,

.1)

с W + V

a

Where A is a coefficient: for high quality materials A=0.8, medium quality

– 0.75 and low quality – 0.65; V is volume of entrained air; C, W –

a

contents of cement and water, kg/m3; R –strength of cement, MPa.

c

146

Numerous experimental data shows, that there are a lot of factors besides

cement-water ratio (C/W), cement strength and aggregate quality such as

placeability of fresh concrete, hardening conditions, presence and quantity of

admixtures etc. which make influence on fine grained concrete strength.

Quality of the aggregate for fine grained concrete make much more influence

on its basic properties than those for conventional heavy concrete. According to

Y.Bagenov data replacement coarse sand for fine sand in concrete can reduce

strength for 25...30%, and sometimes in 2...3 times.

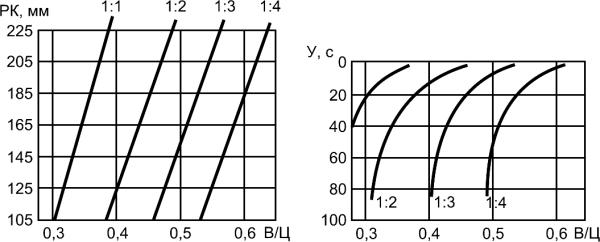

Concrete placeability parameter defines sand - cement ratio at given watercement ratio (Fig. 8.1).

147

FD, mm

P, seс

W/C

W/C

Fig. 8.1 Curves for selection of cement and medium coarseness sand

ratio, that provides given value of flow diameter (FD) and placeability (P)

of cement-sand mixtures (according to Y.M.Bagenov)

148

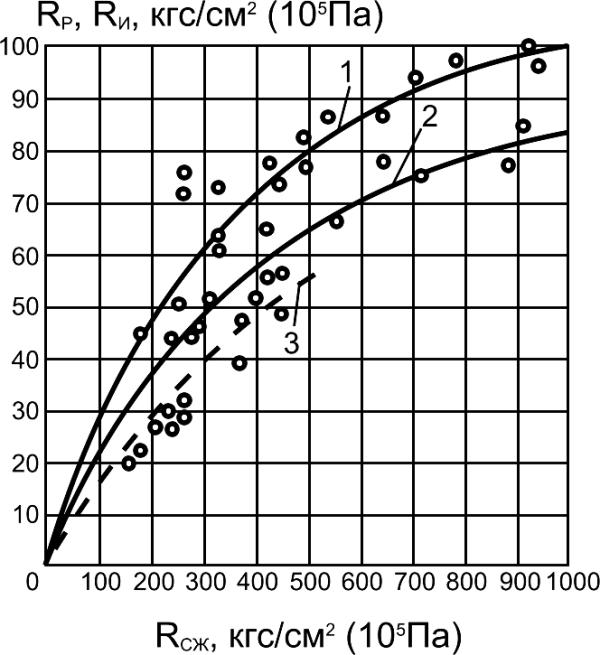

Raised tensile (flexural) strength and compressive strength ratio is distinctive

feature for fine grained concrete (Fig. 8.2).

Rt, Rf, МПа

10

9

Structure peculiarities make

8

influence on deformation

properties of fine grained concrete.

7

They have modulus of elasticity at

6

20...30% lower and higher

5

shrinkage and creep than ordinary

4

concrete. Deformability and creep

3

can be reduced considerably due

2

to the harshness of concrete mix,

application of force compacting

1

method.

10 20 30 40 50 60 70 80 90 100

Rcmp, МПа

Fig.8.2. Dependence of concrete flexural

strength (Rf) and tensile strength (Rt) on

compressive strength (Rcmp):

1 - Rf of sand concrete, 2 - Rf of ordinary

concrete, 3 – Rt of sand concrete

149

8.2. High-strength concrete

Until present there is no direct definition for the types of concrete, which

can be considered as high-strength ones. Conditional border between

conventional and high-strength concrete varies as concrete technology

develops. In the fifties of last century concrete grades 25-40 MPa

considered to be high-strength, in the sixties – 50-60 MPa. Now normally

high-strength concrete is ranged as concrete with compressive strength at

the age of 28 days 70-150 MPa. European standard EN206 envisage

possibility of concrete production and application including 115MPa

concrete grade. Mostly due to effective modifiers (superplasticizers and

silica fume) industrial technology of concrete production at given strength

range have been developed and appropriate standards were worked out.

Such concrete is used widely for load-carrying structures, monolithic

framework of high-rise constructions (Table 8.1), bridges, platforms,

vibrohydropressed tubes. There has been obtained concrete with

compressive strength up to 200 MPa.

150

Table 8.1

Examples of high-strength concrete application

at the high-rise buildings construction

Year

Number of

Concrete strength,

City

of construction

floors

MPa

Montreal 1984

26 119.6

Toronto 1986

68 93.6

New York

1987

72 57

Toronto 1987

69 70

Paris 1988

36 70

Chicago 1989

82 78

Guangow, China

1989

63 70

Chicago 1990

65 84

Frankfurt 1990

58 45

Seattle 1990

58 133

Frankfurt 1991

51 112

151

High-performance concrete is a type of high-strength concrete which has

compressive strength at the age of 2 days 30-50 MPa, at the age of 28 days –

60-150 MPa, frost resistance – more than 600 cycles of freezing and thawing,

water absorption – less than 1-2%, abrasiveness – no more than 0.3-0.4

g/cm2, adjustable deformability parameters.

Obtaining high strength of heavy concrete at high-strength aggregates is

possible due to increasing in concrete density and strength of cement stone

(cohesive factor) and contact zone (adhesive factor). The main direction of

high-strength concrete obtaining is providing extremely low water-cement ratio

(W/C) at comparatively high hydration degree of cement and necessary

compacting of concrete mix. At low W/C ratio obtaining of optimal ratio between

crushed stone and mortar content makes positive influence on concrete

strength.

Cardinal way of W/C ratio reduction without significant workability degradation

of concrete mix are superplasticizers (SP) adding. Unlike ordinary plasticizers

reducing water consumption up to 10-5%, superplasticizers permit to reduce

water consumption at 20-30% and more and to increase concrete strength.

Concrete with high early age strength can be obtained by regulation of SP

and W/C ratio. It can be increased in 2-3 times at adequately high dosage of

the admixture.

152

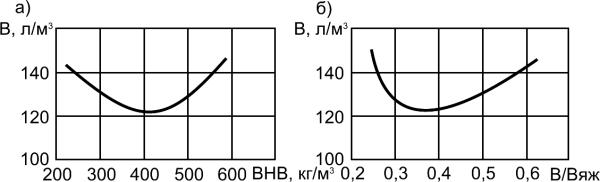

Concrete strength changes almost linearly with cement strength increasing.

Binders of low water requirement (BLWR) obtained by fine milling of

portland cement clinker and mineral admixture with adding powdered

superplasticizer belongs to the effective binders for high-strength

concrete. BLWR have high specific surface (4000-5000 cm2/g), low water

requirement (16-20%) and strength up to 100 MPa. Water amount of

concrete mixes on the basis of binders of low water requirement (BLWR)

is lower at 35-50% than at the ordinary Portland cement (Fig.8.3).

A

B

W, l/m3

W, l/m3

BLWR,

W/C

kg/m3

Fig.8.3 Relationship between water amount of concrete mixes

(slump 1-4 cm) and BLWR content (A), water-cement ratio W/C (B)

153

In the fifties of the last century in Norway it has been suggested to improve

concrete properties by adding ultra fine byproducts of metallurgy industry –

silica fume (SF) and it have been started wide production of concrete with SF

since the middle seventies. It was found out that the most effective

microsilica admixtures are byproducts of crystalline silica and ferrosilicium.

They basically consist of amorphous silica (85-95% SiO ) in the form of

2

particles with diameter 0.1 mkm and have specific surface 1500-2000 m2/kg.

Silica fume adding to the concrete is effective in complex with

superplasticizer admixture taking into consideration increasing in mix water

requirement.

Also other ultra fine silica and aluminosilica materials can be effective in the

composition with superplasticizer.

154

8.3. Polymer-impregnated and

polymer-cement concrete

Polymer-impregnated concrete. Polymer-impregnated concrete is

concrete impregnated by polymer compositions or monomers with

subsequent polymerization. Polymer-impregnated concrete is included into

“P-concrete” group collecting different types of concrete where polymers

are used both as admixtures and basic components. Polymer-impregnated

concrete divides depending on impregnating material type: monomers

(styrene, methylmetacrylate etc.), viscous organic binders (bitumen,

paraffin etc.).

At concrete impregnation its structure changes, at first open capillary

porosity decreases drastically, cement stone and aggregate contact

zone is condensed. As a result water absorption reduces and

compressive strength and other mechanical properties increase

significantly.

155

There are shown comparison of the properties of ordinary initial concrete and

impregnated concrete at polymerization by metylmetacrylate (according to

Y.Bagenov data) in Table 8.2.

Table 8.2

Properties of ordinary initial concrete and polymer-impregnated concrete

Parameter

Initial concrete

Polymer-impregnated

concrete

Strength, MPa:

compressive

30...50

100...200

tensile

2...3

6...19

flexural

5...6

14...28

Modulus of elasticity at compression, MPa

2.5.104...3.5.104

3.5.104...5.104

Limit deformation at compression

0.001

0.002

Bond strength with reinforcement, MPa

1...2

10...18

Shrinkage

50.10–5

0...5.10–5

Creep

(40...60).10–5

(6...8).10–5

Electrical resistance, Om

105

1014

Water absorption, %

3...5

1

Frost resistance, cycles of freezing and

200

5000

thawing

Corrosive resistance to sulfates and acids

Insufficient

High

156

Polymer-cement concrete. Polymer-cement concrete is concrete modified

with polymer admixtures. Cresson had received first patent on application of

polymer cement with latex admixture in 1923.

Modified cement mixes differ from ordinary mixes due to their ability to water

keeping that increases when polymer-cement ratio increases. That permits to

improve placeability, prevent “drying” and reach good adhesion with porous

base.

One of the main results of polymer admixtures adding is tensile strength

increasing of cement concrete and their deformability. At adding of

polyvinylacetate (PVA) and latexes admixtures flexural strength increasing in

2-3 times. There is also observed increasing in limit extensibility and adhesion

to old concrete and reinforcement. PVA adding as an admixture to mortars

increases extensibility up to 2 times.

At selection of the application area of polymer-cement mortars and concrete

there are taken into consideration their specific properties and advantages

(Tab.8.3).

157

Table 8.3

Technical application areas of mortars and concrete modified by latex

(according to I. Okama)

Materials group

Materials assignment

Floors for public buildings, storages, administration buildings,

Floor coverings

shops, toilets

Road and abrasion

Crosswalks, stairs, railway platforms, road coverings

resistance coverings

Concrete flat roofs, masonry blocks, water cisterns, swimming

Watertight structures

pools, dikes for silage

Mortars for adhesion of finishing, heat-insulating and other

Binding compositions

materials;

Bonding new concrete to old one and new mortar to old one

Drainpipes, floors of chemical plants, mortars for acid resistant

Anticorrosive

tiles, basements for machinery, floors for chemical laboratories,

compositions

drug-store storages

Ship decks, bridges coverings, trains floors, coverings for

Toppings

pedestrian overpasses

158

8.4. Fiber reinforced concrete

Fibrous or fiber reinforced concrete is a group of composite materials

including short chopped fibers in cement matrix. There are different types of

fiber made of steel, glass, synthetic materials, asbestos, carbon etc.

For composite materials with discrete fibers modulus of elasticity (E) and

flexural strength (R ) can be approximately calculated from following:

fl

E=KrEfVf+EmVm, (8.2)

Rfl= KrRfVf+RmVm , (8.3)

Where K – reinforcement coefficient of concrete, E and E – modulus of

r

f

m

elasticity of fiber and matrix, R and R – flexural strength of fibers and

f

m

matrix, V and V – volume content of fibers and matrix.

f

m

159

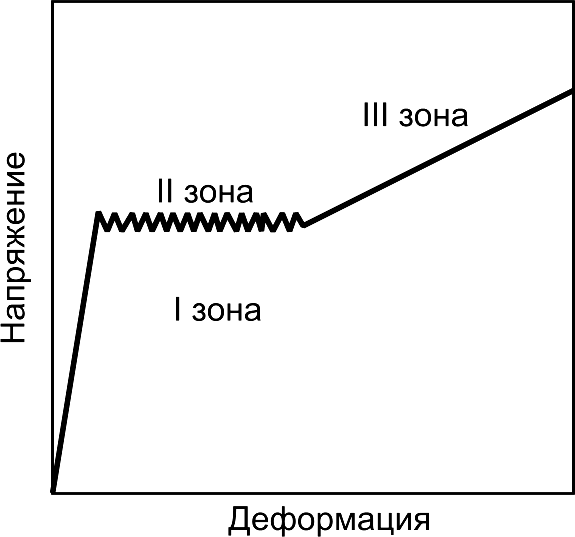

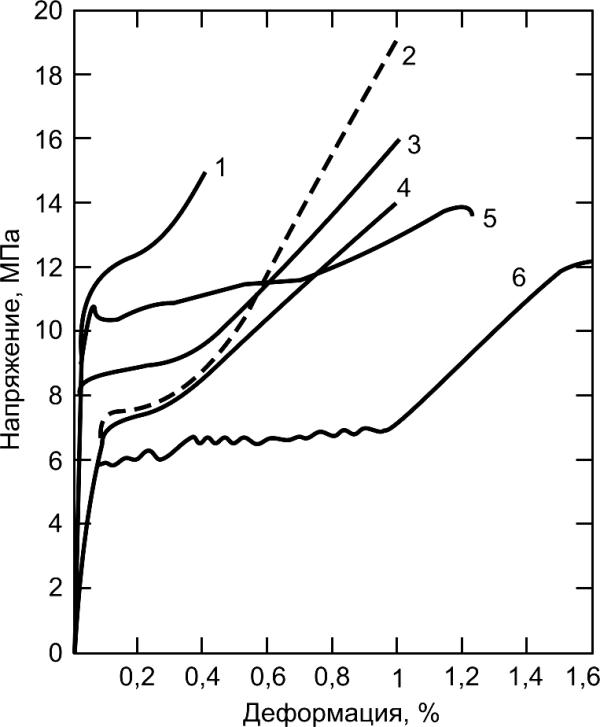

Typical stress – strain diagram of fibrous concrete consists of 3 zones (Fig.8.4, 8.5).

3 zone

2 zone

a

Stress

tress, MP

1 zone

S

Strain

Fig. 8.4. Typical curve of stress –

strain dependence for cement

Strain, %

compositions reinforced by fiber

Fig. 8.5. Curves of stress – strain dependences for

several fiber reinforced cement composites:

1 – Portland cement – steel wire, 1.5% by volume; 2 –

The same, 1% by volume, 3 – High-alumina cement –

fiberglass, 0.067% by volume; 4 – Portland cement –

zirconium fiberglass, 5% by volume; 5 – Portland cement

– polyamide fiber, 1.93% by volume; 6 –gypsum –

fiberglass, 1% by volume

160

At fibrous concrete destruction maximum work done at burst (W ) is expressed

b

by formula:

Wb=VfRflcr/12, (8.4)

Where R – flexural strength of fibers, V – volume content of fibers; l is

f

f

cr

critical length of fiber.

Steel fibrous concrete. Steel fibrous concrete is the most common fibrous

concrete on the basis Portland cement reinforced by steel fiber. Steel fiber is

presented usually by cuts of wire. Fibers can have different cross-area –

round, oval etc. with dimensions from 0.2 to 1.6 mm and length from 10 to 160

mm. Fibers surface can be sectional and smooth. Amount of added fibers

mostly varies from 0.5 to 2 % by volume. Adding into concrete steel fibers in

the amount of 1-1.5% by volume increases its tensile strength up to 100%,

flexural strength – up to 150-200%, compressive strength increases at 1025%.

161

Glass-fiber reinforced concrete. Along with steel fibrous concrete there is

positive experience of application of glass-fiber reinforced concrete (glass-fiber

reinforced cement) that allows reducing additionally weight of constructions.

Their production is based on adding into cement paste or cement mortar

alkaline-resistant fiber in the amount of 5% by mass. Tensile strength and

flexural strength of glass-reinforced mortar increases the strength of nonreinforced mortar in 2-3 times even after 10 years of air-dry hardening.

Maximum deformation caused by limit tensile stress in glass-reinforced mortar

is in 10 times more than in non-reinforced mortar.

There are combined successfully properties of initial materials and high

strength and durability is reached in the composites on the basis of mineral

binders reinforced by glass fiber.

Fiber made of non-alkaline aluminoborosilicate glass has the largest strength.

Alkaline oxides reduce strength of a fiber.

162

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10 Page 11 Page 12 Page 13 Page 14 Page 15 Page 16 Page 17 Page 18 Page 19 Page 20 Page 21 Page 22 Page 23 Page 24 Page 25 Page 26 Page 27 Page 28 Page 29 Page 30 Page 31 Page 32 Page 33 Page 34 Page 35 Page 36 Page 37 Page 38 Page 39 Page 40 Page 41 Page 42 Page 43 Page 44 Page 45 Page 46 Page 47 Page 48 Page 49 Page 50 Page 51 Page 52 Page 53 Page 54 Page 55 Page 56 Page 57 Page 58 Page 59 Page 60 Page 61 Page 62 Page 63 Page 64 Page 65 Page 66 Page 67