,

S

.9)

p

.

c

δ

Where δ is thickness of cement paste that film and glue aggregate’s grains; S

is total surface of aggregate’s grains.

Fineness and gradation of the aggregate make influence on formation of

structure and properties of no-fines concrete. Volume of voids between grains

also depends on cement content.

Unlike no-fines concrete, aerated lightweight concrete has porous structure

formed by component forming pores. By properties this type of lightweight

concrete takes intermediate place between concrete of dense structure and

cellular concrete. Forming pores of lightweight concrete mix permits to use

heavier porous aggregate without density increasing, to reduce quantity or to

refuse to use porous sand, to apply aggregate with gap grading. Raised

viscosity and workability are characteristic for aerated concrete mixes.

181

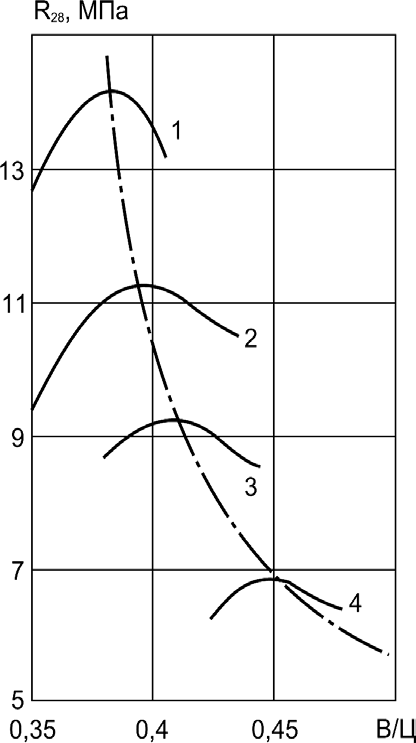

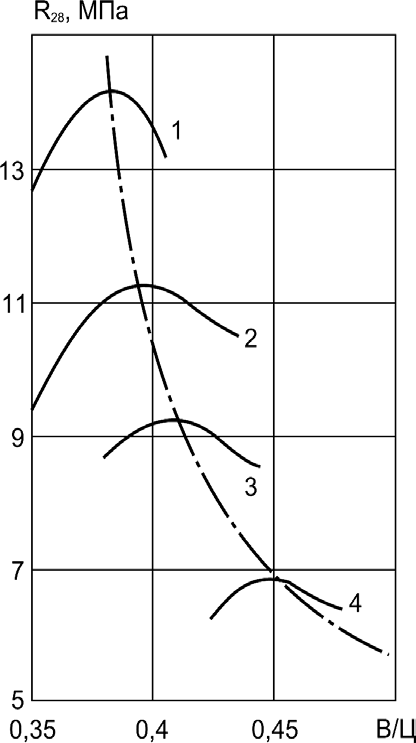

R28, MPa

Forming pores for concrete can be done by

foam, gas or air-entraining admixture.

Foam makes pores usually in noaggregates concrete, air-entraining

admixtures make pores in mixtures with

sand, gas – both mixtures with and without

sand.

0.35 0.4 0.45 W/C

Fig. 9.3. Relationship between

no-fines concrete strength at 28

day (R28) and water-cement

ratio (W /C):

1–concrete composition

(cement: gravel by volume) 1:6;

2–idem 1:7; 3–idem 1:8;

4–idem 1:10

182

9.5. Cellular concrete

Cellular concrete (gas concrete) has been suggested at first in 1889 by Czech

researcher Hoffman which used for mortars effervescence carbon dioxide. In

1914 Owlswort and Dyer (USA) were issued the patent on application of

aluminum and zinc powders to form hydrogen bubbles in cement stone, making

principles of modern gas concrete technology.

Cellular concrete is manufactured from binder, silica component, gas formers or

foaming agents and water. Both clinker and non-clinker (slag-alkaline and

others) cements, lime, gypsum are binders for cellular concrete production.

Cellular concrete is referred to mostly effective materials for enclosing

structures. At density 500-700 kg/m3 they permit to reach strength 3-5 МPа at

optimal structure. Basic factors of cellular concrete strength increasing at

keeping their density are more high fineness of components grinding and their

grading, thorough mixing, selection of optimal mixes compositions and curing

regime.

183

Aluminum powder is most common gas former. Powder adding provides start of

gas emission in alkaline environment after 1...2 min. Aluminum paste is used

along with powder. Gas forming reaction proceeds in following way:

Са

3

(ОН) + 2Al+ 6H O ⇔ CaO

3

⋅ Al O ⋅6Н О + Н

3

↑

2

2

2

3

2

2

As the result of chemical reaction from 1 g of aluminum at normal conditions

1.254 litres of hydrogen is formed, at 50°С hydrogen volume is 1.48 litres.

As foaming agents there are used different surface-active agents (sulphite

yeast, soap agent, etc.) and other substances, which at intensive mixing with

water make stable foams.

Cellular concrete strength (R ) correlates closely with its density (ρ ). Practice

c

c

for strength prediction of these materials there are used different empirical

equations, for example:

R = А 2

(9.10)