Chapter 2

QM Force Provider Company Operational Procedures

SECTION I - COMPANY HQ SECTION AND PLATOON OPERATIONS

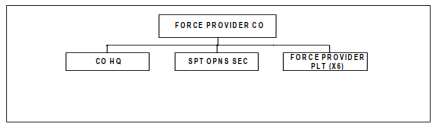

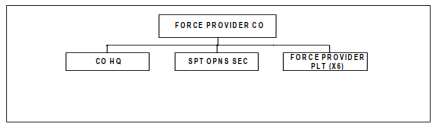

UNIT ORGANIZATION

2-1. This chapter describes operational procedures for the Force Provider Company headquarters sections, the six provider platoons and their functional sections, and system tenant units, including communications and defense considerations. Figure 2-1 below shows the QM Force Provider Company basic unit organization.

Figure 2·1. Organization of QM Force Provider Company

COMPANY HEADQUARTERS SECTION

2-2. The QM Force Provider Company Headquarters provides overall command and control, training, administration, and logistical support required to conduct mission support. The company headquarters staff can coordinate the operations of up to six Force Provider platoons and modules. The company HQ maintains communications with the next higher headquarters; provides direct supervision to the support operations and maintenance section; tasks the platoon leaders of the Force Provider modules; directs the planning, setup, and continuous improvement of unit defenses; and maintains responsibility for the unit's training, safety and environmental protection programs.

2-3. To ensure appropriate accountability for module equipment, the company commander inventories and inspects the serviceability of all equipment during setup of the module. . The Property Book Unit Supply Enhanced (PBUSE) system, the Army's state-of-the-art web-based property accountability system, is used to report and account for module equipment. Missing, damaged, or unserviceable equipment will be documented and kept on file awaiting Financial Liability Investigation of Property Loss and eventual redeployment of the module to AMC for refurbishment. As equipment becomes damaged or unserviceable during operations, it is be reported and documented, and replacement equipment and or parts are ordered. An up-to-date status of all module equipment will be maintained. AR 735-5 and AR 735-11-2 give guidance for maintaining property accountability. Missing items require a Report of Discrepancy (ROD). Equipment damaged in shipping requires a Supply Discrepancy Report (SDR). If received equipment is intact but is not functioning, a Quality Deficiency Report (QDR) must be submitted. All three of these reports may be done electronically via the following website: https://aeps.ria.army.mil/.

2-4. A critical aspect of the redeployment process is that the commander must clear the hand receipt of all module equipment being returned to AMC. AMC will arrange transportation for the module from the operating site to a CONUS depot or in-theater element for refurbishment. To clear a hand receipt with property shortages, a Financial Liability Investigation of Property Loss will be completed. The commander will be held responsible for equipment which cannot be properly accounted for. To facilitate clearing of a hand receipt, the commander will ensure that all module equipment is inspected for serviceability and thoroughly cleaned before it is packed. Unserviceable items will be tagged with a description of the damage or malfunction before they are packed. All module equipment will be inventoried and returned to the original container using the packing list and instructions in the panel of each container's door. All missing, damaged, or unserviceable equipment will be reported and documented. This documentation will then be used to simplify the reconciliation of the property records and to facilitate the clearing of the hand receipt.

SUPPORT OPERATIONS SECTION

2-5. The Support Operations Section exercises staff supervision over the supply, maintenance, and field service support operations and advises the commander in these functional areas. The section also provides the coordination and management of all contracting and engineering support operations.

2-6. The purchasing/contracting officer manages the purchase of all military or local items required by the Force Provider Company. The purchasing/contracting officer coordinates with the ASCC in the review of options for each dependency and determines whether military resources or contract support is the most appropriate and cost effective alternative. The purchasing/contracting officer will ensure that Force Provider needs are detailed and thoroughly stated in the contract documents. If contract administration is coordinated at a higher level, the purchasing/contracting officer will take appropriate actions to ensure that the needs of unit are met.

2-7. The general engineering officer plans and coordinates the site setup for Force Provider. He also supervises all engineering functions within the modules. The general engineering officer should be a Force Provider expert and will oversee critical elements of setup and operation. He coordinates and/or manages the proper storage and disposal of gray water and black water waste. FM 5-104 and FM 5-116 provide guidance in performing engineering functions.

2-8. The operations NCO monitors and supervises section operations and advises the company HQ on tasks involving Force Provider operations and procedures. The laundry NCO coordinates all laundry, clothing, and shower functions including administrative actions. He reports to and advises the operations NCO. The preventive medicine NCO and specialist coordinate FHP support and conducts water and other environmental tests. These Soldiers advise the operations NCO about the sanitary status of laundry, shower, latrine, water distribution and storage, and food service operations. They also advise company personnel when sanitary or health conditions are unacceptable or inadequate.

COMPANY MAINTENANCE SECTION AND PLATOON MAINTENANCE TEAMS

2-9. The company maintenance section (organic to the company HQ) and the six platoon maintenance teams (organic to the six platoon HQs) provide field level maintenance to 10-20 level technical manual standards IAW AR 710-1 for all organic equipment except COMSEC and communications-electronics equipment. Organic equipment includes wheeled vehicles, forklifts, generators, tents, environmental control units (heaters/air conditioners), refrigerators, laundry and bath units, fuel and water systems, lighting units, and plumbing fixtures. Under the Global Combat Support System - Army (GCSS-A), equipment will be maintained via Standard Army Management Information System (STAMIS) for maintenance operations (the Standard Army Maintenance System - SAMS) and the requisitioning, tracking and replenishment of repair parts. Equipment services will be documented IAW AR 750-1, DA PAM 750-8 and EUM (AISM-25-L21-AHN-ZZZ-EM). Other critical areas of responsibility for the maintenance personnel include: equipment operator qualification and testing; equipment dispatch control; vehicle recovery operations; equipment damage assessments; scheduling, conducting and recording of preventive maintenance checks and services; equipment fault records; Army Oil Analysis Program matters; materiel readiness matters and Army Materiel Status System (AMSS) updates; tool and test equipment control and maintenance; safety, environmental and security matter compliance; and the maintenance of technical publication reference material.

FORCE PROVIDER PLATOON HEADQUARTERS

2-10. The Force Provider Platoon Headquarters provides basic command and control, training, administration, and logistical support for the operations of one Force Provider module under the direction of the company commander. The platoon headquarters will also supervise billeting and tenant unit in- processing and out-processing functions. Descriptions of the platoon's five functional area sections: facilities support, food service, laundry and shower, water distribution, and petroleum distribution are outlined below. Each module is equipped with a System Support Package (See Appendix B) which contains repair parts to sustain operations for approximately 30 days. Once operations have begun, it will be necessary to make arrangements within the theater for maintenance of equipment and for subsequent resupply of operator and unit level repair parts and material.

2-11. The day-to-day operation of Force Provider will depend on METT-TC. The tenant units and Force Provider platoon will communicate daily regarding plans and routines. Force Provider personnel should be made aware of any special activities planned by the tenant units. Likewise, the tenant unit should be made aware of the daily schedule of services and equipment available in the module.

2-12. Soldiers arriving at Force Provider will maintain unit integrity. A representative from the Force Provider platoon headquarters will meet with incoming tenant unit representatives to conduct a briefing concerning camp operations, camp policies, and tenant unit responsibilities. Tenant unit responsibilities are discussed in Section II of this Chapter. An in-processing briefing template is available at Appendix C. Ensure that the in-processing brief covers the following policies:

• Check in

• Smoking

• Alcohol

• Guests

• Gender separation

• Quiet time

• Vehicle parking

• Other policies concerning conduct

• Check out

2-13. Prior to tenant unit occupation of billeting facilities, representatives from both the incoming tenant unit and the Force Provider platoon conduct a walkthrough inspection to determine the condition of the billeting tents and other areas that the tenant will occupy. All discrepancies will be documented and kept on file. The commander of the tenant unit will make billeting assignments. Tenant unit Soldiers will clean and maintain their billeting area and designated areas of the Force Provider camp. Force Provider personnel will ensure that each billeting tent remains stocked with the requisite cleaning supplies and that a copy of the camp rules, service schedule, and no smoking notices are posted inside each facility. At least one Force Provider Soldier should be assigned to assist tenant units in the resolution of billeting-related issues and that any necessary repairs are accomplished as soon as possible.

2-14. Prior to departure, the tenant unit will police the billeting tents and their other designated areas. A representative of the tenant unit and the Force Provider platoon will conduct a walk-through inspection and record all discrepancies. Any discrepancies not already recorded on the in-processing walk-through inspection document will be assessed. The tenant unit commander will be held accountable for damages. Excessive damage caused by negligence or a lack of discipline will be investigated and punitive action taken as required. A representative of the tenant unit will also check out with the MWR and laundry sections. A tenant unit will not be cleared for departure until all MWR equipment checked out by unit personnel has been accounted for and until all unit personnel laundry has been returned. Platoon headquarters should develop inspection documents and check out forms to facilitate unit out-processing.

FACILITIES SUPPORT SECTION

2-15. Facilities Support Section personnel operate and maintain power generation equipment when organic generators are used. When in use, the generators will be clustered in groups of three. Operations within each cluster will be rotated every seven hours on a two-on and one-off schedule. This rotation will allow preventive and corrective maintenance to be performed without interruption of power to subsystems. A simple switching network is designed into each generator cluster to facilitate this rotation. If commercial or prime power is used, organic generators should be arranged to provide backup power support if an outage, overload, attack, or sabotage occurs.

2-16. The facilities maintenance personnel also maintain climate control equipment such as the environmental control units and heaters, refrigeration units, electrical subsystems and equipment, pipes, plumbing fixtures, and other equipment. All preventive maintenance will be performed IAW the appropriate technical manuals. A schedule will be maintained by the section leader for performing all applicable preventive maintenance checks and all equipment services will be documented using the Standard Army Maintenance System.

2-17. Section personnel conduct routine inspections and PMCS of assigned equipment. They work with other sections to assist in keeping subsystems fully operational. All malfunctions or problems are documented using the Standard Army Maintenance System so that a detailed equipment history can be maintained for each item. This will aid future engineering improvements and provide valuable lessons learned which ultimately will reduce repair time. A representative of the section will be on duty at all times to respond to malfunctions or problems which may occur.

2-18. Prime Power Team. When Force Provider is operated using commercial or prime power, a utilities team or an engineer prime power battalion unit will be attached to the Force Provider Company. Facilities Support Section personnel will work closely with the attached element. They will coordinate to maintain uninterrupted electrical service to each module.

FOOD SERVICE SECTION

2-19. The Food Service Section sets up, operates, performs preventive maintenance, and dismantles the food service subsystem. It also provides three cook-prepared meals per day to tenants, attached personnel, and Force Provider personnel. The food service subsystem is comparable to a standard garrison kitchen and uses only electrical appliances.

2-20. During peak occupancy, it may be necessary to rotate dining tent meal times to accommodate all personnel and serve each meal over a minimum of a two-hour period. Meal schedules may be designed to rotate times by section, detachment, or tenant unit depending on occupancy status. Meal schedules should be briefed during in-processing and posted inside each billeting tent. The food service subsystem is cleaned by the food service section and any assigned tenant unit personnel on kitchen patrol (KP). Soldiers using the dining facility will be required to police their area upon completion of their meal, dispose of uneaten food or refuse in designated containers, and return utensils to the designated area. After completion of the evening meal and a thorough cleaning, the food service dining tent may be used as a convenient location for MWR personnel to show movies or to conduct other large group activities.

2-21. Food service personnel will maintain sanitary conditions at all times. The food service section leader and designated leaders will perform routine inspections to ensure all food service personnel and KP personnel are maintaining proper sanitary conditions. The preventive medicine NCO will also conduct periodic inspections and tests to ensure that all food is prepared under sanitary conditions.

2-22. The gray water collection system for the food service subsystem contains an in-line grease trap. Grease collected in the trap is contaminated with gray water and is considered hazardous waste. Food service personnel will routinely monitor the grease trap. Grease must be periodically removed and disposed of as hazardous waste by food service personnel. Care should be taken when cleaning the grease trap to prevent personal injury or damage to the environment. Appropriate personal protective equipment will be used. Spills or leaks will be contained and cleaned up. Grease awaiting proper disposal will be stored in approved containers and labeled as hazardous waste.

LAUNDRY AND SHOWER SECTION

2-23. The laundry and shower section is responsible for the setup, operation, preventive maintenance, and dismantlement of the laundry, shower and latrine subsystems. The section provides services which allow each supported Soldier one shower per day, one washing of 15 pounds of laundry per three-day period, and unlimited use of the containerized latrine.

2-24. Force Provider uses one containerized batch laundry (CBL) that uses two high-capacity commercial washer/extractors and two commercial dryers. The entire CBL subsystem may be operated by one laundry and shower specialist. Additional personnel are made available during designated hours to receive, process, and reissue laundry.

2-25. The laundry and shower section has the capability to clean 15 pounds of laundry for each Soldier per three-day period at maximum occupancy with a 24-hour turnaround time. All clothing items, sleeping bags, and sleeping linen are included in a Soldier's 15 pound laundry pack. Additional laundry production time must be allotted for shower towels and food service linens. Operators periodically monitor the fuel supply level for the water heater. They notify the petroleum distribution section when the fuel level reaches 1/3 or less capacity. During less than maximum utilization, laundry and shower section personnel may provide additional laundry services if required.

2-26. One containerized batch laundry subsystem is used in each Force Provider module. Routine preventive maintenance and services are critical and their thorough performance will prevent complex maintenance problems down the road. In order to enable the smooth operation of the CBL, a schedule for turn in, processing, and return of laundry is developed, briefed during in-processing, and posted inside each billeting tent.

2-27. The containerized batch laundry produces gray water which is considered hazardous waste. Personnel must wear appropriate personal protective equipment when working with items contaminated with gray water. Spills or leaks will be contained and cleaned up, and gray water awaiting proper disposal will be stored in approved containers and labeled as hazardous waste.

2-28. Each Soldier is authorized one shower per day. Designated laundry and shower section personnel will attend to each shower system. These personnel ensure that towels and soap are available and that the facilities are safe, sanitary, and in good working order. Section personnel will clean and sanitize each shower facility daily and as required otherwise, preferably without interfering with scheduled operations. Shower schedules will allow for gender separation, maximum operational use, and preventive maintenance and cleaning time. Gender separation is accomplished by scheduling an amount of time for each gender in proportion to that gender's population percentage within the camp. Times for each gender are set throughout each 24-hour period. The schedule is briefed during in-processing and is posted in all billeting tents.

2-29. The shower subsystem produces gray water which is considered hazardous waste. Personnel must wear appropriate personal protective equipment when working with items contaminated with gray water. Spills or leaks will be contained and cleaned up, and gray water awaiting proper disposal will be stored in approved containers and labeled as hazardous waste.

2-30. Laundry and shower section personnel clean and maintain the latrines and maintain the associated supplies of toilet paper and soap. The level of waste in the black water holding tank is routinely monitored. The laundry and shower section leader is notified to evacuate the tank once the tank is no more than % full. The general engineering officer assigned to the company's support operations section is responsible for coordinating and supervising the disposal of black water. Included in the Force Provider module is a waste water evacuation tank/trailer (WWET/T) to remove black water from the latrine's internal holding tank.

2-31. The containerized latrine produces black water which is considered hazardous waste. Personnel must wear appropriate personal protective equipment when working with items contaminated with black water. Spills or leaks will be contained and cleaned up, and black water awaiting proper disposal will be stored in approved containers and labeled as hazardous waste.

2-32. Each latrine unit will be inspected daily by a Preventive Medicine NCO to ensure that it is safe, sanitary, and free of insects. If sanitary services are contracted, the Preventive Medicine NCO will be involved in the process to ensure that a desired standard of cleanliness is maintained.

2-33. Latrines should not normally be used by both genders at the same time. They should be designated for exclusive use in percent increments which most closely represent camp population. However, if the situation demands, a Male/Female "flip sign" may be used on the latrines. Gender designation of latrines will be included in the in-processing brief and signs showing gender designation will be clearly posted on the outside of each latrine. If host nation personnel will be using the latrines, signs should be posted in the host nation language.

2-34. Feminine hygiene products may not be disposed of in latrines toilets. Signs prohibiting this practice will be posted in latrines designated for female use. Appropriate waste receptacles will provided for disposal of these items. The final disposal of these items must be made as appropriate for the area of operation(s) (AO).

WATER DISTRIBUTION SECTION

2-35. Force Provider uses fabric storage tanks coupled with an expansion tank which maintains positive pressure and automatically operates an electric pump in response to water demand. Hypo-chlorination is accomplished during the filling of the tank and through recirculation of water through an intake/out-take loop which can be opened or closed to re-circulate water through the storage tank. Potable water distribution and storage for Force Provider is performed using current water doctrine publications.

2-36. The water source for Force Provider can be from a QM Water Purification and Distribution Company, an approved host nation commercial water system, by contractor delivery from an approved water source, or from on-site wells constructed by an engineering detachment. All potable water to be used as a source for the Force Provider water distribution and storage system must be tested and certified by the Preventive Medicine NCO from the company support operations section.

2-37. Two water distribution section personnel will be available for duty at all times while the potable water storage and distribution sites are in operation. The primary responsibilities of these personnel are to: maintain proper chlorination levels within each water storage and distribution system; monitor water usage; receive water deliveries; conduct water quality analysis testing; perform preventive maintenance on the equipment; and complete applicable reports, logs and forms. Section personnel will also operate water supply points to dispense water into water tank trailers or other approved containers.

2-38. Security of the water storage and distribution sites will be maintained to prevent water source tampering or sabotage. These sites will be routinely checked by security patrol personnel.

PETROLEUM DISTRIBUTION SECTION

2-39. Petroleum storage and distribution operations will be conducted using guidance from current doctrine. Force Provider bulk fuel resupply support is provided through military channels or via certified host nation sources. All host nation source fuel to be consumed by the Force Provider system must be tested and certified as meeting established standards by qualified petroleum distribution section personnel.

2-40. Two petroleum distribution section personnel will be available for duty at all times while the bulk fuel storage and distribution sites are in operation. The primary responsibilities of these personnel are to: monitor bulk fuel usage; receive bulk fuel deliveries from certified sources; conduct petroleum product analysis and testing; issue bulk fuel to vehicles, other equipment and into approved storage containers; perform preventive maintenance on equipment; and complete fuel reports, logs, and forms.

2-41. Petroleum distribution section personnel will ensure that the bulk fuel distribution and storage system and all vehicles and containers are properly grounded during fuel issue or delivery. All bulk fuel distribution and storage sites will be designated as no smoking areas and appropriate signs will be clearly posted in English and the host nation language. Firefighting equipment will be conveniently available to the site and a fire extinguisher will always be placed within easy access during issue and delivery operations. Petroleum products are also considered hazardous waste and a hazard to the environment and to personnel. All leaks will be contained and cleaned up immediately. Personnel will use appropriate personal protective equipment and avoid direct contact with petroleum products.

2-42. Security of the petroleum storage and distribution sites will be maintained to prevent tampering or sabotage. These sites will be routinely checked by security patrol personnel.

2-43. Electric power generators, when in use, will consume the largest amount of Force Provider operational bulk fuel. Each generator cluster will employ a 500-gallon collapsible fabric fuel drum to supplement the generator internal fuel tanks. During normal operations, these fuel drums will require replenishment approximately every three days. Refueling of these drums is usually accomplished by tanker delivery via the camp's perimeter roadway. Petroleum distribution personnel are also responsible for the setup, operation, preventive maintenance, and dismantlement of these fuel drums. Section personnel will perform routine inspections of these drums to ensure proper operation and environmental protection.

ADMINISTRATIVE, CHAPLAIN, MEDICAL, AND MWR FACILITIES

2-44. Administrative, chaplain, medical, and MWR services will be provided by attached personnel from the ASCC, tenant unit personnel, or detachments from other units using the Force Provider system. Specific administrative and MWR equipment is provided within each module. To provide effective overall service to tenant units, the following should be considered when setting up these facilities:

• Make every effort to provide private spaces within the administrative tents for the discussion of personnel/legal/finance matters, religious counseling and medical treatment.

• Consider the mission, local weather trends, and the needs of tenant units when planning the setup of MWR fields and the types and quantities of MWR equipment to make available.

• Set up a secure area for the storage of AAFES items. A TRICON should be made available for the storage of AAFES goods, and security patrols of these areas will be necessary. If AAFES provides telephone and/or automated teller machine (ATM) equipment, they should be located in a visible