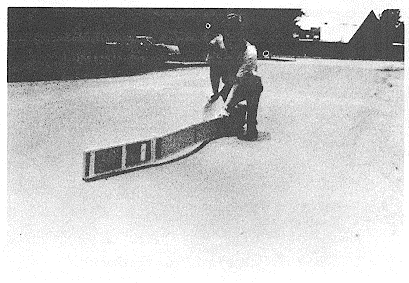

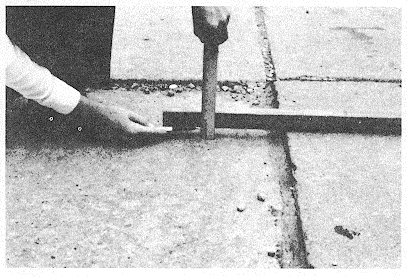

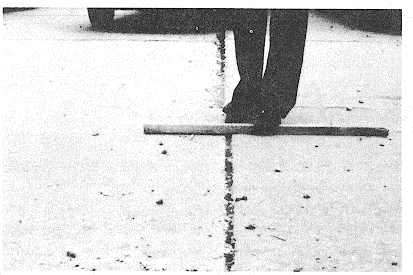

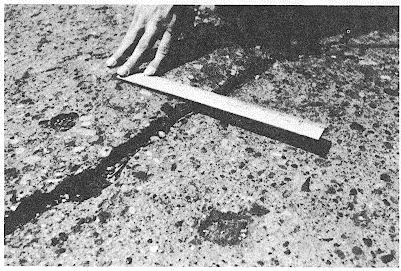

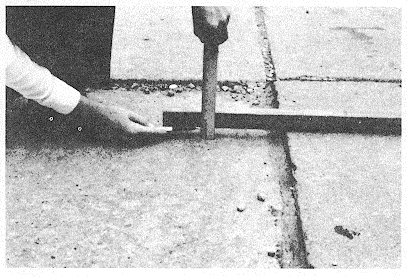

by laying a straightedge across the rut, measuring its depth, then using

measurements taken along the length of the rut to compute its mean depth in

inches.

Name of Distress:

Shoving.

Description:

Shoving is a permanent, longitudinal displacement of a localized area of the pavement surface caused by traffic loading. When traffic pushes against the pavement, it produces a short, abrupt wave in the pavement surface. This

distress normally occurs only in unstable liquid asphalt mix (cutback or

emulsion) pavements.

Shoves also occur where asphalt pavements abut PCC pavements; the PCC

pavements increase in length and push the asphalt pavement, causing the

shoving.

Severity Levels:

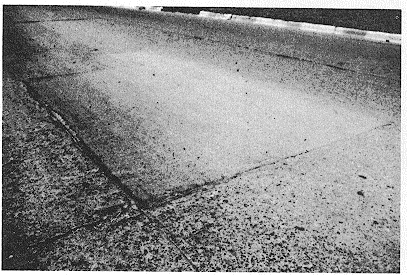

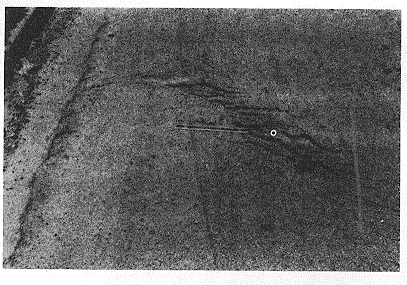

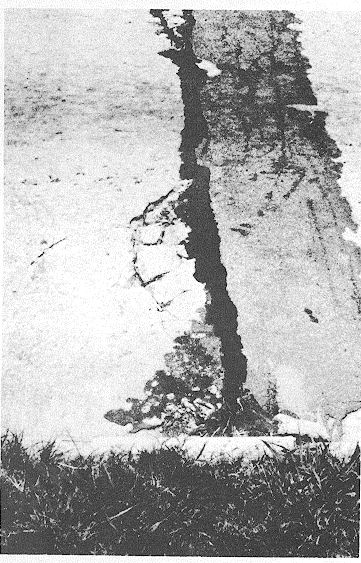

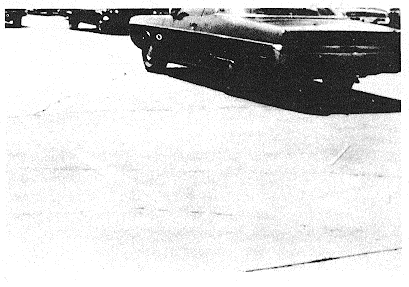

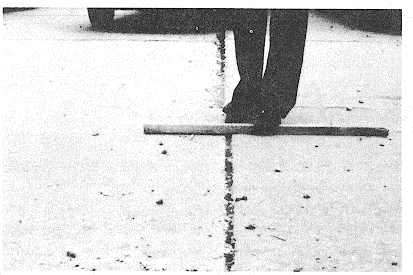

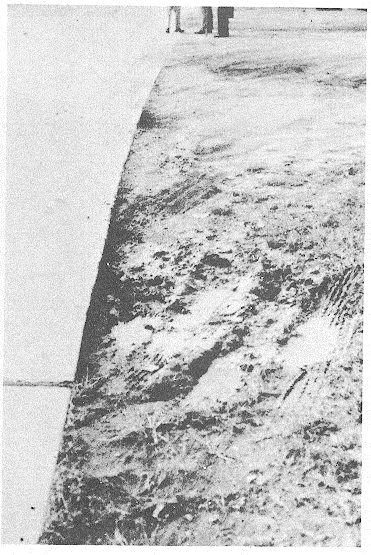

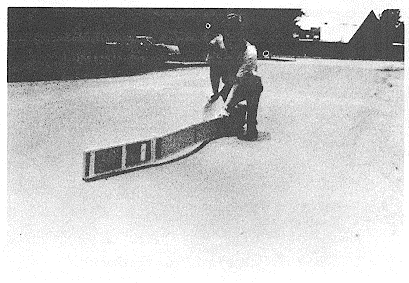

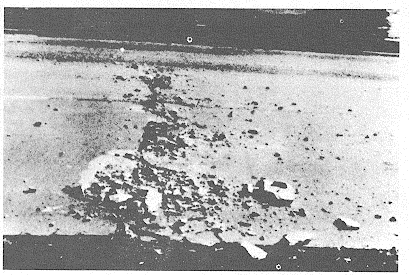

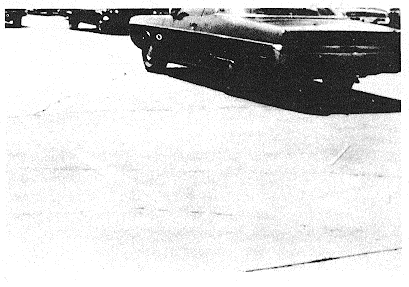

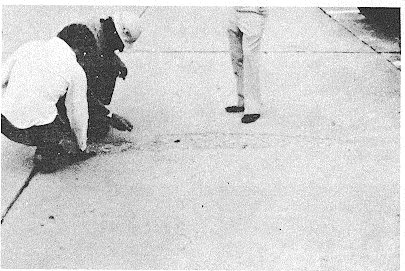

L-Shove causes low-severity ride quality (fig B-60).

B-20

TM 5-623

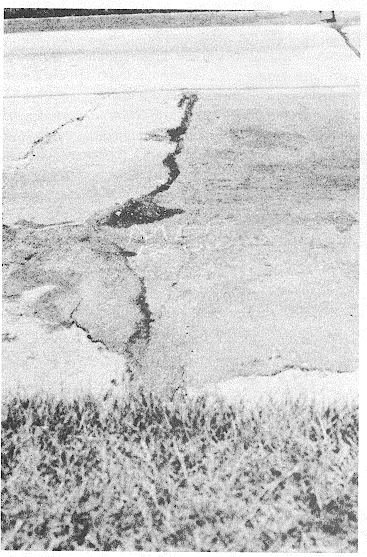

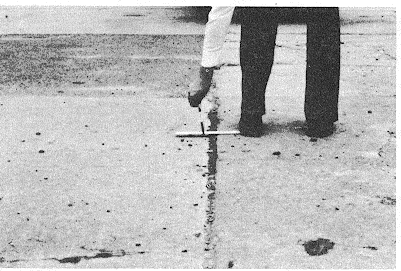

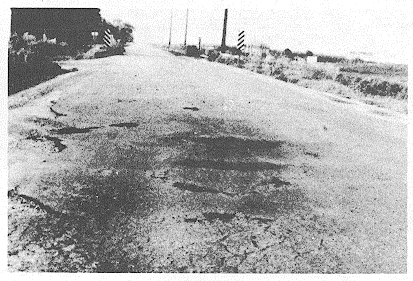

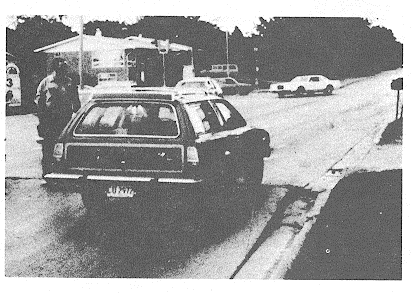

M-Shove causes medium-severity ride quality (fig B-61).

Figure B-60. Low-severity shoving.

Figure B-61. Medium-severity shoving approaching high

severity.

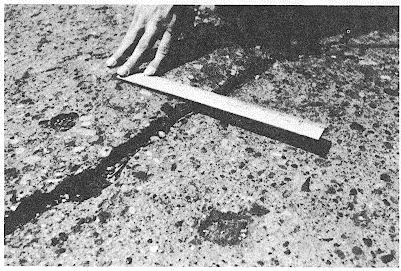

H-Shove causes high-severity ride quality (fig B-62).

How to Measure:

Shoves are measured in square feet of surface area.

Shoves occurring in patches are considered in rating the patch, not as a separate distress.

Name of Distress:

Slippage Cracking.

Description:

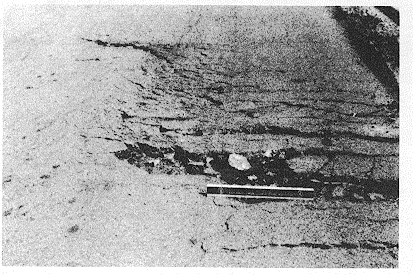

Slippage cracks are crescent or half-moon-shaped cracks having two ends

pointing away from the direction of traffic. They are produced when breaking or turning wheels cause the pavement surface to slide or deform. This

distress usually occurs when there is a low-strength surface mix or a poor

bond between the surface and the next layer of the pavement structure.

Severity Levels:

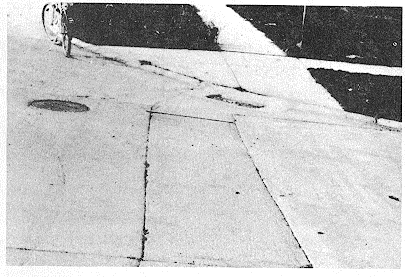

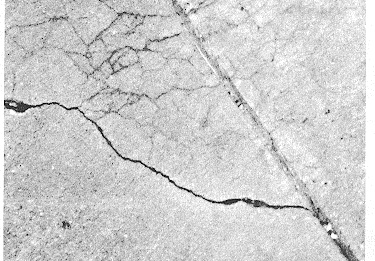

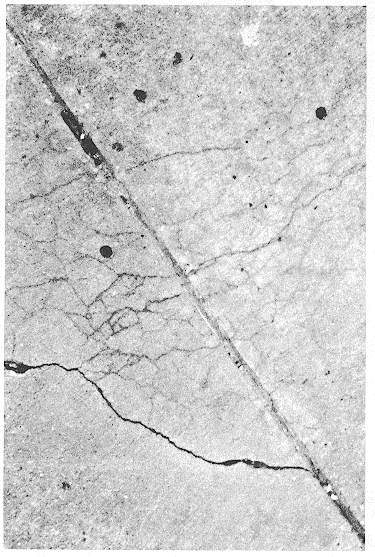

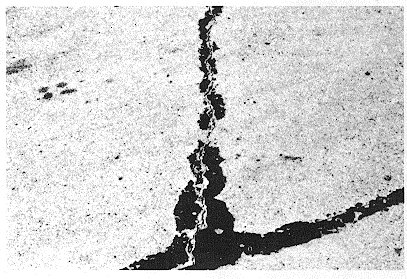

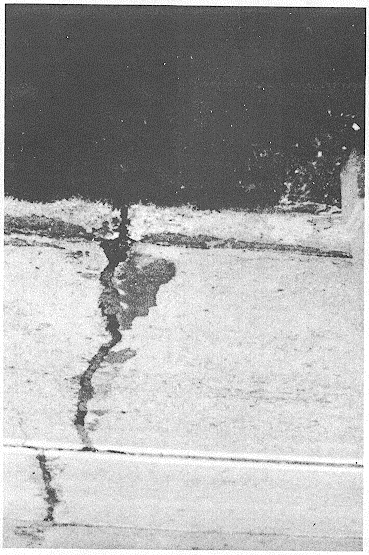

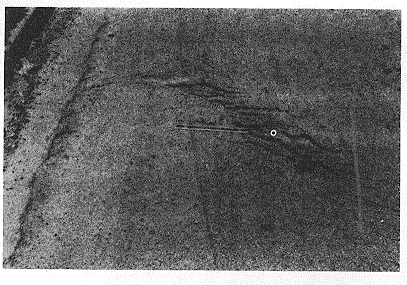

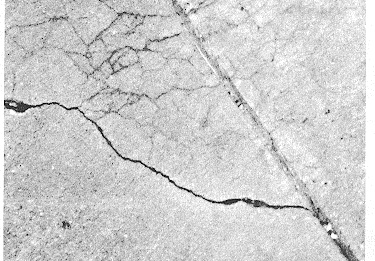

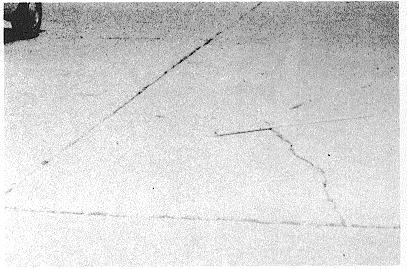

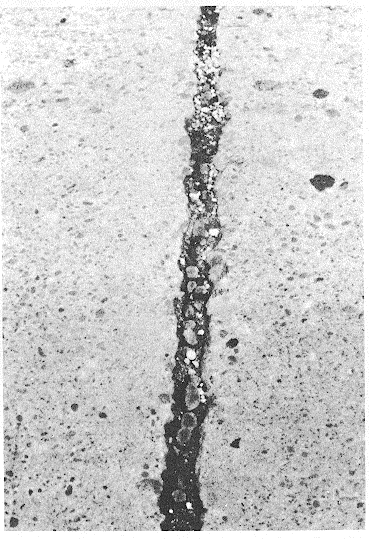

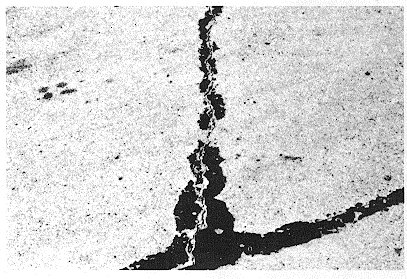

L-Average crack width is less than % inch (fig B-63).

Figure B-62. High-severity shoving.

Figure B-63. Low-severity slippage cracking.

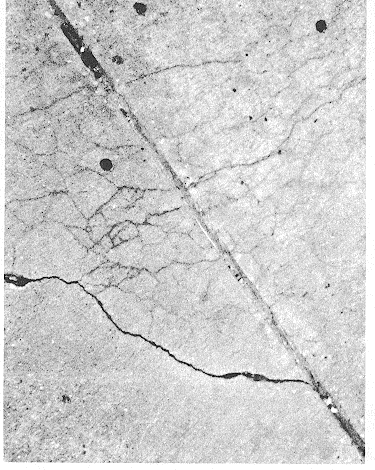

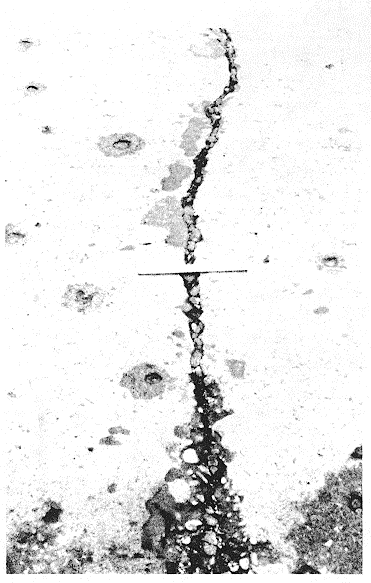

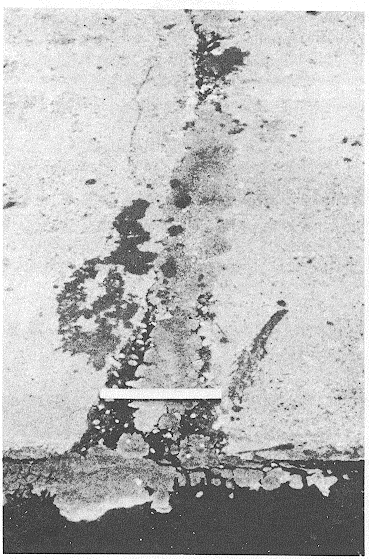

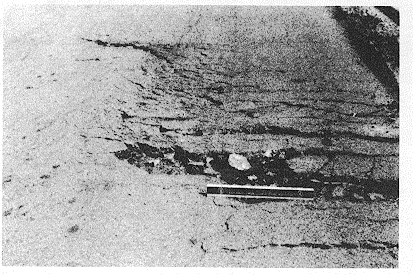

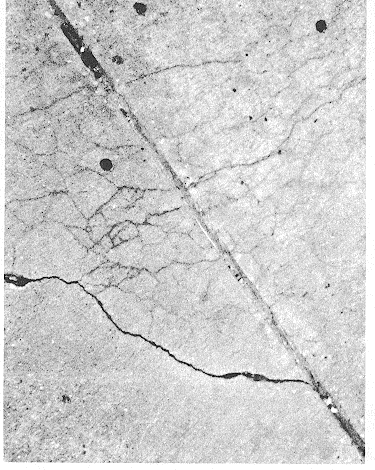

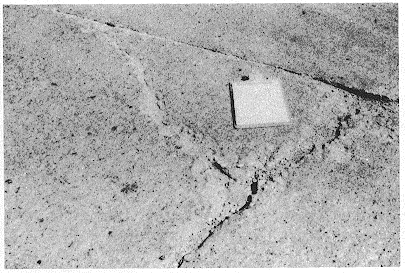

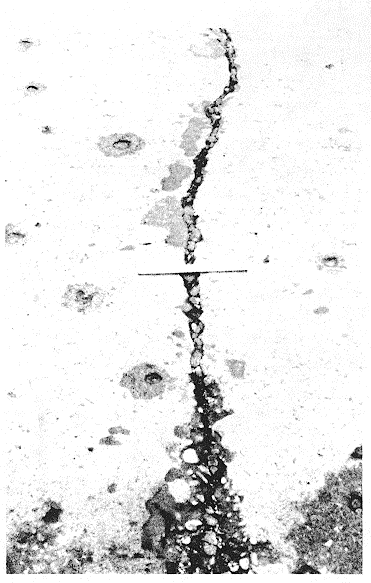

M-One of the following conditions exists (fig B-64):

1.

Average crack width is between X and 1 inches.

2.

The area around the crack is broken into tight-fitting pieces.

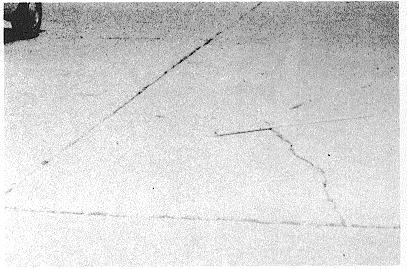

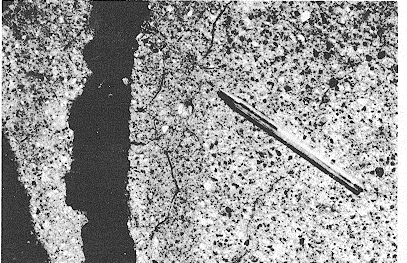

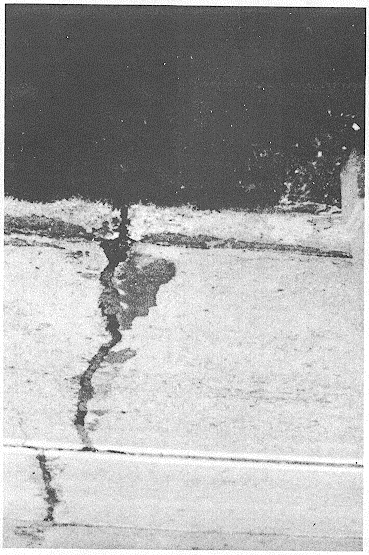

H-One of the following conditions exists (fig B-65):

B-21

TM 5-623

Figure B-65. High-severity slippage cracking.

Figure B-64. Medium-severity slippage cracking.

1.

The average crack width is greater than 1I inches.

2.

The area around the crack is broken into easily removed pieces.

How to Measure:

The area associated with a given slippage crack is measured in square feet and rated according to the highest level severity in the area.

Name of Distress:

Swell.

Description:

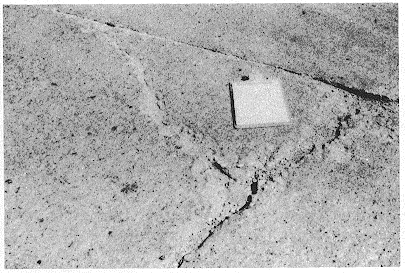

Swell is characterized by an upward bulge in the pavement’s surface-a long,

gradual wave of more than 10 feet long. Swelling can be accompanied by

surface cracking. This distress is usually caused by frost action in the

subgrade or by swelling soil.

Severity Levels:

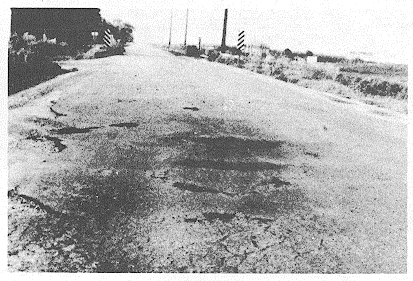

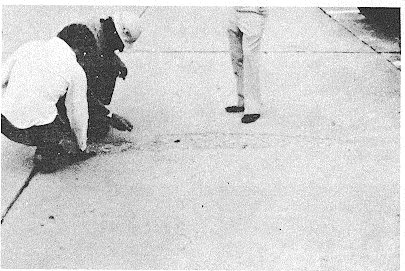

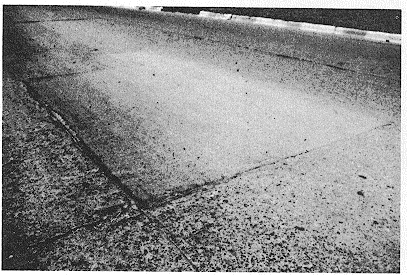

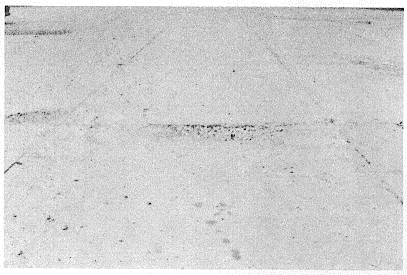

L-Swell causes low-severity ride quality. Low-severity swells are not always easy to see, but can be detected by driving at the speed limit over the pavement

section. An upward acceleration will occur at the swell if it is present. (See

fig B-66.) M-Swell causes medium-severity ride quality. (See fig B-66.) H-

Swell causes high-severity ride quality. (See fig B-66.)

Figure B-66. Example swell; severity level is based on ride quality criteria.

How to Measure:

The surface of the swell is measured in square feet.

Name of Distress:

Weathering and Raveling.

B-22

TM 5623

Description:

Weathering and raveling are the wearing away of the pavement surface caused

by the loss of asphalt or tar binder and dislodged aggregate particles. These distresses indicate that either the asphalt binder has hardened appreciably or that a poor-quality mixture is present. In addition, raveling may be caused by certain types of traffic, e.g., tracked vehicles.

Severity Levels:

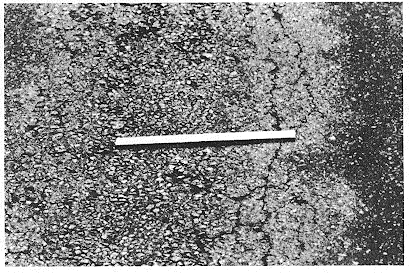

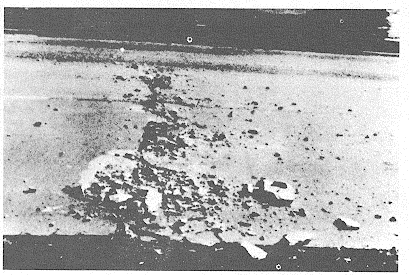

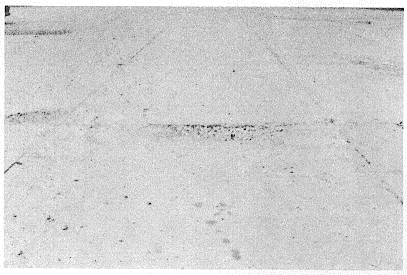

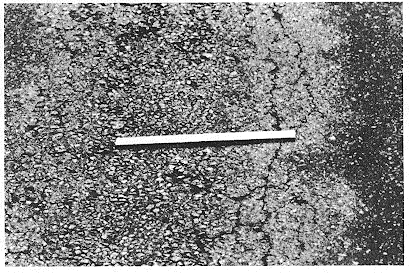

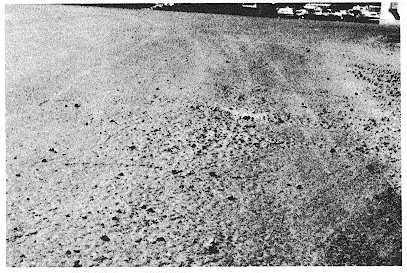

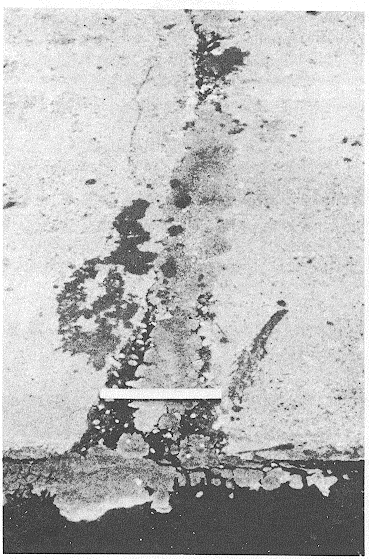

L-Aggregate or binder has started to wear away. In some areas, the surface is

starting to pit (figs B-67 and B-68).

Figure B-67. Low-severity weathering and raveling.

Figure B-68. Low-severity weathering and raveling

caused by tracked vehicles.

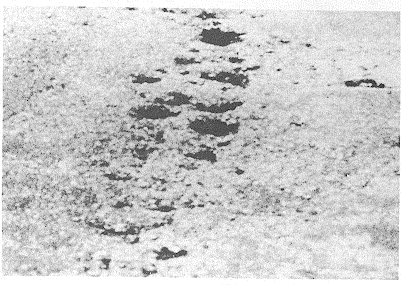

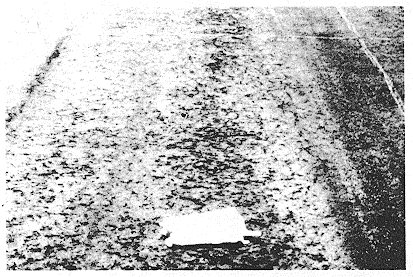

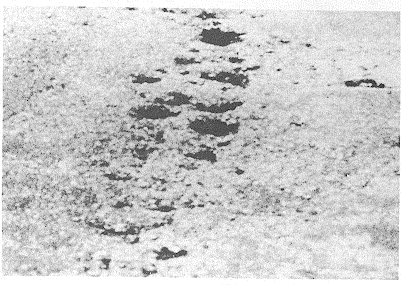

M-Aggregate and/or binder has worn away. The surface texture is moderately

rough and pitted (figs B-69 and B-70).

Figure B-69. Medium-severity weathering and raveling.

Figure B-70. Medium-severity weathering and raveling.

H-Aggregate and/or binder has been considerably worn away. The surface

texture is very rough and severely pitted. The pitted areas are less than 4

inches in diameter and less than 3 inch deep; pitted areas larger than this are

counted as potholes (fig B-71).

B-23

TM 5-623

How to Measure:

Weathering and raveling are measured in square feet of surface area.

ALPHABETICAL LISTING OF DISTRESS TYPES-JOINTED CONCRETE PAVEMENTS

Name of Distress:

Blow-up/Buckling.

Description:

Blow-ups or buckles occur in hot weather, usually at a transverse crack or joint that is not wide enough to permit slab expansion. The insufficient width is usually caused by infiltration of incompressible materials into the joint space.

When expansion cannot relieve enough pressure, a localized upward

movement of the slab edges (buckling) or shattering will occur in the vicinity of the joint. Blow-ups can also occur at utility cuts and drainage inlets.

Severity Levels:

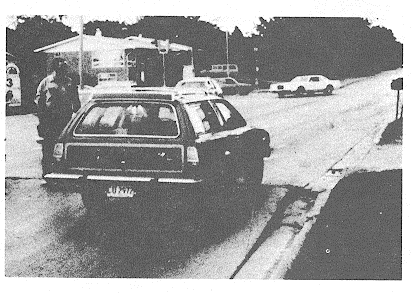

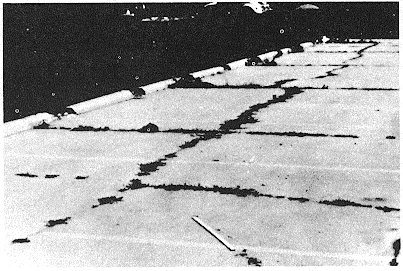

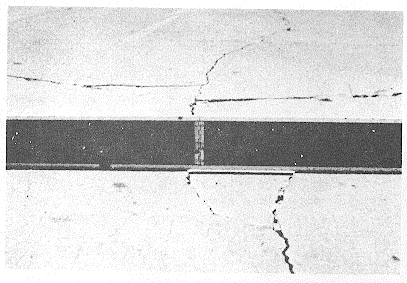

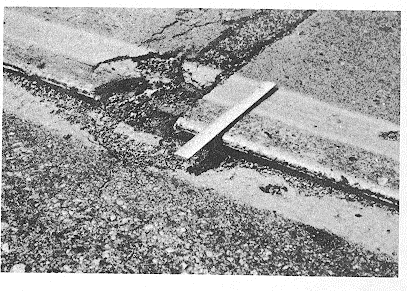

L-Buckling or shattering causes low-severity ride quality (fig B-72).

Figure B-71. High-severity weathering and raveling.

Figure B-72. Low-severity blow-up/buckling.

M-Buckling or shattering causes medium-severity ride quality (figs B-73 and B-

74).

B-24

TM 5-623

Figure B-74. Medium-severity blow-up/buckling.

Figure B-73. Medium-severity blow-up/buckling.

H-Buckling or shattering causes high-severity ride quality (fig B-75).

Figure B-75. High-severity blow-up/buckling approach inoperative conditions.

How to Count:

At a crack, a blow-up is counted as being in one slab. However, if the blowup occurs at a joint and affects two slabs, the distress should be recorded as

occurring in two slabs. When a blow-up renders the pavement inoperable, it

should be repaired immediately.

Name of Distress:

Corner Break.

B-25

TM 5-623

Description:

A corner break is a crack that intersects the joints at a distance less than or equal to one-half the slab length on both sides, measured from the corner of the

slab. For example, a slab with dimensions of 12 by 20 feet that has a crack 5

feet on one side and 12 feet on the other side is not considered a corner

break; it is a diagonal crack. However, a crack that intersects 4 feet on one side and 8 feet on the other is considered a corner break. A corner break

differs from a corner spall in that the crack extends vertically through the entire slab thickness, while a corner spall intersects the joint at an angle.

Load repetition combined with loss of support and curling stresses usually

causes corner breaks.

Severity Levels:

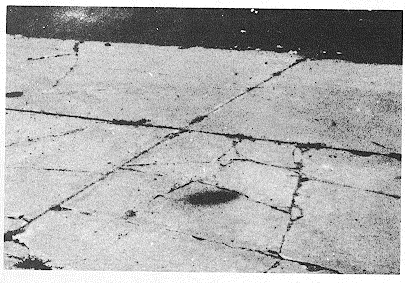

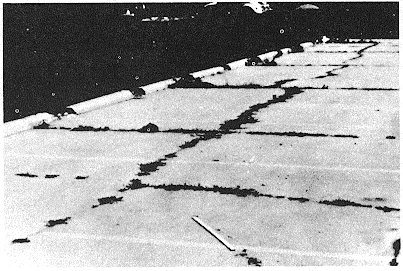

L*--Break is defined by a low-severity crack and the area between the break and

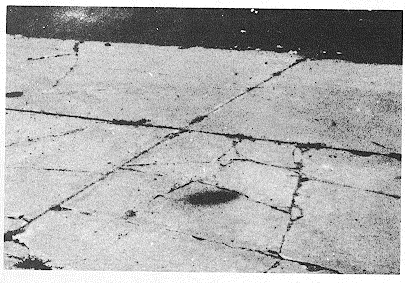

the joints is not cracked or may be lightly cracked (figs B-76 and B-77).

Figure B-76. Low-severity corner break.

Figure B-77. Low-severity corner break.

M*-Break is defined by medium-severity crack and/or the area between the break

and the joint is mediumly cracked (fig B-78).

H*--Break is defined by a high-severity crack and/or the area between the break

and the joints is highly cracked (fig B-79).

*See linear cracking for a definition of low-, medium, and high-severity cracks.

B-26

TM 5-623

Figure B-78. Medium-severity corner break. Defined by

Figure B-79. High-severity corner break.

a medium-severity crack.

How to Count:

Distressed slab is recorded as one slab if it::

1.

Contains a single corner break.

2.

Contains more than one break of a particular severity.

3.

Contains two or more breaks of different severities.

For two or more breaks, the highest level of severity should be recorded. For example, a slab containing both low and medium-severity corner breaks

should be counted as one slab with a medium corner break.

Name of Distress:

Divided Slab.

Description:

Slab is divided by cracks into four or more pieces due to overloading and/or inadequate support. If all pieces or cracks are contained within a corner

break, the distress is categorized as a severe corner break.

Severity Levels:

Severity of

Number of pieces in cracked slab

majority of

cracks

4 to 5

6 to 8

More than 8

L

L

L

M

M

M

M

H

H

M

H

H

See figures B-80 through B-84.

Figure B-80. Low-severity divided slab. Majority of

Figure B-81. Medium-severity divided slab.

cracks are low severity access than 1/2 inch wide and no

faulting).

B-27

TM 5-623

Figure B-82. High-severity divided slab caused by high-

Figure B-83. High-severity divided slab.

severity cracks.

Figure B-84. High-severity divided slab.

How to Count:

If the slab is medium or high-severity, no other distress is counted.

Name of Distress:

Durability ("D") Cracking.

Description:

"D" cracking is caused by freeze-thaw expansion of the large aggregate which, over time, gradually breaks down the concrete. This distress usually appears as a pattern of cracks running parallel and close to a joint or linear crack.

Since the concrete becomes saturated near joints and cracks, a dark-colored

deposit can usually be found around fine "D" cracks. This type of distress may eventually lead to disintegration of the entire slab.

Severity Levels:

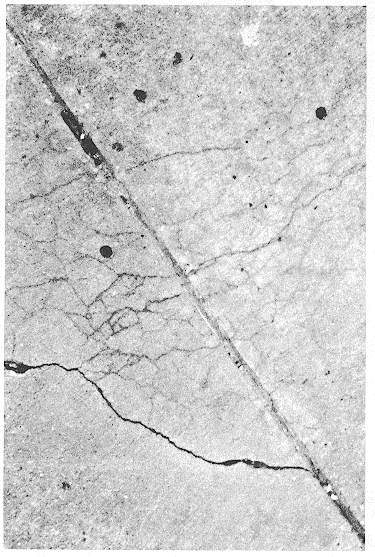

L-"D" cracks cover less than 15 percent of slab area. Most of the cracks are

tight, but a few pieces may have popped out (figs B-85 and B-86).

B-28

TM 5-623

Figure B-86. Low-severity durability cracking.

Figure B-85. Low-severity durability cracking.

M-One of the following conditions exists (fig B-87):

Figure B-87. Medium-severity durability cracking.

1.

"D" cracks cover less than 15 percent of the area and most of the pieces have popped out or can be easily removed.

2.

"D" cracks cover more than 15 percent of the area. Most of the cracks are tight, but a few pieces may have popped our or can be easily removed.

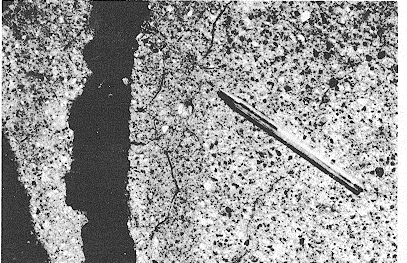

H-"D" cracks cover more than 15 percent of the area and most of the pieces have

popped out or can be easily removed (see figs B-88 and B-89).

B-29

TM 5-623

Figure B-88. High-severity durability cracking.

Figure B-89. High-severity durability cracking.

How to Count:

When the distress is located and rated at one severity, it is counted as one slab.

If more than one severity level exists, the slab is counted as having the higher severity distress. For example, if low and medium "D" cracking are on the same slab, the slab is counted as having medium-severity cracking only.

Name of Distress:

Faulting.

Description:

Faulting is the difference in elevation across a joint. Some of the common

causes of faulting are:

1.

Settlement because of soft foundation.

2.

Pumping or eroding of materiel from under the slab.

3.

Curling of the slab edges due to temperature and moisture changes.

Severity Levels:

Severity levels are defined by the difference in elevation across the crack or joint.

Severity level

Difference in elevation

L

1/8 to 3/8 inch

M

3/8 to 3/4 inch

H

> 3/4 inch

See figures B-90 through B-93.

Figure B-90. Low-severity faulting.

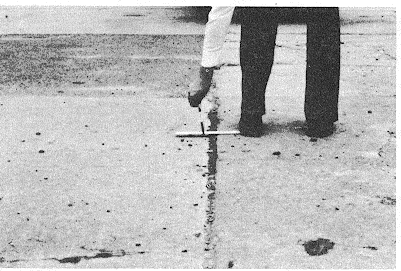

Figure B-91. Medium-severity faulting.

B-30

TM 5-623

Figure B-92. Medium-severity faulting.

Figure B-93. High-severity faulting.

How to Count:

Faulting across a joint is counted as one slab. Only affected slabs are counted.

Faults across a crack are not counted as distress, but are considered when

defining crack severity.

Name of Distress:

Joint Seal Damage.

Description:

Joint seal damage is any condition which enables soil or rocks to accumulate in the joints or allows significant water infiltration. Accumulation of

incompressible materials prevents the slabs from expanding and may result

in buckling, shattering, or spalling. A pliable joint filler bonded to the edges of the slabs protects the joints from material accumulation and prevents water

from seeping down and softening the foundation supporting the slab.

Typical types of joint seal damage are:

1.

Stripping of joint sealant.

2.

Extrusion of joint sealant.

3.

Weed growth.

4.

Hardening of the filler (oxidation).

5.

Loss of bond to the slab edges.

6.

Lack or absence of sealant in the joint.

Severity Levels:

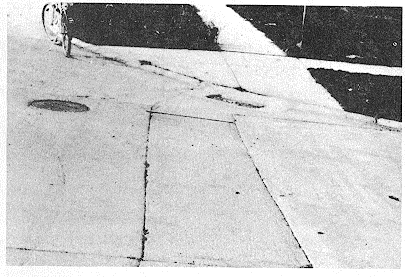

L-Joint sealant is in generally good condition throughout the section. Sealant is

performing well, with only minor damage (see above) (fig B-94).

M-Joint sealant is in generally fair condition over the entire section, with one more of the above types of damage occurring to a moderate degree. Sealant

needs replacement within 2 years (fig B-95).

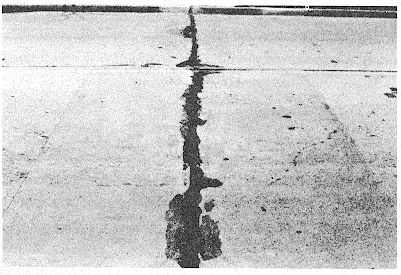

Figure B-94. Low-severity joint seal damage.

Figure B-95. Medium-severity joint seal damage.

B-31

TM 5-623

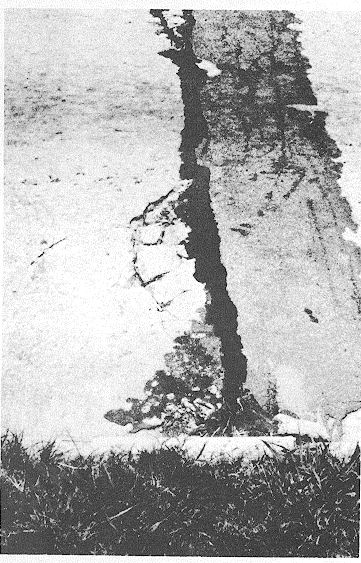

H-Joint sealant is in generally poor condition over the entire section, with one or more of the above types of damage occurring to a severe degree. Sealant

needs immediate replacement (figs B-96 and B-97).

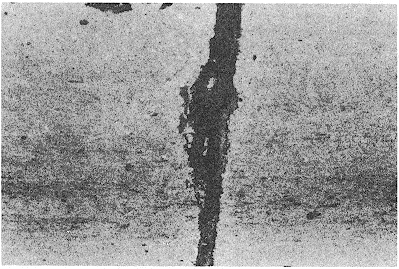

Figure B-96. High-severity joint seal damage.

Figure B-97. High-severity joint seal damage.

How to Count:

Joint seal damage is not counted on a slab-by-slab basis, but rated based on the overall condition of the sealant over the entire area.

Name of Distress:

Lane/Shoulder Drop Off.

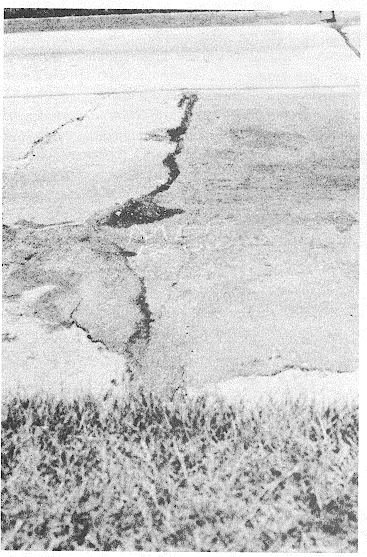

Description:

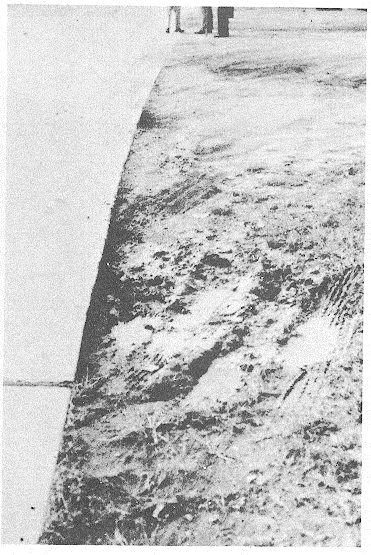

Lane/shoulder drop off is the difference between the settlement or erosion of the shoulder and the pavement travel-lane edge. The elevation difference can be a safety hazard; it can also cause increased water infiltration.

Severity Levels:

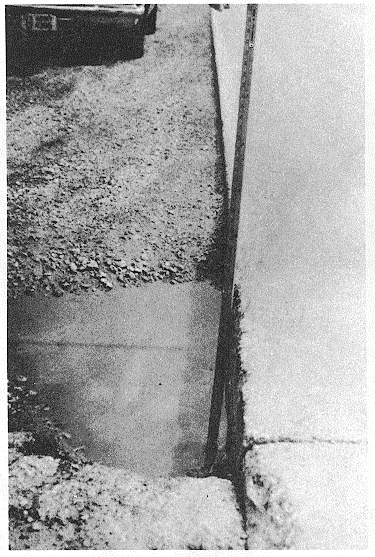

L-The difference between the pavement edge and shoulder is 1 to 2 inches (fig B-

98).

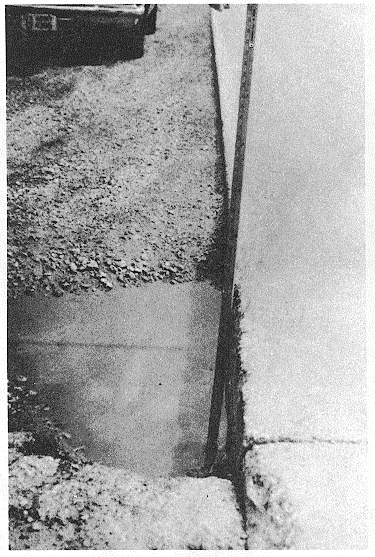

M-The difference in elevation is 2 to 4 inches (fig B-99).

B-32

TM-5-623

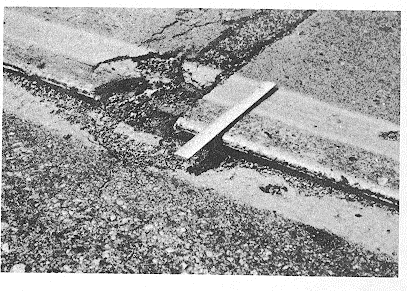

Figure B-98. Low-severity lane/shoulder drop off.

Figure B-99. Medium-severity lane/shoulder drop off

H-The difference in elevation is greater than 4 inches (fig B-100).

B-33

TM 5-623

Figure B-100. High-severity lane/shoulder drop off.

How to Count:

The mean lane/shoulder drop off is computed by averaging the maximum and

minimum drop along the slab. Each slab exhibiting distress is measured

separately and counted as one slab with the appropriate severity level.

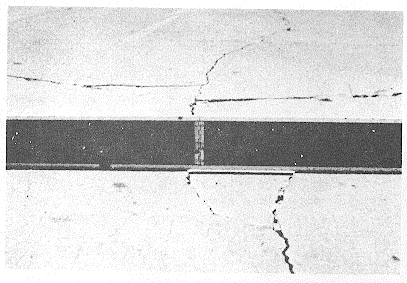

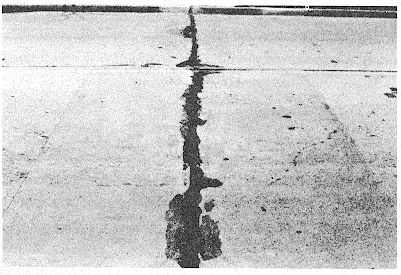

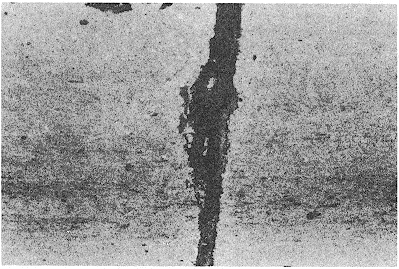

Name of Distress:

Linear Cracking (Longitudinal, Transverse, and Diagonal Cracks).

Description:

These cracks, which divide the slab into two or three pieces, are usually caused by a combination of repeated traffic loading, thermal gradient curling, and

repeated moisture loading. (Slabs divided into four or more pieces are

counted as Divided Slabs.) Low-severity cracks are usually related to warp or friction and are not considered major structural distresses. Medium or high-severity cracks are usually working cracks and are considered major

structural distresses (fig B-101 through B-106).

B-34

TM 5-623

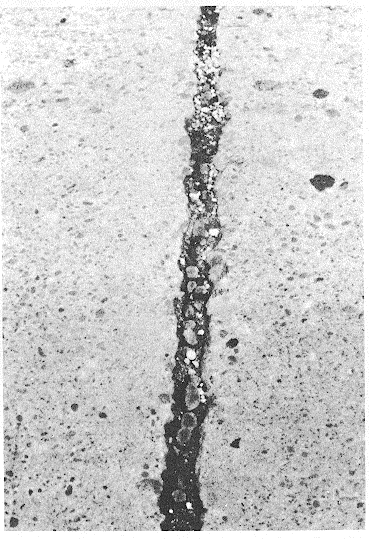

Figure B-101. Low-severity linear cracking in a

nonreinforced

concrete slab.

Figure B-102. Low-severity linear cracking in a

nonreinforced

concrete slab.

Figure B-103. Medium-severity linear cracking in a

reinforced

concrete slab.

B-35

TM 5-623

Figure B-104. Medium-severity linear cracking in a reinforced concrete slab.

Figure B-105. High-severity linear cracking in a nonreinforced concrete slab.

B-36

TM 5-623

Figure B-106. High-severity linear cracking in a nonreinforced concrete slab.

Hairline cracks that are only a few feet long and do not extend across the entire slab are counted as shrinkage cracks.

Severity Levels:

Nonreinforced Slabs: L-Nonfilled* cracks less than or equal to Y inch or filled cracks of any width with the filler in satisfactory condition. No faulting exists.

M-One of the following conditions exists:

1.

Nonfilled crack with a width between Y and 2 inches.

2.

Nonfilled crack of any width up to 2 inches with faulting of less than X inches.

3.

Filled crack of any width with faulting less than % inch.

H-One of the following conditions exists:

1.

Nonfilled crack with a width greater than 2 inches.

2.

Filled or nonfilled crack of any width with faulting greater than % inch.

Reinforced Slabs.

L-Nonfilled cracks with a width of Y8 to 1 inch; filled crack of any width with the filler in satisfactory condition. No faulting exists.

M-One of the following conditions exist:

1.

Nonfilled cracks with a width between 1 and 3 inches and no faulting.

2.

Nonfilled crack of any width up to 3 inches with up to v8 inch of faulting.

3.

Filled crack of any width with faulting less than % inch.

H-One of the following conditions exists:

1.

Nonfilled crack with width over 3 inches.

2.

Filled or nonfilled crack of any width with faulting over % inch.

*Filed cracks where filler is unsatisfactory are treated as nonfilled.

B-37