Chapter 4

Force Provider Environmental Guidance and Safety

Procedures

SECTION I - ENVIRONMENTAL CONSIDERATIONS AND STEWARDSHIP

ENVIRONMENTAL RESPONSIBILITIES

4-1. The Army vision includes the goal to be a national leader in environmental and natural resource stewardship for present and future generations. The definition of stewardship is to take care of property while also caring about the rights of others. QM Force Provider Company personnel embrace this role and endeavor to exemplify their care and concern for the environment throughout all facets of system operations. Operations must be planned to be carried out without harming the local environment. Future plans call for adapting Force Provider sub-systems to conserve additional resources and move toward the ultimate objective of a completely self-sustaining system. The shower water re-use system currently in development is an example of where the system is headed in terms of future operations in support of conservation and care for the environment. Sound environmental stewardship enables Force Provider leaders to better take care of Soldiers and also conserve resources vital to combat readiness. The purpose of the environmental protection stewardship program is to standardize environmental protection compliance with federal, state, local, and host nation laws and regulations. FM 3-100.4 Environmental Considerations in Military Operations provides guidance and information on basic environmental protection stewardship. Noncompliance with the program may result in:

• Damage to the environment and to natural resources

• Endangerment of personnel health and safety

• Severe civil or military penalties

ENVIRONMENTAL PROTECTION STEWARDSHIP GOALS AND REQUIREMENTS

4-2. The Army no longer merely complies with the laws and regulations of environmental protection stewardship. It leads in environmental protection matters by setting goals and requirements for its leaders. The goals of the Army's environmental stewardship protection program are:

• Compliance. Ensure that all Army sites and operations attain and sustain 100 percent compliance with environmental laws and regulations in a climate of changing requirements. Army sites or operations could be subject to a notice of violation or a fine for not following host nation, local, state, or federal environmental directives.

• Prevention. Adopt and use integrated management approaches in all Army mission areas to prevent and reduce the volume and toxicity of all categories of environmental pollution.

• Conservation. Conserve, protect, and enhance environmental and cultural resources entrusted to the Army's stewardship of future generations using all practical and available means consistent with the Army mission.

4-3. The requirements of the Army's environmental stewardship protection program are:

• Appraisal. Require an appraisal to determine potential environmental impacts.

• Training. Require all key Army decision-makers and planners to attend National Environmental Policy Act (NEPA) training.

• Restoration. Ensure strict compliance with all spill and release reporting, timely resource requests and allocations, and clean-up requirements of all Army contaminated sites, as quickly as resources are made available to protect human health and the environment.

• Environmental consideration. Ensure that all available environmental and cultural resources are incorporated early in the mission decision-making and planning process.

RESPONSIBILITIES OF PERSONNEL

4-4. Each member of the QM Force Provider Company must comply with the environmental protection stewardship program.

4-5. The QM Force Provider Company Commander's environmental responsibilities are to:

• Comply with all applicable environmental protection laws and regulations.

• Know the National Environmental Policy Act (NEPA), hazardous materials (HM), hazardous waste (HW), hazardous communications (HAZCOM) efforts, and spill contingencies.

• Set up the unit's HM/HW management policy.

• Ensure that personnel comply with the provisions, laws, and regulations outlined in the program, to include all applicable procedures for documentation, inspections and follow-ups.

• Appoint and ensure that the environmental compliance officer (ECO), the HM/HW coordinator, and senior personnel have received appropriate training.

• Ensure that all personnel who may be exposed to HM or HW when performing their duties receive training about potential hazards and relevant precautions within 90 days of assignment.

• Ensure personnel receive annual refresher training about potential hazards and relevant precautions.

• Commit subordinate leaders to environmental protection.

• Continuously assess the influence of the mission on the environment.

4-6. The QM Force Provider Company Executive Officer's environmental responsibilities are to:

• Serve as the unit's ECO.

• Serve as the commander's eyes and ears for environmental protection matters.

• Conduct periodic assessments of the unit's environmental protection program and the unit's level of compliance.

• Act as liaison between the unit and the higher headquarters responsible for managing environmental protection compliance programs and provide information on training requirements and certifications needed by unit personnel.

• Commit subordinate leaders to environmental protection.

• Analyze the influence of the environment on the mission.

4-7. The Maintenance Officer and/or Motor Sergeant's environmental responsibilities are to:

• Serve as the unit HM/HW coordinator.

• Serve as the unit spill coordinator.

• Maintain accountability for all HM and HW.

• Ensure that HM and HW are stored and disposed of properly.

• Ensure that HM and HW spills are immediately contained and reported to the local fire department and to the ECO.

• Report inoperative treatment and collection facilities (oil/grease interceptors, floor drains, catch basins, waste tanks) to the ECO.

4-8. The Section Leaders and Noncommissioned Officers' environmental responsibilities are to:

• Protect the environment with daily sound decisions.

• Ensure Soldiers are aware of Army environmental protection ethics.

• Train Soldiers to be good environmental protection stewards.

• Identify environmental risks associated with the tasks they and their Soldiers perform.

• Plan and conduct environmental sustainability actions and training.

• Protect the environment during training and other activities.

• Continuously assess the influence of the mission on the environment.

• Integrate environmental considerations into unit activities.

• Train peers and Soldiers to identify the environmental effects of plans, actions, and mission.

• Counsel Soldiers on the importance of protecting the environment and the results of not complying with environmental laws.

• Incorporate environmental considerations into after action reviews (AARs).

• Report spills of HM or HW immediately.

• Provide ideas through the chain of command concerning the improvement of the unit's environmental protection program.

• Support the Army recycling program.

4-9. All Soldiers' environmental responsibilities are to:

• Follow the unit's environmental protection stewardship policies, unit standing operating procedures (SOPs), Army regulations (ARs), and environmental laws and regulations.

• Make environmentally sound decisions in day-to-day activities.

• Identify environmental risks in individual and team tasks.

• Report spills of HM or HW immediately.

• Provide ideas through the chain of command concerning the improvement of the unit's environmental protection program.

• Support the Army recycling program.

UNIT-LEVEL ENVIRONMENTAL TRAINING PROGRAM

4-10. An effective environmental protection stewardship training program allows personnel to carry out their responsibilities without undue damage to the environment or to personnel safety. It is the responsibility of the Company Commander to ensure that all personnel are trained on environmental hazards and the appropriate precautions for reducing or eliminating damage to the environment or risk to personnel.

4-11. All personnel should receive environmental awareness and protection training within 90 days of assignment and annually thereafter. All personnel will be trained to do their tasks in compliance with environmental laws and regulations. They must also respond properly to emergencies. All environmental protection and HM/HW training must be properly documented and kept on file in the operations/training office. Issues that should be addressed in the unit's environmental protection training program are:

• HM management

• HW management

• Hazardous communications (HAZCOM)

• Pollution prevention

• Hazardous waste minimization (HAZMIN)

• Spill prevention and response

• Recycling program

ENVIRONMENTAL PROTECTION ISSUES

4-12. Hazardous Material Requisitioning. The HM/HW Coordinator will maintain an up-to-date list of all the unit's hazardous materials, documents, and corresponding manuals. The unit inventory should be kept as small as possible to reduce potential for incident. The least hazardous or potentially hazardous material needed to do the required task should be requested.

4-13. Hazardous Material Storage. Storage of hazardous materials can create safety hazards and extended term storage may lead to environmental hazards. Hazardous materials will be stored in their original or approved containers. All containers must be clearly labeled with the appropriate material safety data sheet (MSDS) information. An MSDS sheets will be kept in the appropriate hazard communications manuals. HM will be used on a first-in first-out basis. Surplus quantities of HM, which need an extended period of storage, will be turned in.

4-14. Hazardous Material Turn-In. POL products will be stored with secondary containment measures. To stop spillage outside the immediate area, berms that can hold one and one-half times the volume of the largest container stored in the area will be constructed. All HM and HW must be stored so that they are protected from the elements and to maintain container integrity. All containers must be inspected for leaks and for incomplete, unreadable, or out-of-date labels weekly. HW will be inspected weekly. Inspection results will be documented in a log and made accessible to federal, state, or local inspectors. Inspection logs will contain the following:

• Description of waste

• Location

• Quantity

• Date accumulation started

• End of 90-day period

• Date removed to DRMO or other agency

• Remarks (condition of containers)

• Inspector's printed name, signature, and date of inspection

4-15. Defense reutilization and marketing offices (DRMO) provide guidance for local turn in of HW and unused HM. All HW waiting turn-in must be documented using an accumulation log. The log provides the date the container was opened, date and quantity of each addition to the container, name of the person adding HW to the container, the date the container was filled or closed, and the date of turn-in to DRMO or other authorized agency. All turn-in documents for HM and HW and the accumulation logs for HW must be kept on file by the unit for two years.

4-16. Hazardous Waste Accumulation. HW will be labeled, accumulated on a non-permeable bermed hardstand, and located at least 50 feet from any buildings. HW must be protected from the elements. Used greases, solvents, brake fluids, hydraulic fluid, and antifreeze are examples of substances that should be stored in separate containers. To safeguard against spills and prevent water seepage, keep HW containers closed except when depositing waste. If threaded caps on 55-gallon drums are missing, replace them through unit maintenance channels.

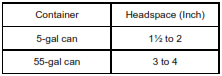

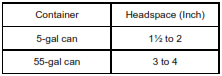

4-17. Sufficient headspace must be allowed in the containers to prevent overflow from the expansion of HW. Table 4-1 provides the headspace requirements.

Table 4·1. Headspace for Containers

4-18. To be accepted for turn-in, the HW must be stored in safe, non-leaking, durable containers. Leaking containers must be over-packed in steel removable-head drums. Containers leaking liquid must be packed in absorbent material. A leaking 55-gallon drum may be over-packed in an 85-gallon drum. The absorbent material must be able to soak up all of the liquid contents of the drum; therefore, 6 inches of absorbent must be on the bottom and top of the interior container, with at least 2 inches along the sides. Leaking containers of non-liquid hazardous waste may not need to be over-packed with absorbent material. Many liquids, such as battery acid, cannot be packed in steel containers.

4-19. Spill Response. A reportable spill is one that involves any amount of hazardous material which may harm the environment or personnel. The hazardous materials most commonly associated with Force Provider are fuel, oil, hydraulic fluid, grease, solvent, gray water, and black water. While other potentially hazardous substances exist, these are the most prevalent and require effective management planning.

4-20. In areas where HM are used or stored or where HW is stored, appropriate supplies, equipment, and personal protective items must be readily available to allow an immediate response to spills or accidents. Refer to the MSDS for a specific product or contact the HW/HM section of the DRMO for guidance on the spill response items and equipment required to safely respond to a spill incident.

4-21. If a hazardous waste spill occurs, available personnel will immediately take the following steps:

• Ensure the safety of those in the area.

• Evacuate the area if necessary

• Report the spill to supervisors. Sound the alarm or give a verbal warning. Have someone call the fire department if the spill is something that cannot be handled safely.

• Extinguish smoking materials and all other sources of ignition.

• Take personal precautions as detailed on the MSDS for the spilled material.

• Stop the leak or flow, if possible (shut off valves, tip drums, plug holes).

• Contain the spill by using absorbent material. Make dams to prevent materials from spreading or entering water or storm drains.

• Clean up material with a non-sparking shovel or broom. Place the residue in a serviceable container with lid, marked "Hazardous Waste - Contaminated Absorbent." Check with the ECO for proper disposal.

• If the spill resulted from a leaky container, transfer the product to a serviceable container. Label the container as follows:

• For fuel, oil, or hydraulic fluid spills label the container "POL Spill Residue."

• For flammable liquid spills, including solvents, paints, paint thinners, and alcohol, label the container "(name of liquid) Spill Residue-FLAMMABLE."

• For acid spills, label the container "(name of acid) Spill Residue ACID"

• Store the container in the HW area while waiting turn-in.

• Turn-in to DRMO or other authorized agency.

• A written report must be generated to describe the details of the incident, corrective actions taken, and measures instituted to prevent recurrence.

SECTION II - SAFETY

PROMOTING SAFETY AWARENESS

4-22. Safety in the field is not all common sense. Soldiers are encouraged to continually conduct their work safely and to assist others in working safely. Leaders must set the example. They must train Soldiers in the techniques and procedures for working safely and avoiding unnecessary accidents or injury. AR 385-

10 and AR 385-40 provide information on the Army's safety program, and FM 4-25.11, First Aid outlines actions to take if an injury occurs.

4-23. The commander ensures that all personnel are performing safely in their jobs. He must also ensure that their job descriptions clearly delineate safety responsibilities. All supervisors and Soldiers will receive safety training. Supervisors will be trained to recognize and eliminate hazards and to develop other required skills to implement the Army's safety program at the working level. Soldiers will receive specialized job, safety, and health training. This training will include Occupational Safety and Health Agency (OSHA) criteria and the hazards associated with any materials or operations in the workplace.

LIFTING HAZARDS

4-24. The setup, operation, and dismantling of the Force Provider module is labor intensive. It requires personnel to do a large amount of lifting and bending. Many items associated with the module, such as the M80 water heaters or the sewage ejection pump (SEP), weigh in excess of 400 pounds and require a forklift or a minimum of a 6-man lift to position. The erection of the TEMPER tent requires extensive amounts of bending and lifting. If done improperly, this may affect the health and safety of personnel. Supervisors will ensure that all Soldiers use proper lifting techniques and body mechanics when setting up, operating, and dismantling the Force Provider module. Soldiers will be tasked in teams suitable to the lifting needs of the job. Forklifts and other equipment will be used whenever possible to reduce the risk of personnel injury.

ELECTRICAL HAZARDS

4-25. Each Force Provider module uses electrical power. Electricity in field conditions presents unusual safety hazards which must be managed to prevent personnel injury or death. To prevent electrical shock, each subsystem and structure will be thoroughly grounded using an earth ground. The proper electrical grounding rods are provided in the Force Provider shipping containers. Electrical system grounding should be inspected periodically to ensure proper grounding is constantly maintained for the electrical systems of all subsystems and structures.

4-26. Electrical cables should be inspected periodically for cuts, abrasions, and connectivity. Power should be removed from cut or abraded cables which will be repaired or replaced. Field conditions may require electrical cables to lay in mud or standing water. If possible, sandbags and other nonconductive materials such as wood must be used to raise cables off of the ground. If required, cables may also be buried to ease the movement of equipment and personnel, and to prevent damage or electrical shock.

4-27. A Soldier will NEVER be allowed to work on electrical equipment with power applied. Soldiers will shut off electrical power, disconnect the power source, if necessary, and tag out the power source until all repairs are complete. Soldiers will also the buddy system whenever performing work on electrical equipment.

EXPOSURE TO HAZARDOUS MATERIALS OR WASTE

4-28. Force Provider uses and generates hazardous material and waste which is dangerous to personnel. Personal protective equipment will therefore be available for use.

4-29. Force Provider uses a great amount of fuel to power the tactical generators, organic vehicles and equipment. Fuel is a personnel hazard in the form of contact, flammability, ingestion, and inhalation. It must always be handled with care. Fuel storage areas will be clearly marked and designated as "no smoking" areas. These markings will also include the languages of the host nation where applicable.. Proper grounding procedures will be used whenever transferring fuel from one item to another. Fuel storage facilities or containers will always be properly grounded.

4-30. Fuel also presents a danger in the form of carbon monoxide. Expended fuel produces carbon monoxide gas, which if inhaled for an extended period of time, can cause injury or death. Engine exhausts must be appropriately vented into outside air. Soldiers must not be permitted to work in unventilated areas where carbon monoxide gas may be present.

4-31. Wastewater generated from the operations of the 12-head shower and the containerized batch laundry is considered gray water. Gray water contains detergents, bleaches, and other substances which may be hazardous to personnel. It is a personnel hazard in the form of contact and ingestion. Every effort should be made to eliminate or reduce exposure to gray water. If Soldiers must work with components containing gray water, appropriate personnel protective equipment should be worn. If a person comes in contact with gray water, they must immediately and thoroughly flush the exposed area with soap and potable water.

4-32. The containerized latrine uses internal storage tanks to contain human wastes. Black water is a personnel hazard in the form of contact, ingestion, and inhalation modes. It is a hazardous waste. Soldiers who must work with items containing or contacting black water should wear appropriate personal protective equipment to reduce risk. If they come in contact with black water, they must thoroughly flush the exposed areas with soap and potable water. For extreme exposure, medical treatment must be sought immediately after decontamination.

4-33. Force Provider uses highly chlorinated water to sanitize the potable water subsystems before it is dismantled. Highly chlorinated water is toxic to personnel. It is considered hazardous waste. Highly chlorinated water presents a hazard to personnel in the form of contact, ingestion, and inhalation. Soldiers that work with items containing or contacting highly chlorinated water must wear appropriate personal protective equipment to eliminate or reduce risk. If a person comes in contact with highly chlorinated water, they must thoroughly flush the exposed areas with soap and potable water. For extreme exposure, medical treatment must be sought immediately after decontamination.