5.6

2.6

coefficient / (10-6/ºC)

Dielectric constant

5.7 9.7 12.5 10.9 9

11.8

Resistivity/(Ω·cm) >1013 150 108 1011 >1010

105

Electron mobility

2200 400 8500 1350 1250

1500

/(cm2/V·s)

Hole mobility

1800 50 400 120 850

600

/(cm2/ V·s)

Breakdown

1000 400 40 0.15 >100

30

field/(104V/cm)

Thermal conductivity

20 5 0.46 1.3

1.5

/(W·cm-1·K-1)

Electron sacturated

2.7 2.5 1

2.2

1

velocity/(107cm/s)

Working temperature

<800 130 300 >300

77

/( ºC)

Table 1. Comparison of properties between diamond, GaN, SiC and commonly used

semiconductors

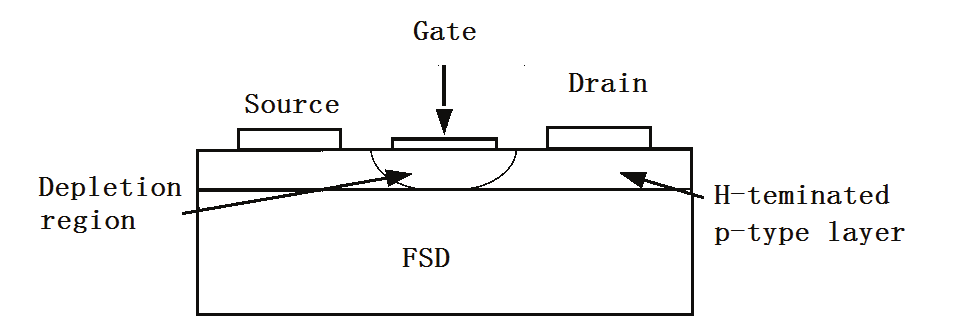

In this paper, high quality freestanding diamond (FSD) films and formation of H-terminated

p-type channel on the diamond film surface were investigated and the origin of this H-

terminated high-conductivity layer was discussed. The realization and properties of the

optically activated MESFETs were also described here.

2. Preparation and characterization of FSD films

In this work, a microwave plasma chemical vapour deposition (MPCVD) technique at 2.45

GHz using a gaseous mixture of methane, hydrogen was applied to deposit FSD films on p-

type low resistivity single crystalline silicon substrates. All three gases were metered into

the chamber using mass flow controllers. The deposition parameters for FSD films were

shown in table 2.

Flux of hydrogen

Flux of methane

Chamber pressure

Substrate

(sccm)

(sccm)

(KPa)

temperature (ºC)

100 1 4.5 800

Table 2. Parameters for FSD deposition

After deposition, the silicon substrates were chemically etched to obtain FSD films with a

smooth surface at the nucleation side. The FSD films were disposed in mixed solution of

H2O2 and H2SO4 for 15 min to eliminate non-diamond surface layer of the diamond films.

Thin-Film Diamond Phototransistors

75

These samples were then cleaned by ultrasonic vibration in deionized water. A thermal

annealing treatment in nitrogen atmosphere at 650°C for an hour was performed to further

improve the quality of the diamond films. The thickness of the film was about 110μm, as

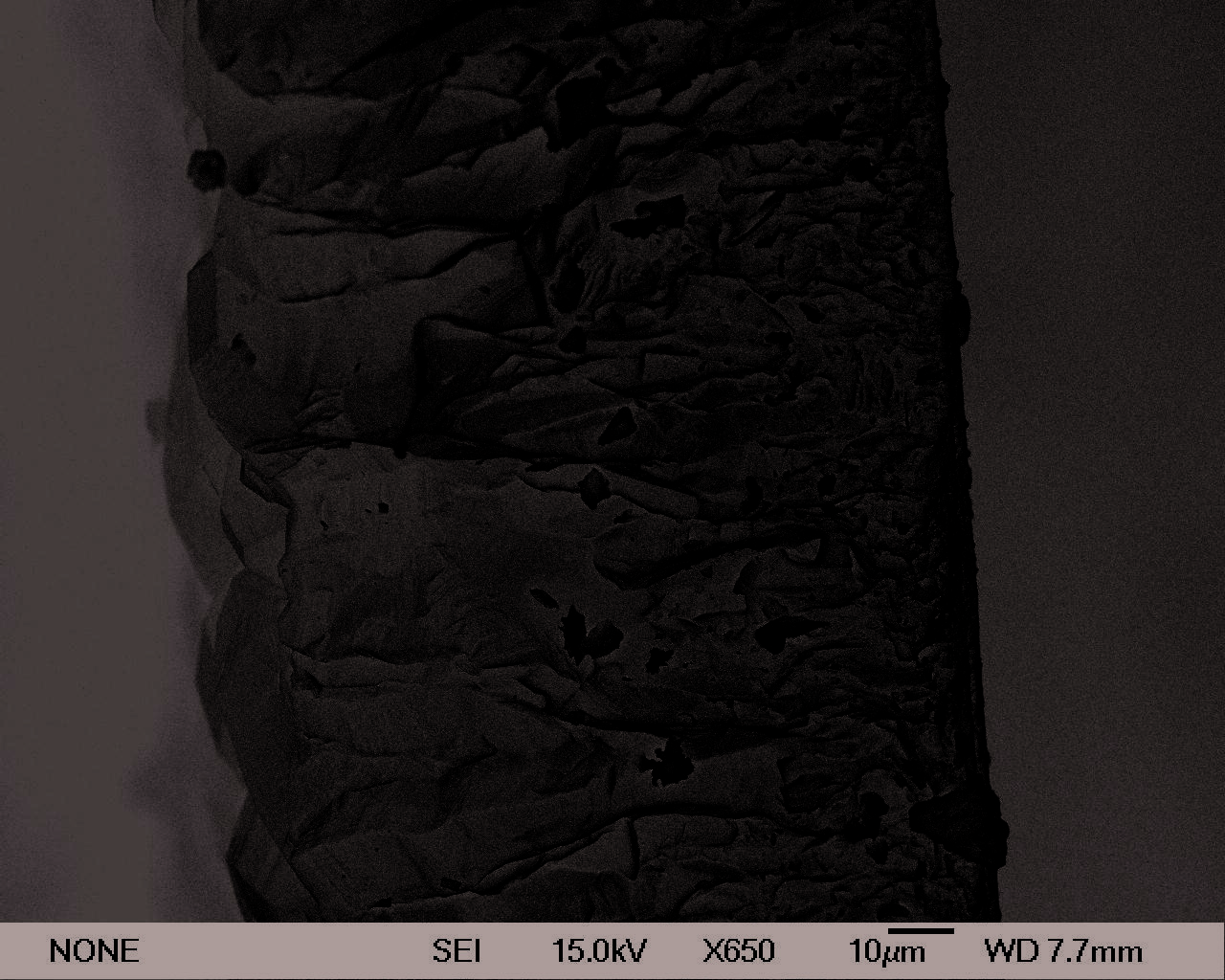

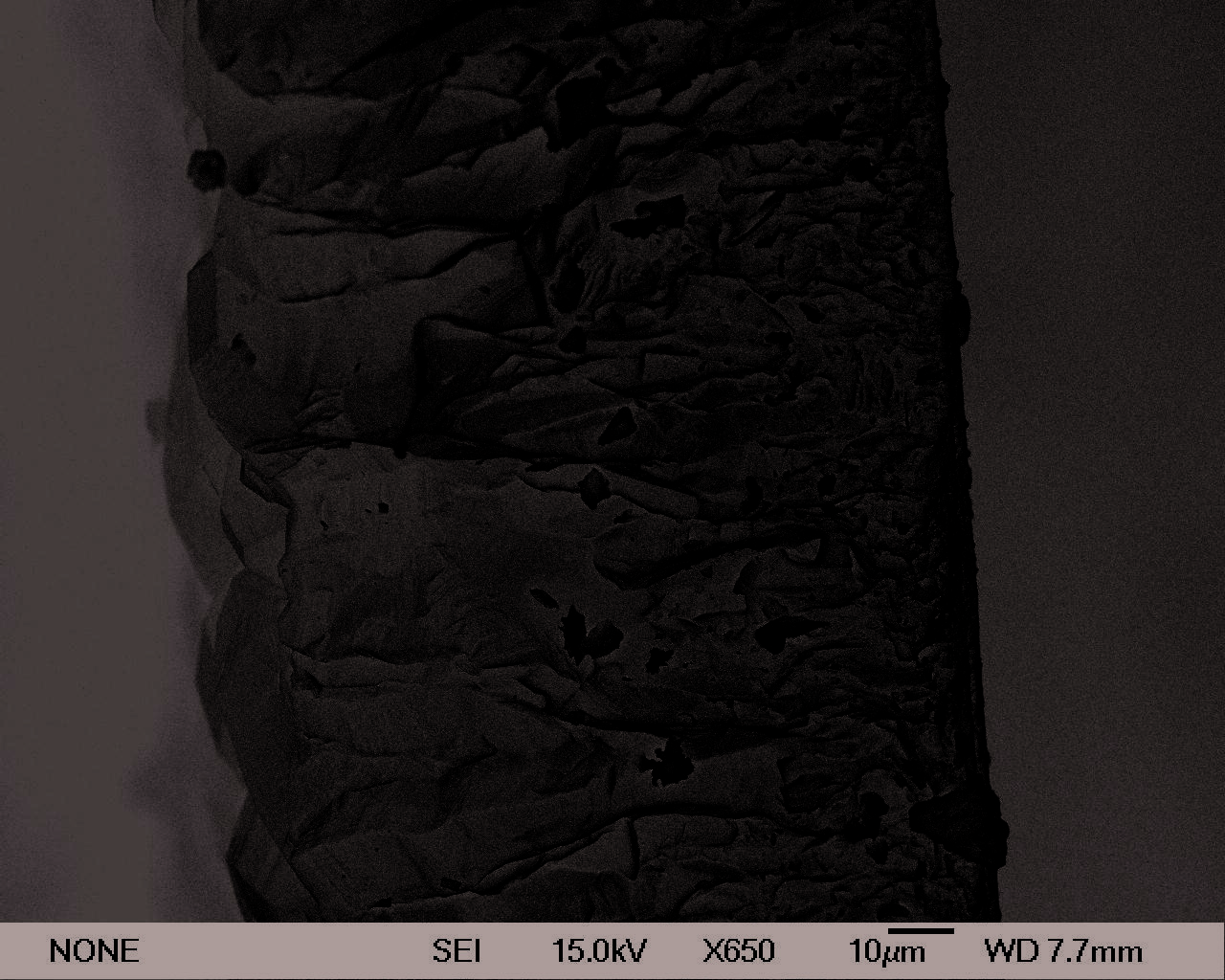

shown in Fig.1.

Fig. 1. Cross section image of the FSD film

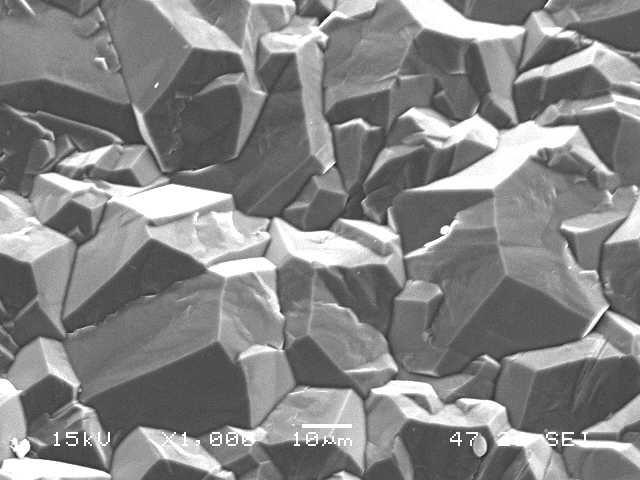

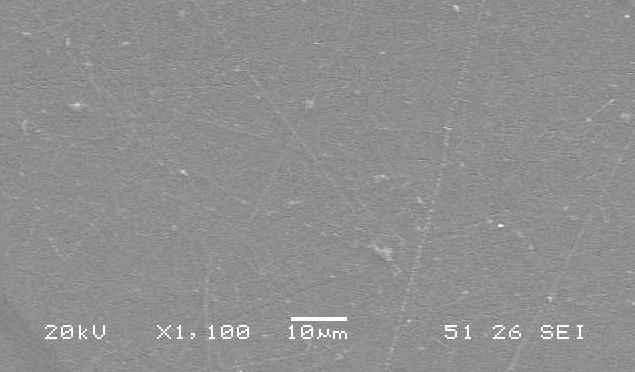

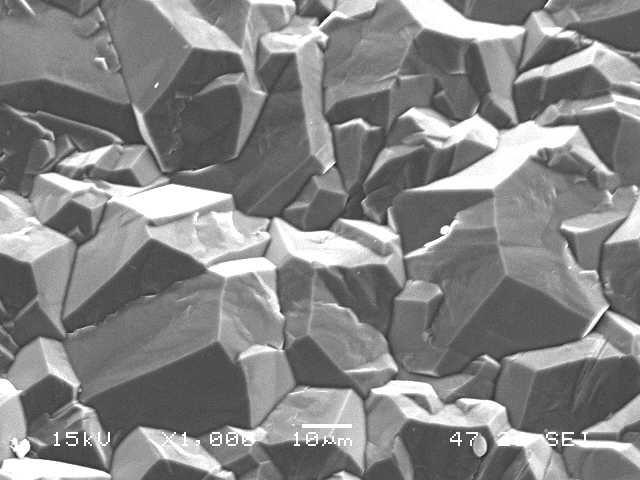

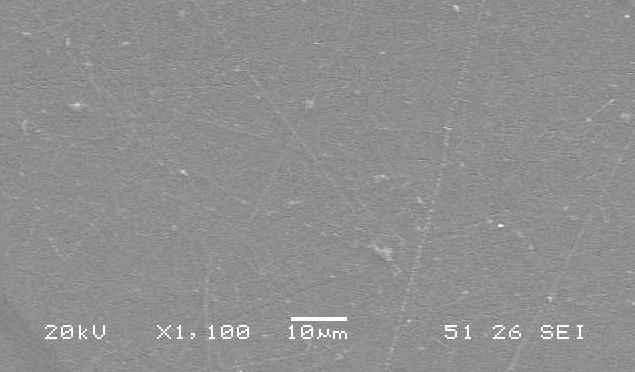

Figure 2 and figure 3 showed SEM images of growth surface and nucleation surface of FSD

films. The mean grain size of growth surface of the FSD film range from a few micrometers

to tens of micrometers and the growth surface was very rough. Whereas, the nucleation

surface was very smooth

Fig. 2. SEM image of growth surface of FSD

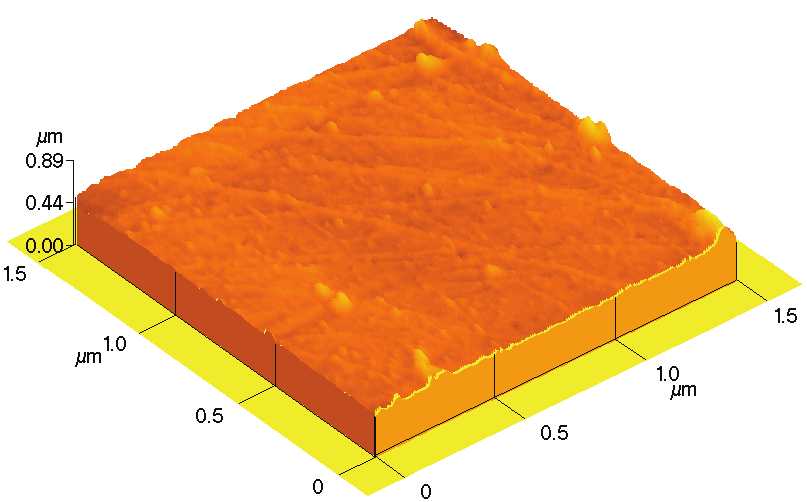

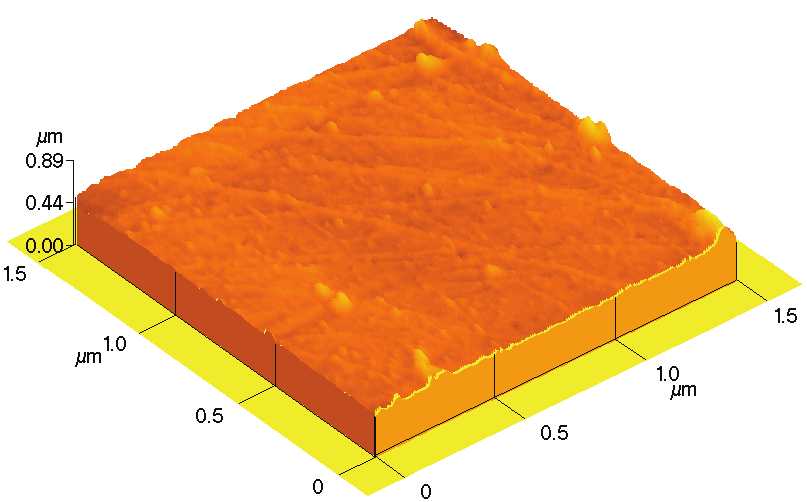

The typical AFM images of the nucleation side of FSD film are shown in Fig. 4, from which

it could be seen that the nucleation side was very smooth with a mean surface roughness of

about 10 nm in a scanning area of 1.5×1.5 μm2. The result was consistent with that obtained

from SEM images.

76

Optoelectronic Devices and Properties

Fig. 3. SEM image of nucleation surface of FSD

Fig. 4. AFM image of nucleation surface of FSD film

The Raman spectrum of the nucleation side of freestanding diamond film was shown in

Fig.5. For both FSD films with and without post-treatment, a strong Raman scattering peak,

located at about 1332cm-1, is the characteristic of diamond and a weaker Raman scattering

band, existed in range of 1400~1600cm-1, is the characteristic of non-diamond carbon [16]. It

is well known that the Raman signal for non-diamond carbon phase is about 75 times of that

for diamond. So Raman spectroscopy is also used to estimate the non-diamond carbon

content (Cnd) [17]: Cnd =1/ [1+75(Idia/Ind)], where Idia is Raman peak intensity for diamond

crystals and Ind is Raman peak intensity for non-diamond carbon phase. Therefore, the Raman

results from Fig.5 indicated a high quality diamond of nucleation side of FSD diamond films

with low content of non-diamond carbon. The Fig.5 also revealed that post-treatment (wet

chemical etch, annealing process) was helpful to improve the quality of FSD films.

Thin-Film Diamond Phototransistors

77

after treatment

1332cm-1

before treatment

.u.)

ity (ansteIn

1333cm-1

1200

1400

1600

Raman shift (cm-1)

Fig. 5. Raman spectrum of nucleation side of freestanding diamond film

3. Preparation and characterization of H-terminated p-type channel on FSD

films

The FSD films prepared above were exposed to hydrogen plasma at 750°C using a MPCVD

apparatus. The time of hydrogen plasma treatment on the p-type behavior of undoped FSD

nucleation surfaces were investigated by Hall Effect measurement. The electrical properties of

the FSD nucleation surfaces following different annealing temperature were also measured.

Figure 6 shows the sheet carrier density and sheet resistivity of p-type FSD films as a function of

time of hydrogen plasma treatment. The sheet carrier density rises with the time of hydrogen

plasma treatment and a stable value is achieved after about 30 min, whereas the sheet resistivity

reduces with time, with stable value being achieved after the same period of time.

The sheet carrier density and sheet resistivity of p-type FSD films as a function of annealing

temperature in air and in vacuum were shown in Fig.7 and Fig.8, respectively. All the FSD

films are exposed to hydrogen plasma treatment for 30 min at 750°C before a 180 min

annealing process. The values of sheet carrier density and sheet resistivity remained in a

relative stable range but change dramatically after annealing at temperature above 250 °C in

air, whereas the sheet carrier density and sheet resistivity kept a stable value up to 600°C in

vacuum.

Figure 9 and Fig.10 showed the values of sheet carrier density and sheet resistivity obtained

as a function of time that a sample had been annealed at various temperatures in air. The

data presented are typical of that obtained for many samples. Following annealing at 100 °C,

little variation was apparent in measurements taken over a prolonged period. However, if

the film was annealed at higher temperatures of 200 °C and 250°C the sheet carrier density

was seen to decrease with time, although a stable value was reached after a given period,

78

Optoelectronic Devices and Properties

whereas the film resistivity showed a reversed trend, gradually increasing to a stable

resistivity with the increase of annealing.

12

10

Sheet carrier density

Sheet resistivity

)

2

Sheet

/cm

8

12

10

resi

(10

st

6 ivity

8

r density

(10

rrie

4

4

Ω/cm

eet ca

2

)

6

Sh

2

5

10

15

20

25

30

Duration of hydrogen plasma treatment (min)

Fig. 6. Sheet carrier density and sheet resistivity of FSD against duration of hydrogen

plasma treatment

Sheet carrier density

Sheet resistivity

) 10

100

2 m

Sh

/c

eet

12

resi

1

(10

10

ty

stivity

0.1

r densi

1

(10

rrie

6

Ω

ca

/cm

0.01

0.1

2

)

Sheet

1E-3

0.01

0

50

100

150

200

250

300

Annealing te

mperature (oC)

Fig. 7. Sheet carrier density and sheet resistivity of FSD against annealing temperature in air

Thin-Film Diamond Phototransistors

79

15

0.3

Sheet carrier density

Sheet resistivity

)2m

Sheet

/c12 10

r

(10

0.2 esi

ty

stivity (

er densi

10

5

0.1

6

Ω/cm

2

)

Sheet carri

0

0.0

0

200

400

600

800

Annealing te

mperature (oC)

Fig. 8. Sheet carrier density and sheet resistivity of FSD against annealing temperature in

vacuum

14

)

2

12

/cm

12

10

(10

8

nsity

6

4

250oC

200oC

Sheet carrier de 2

100oC

0

50

100

150

200

250

300

Annealing time ( min)

Fig. 9. Sheet carrier density against time of annealing

It’s well known that the growth of diamond films at low pressure is a kinetic

nonequilibrium process because of the thermodynamic instability of diamond under these

conditions [18]. During such a nonequilibrium growth process, hydrogen plasma or atomic

80

Optoelectronic Devices and Properties

hydrogen radicals get rid of the graphitic phase, and sp3 species are rearranged to form

crystalline diamond by gradually adjusting their positions and orientations near the growth

face region [19]. The incompletely grown subsurface layer, where vacancies and dangling

bonds were concentrated, was continuously transformed into the ‘‘perfect’’ bulk diamond

[20]. Thus an imperfect thin layer will always exist on the diamond growth face. Hayashi et

al. also reported that high density hydrogen was incorporated into the subsurface region

rather than in bulk of as-grown diamond films by secondary ion mass spectroscopy (SIMS)

[21]. Therefore, the diamond surface conductivity may be related to the complexes of

absorbed hydrogen atoms with carbon dangling bonds. For example, if two adjacent carbon-

dangling bonds share one hydrogen atom, an acceptor state should be generated in the band

gap, since each hydrogen atom has only one electron.

0.25

250oC

2 ) 0.20

200oC

m

100oC

/cΩ6

10 0.15

(

vity sti 0.10

si

t ree 0.05

She

0.00

0

50

100

150

200

250

300

Annealing time ( min)

Fig. 10. Sheet resistivity against time of annealing

Starting from this point, the above experimental results can be well understood. The

nucleation surface of the CVD diamond film is full of defects (e.g., vacancies, dangling

bonds). The hydrogen plasma treatment may promote the complexes of hydrogen atoms

with vacancies and dangling bonds. After a period of time, a stable value of the sheet carrier

density is achieved when almost all the vacancies and dangling bonds are hydrogenated.

The sheet carrier density reduces after annealing at a temperature high enough, which is

due to desorption of hydrogen from the surface.

The loss of chemisorbed hydrogen from diamond surfaces requires temperatures of ~700 °C

to occur with any significant rate[22], so the simple loss of surface hydrogen would not

appear to account for the observations made here at temperature lower than 600°C in

vacuum. However, the loss of hydrogen from diamond could occur at temperatures lower

than 300 °C in air due to oxidation[23].

The fact that the sheet carrier density remains in the range of 1012 -1013 cm2 following a

annealing process below 250 °C in air and 600°C in vacuum suggests that the fabrication of

Thin-Film Diamond Phototransistors

81

devices which would operate up to this temperature using hydrogenation as a source of

carriers appears viable.

diamond

2d order

CHx

.u.)

nsity (a

Inte

(a)

(b)

2000

2500

3000

3500

4000

Raman shift ( cm-1)

Fig. 11. Ultraviolet Raman scattering spectra for hydrogenated diamond nucleation surface

sample (a) and annealed diamond surface sample (b)

2923

2851

2826

ance

(a)

Absorb

(b)

2600

2800

3000

3200

3400

Wavenumber (cm-1)

Fig. 12. Infrared spectra for hydrogenated diamond nucleation surface sample (a) and

annealed diamond surface sample (b)

82

Optoelectronic Devices and Properties

In order to take a further insight into surface conductivity of the nucleation surface of

diamond films, the ultraviolet Raman scattering spectroscopy was used to characterize

hydrogenated nucleation surface of diamond sample (a) and 500°C annealed (in air)

diamond surface sample (b). The magnified profiles of ultraviolet Raman scattering spectra

scanned in the 2000 -4000 cm−1 region were shown in Fig. 11. From the figure, sample (a)

and sample (b) both had a strong peak at about 2468.49 cm-1, representing the second order

of the diamond peak, and a weaker peak at about 2669.52 cm-1 and at 3148.26 cm-1,

representing the second order of the D band and G band of graphine respectively. However,

sample (a) had a stronger peak at 2930.93 cm-1 which indicates sp3 CHx [24], in comparison

with annealed nucleation surface of sample (b). It meant that, after annealed at a

temperature of 500 ºC in air, hydrogen desorbed from the nucleation surface of FSD films.

The internal reflection infrared spectrum obtained from sample (a) hydrogenated nucleation

surface of diamond and sample (b) 500°C annealed (in air) diamond surface were shown in

Fig. 6, from which the symmetric C-H stretching modes s at 2826 cm-1, symmetric stretching

mode of CH2 at 2851 cm-1 and the antisymmetric stretching mode of CH2 at 2923 cm-1 can be

observed in films after hydrogen plasma treatment[23,25]. However, there was no obvious

hydrocarbon adsorbates from the spectrum of Fig. 11(b) obtained after annealing at 500 °C

in air, which indicated that the hydrogen desorbed from the surface of diamond film after

annealing. All the above results confirmed that the diamond surface conductivity was

related to the complexes of absorbed hydrogen atoms with carbon dangling bonds.

4. Fabrication and characterization of phototransistor based on diamond

MESFETs

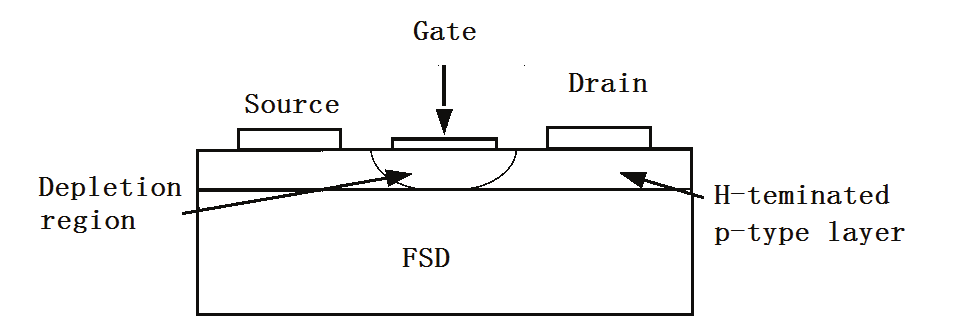

The FSD films were used to fabricate devices of MESFET. The fabrication of surface devices

using the nucleation surface of the FSD films solved the problem of the surface roughness

without the need of any kind of polishing. The smoothness of the nucleation surface allows

a higher control of the electrodes. And the problem of the high resistivity can be easily

overcome by a proper exposure of the surface to hydrogen plasma, as described above.

FSD films using for device fabrication were prepared as decribed in paragraph 2. Then, FSD

films were exposed to hydrogen plasma at 750°C for 30min using a MPCVD apparatus.

Fig. 13. A schematic the diamond MESFET device structure

Gold Ohmic contacts were evaporated as source (S), drain (D) and Aluminum contacts as

gate (G) by standard lithographic procedures. The thickness of the drain/source and gate

Thin-Film Diamond Phototransistors

83

contacts was 300nm and 200nm, respectively. The channel length and width were 10 μm

and 5 mm, respectively. The distance between Al electrode and Au electrode is about 10μm.

A schematic picture of the device structure and optical micrograph of the device were

shown in Fig. 12 and Fig.13, respectively. All devices were packaged and wire bonded prior

to testing.

Fig. 14. Optical micrograph of the MESFET device

Current-Voltage (I–V )behaviour of the gold-gold electrodes and aluminum-gold electrodes

on Hydrogen-teminated nucleation surface of FSD films were shown in Fig.14 (a) and Fig.14

(b). The I–V characteristics of adjacent Au contacts were near to linear, indicating Ohmic-

like behavior, however Al-Au electrodes showed a strongly asymmetric I-V behavior, due to

the presence of a Schottky barrier at the Al-diamond interface.

Figure 15 showed the Current-Voltage (I-V) behaviour of the source and drain electrodes

without any applied gate voltage. The gold electrodes, evaporated directly on the

Hydrogen-teminated nucleation surface of FSD films, behave as ohmic contacts. The small

asymmetry in the characteristics is related probably with a slight heating of the electrode

when the current starts to flow, increasing the resistivity of the material and producing an

extra decrease of the current [26].

Hydrogen-teminated FSD film MESFET structures, with an Al gate and Au source and drain

contacts, showed clear modulation of channel current as a gate bias was applied. The drain

current as a function of drain-source voltage (VDS) plotted for differing gate bias (VGS) was

shown in Fig.16. Field effect was seen for negative VGS, revealing a p-channel. There was no

current for VGS= 0 V, and channel current considerably increased as VGS was increased,

indicating the device was an enhancement-mode MESFET. For all gate bias values, IDS

saturated for higher VDS, indicating channel pinch-off.

Figure17 showed IDS against VDS with gate voltages of -0.1V which was illuminated with 200

nm light with varying intensity. The effect of the light is clearly to enhance the channel

current level, with increasing optical powers giving higher saturated IDS values. The results

suggest that phototrasistors based on hydrogenated diamond MESFETs may be ideally

suited for UV switching applications. The devices are not ‘‘visible blind’’ in the way that

photoconductive structures can be, but they do offer the potential of high switching speed

allied to high sensitivity.

84

Optoelectronic Devices and Properties

(a)

μA)

5

ent (

Curr

0

-10

-5

0

5

10

Voltage (V)

-5

7.5

(b)

5.0

Α)m 2.5

ent (

Curr

0.0

-2.5

-4

-2

0

2

4

Voltage (V)

Fig. 15. Current-Voltage behaviour of the gold-gold electrodes (a) and aluminum-gold

electrodes (b)

A PTI optical system and monochromator combination was used to investigate the response

of the device across the spectral range 200–350 nm. Responsivity of diamond

phototransistors as a function of illuminating wavelength with VDS of -12V was shown in

Fig.18. For the phototransistor, a pronounced increase in responsivity could be seen at

around 230 nm, which corresponds to the band-gap energy of diamond. The response at the

longer wavelengths (>300nm) was much smaller.

Thin-Film Diamond Phototransistors

85

1.0

0.5

0.0

(μA)

I DS

-0.5

-1.0

-10

-5

0

5

10

VDS(V)

Fig. 16. Current-Voltage behaviour of the source and drain electrodes without any applied

gate voltage

VGS

0

0.0V

-0.5V

μA) -20

(

DSt Ien -1.0V

rr -40

Cu

-1.5V

-60

-14

-12

-10

-8

-6

-4

-2

0

Voltage V (V)

DS

Fig. 17. Output characteristics of Hydrogen-teminated FSD film MESFET structures for

negative bias. Drain–source voltage (VDS) swept between 0 and -12 V; gate voltages (VGS)

swept between 0 and -1.5 V

86

Optoelectronic Devices and Properties

0