Chapter 2

List of Sensors And Their Specifications

There are numerous sensors we have to list here and then discuss. Let’s start!

We already discussed very briefly the classification of sensors earlier in the book. That was just to give the readers a simple idea about the variety of sensors. There are still a lot of sensors left that aren’t even mentioned yet. We are going to discuss each one of them including their specifications, working principles, and applications.

Types of sensors

Sensor/Detectors/Transducers are electrical, electrical, or electronic gadgets made out of strength hardware or delicate materials, for deciding whether there is a presence of a specific substance or function.

Numerous types of sensors, indicators, and transducers are accessible including those for recognizing an actual presence like fire, metals, breaks, levels, or gas and synthetics, among others.

Vision and Imaging Sensors

Vision and Imaging Sensors/Detectors are electronic gadgets that distinguish the presence of objects or colors inside their fields of view and convert this data into a visual picture for show. Key details incorporate sensor type and proposed application, alongside specific transducer highlights.

Vision and imaging sensors are utilized in many assembling tasks for quality control, presence detecting, situating and arranging, marking examining, holding and managing, and so forth. The sensors might have underlying touch screens for locally available programming or they might be modified distantly.

In such a manner, they can go about as numerous different sensors do and convey output messages to control systems to coordinate activities on parts (or not) – launching a bombed bundle, for example. Such frameworks are named "installed vision" frameworks to depict a gadget that incorporates the picture securing segments as well as the picture handling framework too, once in a while called a "smart" camera.

Different degrees of implanted vision are accessible, and the term is something of an industry trendy expression. Both monochrome and shading sensors are accessible. In any event, for some assignments where tones or color should be recognized, a monochrome system is regularly capable. Shade processing is quite difficult in comparison.

Most sensors will utilize light rings around their focal points to give adequate brightening to the optics. In some cases, valuable lighting is utilized. Lights can be white, red, blue, or green, contingent upon the necessity of the imaging task. Deformities on surfaces now and then appear better to the unaided eye under green light. Backdrop illumination is here and there used to improve the outline of an intricate shape whose subtleties may be lost under front lighting. Infrared and bright lighting alternatives are additionally accessible.

Focal points are replaceable to convey different wide-point or fax pictures. Imaging sensors are by and large quick enough to catch pictures as items move past them. For rapid lines like printing, other picture detecting strategies are utilized, as talked about underneath.

Inspection

Vision sensors can be customized to identify numerous sorts of highlights. For instance, a territory sensor is utilized to identify missing highlights in a machined part, like an opening or multiple openings. It very well may be utilized to lead a pack assessment to be certain each blister is filled. Imperfection sensors are utilized to find scratches on a surface or unfamiliar matter on bundling material or to check highlights under sub-ideal lighting.

Match sensors are utilized to contrast examples like engravings with reference designs, to check name situations on bundles, or to affirm that a weld nut is in position. A sort sensor could be utilized to check a section against different examples for arranging it. It very well may be utilized also to confirm that every one of the segments of a careful unit is set up. These are not individual sensors yet rather unmistakable working modes for a similar individual sensor. Sensors can be modified to institute any of the different cache modes.

Vision sensors are generally clear in their arrangement and programming. Picture catch of a "great" part can be utilized as a source of perspective and different spaces of interest chose in the product for correlation with the known great picture.

Dimensional information is assembled by tallying pixels, hence making it conceivable to check an opening or other part included for breadth, for example.

The arrangement generally happens with the camera in a fixed situation for reviewing and a considerable lot of the arrangement steps, like centering, are a one-time set and fail to remember activity.

Inspection systems are not restricted to stopping point applications. Systems can be utilized at transitional strides in an assembling interaction to check, for instance, a right gets together in succession. In this camera-tuned-in situation, the examination framework could signal an off-base gathering as it occurs and have the constructing agent right the issue preceding proceeding onward to an ensuing advance simultaneously.

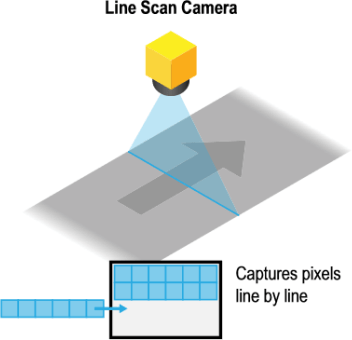

Line Scan Cameras

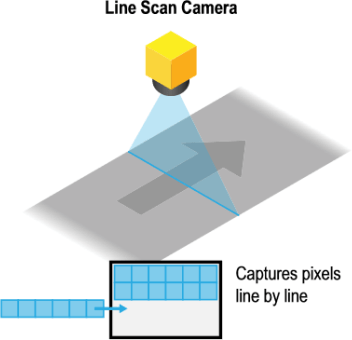

Investigating discrete parts with vision sensors is an unexpected issue in comparison to examining ceaseless tasks, for example, printed networks or sheet steel where the item moves by incredibly rapidly.

While region cameras are now and then utilized in such applications and the subsequent pictures "sewed" together in programming, another arrangement is the utilization of a line examine camera.

These cameras are sequenced with the speed of the moving material to take a solitary line depiction utilizing lines of pixels. Such cameras could be utilized on a vegetable arranging line to eliminate trash and unsatisfactory items from the line utilizing downstream air jets.

By and large, these cameras require separate picture handling and are not independent vision sensors, in essence.

3D Cameras

Three-D cameras utilize a few strategies for deciding 3D imaging, including sound system vision, the season of flight, and laser triangulation. Each has its pluses and minuses. Sound system vision can be precise yet inadmissible in low light, and it consumes processor time; season of-flight is useful for estimating distances and volumes and is frequently utilized for palletizing activities and on self-governing vehicles; and, laser triangulation is acceptable in low light and for complex surfaces yet will, in general, be moderate.

Triggering off

Vision sensors can be set to catch pictures in different ways. Called setting off, the sensors react to the input by catching a picture and investigating it. For instance, the sensor can utilize an inside clock to catch a picture of each x number of seconds.

An outer source, for example, a machine regulator can advise the sensor to catch a picture depending on some condition of the machine. The sensor may likewise be set to run consistently, or be activated from a sign getting through a mechanical Ethernet or from outer, manual information.

Temperature or Thermal Sensors

Temperature Sensors are electronic devices that identify heat sources and give the signal to the input systems and display the processed information on gadgets. A temperature sensor normally depends on an RTD or thermistor to quantify temperature and convert it to an output voltage. Key details incorporate sensor/identifier type, most extreme and least quantifiable temperatures, just as the elements of the distance across and length.

Temperature sensors are utilized to measure the thermal qualities of gases, fluids, and solids in many interaction businesses and are designed for both general and particular uses.

The term temperature sensor refers to a class of gadgets that give an estimation of the temperature of items, and either show straightforwardly or produce an output signal whose worth can be converted into a temperature display. Temperature is a basic estimation of nuclear power and can be considered as a proportion of the normal active energy of the particles and atoms of a material.

There are specific part numbers also which helps to find specific thermal sensors for example

D6T-1A-01

High affectability empowers the location of fixed human presence. Its application isn't restricted to any one area however it is valuable and fit for acting in energy and family areas as well.

It is profoundly precise and leaves a little impression and it is not difficult to work with. D6T series sensors can recognize human presence by detecting changes in human internal heat level as for the encompassing temperature.

OMRON's extraordinary MEMS and ASIC innovation accomplish a high accuracy Super commotion resistance with an advanced output High-accuracy region temperature discovery with low crosstalk field of view qualities

D6T-1A-02

The D6T-1A-02 Omron Sensor is a board mounted temperature sensor or MEMS thermal sensor which is used to detect the surface temperature of any object without making a contact. It can identify human body temperature in comparison to the surroundings.

The D6T-1A-02 Omron Sensors are made up of a small circuit board with a silicone lens and thermopile sensor and the logic circuit making it a very efficient thermal sensor for human detection.

D6T-32L-01A

It has a contactless estimation making energy- productive and happy living spaces. High Accuracy, Smaller Footprint, East to Work With.

OMRON's exceptional MEMS innovation permits joining thermocouple components and ASICs into one bundle coming about to super smaller impression.

MEMS Thermal (PIR sensor) measures the surface temperature of items without contacting them when the thermopile component ingests the measure of brilliant energy from the object.

D6T series sensors can distinguish human presence by detecting changes in human internal heat level regarding the encompassing temperature.

These sensors can identify protests by pinpointing the objective article temperature.

These sensors let you measure temperature without the need to genuinely contact the item. This permits estimating temperature where it was impractical for contact with warm sensors because of space deficiency. The sensors can be utilized in a wide scope of uses including FEMS (Factory Energy Management System).

D6T-44L-06

This permits estimating temperature where it was unrealistic for contact with warm sensors because of space deficiency. The sensors can be utilized in a wide scope of uses including FEMS (Factory Energy Management System). It can distinguish the article by pinpointing the heat source.

Before utilizing the Sensor, obtain a satisfactory agreement and make an earlier evaluation of Sensor attributes in your real system.

D6T-8L-09

This item includes a circuit board size of 14 mm x 18 mm. A considerably more conservative size of 11.6 mm x 12 mm is additionally accessible.

Temperature sensor types

Temperature sensors, by and large, can be categorized as one of these essential sorts:

- Thermocouples

- RTDs (Resistance Temperature Detectors)

- Thermistor Temperature Sensors

- Semiconductor Temperature Sensors

- Thermometers

- Vibrating Wire Temperature Sensors

Most of these (the exemption being infrared temperature sensors) are contact sensors, implying that the sensor or test should physically touch or contact the item whose temperature is being measured to display.

Except for certain types of thermometers, most temperature sensors are intended to produce an electrical sign output that is utilized to set up the worth of temperature.

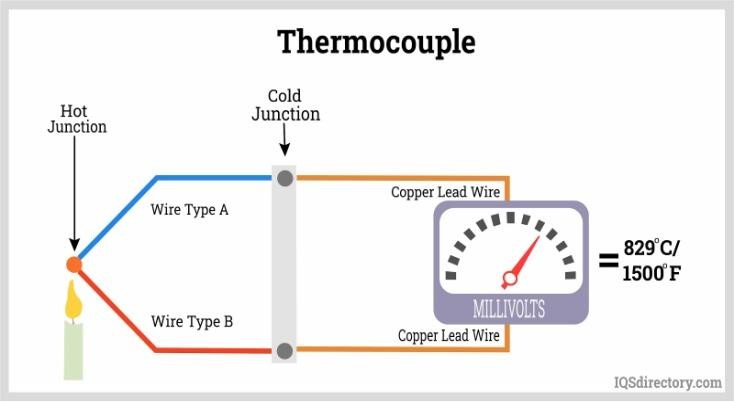

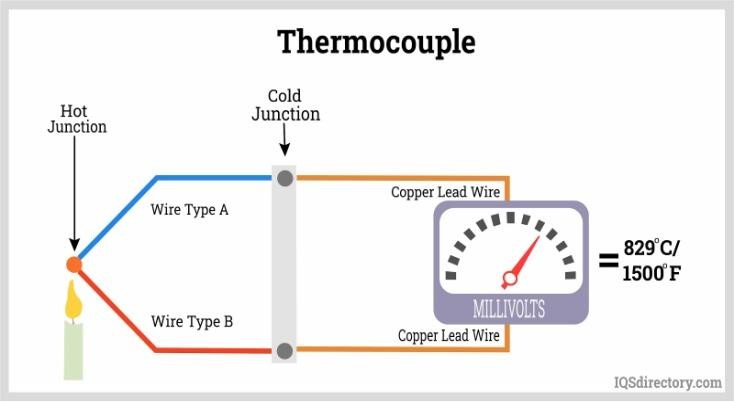

Thermocouples

Thermocouples measure temperature by utilizing a test developed by combining two distinct metals to frame an intersection toward one side and to which a voltmeter is associated at the opposite end. The finish of the test called the hot intersection (where the metals are joined) is utilized to contact the item whose temperature is being estimated, while the opposite finish of the test called the cool intersection is sitting at a reference temperature. An expected distinction in Volts recorded on the voltmeter will be available whose esteem relatively addresses the temperature contrast between the hot and cold intersections of the thermocouple.

Most thermocouples are canvassed in a defensive sheath to separate the metals from the surrounding temperature and to give some level of security against consumption. Sheath materials incorporate 1316 hardened steel, 304 tempered steel, or Inconel 600 as specific illustrations.

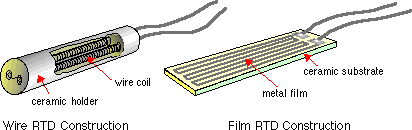

RTDs (Resistance Temperature Detectors)

Resistance Temperature Detectors, condensed RTDs, are temperature sensors that use the adjustment of the electrical obstruction that happens in a conductive material to set up an incentive for the temperature.

Transmitters of power, like metal, display electrical opposition that is a proportion of the relative straightforwardness with which electrical flow will move through the conduit when a given voltage or potential distinction is applied.

As the temperature changes, the electrical resistance also changes, which is measured in Ohms, with higher temperatures bringing an increment in resistance? RTDs comprise a resistive component through which a little electrical flow is passed, commonly in the scope of 1-5 milliamps, and the opposition is estimated.

Any temperature changes will modify the worth of the opposition estimate, which can be compared to temperature esteem by knowing the properties of the materials utilized for the resistive component. Platinum is a metal of decision utilized in RTDs inferable from the way that it is exceptionally steady, is artificially dormant, can work over a huge scope of temperature, and displays a solid direct connection between its opposition and temperature.

This last trademark improves on the way towards changing over electrical obstruction into temperature readings. Different decisions for resistive components in RTDs incorporate Nickel and Copper. The material utilized in RTDs is indicated by their temperature coefficient of obstruction (TCR), which is a proportion of how the electrical opposition of the material changes regarding a one-degree change in temperature.

Metals and electrically conductive materials display a positive worth of TCR, while semiconductors and non-metallic substances would show a negative TCR, implying that they become less resistive with expansions in temperature.

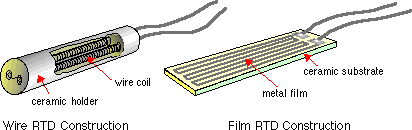

RTDs are fabricated normally built as either slight film or wire wound type. Film type RTDs use platinum that is plated onto a clay plate which is epitomized in glass, while wire-wound RTDs use platinum wire twisted around an earthenware center and fixed with glass encapsulated.

Distinctive sensor wiring setups are utilized with RTDs, for the most part, 2-wire, 3- wire, or 4-wire. Utilizing 2 wires gives a basic game plan however experiences precision given that the opposition of the wire leads can't be confined from the deliberate obstruction esteem.

The 3-wire setup takes into account two separate estimations to be made, permitting the effect of the wire lead protection from is deducted out from the all- out obstruction estimation, giving net opposition esteem. The 4-wire setup takes into account direct estimation of the sensor protection from being made, barring the effect of the lead wires.

A Wheatstone connect plan is ordinarily used to play out the obstruction estimations related to RTDs to set up temperature estimates.

Thermistor Temperature Sensors

Thermistors, a term got from a connection of the words thermally delicate resistors, are temperature detecting gadgets that utilize the property of the adjustment of electrical opposition that happens with temperature as methods for giving a display to the temperature esteem.

These passive gadgets show an exact change in their electrical opposition that is relative to the progressions in temperature of the gadget. There are two essential kinds of thermistors – Negative Temperature Coefficient (NTC) thermistors and Positive Temperature Coefficient (PTC) thermistors.

Negative Temperature Coefficient (NTC) thermistors are ones whose obstruction diminishes with an expansion in temperature, while Positive Temperature

Coefficient (PTC) thermistors show an increment in electrical opposition with expanding temperature.

The NTC thermistor is most regularly utilized in temperature detecting applications, while the PTC thermistor has been utilized in electrical circuit assurance applications like restricting the inrush flow or flood security for a circuit or gadget.

Thermistors are accessible in a wide variety of bundles, and structures including plate, chip, dot, or bar contingent upon the requirement for working temperature reach and reaction time. They can be bundled or epitomized in epoxy pitch, glass, prepared on phenolic, or painted.

By and large, they are little, easy temperature sensors that offer quick reaction times over a restricted working temperature range. They likewise have a bigger change in obstruction esteem per unit change in temperature, in this way offering potential for greater affectability and precision in readings.

Restrictions of thermistors are that they include non-direct temperature reaction bends, in contrast to RTDs, and are dependent upon self-warming if the excitation flows are excessively high. They additionally have a restricted temperature range and can get temperamental at higher temperatures. The temperature bends additionally fluctuate from one maker to another, confounding compatibility.

Applications for thermistors incorporate aviation, machines, auto, interchanges, HVAC, instrumentation, clinical, military, and refrigeration.

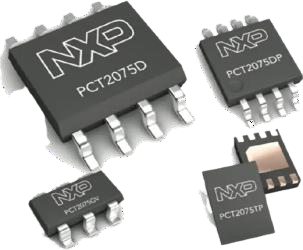

Semiconductor Temperature Sensors

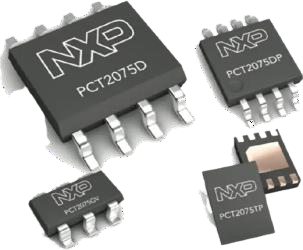

Semiconductor temperature sensors, at times called strong state temperature sensors, are temperature sensors that are created into Small Outline Integrated Circuit (SOIC) or other bundle styles, for example, TO-223 that would then be able to be mounted onto printed circuit boards (PCBs). The gadgets utilize semiconductor diodes or semiconductors whose voltage-current attributes have temperature reliance.

The primary types of semiconductor temperature sensors include:

- Voltage Output Temperature Sensors

- Current Output Temperature Sensors

- Digital Output Temperature Sensors

- Resistance Output Temperature Sensors

- Diode Temperature Sensors

These types of temperature sensors have genuinely great linearity to their output with temperature and can give sensible accuracy in readings over their reach given that they are effectively aligned. They do have a restricted temperature range, notwithstanding, and are not reasonable for the estimation of high temperatures.

Thermometers

Thermometers are the most seasoned and most natural type of temperature sensor being used in industry and families. Thermometers come in various kinds, perhaps the most unmistakable of these being the fluid thermometer.

This kind of thermometer comprises a cylinder ordinarily made of glass containing a liquid-like liquor or mercury, whose volume changes proportionately with temperature.

The cylinder is marked to a scale that has been aligned to show the temperature straightforwardly in either the Fahrenheit or Celsius (centigrade) scales. Various assortments, for example, handheld, pocket, and dark or red-hued display fluid are accessible.

Another thermometer assortment utilizes a bi-metal loop which is connected to a faceplate with a needle dial and graduations for the temperature perusing. Each metal utilized in the bimetallic strip has an alternate warm coefficient of development with temperature, which brings about the curl loosening up and twisting as the temperature changes. This rotational development positions the needle against the faceplate to mirror the current temperature perusing.

Infrared thermometers are non-contact electronic thermometers that show an advanced perusing of temperature rather than reading a simple scale. The gadgets sense the degree of dark body radiation produced by the article and convert that radiation level into a perusing of temperature.

The thermometer centers the energy through a perspective onto a thermopile which creates an electrical yield that is proportionate to the measure of heat retained. Infrared thermometers can record and store esteems, valuable to save time and make the methodology more proficient.

Infrared thermometers are utilized to record patient temperatures in zones like the tympanic film (eardrum) which is excessively touchy for the utilization of a standard contact thermometer. They are also significant for firemen to use as they can detect the temperature of walls to evaluate how fire has spread without expecting to destroy the wall to genuinely investigate it or check for problem areas in a consuming structure.

The way that the unit can take readings on a non-contact premise implies that the gadgets are additionally valuable in applications where direct contact would be unsafe to the workforce or hardware.

While thermometers are valuable, they are restricted by the way that numerous models require manual activity, are delayed to record and recuperate from a perusing, are not incredibly exact, and have a restricted reach in temperature over which readings might be made.

Not with standing these constraints, there are various models of thermometers available and they discover application in an assortment of employments, including:

- Agricultural and Dairy

- Air Conditioning

- Appliances

- Aquariums

- Baking and Cooking

- Boilers and Furnaces

- Breweries and Distilleries

- Candy Making

- Canning

- Confectionary

- Fruit Testing

- Greenhouses

- Heating Pads

- Laboratories

- Medical and Clinical patient fever checking

- Power Plants

- Railroad Refrigerator Cars and Cold Storage

- Swimming Pools (fixed and skimming)

- Veterinary

Vibrating Wire Temperature Sensors

Vibrating wire temperature sensors comprise an attractive, high elasticity wire that is extended between and whose closures are joined to a unique metal. The strain that exists in the wire is straightforwardly affected by temperature.

As the temperature changes, it also changes the wire strain, which modifies the common full recurrence of the suspended wire. The recurrence is corresponding to temperature and can be utilized to set up the temperature of the sensor.

Vibrating wire temperature sensors are utilized for estimating the temperature of the water, soil, and solid designs.

Radiation Sensors

Radiation Sensors/Detectors are electronic gadgets that sense the presence of alpha, beta, or gamma particles and give signs to counters and show gadgets. Key determinations incorporate sensor type and least and most extreme distinguishable energies. Radiation finders are utilized for reviews and test checking.

Semiconductor Temperature Sensors

Semiconductor temperature sensors, at times called strong state temperature sensors, are temperature sensors that are created into Small Outline Integrated Circuit (SOIC) or other bundle styles, for example, TO-223 that would then be able to be mounted onto printed circuit boards (PCBs). The gadgets utilize semiconductor diodes or semiconductors whose voltage-current attributes have temperature reliance.

The primary types of semiconductor temperature sensors include:

- Voltage Output Temperature Sensors

- Current Output Temperature Sensors

- Digital Output Temperature Sensors

- Resistance Output Temperature Sensors

- Diode Temperature Sensors

These types of temperature sensors have genuinely great linearity to their output with temperature and can give sensible accuracy in readings over their reach given that they are effectively aligned. They do have a restricted temperature range, notwithstanding, and are not reasonable for the estimation of high temperatures.

Principles of Radiation

Radiation can be considered as the energy that is delivered as either beam or as high-speed particles. In the exemplary model of nuclear construction, molecules involve various particles, for example, protons and neutrons that possess the core of the iota, and electrons that possess the external shells of the iota. Molecules may rot and deliver energy as radiation as they endeavor to move from a shaky state to a steadier one.

Various types of radiation exist in nature. Comprehensively talking, radiation can be portrayed as being of two essential classes:

- Electromagnetic radiation, which can be considered as the discharge of pure energy. Instances of electromagnetic radiation incorpor