions like harbors or stockrooms. The task fixates on a hub that can pinpoint an inward failure and make a remedial move to improve both unwavering quality and energy proficiency. This decreases the hub's weakness and reduces maintenance costs. The plan perceives the impediments of such sensors: confined battery self-governance, energy collecting subject to untrustworthy fuel source conduct, restricted preparing and capacity assets, and a requirement for remote correspondences.

A viable model: a practical example

An application created by Texas Instruments gives a pragmatic illustration of a smart sensor, and how its structure blocks cooperate to produce helpful data from simple current and temperature estimation, just as giving the insight to different capacities referenced. The application utilizes a variation of their super low-power MSP430 MCU reach to assemble a savvy shortcoming pointer for electric force dissemination organizations.

When appropriately introduced, deficiency pointers decrease working expenses and administration interferences by giving data about a failed part of the organization. Simultaneously, the gadget expands wellbeing and decreases gear harm by diminishing the requirement for risky deficiency symptomatic strategies. Shortcoming markers, because of their area, are battery-controlled, so low-power activity is additionally profoundly attractive.

The deficiency pointers — which are introduced on the intersections of the overhead electrical cable organization — send estimation information about the temperature and flow in power transmission lines remotely to the concentrator/terminal units mounted on the shafts. The concentrators utilize a GSM modem to pass the information to the cell organization to transfer real-time data to the main station. The main station can also control and run diagnostics on the deficiency pointers through this equivalent information way.

Consistent association with the main station enjoys a few benefits. The first is the capacity to remote screen issue conditions instead of looking for them in the field. A smart fault indicator can also continually screen temperature and current so the regulator at the primary station has continuous status data about the force dissemination organization. Likewise, power utility suppliers can rapidly distinguish the fault area, limit power vacation, and even make a move before a failure happens. Laborers at the main station can run diagnostics on the shortcoming markers at expected spans to watch that they are working effectively.

Genuine Examples

1. ABB: Smart mechanical technology

Power and advanced mechanics firm ABB is perhaps the most noticeable to accept the idea of prescient support, utilizing connected sensors to screen its robots' maintenance needs — across the globe — and trigger fix before parts break. Additionally identified with IoT is the organization's collective mechanical technology. Its YuMi model, which was intended to work together close by people, can acknowledge input through Ethernet and modern conventions like Profibus and DeviceNet.

2. Airbus: Factory of the Future

To say that gathering a business jetliner is an intricate undertaking would be putting it mildly. Such art has a great many parts and a huge number of gathering steps, and the expense of slip-ups during the interaction can be huge. To handle the intricacy, Airbus has dispatched an advanced assembling drive known as Factory of the Future to smooth out activities and support the creation limit. The organization has coordinated sensors to devices and machines on the shop floor and given specialists wearable innovation — including modern smart glasses — intended to diminish blunders and support security in the work environment. In one method, known as lodge seat denoting, the wearables empowered a 500% improvement in efficiency while reducing most of the mistakes.

3. Amazon: Reinventing warehousing

The online retail monster doesn't frequently get called an IIoT organization; in any case, no doubt, the organization is a trailblazer with regards to warehousing and coordination. The MIT Technology Review has described it as below:

Amazon is "trying the restrictions of computerization and human-machine joint effort." While the organization's desires to utilize drones for conveyance have won significant media consideration, the company's satisfaction distribution centers utilize multitudes of Wi-Fi-associated Kiva robots. The essential thought behind the Kiva innovation, which Amazon procured for $775 million in 2012, is that it bodes well to have robots find racks of items and carry them to laborers instead of having representatives go to the racks to chase for items. In 2014, the robots helped the organization cut its working expenses by 20%, as per Dave Clark, a senior VP at Amazon.

4. Boeing: Using IoT to drive fabricating proficiency

Aeronautics pioneer William Boeing jested that it "benefits nobody to excuse any clever thought with the assertion, 'It isn't possible.'" The global flying organization established in Boeing's name still buys into that ethos. It is presently running after the drawn-out objective of making its administration contributions more significant than its items while being the most important data supplier in flight. The organization has effectively taken huge steps in changing its business. Boeing and its Tapestry Solutions auxiliary have forcefully conveyed IoT innovation to drive productivity all through plants and supply chains. The organization is additionally consistently expanding the volumes of associated sensors implanted into its planes.

5. Bosch: Track and follow pioneer

In 2015, Bosch dispatched what might be the Industrial Internet Consortium's first proving ground. The essential motivation behind the purported Track and Trace program is that laborers would spend a sizable measure of their time chasing down apparatuses. So the organization added sensors to its apparatuses to follow them, beginning with a cordless nutrunner. As the goal of the following turns out to be more exact, Bosch intends to utilize the system to control assembling tasks.

6. Caterpillar: An IIoT pioneer

Heavy-hardware producer Caterpillar has for some time been an IoT projects pioneer. As of late, the organization, which currently passes by "Feline," has been flaunting the products of its interests in IoT innovation. For example, consider how it is utilizing IoT and augmented reality (AR) applications to give machine administrators an initial perspective on everything from fuel levels to when air channels need supplanting. On the off chance that an old channel terminates, the organization can send essential guidelines for how to supplant it through an AR application. The organization's marine resource knowledge division is also a pioneer. A year ago, Forbes ran an article clarifying how the organization utilized sensor-driven investigation to get a good deal on boats and delivery vessels.

7. Fanuc: Helping to limit vacation in industrial facilities

Mechanical technology producer Fanuc is not kidding about diminishing vacation in modern offices. Utilizing sensors inside its mechanical technology combined with the cloud-based examination, the organization can foresee when the failure of a part, for example, an automated system or process gear is fast approaching. While prescient upkeep is a natural idea, Fanuc has accepted it more forcefully than most. A year ago, GM granted Fanuc's Zero Downtime (ZDT) system its Supplier of the Year Innovation Award.

8. Gehring: A pioneer in connected manufacturing

Gehring Technologies, a 91-year-old organization that makes machines for sharpening metal, was right on the time to accept IIoT innovation. Presently, the organization empowers its clients to see live information on how Gehring's machines work before they put in a request. It does as such by utilizing computerized innovation, radiating continuous data from another machine to a client to guarantee that it meets the client's necessities for accuracy and effectiveness. Gehring utilizes a similar cloud-based constant following to decrease personal time and improve its assembling efficiency through observing its connected manufacturing system, imagining and breaking down information from its machine devices in the cloud.

9. Hitachi: An incorporated IIoT approach

The Japanese organization stands apart from other modern organizations as far as its reconciliation and experience across operational and data innovation. While most other modern combinations influence associations to fill in the holes in their IoT information, Hitachi is more autonomous. The organization has more than 16,000 representatives focused on innovation in some limits. While it offers an IoT stage known as Lumada, Hitachi additionally makes plenty of items utilizing connected innovation, including trains, which the organization is starting to sell as a service. Hitachi has additionally fostered an IoT-upgraded manufacturing model that it claims has cut manufacturing lead times considerably inside its Omika Works division, which fabricates foundation for power, traffic, steel producing, and different ventures.

10. John Deere: Self-driving farm vehicles and that's just the beginning

As the field of agriculture turns out to be all the more a science and less of craftsmanship passed down the generational line, John Deere is reacting by sending Internet of Things innovation — maybe most remarkably with self-driving farm vehicles. As The Washington Post wrote in 2015, Google didn't lead oneself to drive vehicle unrest. John Deere did. The organization also turns out to be a pioneer in GPS innovation. Also, the organization has conveyed telematics innovation for prescient support applications.

11. Kaeser Kompressoren: Air service

Established in 1919, the German creator of pneumatic machines, compressed air dryers, and channels is a trailblazer with regards to coordinating computerized interchanges into its items. The organization offers "advanced twins" for its items and supports prescient upkeep. One of its most popular Industry 4.0 endeavors identifies with its plan of action development as selling "air as a help," which is an amazing accomplishment for an organization that has sold hardware for as far back as the century.

12. Komatsu: Innovation in mining and substantial hardware

The Japanese substantial hardware producer has plenty of IIoT advancements. Beginning in 2011, it has conveyed connected innovation in its Japanese creation offices. Komatsu has connected the entirety of its robots at its focal creation offices to the web, empowering directors to watch out for worldwide tasks continuously. The organization is an inventive power in mining. Its enormous self-driving trucks can be seen in Rio Tinto's Mine of the Future in Australia. Komatsu as of late procured U.S. mining gear creator Joy Global, which had created associated longwall shearers for coal mining that can remotely send 7,000 information focuses each second to the organization's server farm.

13. KUKA: Connected mechanical technology

German mechanical technology expert KUKA has an IoT technique that reaches out to entire production l