Appendix F

Hazardous Material/Hazardous Waste Management

Procedures for Field Operations

This appendix provides guidance for assisting units in the proper management of HM/HW during operations. Proper management practices will safeguard the health of military personnel and protect the environment. Additionally, these measures will ease logistical burdens and produce cost savings through HW minimization and P2. They are intended to assist military personnel in the development of unit and operation-specific SOPs for HM/HW management in any AO. Although this appendix focuses on maneuver brigade and battalion operations, the information provided may be adapted to company- and platoon-size units during any operation.

REFERENCES

F-1. Key references for HM/HW handling are as follows:

• 29 CFR and 40 CFR.

• Applicable laws and regulations regarding HM usage and waste management (consult your higher headquarters or supporting environmental management office).

• OPLANs and OPORDs.

• TM 38-410.

• Unit SOPs.

• USACHPPM TG-217.

RESPONSIBILITIES

F-2. Many commodities used by the military are hazardous or contain HMs with special requirements for storage and handling. The dangers posed by these items may be serious, and personnel should be aware of the domestic and international laws and regulations associated with them. These laws and regulations place special emphasis on communicating the hazards associated with these products, as exposure may result in serious personal injury, permanent disabilities, and even death. Property and the environment may also be damaged or destroyed. It is imperative that all military personnel recognize and understand the hazards associated with these commodities.

HAZARDOUS MATERIAL/HAZARDOUS WASTE MANAGEMENT PROGRAM

F-3. Proper management of HM/HW during operations is critical to the protection of human health and the environment. Without a management program backed by command emphasis, military personnel, and the environment are at risk of potential exposure to HM/HW.

IMPORTANCE OF HAZARDOUS MATERIAL/HAZARDOUS WASTE MANAGEMENT

F-4. Severe injuries or irreparable environmental damage could result from improper HM/HW management. In addition to protecting human health and the environment, proper management of HM/HW produces cost savings through HW minimization and P2. A portion of the funds used for cleanup procedures due to mismanagement of HM/HW may impact unit training budgets and military readiness.

HAZARDOUS MATERIAL/HAZARDOUS WASTE MANAGEMENT PLANS

F-5. The key to a successful management program lies in planning and informing. HM/HW management plans should be specific for the given operation, and commanders must place an emphasis on the program to ensure that all personnel are aware of the requirements. Plans may be altered based on the mission or tactical situation, but informing the command of proper procedures is critical in maintaining a successful program.

KEY ASPECTS OF HAZARDOUS MATERIAL/HAZARDOUS WASTE MANAGEMENT

F-6. Several important aspects exist in HM/HW management. At a minimum, personnel must know how to properly handle, transport, and store HM and how to properly collect and dispose of HW. Proficiency in these management practices will ensure that neither personal safety nor the environment is jeopardized during operations.

SPILL RESPONSE PLANS

F-7. Emergency HM/HW spill response plans must be prepared before any operation. These plans should address all aspects of spill response, to include site-specific response procedures and spill response equipment requirements for each major HM/HW operation. They should be distributed throughout the unit before any operation.

HAZARDOUS MATERIAL/HAZARDOUS WASTE FIELD PROCEDURES

F-8. Using the correct procedures for HM/HW handling is critical to protection measures and environmental protection. Field environment operations, whether during training or deployment, present additional hazards to the management of HM. Proper measures-including enforcement of the use of PPE and proper procedures for the handling, storing, and transporting of HM/HW-must be developed and implemented. See the following vignette.

Issue

Field expedient HW accumulation sites pose environmental and safety risks.

Discussion

The DRMO Forward Support Team-Europe established two main HW accumulation sites and nine feeder sites in Iraq for storing large volumes of waste oil generated in- country. Mission variables dictated that the inherent risks of convoy operations in the hostile environment were high, requiring commanders to reduce the frequency of HW convoys or to discontinue transport altogether. Commanders were forced to set up their own HW accumulation site inside their base camps.

These areas had problems associated with-

• HWs that were not segregated.

• Lack of secondary containment.

• Leaders that did not provide proper supervision on the sites.

• Sites that were situated too close to camp perimeters-creating a protection issue. (Sites are a potential target for hand grenades and IEDs.)

• Actions that put the health and safety of Soldiers and Marines at risk.

Techniques and Procedures

• Commanders must ensure that personnel are trained in the handling of HM/HW

before setting up a base camp HW accumulation site.

• Leaders must familiarize themselves with the combatant command's (command authority) requirements for managing HW in-theater and ensure compliance.

• Trained personnel and leaders must supervise site operations and Soldiers and Marines to ensure proper handling and management of HW.

• When setting up an HW accumulation site, units must-

▪ Identify a manager for the HW accumulation site.

▪ Identify the types of HW materials present.

▪ Specify the authorized amounts of HW collected.

▪ Segregate the HWs.

▪ Locate the HW accumulation site at a safe distance from troop bedding/duty areas and perimeters (a minimum of 50 feet).

▪ Maintain adequate storage and proper collection containers on hand.

▪ Provide electrical grounding for containers.

▪ Label the containers.

▪ Maintain MSDSs on hand for each item.

▪ Set up an emergency wash/decontamination site.

▪ Plan for adequate secondary containment.

▪ Plan for spills and maintain appropriate PPE and spill kits readily available.

▪ Secure the HW accumulation site.

▪ Supervise all activities within the HW accumulation site.

Note. The fence is the perimeter around the HW accumulation site, not the base camp perimeter.

HAZARDOUS MATERIAL/HAZARDOUS WASTE HANDLING

F-9. The most important aspect of HM/HW handling is in identifying the hazard(s) associated with each individual chemical. Once appropriate hazards are identified, steps may be taken to minimize personnel and environmental exposure. Hazardous characteristics may be found on the MSDS for each chemical.

F-1O. MSDSs provide critical information for safeguarding human health and protecting the environment. They include information on the hazardous characteristic(s) of the chemical, the appropriate PPE, spill response procedures, signs and symptoms of overexposure, and first aid procedures. MSDSs may be obtained through the unit supply channels and should be maintained at the following operations: HM storage and HW accumulation sites, tactical-refueling operations, maintenance operations, and medical treatment facilities. It is important to note that MSDSs are material and manufacturer-specific, which means that each chemical brand name contains a different MSDS. HW managers should ensure that appropriate MSDSs are available during operations.

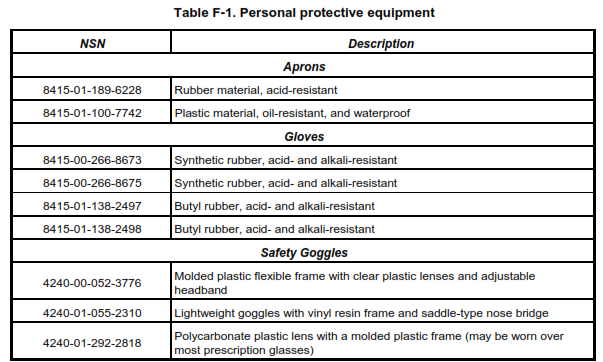

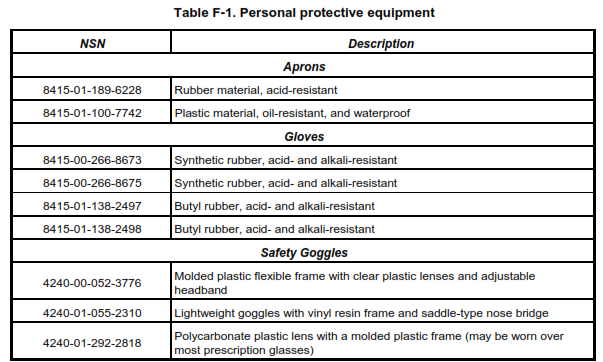

F-11. Primary operations requiring the use of PPE include the transportation and accumulation of HM/HW, tactical-refueling operations, and maintenance operations. In the event that MSDSs are not available and cannot be obtained during an operation, a field expedient PPE should be used to help protect personnel when handling HM/HW or in the event of a spill. Table F-1 lists national stock numbers (NSNs) for PPE commonly used when handling HM/HW in a field environment.

HAZARDOUS WASTE COLLECTION

F-12. HW should be collected at the point of generation. The key to proper collection is in segregating, containerizing, and labeling the waste. HW managers should coordinate with brigade and battalion S-4s to ensure that all units have the resources needed for proper collection. Units establish HW accumulation sites to temporarily store HW until arrangements can be made to remove it. Each waste stream needs to have its own container. Containers need to be inspected for dents, leaks, and corrosion; should be labeled; and should be kept closed when not being filled. HW containers should be removed from the site as soon as possible after being filled to 85 percent capacity. Secondary containment needs to be established, and the site needs to be protected from damage (such as accidental spills, vehicle accidents, and weather effects) and possible hostile actions (such as a mortar attack). HW accumulation sites should be located away from troop billeting areas and should be located to avoid potential contamination of water sources (such as storm drains, drainage ditches, and water courses).

WASTE SEGREGATION

F-13. Generators of HW must ensure that waste streams remain segregated. Improper segregation of HW streams at the point of generation could result in an incompatible waste mixture, posing a significant health risk. In addition, a mixture of HW and non-HW (such as general trash) must be managed and disposed of as HW, drastically increasing HW disposal costs. Proper segregation at the point of generation will simplify the overall management process, protect human health and the environment, reduce disposal costs, and enhance the potential for recycling the HW.

CONTAINERIZING HAZARDOUS WASTE

F-14. HW must be collected in appropriate containers. The best type of container is the original container (if it is capable of being closed) in which the material was shipped in before being rendered a waste. If the original container is not available or the waste volume exceeds the capacity of the original container, use any container compatible with the waste stream. When filling a container, ensure that adequate headspace remains to allow for expansion of the material (3 to 4 inches in a 55-gallon drum, 1.5 to 2 inches in a 5-gallon can, and 1 inch in a 1-gallon can). Only nonsparking tools should be used when containerizing a reactive or flammable waste.

HAZARDOUS MATERIAL/HAZARDOUS WASTE TRANSPORTATION PROCEDURES

F-15. HM/HW should be transported only in approved vehicles. These vehicles should contain appropriate placards and manifests for the materials being transported. In addition, drivers must be certified to transport hazardous cargo. Certification training may be coordinated through the supporting transportation unit. The supporting transportation unit can also provide site-specific information or waive certain requirements, based on the tactical situation encountered during the operation.

EMERGENCY EQUIPMENT

F-16. Personnel transporting hazardous cargo should be supplied with the required PPE. In addition to PPE, each vehicle approved for HM/HW transport must be supplied with a spill response plan and the appropriate spill response equipment.

F-17. Units should be prepared to respond to emergency operations. The unit should maintain-

• Spill kits. Based on unit mission and the type of HM/HW used, spill kits provide containment and cleanup should an accidental spill occur.

• Fire extinguisher. Each storage area containing flammable materials or waste is supplied with an

ABC-type (monoammonium phosphate) fire extinguisher.

• Emergency eyewashes. Potable water must be readily available for emergency eye washing.

This will help in providing first aid measures on-site in the event of a leak or spill.

• PPE. Two sets of the PPE are readily available at each storage area. Reference the MSDSs for the required PPE.

• Spill response. A spill response plan and spill response equipment are readily available at each accumulation area.

HAZARDOUS MATERIAL/HAZARDOUS WASTE STORAGE

F-18. As a rule, an HW accumulation site is considered a storage area when it contains more than 55 gallons of HM/HW. HW accumulation sites are temporary sites where HW may be stored for up to 90 days. Storage sites should be identified during the predeployment phase of the operation or as soon as the unit establishes its operating area. Set up HM/HW storage areas at least 15 meters (50 feet) downwind and down gradient of personnel billeting and dining facility operations. Eight-digit grid coordinates and inventories of the storage areas should be maintained in the event that the unit must rapidly evacuate the area.

F-19. HW accumulation site areas must be properly secured within the unit's AO to prevent unauthorized access from both U.S. and foreign nation personnel. The material stored may be considered valuable to the local population and scavengers. Concertina wire may be necessary to properly secure the storage area.

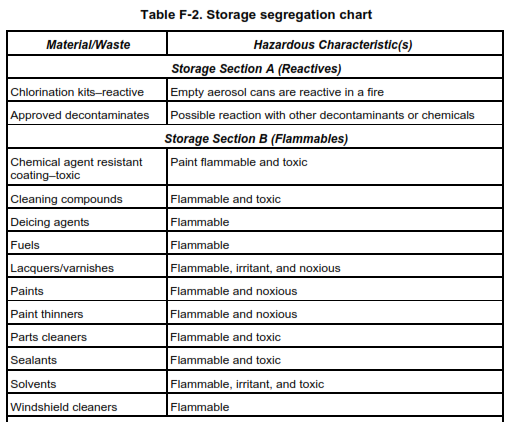

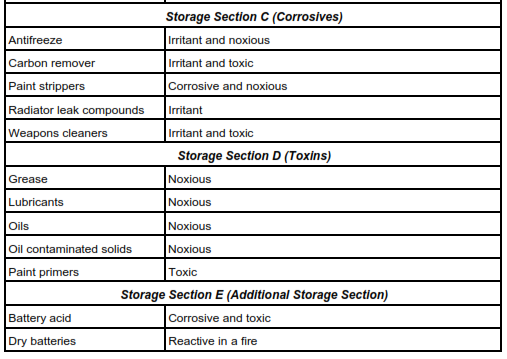

F-20. HW accumulation sites must be segregated into the following four general categories or sections:

• Reactives.

• Flammables/ignitables.

• Corrosives.

• Toxics.

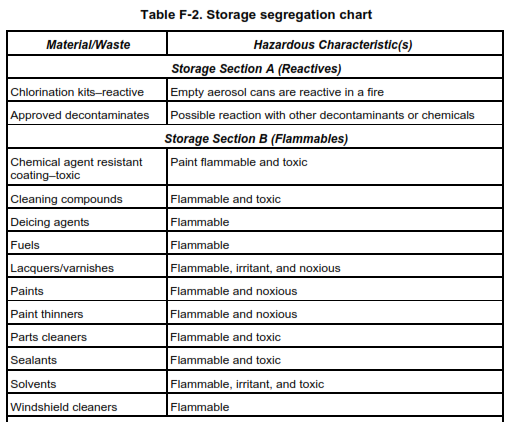

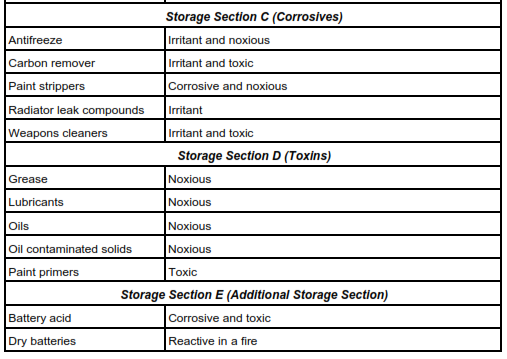

F-21. Further segregation may be required based on the compatibility of individual materials (reference MSDSs for each material to identify appropriate storage sections). Each storage section must be separated by a distance of 6 feet or a physical barrier to prevent incompatible materials from mixing and producing an adverse chemical reaction or toxic fumes. A recommended storage segregation chart for materials commonly used during operations is shown in table F-2. Containers holding reactive or flammable materials or waste should be grounded during storage, and only nonsparking tools should be used when handling these containers.

SECONDARY CONTAINMENT

F-22. Secondary containment is designed to protect human health and the environment in the event of a leak or spill. Proper secondary containment includes hardstands, tarps, plastic liners, and sandbags. For storage of materials on a hardstand, ensure that the containers are placed on a pallet with a sandbag perimeter for containment of spilled liquids. If a hardstand is not available, place all materials within each category on a tarp or plastic liner with sandbags surrounding the containers. Secondary containment should be large enough to contain 10 percent of the overall volume or 100 percent of the volume of the largest container of HM/HW stored, whichever is larger. An additional tarp or plastic liner should be available to cover the tops of the containers during adverse weather conditions.

CONTAINERS

F-23. All containers must be kept closed and maintained in good condition at all times. Supervisors should not permit open funnels or tubes to be attached to containers. Rusty or residue-covered containers are unacceptable.

STORAGE OF FUEL CANS

F-24. Five-gallon fuel cans are usually scattered throughout a unit during operations. They should be consolidated within each company or platoon AO, placed on a tarp or piece of plywood, and surrounded by a soil berm or sandbags for secondary containment, if possible. This will prevent spills from adversely affecting personnel or the environment. When filling fuel cans, personnel must ensure that 1.5 to 2 inches of headspace remains to allow for vapor expansion.

BATTERY STORAGE

F-25. An activity that includes battery storage must provide fire suppression equipment. In addition, storage areas and equipment must be approved by the local fire department. A point of contact must also be provided to the local fire department. TM 38-410 and TB 43-0134 outline the requirements to-

• Protect bulk storage of batteries with sprinklers.

• Keep batteries cool, dry, and away from open flame, heat, and combustibles and in a well- ventilated area with temperatures not to exceed 130 degrees Fahrenheit (54 degrees Celsius). Refrigeration is not necessary.

• Do not mix new and used batteries because it is difficult to distinguish between them. Many next generation batteries contain state of charge indicators.

• Segregate storage from other HM and other battery chemistries. It is critical that lead acid batteries be kept away from nickel cadmium or nickel metal hydride batteries.

• Protect batteries against being damaged, crushed, punctured, or short-circuited.

• Do not smoke or eat in battery storage areas.

• Store batteries separately from other HM.

• Use open flame devices only under proper supervision and with adequate safeguards.

• Do not accumulate nonhazardous solid waste batteries.

• Do not store batteries collected for turn-in to the DRMO more than 90 days.

• Ensure that fire extinguishers are available. Use an AB-type (water) fire extinguisher to fight fires involving small quantities of batteries.

RECORDKEEPING

F-26. Detailed HW records start at the accumulation site. A log should be kept of the type of waste received, the quantity received, the date received, and information on the unit that generated the waste. This log should be kept at all accumulation areas at brigade and battalion level. The unit HW manager is responsible for completing the appropriate turn-in documentation and applicable local forms. These should be completed once the waste is retrograded from the maneuver battalion accumulation areas to the brigade storage area. The unit should prepare a plan for the closure of HW accumulation sites. This plan should detail the way in which all waste and waste residues will be removed from the accumulation areas when they are no longer needed or in use.

INSPECTIONS

F-27. HW managers should conduct daily inspections of HM/HW accumulation areas. They will ensure that all requirements described above are met and that containers are in good condition.

HAZARDOUS WASTE DISPOSAL

F-28. Two primary disposal options for HW exist that can be implemented in any joint operations area (JOA): disposal through an approved contractor or retrograding HW back to CONUS. Units must not incinerate or bury any HW unless explicitly approved by both U.S. and foreign nation authorities. Commanders must determine the most viable means of approved HW disposal before entering the JOA by contacting their higher headquarters/supporting DRMO.

SUPPLY ACTIONS

F-29. Supply officers should maintain a system to monitor the amount of HM on hand to ensure that units are not stockpiling HMs. Excess HM storage may lead to unnecessary personal or environmental exposure. Supply and logistics personnel should coordinate among themselves and with the various environmental agencies to identify available alternative products, which can reduce the overall HW production.

TACTICAL-REFUELING OPERATIONS

F-30. POL personnel should conduct tactical-refueling operations at a designated logistics release point. Conducting tactical-refueling operations in a unit's AO should be avoided due to safety hazards associated with maneuvering a fuel tanker or heavy, expanded-mobility tactical truck (HEMTT) and conducting grounding operations at each vehicle. POL personnel should conduct actual refueling whenever possible.

F-31. During refueling operations, secondary containment (such as large drip pans) should be placed under the vehicle and under the fuel hoses. When refueling 5-gallon fuel cans, the cans should be placed inside the drip pans used for secondary containment. This will prevent small-volume fuel spills from accumulating and contaminating the soil. The spilled fuel should be transferred to a labeled 5-gallon waste fuel container and disposed of as HW. Ensure that proper emergency equipment is present during all refueling operations.

FIELD MAINTENANCE OPERATIONS

F-32. Maintenance operations should be conducted on a hardstand, tarp, or plastic liner, if available. Maintenance personnel will be required to supply their own PPE, spill response equipment, potable water for emergency eye washing, and liquid waste. All wheeled vehicles should contain drip pans, and all tracked vehicles should contain belly plates. Collected fluids must be placed in appropriate waste containers and disposed of as HW. Each company-size unit must maintain one labeled 5-gallon container for drip pan waste.

F-33. All drained fluids must either be returned to the vehicle or placed in an appropriate waste container for recycling or disposal as an HW. Maintenance areas should be supplied with two labeled 55-gallon liquid-waste containers for each of the following waste streams: used oil, waste fuel, waste antifreeze, and POL-contaminated solids. HW managers can coordinate the proper set up of accumulation site and the turn-in of waste containers and acquire empty 55-gallon liquid-HW containers from the appropriate support platoon.

DINING FACILITY OPERATIONS

F-34. Dining facility personnel may use M-2 burners, which operate on motor gasoline, during operations. Major safety and environmental issues include fuel storage, filling, and lighting operations.

F-35. Whether using motor gasoline or diesel fuel, filling operations should be conducted on a tarp or plastic liner with a soil berm or sandbag perimeter for secondary containment in the event of a spill. Spilled fuel must be collected immediately using an absorbent material. The used absorbent material should be placed in a plastic bag and disposed of as HW.

F-36. Lighting operations must be conducted at least 50 feet away from fuel storage and M-2 burner filling operations. Lighting operations should be conducted on open soil so that any residual fuel will freely burn during the operation.

OPERATION OF HEATERS, GENERATORS, AND LIGHT SETS

F-37. Personnel who use field heaters must ensure that the fuel supply (usually a 5-gallon fuel can) possesses secondary containment in the event of a leak or spill. The best way to provide this secondary containment is to elevate the fuel supply on a tripod or the back of a vehicle and place a drip pan under the fuel hose to collect any spilled fuel. The overflow fuel line should also have secondary containment, and all leaking fuel lines must be repaired or replaced. Collected fluids must be placed in appropriate waste containers and disposed of as HW. Each company-size unit should maintain one labeled 5-gallon container for waste fuel from the operation of heaters.

F-38. Generators and light sets must be operated in a manner protecting the environment from potential contamination. To provide this protection, operate generators on a piece of plywood and completely surround the generator with a soil berm or sandbag perimeter. This will prevent leaking fuel from contaminating the surrounding soil. Another alternative is to operate generators on a trailer and ensure that all spilled fuel is collected and placed in appropriate waste containers; each company-size unit should maintain one labeled 5-gallon container for waste fuel from the operation of generators. In addition, personnel should conduct preventive maintenance checks and ensure that all leaking generators are repaired or replaced.

SPILL RESPONSE

F-39. While good HM/HW management practices will minimize the chance of spills and thereby avoid the additional effort required to clean up any incidents, accidents will still happen. When they do, it is imperative that personnel are trained and prepared to mitigate the damage and to clean up the spills.

SPILL RESPONSE PLAN

F-40. A spill response plan must be available for each operation. The following major operations should have a copy of this plan: tactical refueling, maintenance, and HM/HW accumulation and transportation. The plan should address, at a minimum, site-specific response procedures and spill response equipment requirements for each major operation.

SPILL RESPONSE PROCEDURES

F-41. In the event of an HM/HW spill, the procedures listed below must be implemented immediately by trained personnel within the unit. Personal safety must never be compromised during the response. Should the situation exceed unit capabilities, evacuate the area, inform the chain of command, and contact the local HM spill response team or range control. Emergency telephone numbers or radio frequencies should be obtained and distributed throughout the unit as necessary before the operation begins. Personnel-

• Protect themselves. Use the required PPE for the spilled material specified in the MSDS and evacuate all nonessential personnel from the immediate area.

• Stop the flow. The flow of HM/HW must be stopped at the source to control the spill. This may be as simple as placing the container upright or closing a valve. In the event of a spill of flammable material, use only nonsparking tools and ensure that metal-to-metal contact is avoided.

• Contain the spill. Proper containment includes placing drip pans where the material contacts the soil, placing soil berms or sandbags around the contaminated area, and placing absorbent material in the area of the spill. The purpose of this step is to prevent the spread of contamination.

• Report the spill. Notify the chain of command and unit HW manager immediately.

• Clean the spill. Equipment used to clean a spill must be chosen carefully. Use only nonsparking tools if the material is flammable or explosive. For corrosive materials, use equipment that will not corrode or deteriorate (for example, nonmetallic equipment). Collect used absorbent and contaminated soil in plastic bags and transfer the bags into a labeled sturdy container to be disposed of as HW.

• Replace spill response equipment. Obtain replacement spill response equipment through the unit supply channels to ensure that personnel can properly respond in the event of another spill.

SPILL RESPONSE EQUIPMENT

F-42. Spill response equipment is essential to protecting the environment in the event of an HM/HW spill. The type and amount of spill response equipment needed depends on the operation. Units may also need to acquire hydrophobic-absorbent materials for operations conducted in areas susceptible to large amounts of precipitation. Spill response equipment required for specific operations is discussed in the following paragraphs.

Tactical-Refueling Operations

F-43. Tactical-refueling operations are limited to the handling of fuel products, such as diesel and motor gasoline. The extent of the operations and load-carrying capabilities of fuel tankers and HEMTTs restricts the amount and type of spill response equipment needed. In the event of a major spill during refueling operations, personnel primarily need two nonsparking picks and two nonsparking shovels to excavate contaminated soil and several large plastic bags to contain the excavated soil for disposal as HW. Approximately 10 pounds of absorbent and several small plastic bags are sufficient to respond to small- volume spills on a hardstand. Nonsparking tools should also be readily available. Additional resources may be obtained through supply channels as required.

Field Maintenance Operat