Support

Operations

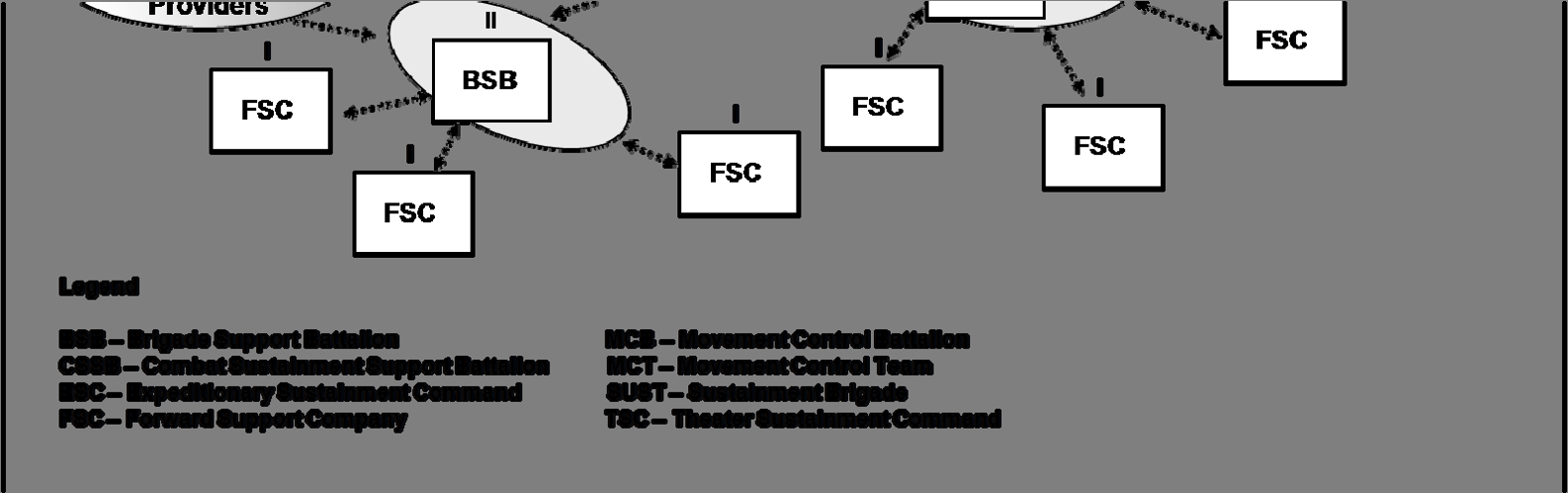

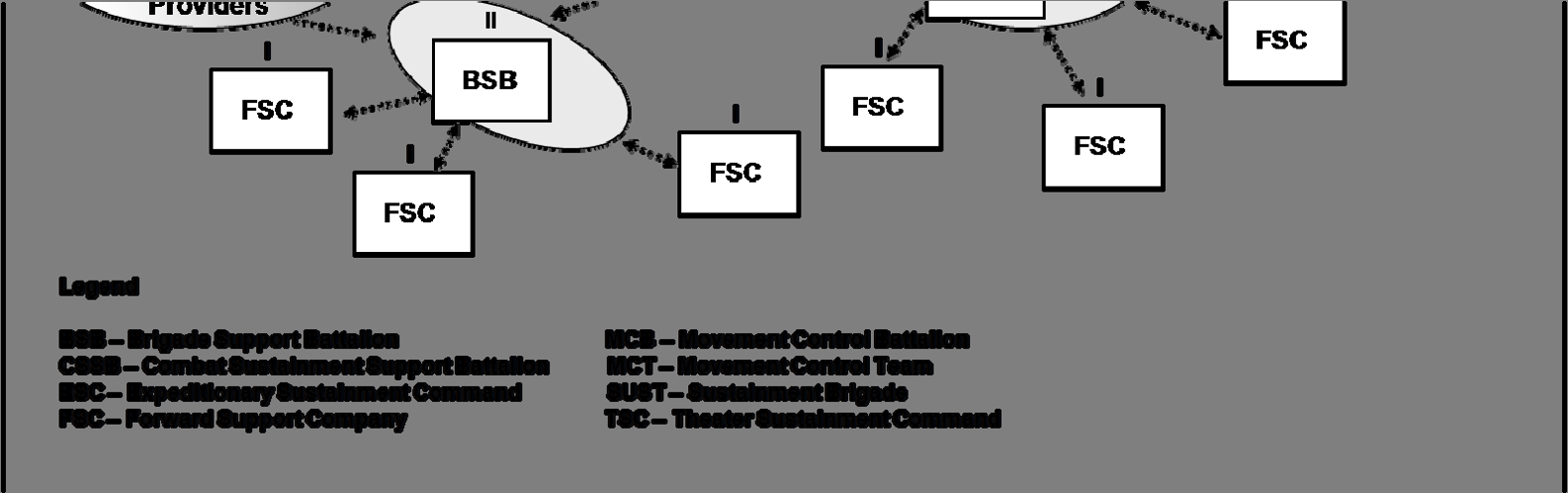

4-68. TSC distribution managers interface with USTRANSCOM, DLA, JDDOC and JTF-PO to ensure the efficient and coordinated flow of units, supplies, equipment, and materiel from theater points of entry to final destinations in a theater of operations or AO/JOA. In addition to providing for a seamless interface between the strategic and operational levels, this coordination optimizes the utilization of common-user land transportation (CULT) assets and other modes of transportation to maximize distribution, force deployment, and sustainment.

4-69. As a result of this joint interface and an integrated intratheater ITV network, combatant commanders at all echelons have the capability to see units and sustainment in motion, permitting them to effectively make decisions and implement action. These same capabilities give logisticians a COP that enables control throughout the distribution system.

Figure 4-4. Simplified View of a Notional Intratheater Distribution System

CONVOY PLANNING

4-70. The TSC and its subordinate commands conduct detailed mission planning assessments in preparation for long haul and local convoy movements. As demonstrated by recent combat operations in Iraq, logistics units face a number of asymmetrical threats as they conduct convoy operations on a noncontiguous battlefield. In today’s operational environments there is no such thing as an administrative move.

4-71. Convoys may be exposed to a variety of threats that range from vehicle-borne improvised explosive devices to complex ambushes employing improvised explosive devices (IED), rocket-propelled grenades, and small arms to artillery barrages and enemy aircraft. Detailed mission analysis mitigates risk and increases the probability of mission success. FM 4-01.45, Tactical Convoy Operations, provides detailed information on tactical convoy operations.

4-72. In general, the TSC, in coordination with the supporting maneuver enhancement brigade (MEB), joint security coordination center (JSCC), or other Army forces, selects convoy routes by identifying, evaluating, and comparing those factors which tend to facilitate convoy movement and control—movement restrictions, route classification, traffic flow, choke points, and rest halts. Implicit in this task, is the requirement to develop a thorough understanding of the current enemy situation along the route to include the identification of danger 12 February 2010

FM 4-94

4-13

Chapter 4

areas and potential ambush sites. Depending on the level of threat, the supporting MEB or local terrain manager may provide a convoy escort or it may establish a movement corridor that provides for coordinated responses to Level I and Level II threats.

4-73. For the TSC, convoy operations are routinely conducted on a changing basis to provide an increased measure of operational security. This is especially true in known danger areas where sniper and IED incidents may occur. Other convoy protection measures include planning for and coordinating aircraft or UAS route reconnaissance, close air support by fixed- and rotary-wing aircraft, fire support, and electronic countermeasures to help defeat IED threats.

4-74. Unarmed contractors and third country nationals (TCN) may be part of a convoy. When this occurs, additional protection measures may include assigning additional security force personnel and/or dispersing civilian vehicles throughout the convoy (due to limited communications capabilities) to enhance C2. The use of contractors and TCNs may generate additional requirements for rehearsals and interpreters prior to convoy movement.

SECTION IV: PROVIDE MATERIEL MANAGEMENT

4-75. The TSC provides the ASCC with a centralized materiel management capability that provides increased efficiencies and effectiveness by reducing redundant materiel management layers, centralizing materiel management functions, and employing a theater-wide view of resources. The result of which is responsive support to Army requirements and reduced CWT.

4-76. The TSC performs materiel management for all classes of supplies (less medical—CL VIII materiel management is provided by the MDSC) and maintenance management for those activities for which the TSC

has control and responsibility. TSC personnel perform the day-to-day planning for operations; providing the theater interface between strategic and operational-level support. TSC materiel management responsibilities include managing, cataloging, requirements determination, requirements validation and prioritization for procurement, distribution, redistribution of excess, and retrograde of materiel. The TSC performs these functions within the parameters of policies, plans, priorities, and allocations developed in coordination with the ASCC G-4.

Note. Inherent in TSC maintenance management responsibilities is the requirement to integrate sustainment maintenance activities in support of the ASCC to include coordinating with USAMC or other elements that may control or have over sight of these entities.

4-77. In accordance with ASCC support priorities, the TSC provides direction for receiving, storing, and issuing theater stocks. When the required stocks are not available or stock replenishment is required, the TSC

passes requirements to the appropriate CONUS national inventory control point (NICP). For requirements being considered for local procurement, the TSC validates the requirement prior to forwarding it to the local procuring activity.

4-78. Requisitions flow from the requesting unit directly to systems controlled by TSC materiel managers in accordance with standard operating procedures. The corps/theater automatic data processing service center (CTASC) then directs a sustainment brigade to fill the requirement based upon that brigade’s ability to support the requirement or passes the requirement to the appropriate NICP. This streamlined process permits the TSC to reach across TSC theater-wide resources and capabilities to satisfy Army requirements. Enabled by asset visibility, this approach not only reduces but also minimizes the level of stocks required to be stored throughout the theater.

4-79. This centralized materiel management is not exclusive. ESCs, if deployed, as well as sustainment brigades have unique roles in materiel management (see Figure 4-5). Typically, ESC materiel management capabilities are focused on maintaining situational awareness of order status that enables effective distribution management within a region, theater of operations, or AO/JOA. In a similar manner, sustainment brigade materiel management capabilities are focused on the management of subordinate supply support activities (SSAs) that support the brigade’s area support mission.

4-14

FM 4-94

12 February 2010

Support

Operations

THEATER SUSTAINMENT COMMAND:

•

Theater Focused.

•

Manages all classes of supply except Class VII & Class X.

•

Controls corps/theater automatic data processing center parameters.

•

Coordinates with National providers.

•

Issues materiel directives to sustainment brigades.

•

Conducts manager review file management.

•

Generates over-age repairable item list report.

•

Assists Brigade Support Battalion in establishing authorized stockage list storage requirements.

EXPEDITIONARY SUSTAINMENT COMMAND:

•

Area of operations/joint operations area focused.

•

As directed by the TSC, performs materiel management of specified classes of supply.

•

Assists in expediting critical supplies.

SUSTAINMENT BRIGADE:

•

Area support focused.

•

Monitors, advises, and coordinates distribution of supplies in support of units in the area of operations.

•

Manages Combat Sustainment Support Battalion inventory.

•

Executes materiel directives from Theater Sustainment command.

•

Manages bulk commodities and Class V.

Figure 4-5. TSC, ESC, and Sustainment Brigade Materiel Management Functions

4-80. TSC materiel managers develop plans, policies, programs, and procedures involving supply activities; maintain liaison with supported and supporting units; and recommend allocation of resources and materiel management functions to support mission requirements. TSC materiel managers:

• Execute theater management of Class I, II, III, IV, V, VI, VII, and IX.

• Recommend cross leveling of general and aviation repair parts.

• Establish and manage CTASC parameters.

• Assist in expediting critical commodities.

• Provide customer service regarding problems with managed commodities.

• Coordinate with the distribution integration and mobility branches for status on the distribution of commodities they manage.

• Direct the receipt, storage, and issue of theater stocks in accordance with the ASCC support priorities.

• Pass requirements to the appropriate national inventory control point.

• Validate the local procurement requirements prior to submission to the local procuring activity.

• Identify items requiring retrograde; issue directives for depot level repairables.

• Track the flow of items in the retrograde system.

4-81. The standard Army retail supply system (SARSS) is the primary STAMIS used for materiel management purposes; supporting materiel management functions for supply classes II, IIIP, IV, VII, and IX. Table 4-1

below lists the theater-level SARSS functions TSC materiel managers routinely perform.

12 February 2010

FM 4-94

4-15

Chapter 4

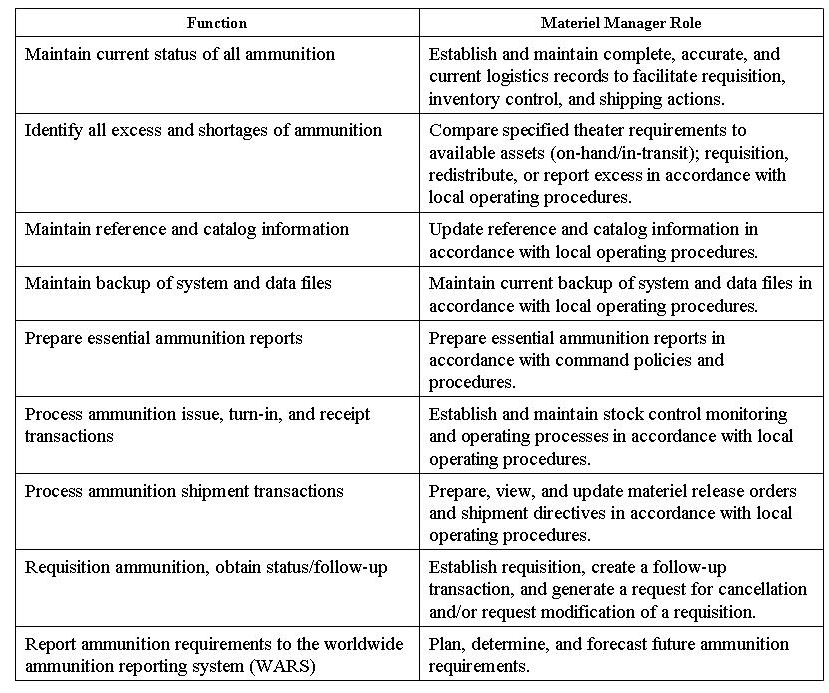

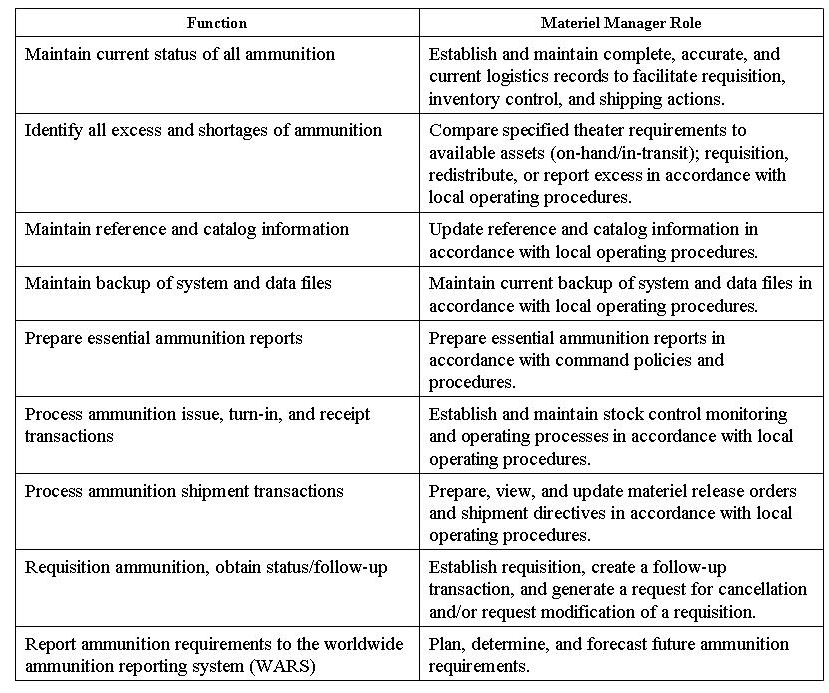

Table 4-1. TSC Materiel Management Functions—SARSS

Function

Materiel Manager Role

Maintain current status of high priority/high dollar

Track requisitions; provide status report. Liaison with

requisitions.

national level providers for theater requirements.

Perform miscellaneous management tasks as required.

Perform end of year closeout tasks; serial number tracking;

relation table updates; supply discrepancy reports; monthly

readiness reports; etc., in accordance with local procedures.

Manage authorized stockage list files.

Conduct demand retention analysis; manager stockage level

updates; account balance file clean up; etc., in accordance

with local procedures.

Maintain maintenance workload file.

Monitor operations, report status, conduct trend analysis,

and recommend workload alternatives as required.

Maintain catalog information.

Update catalog information in accordance with local

procedures.

Manage critical items list.

Consolidate theater critical items lists; provide status;

liaison with national level providers.

Provide customer service assistance.

Analyze problems. Provide recommended solutions.

Maintain document history files. Research/review

transactions.

Maintain local purchase manager review and suspense files.

Review transactions and validate financial requirements in

accordance with local policies.

Maintain manager review file.

Review transactions, validate financial requirements.

Maintain over-aged repairable item list.

Produce, purge, monitor, and report status in accordance

with local policies.

Establish parameter settings and maintain Department of

Establish parameter settings and update/purge Department

Defense activity address codes of supported Army forces.

of Defense activity address codes in accordance with local

policies.

Prepare performance reports.

Produce reports in accordance with local policies, provide

analysis, and recommend corrective measures.

Manage retrograde and referral actions.

Produce reports, enforce retrograde priorities, direct referral

actions, and monitor compliance/flow.

Update SARSS access.

Perform password maintenance in accordance with local

procedures.

Perform supervisory tasks.

Perform quality control checks of subordinate unit materiel

manager activities.

4-82. TSC materiel managers use the standard Army ammunition system—materiel management center (SAAS-MMC) (a component of standard Army ammunition system—modernization [SAAS-MOD]) to provide Class V conventional ammunition management and visibility throughout the theater. SAAS-MOD effectively automates and integrates ammunition management functions among storage sites and theater managers; providing TSC materiel managers with the capability to produce accurate, timely, and near real-time Class V

information concerning facility resources, reference data, ammunition requirements, authorizations, and assets within the theater, theater of operations, or JOA.

4-83. TSC Class V materiel manager functions relate to the overall management of authorizations, requirements, and redistribution of ammunition assets within the theater. Table 4-2 lists the critical theater-level functions TSC Class V materiel managers perform.

4-16

FM 4-94

12 February 2010

Support

Operations

Table 4-2. Critical TSC Materiel Management Functions—SAAS-MMC

4-84. Commodities not supported by a STAMIS are Class I and Class III (B). TSC materiel managers use unit strength figures as the basis for determining Class I requirements. Class III (B) requirements are based on customer generated logistics reports and forecasted using historical consumption data and projected planned operations.

SECTION V: PROVIDE MOVEMENT CONTROL

4-85. The TSC C2s operational-level movement control and multimodal operations in the theater. It is responsible for developing plans, policies, and programs that support the efficient use of Army transportation assets and the efficient flow of supplies, personnel, equipment, and units throughout the intratheater distribution system. The TSC accomplishes this, in part, through effective coordination with the JDDOC to maintain situational awareness of the global distribution system and joint requirements for CULT assets.

4-86. The TSC manages intratheater movements through its subordinate MCB(s); implementing priorities established by the ASCC in support of the GCC concept of operations. Critical TSC tasks include:

• Balancing existing transportation capabilities of the distribution system with the day-to-day and projected operational requirements.

• Preparing estimates, plans, policies, and procedures for movement control, mode operations, and terminal operations.

12 February 2010

FM 4-94

4-17

Chapter 4

• Managing transportation flow capacity by maintaining visibility of resources that are being transshipped at transshipping nodes.

• Coordinating the movement of major units.

• Developing policies and procedures to control, regulate, and expedite the movement of intermodal assets (i.e. leased containers, flatracks, and 463L pallets) within the theater.

• Maintaining liaison with JDDOC, JTF-PO, and HN transportation agencies, mode operators, and supported units.

• Protecting movement control assets.

4-87. In order to more efficiently control movements within the theater, the TSC may decide to divide the theater into transportation movement regions. This approach permits centralized control by the TSC and decentralized execution of movement control functions by subordinate MCBs.

4-88. In addition to facilitating the synchronized flow of units, supplies, equipment, and materiel along main and alternate supply routes, the MCB, through its subordinate movement control teams, performs movement control functions at APODs, SPODs, distribution hubs, and other critical nodes to expedite port clearance and provide for the uninterrupted flow of resources and capabilities in support of Army requirements.

4-89. Operating in accordance with TSC plans and policies, the MCB is responsible for managing the use of trailers, containers, air pallets, and flatracks located throughout the intratheater distribution system. Included in this responsibility is the requirement to coordinate with users to expedite return of these assets to the distribution system. Lessons learned during Operation Desert Storm/Desert Shield (ODS) and Operation Iraqi Freedom (OIF) demonstrate that inter-modal operations are critically affected by the manner in which container management policies are enforced and container management is subsequently executed. Therefore, it is vital to TSC distribution operations that visibility and control of containers be maintained. Adherence to TSC policies will ensure adequate numbers of containers are available to support intratheater distribution system requirements.

SECTION VI: PROVIDE SUSTAINMENT

SUPPLY

4-90. Sustainment requirements are influenced by factors such as deployment timelines, troop density, infrastructure, geography, and theater policies. The TSC staff considers these factors as well as others when developing a concept of support to meet ASCC requirements. Inherent in this is an understanding of the supported commander’s priorities and status of available resources.

4-91. Typically, during the early stages of an operation, the TSC will push certain classes of supplies (I, IIIB, and V) to subordinate sustainment brigades and supported units based upon an analysis of the applicable supported plan, supported commander’s priorities, and planning factors. The TSC may rely upon Army prepositioned stocks (APS) to meet initial surge requirements for sustainment. As distribution capabilities expand, a pull system, based upon anticipated/actual requirements, is implemented to achieve greater effectiveness and efficiencies.

4-92. The TSC provides all classes of supply (less Class VIII) and related services necessary to sustain Army forces throughout a major operation - in the quantities and at the time and place needed. This capability includes requesting, receiving, producing, procuring, storing, protecting, relocating, and issuing the necessary supplies and services. It also includes building the necessary stockage levels in staging areas for conducting an operation and collecting, providing, and processing ITV data.

4-93. Based on parameter settings established by the TSC, the CTASC determines if the requested item is available from within the theater and directs a materiel release order to the sustainment brigade capable of satisfying the requirement. If the item is not available, the CTASC passes the requisition to the appropriate NICP for fill. In most instances, the actions described above are performed by the CTASC automatically in accordance with TSC-controlled parameter settings that include referral tables. This application of centralized 4-18

FM 4-94

12 February 2010

Support

Operations

control and decentralized execution enables responsive and agile support throughout the theater, effectively minimizing CWT.

4-94. In most instances, the TSC will maximize the use of military capabilities and resources to sustain combat operations in high intensity environments. However, in lower threat environments, the TSC will typically maximize the use of contractors, TCNs, and HNS to sustain Army forces.

SERVICES

4-95. The TSC is responsible for planning, resourcing, monitoring, and analyzing field services support to deployed Army forces. TSC field services operations include field laundry, showers, light textile repair, force provider, mortuary affairs, aerial delivery support, and coordination with DLA for hazardous waste removal.

4-96. Services, such as shower and laundry support, are provided on an area basis throughout the theater and may be called forward to support brigade combat team sustainment operations.

4-97. Force provider assets may be employed at major nodes within the theater to provide life support services to units flowing into or out of the theater. Force provider amenities include a dining facility, showers, laundry, and a place to sleep, rest, and relax.

4-98. The TSC, usually in coordination with the joint mortuary affairs office, determines the requirement for and placement of theater MA assets. Requirement and placement considerations include casualty estimates from the ASCC G-3, force structure, and the MA concept of support. MA matrices and overlays, which are part of the COP, and RFID-ITV technology, enable units to expedite remains evacuation. Regardless of the MA subprogram in effect, units evacuate remains through a series of collection points, located throughout the theater, to the theater mortuary evacuation point. In some cases the theater mortuary affairs evacuation point may be bypassed and the remains are then transported directly to the CONUS military mortuary. Commanders and authorized personnel at brigade level and above are able to access the Defense Casualty Information Processing System to track evacuation status.

4-99. TSC planning must ensure sufficient capacity to retrograde personal effects, not only for killed in action, but also wounded in action, separations, incarcerations, and other unanticipated theater departures.

4-100. TSC planners integrate the use of aerial delivery capabilities with other multimodal methods of distribution to expedite the flow of personnel, supplies and materiel throughout the theater, theater of operations, AO, or JOA. Aerial delivery operations may include fixed-wing, rotary-wing, air-land, airdrop, and sling-load. This range of aerial delivery capabilities provides TSC planners with the means to not only coordinate aerial delivery from strategic distances directly to forward locations but also to provide rapid and responsive intratheater support.

MAINTENANCE

4-101. The TSC is the fleet maintenance manager for Army forces deployed in a theater, theater of operations, AO, or JOA. It is in this capacity that the TSC collects, analyzes, and monitors readiness data of subordinate and supported units. This enables the TSC to effectively manage maintenance support to units and systems in accordance with ASCC priorities. Systemic issues, beyond TSC capabilities, are passed to the appropriate national level maintenance manager via the Army field support brigade (AFSB) (OCONUS) for resolution.

4-102. As the fleet maintenance manager for deployed Army forces, the TSC develops plans, policies, programs, and procedures involving the maintenance of ground missile and aviation equipment in accordance with requirements established by the ASCC. The intent of which is to maximize combat readiness through the effective application of field and sustainment maintenance capabilities.

4-103. To this end, TSC maintenance managers work closely with the AFSB (OCONUS) to ensure effective sustainment maintenance support to Army forces; analyzing readiness data for both systemic problems and those associated with the unique aspects of the specific operational environment, such as, environmental conditions and usage levels. This coordination and collaboration also provides the basis for the effective employment of USAMC sustainment maintenance capabilities throughout the theater, theater of operations, AO, or JOA.

12 February 2010

FM 4-94

4-19

Chapter 4

4-104. TSC field maintenance activities involve the collection and analysis of maintenance data and reports; enabling the TSC to enforce ASCC priorities relating to the repair of specific types of equipment or support of specific units. These same activities provide the means to identify significant trends and deviations from established standards; enabling TSC maintenance managers to take action to ensure the maximum number of combat systems remain fully mission capable. TSC actions may include disseminating technical information and the allocation or reallocation of resources and capabilities to support maintenance requirements.

OPERATIONAL CONTRACT SUPPORT

4-105. Operational contract support plays an ever increasing role in operations and is an integral part of the overall process of obtaining support across the spectrum of conflict. Today, and for the foreseeable future, contract support will often be used to augment other support capabilities by providing an additional source for required supplies and services. These supplies and services include all classes of supply (Class VIII, subject to approval by medical personnel, and Class IX may be limited); labor; mortuary services (within specific parameters); laundry; showers; dining facility services; sanitation; transportation; and port operations (if not under the control of SDDC or Air Mobility Command [AMC]). Other contracted services may include billeting, maintenance and repair, printing and copier support, equipment leasing, and access to communication networks, temporary real property leasing, and limited minor construction. Currently, there are three broad types of contracted support: theater support, external support, and system support.

• Theater Support. Theater support contracts support deployed operational forces under prearranged contracts, or contracts awarded from the mission area, by contracting officers under the C2 of the contracting support brigade (CSB). Theater-support contracts are utilized to acquire goods, services, and minor construction support, usually from local commercial sources, to meet the immediate needs of operational commanders. Theater support contracts are the type of contract support that is typically associated with contingency contracting.

• External Support. External support contracts provide a variety of support to deployed forces. External support contracts may be prearranged contracts or contracts awarded during the contingency itself to support the mission and may include a mix of U.S. citizens, TCNs and local national subcontractor employees. The largest and most commonly used external support contract is the logistics civilian augmentation program (LOGCAP). This Army program is commonly used to provide life support, transportation support and other support functions to deployed Army forces and other elements of the joint force.

• System Support. System support contracts are pre-arranged contracts by the USAMC life cycle management commands (LCMC) and separate Assistant Secretary of the Army (Acquisition, life cycle Logistics, and Technology) program executive and product/project management offices. Supported systems include, but are not limited to, newly fielded weapon systems, C2 infrastructure, such as the Army Battle Command System (ABCS) and STAMIS, and communications equipment. System

contractors, made up mostly of U.S. citizens, provide support in garrison and may deploy with the force to both training and re