.

4)

191

Ash is divided on high-calcium (СаО>20%) and low-calcium (СаО<20%).

Crystalline phases are prevalent for the first one, and glass and amorphous-like

clay material is dominant for the second one. High-calcium ash can be divided

on low-sulfate (SО <5%), obtained by coal and peat burning and sulfate

3

(SО >5%) obtained by shale's burning.

3

Slags and ash acquire ability to harden at alkaline, line, sulfate and combined

types of activation. Slag and fly ash materials with different intensity harden in

normal conditions and at steam curing depending on their mineralogical

composition, chemical composition and active phases content, fineness, type

and concentration of activator.

As activators of slag and fly-ash binders are used anhydrous lime, calcium

sulphate hydrate or hemihydrate are used. Application of hydrated lime gives

worse results than lump quicklime.

Cellular, fine-grained, light-weight and heavy-weight concrete are

manufactured on the basis of slag and fly ash binders. Comparatively high

quality of these materials is obtained at steam curing.

192

10.3. Slag-alkaline concrete

Concretes for which common feature is slag-alkaline binders application are

included into group of slag-alkaline concrete. Fundamentals of theory and

technology of National University of Construction and Architecture (Kiev, Ukraine)

have been worked out by V. Glukhovsky.

Approximate composition of heavy-weight concrete, %: ground granulated slag 15...30; alkaline component – 0.5...1.5; aggregates - 70...85.

Physical and mechanical properties of slag-alkaline concrete can vary with

wide range by selecting raw materials, varying concrete mix composition and

applying different technological processes. Parameters of the most of these

type concrete properties are close to parameters of cement concrete and in

some instances they can be appreciably higher.

Until present almost forty years experience is gathered in application of slagalkaline concrete in construction industry. There is shown effectiveness of

production of wide range constructions, assigned for service in different

including hard conditions.

193

1 day

1.0

R

e

c, MPa

0.8

ressiv

0.6

gth 0.4

comp stren 0.2

0.0

Relative

Activator dosage, %

28 days

e

1.0

Humidity of concrete mixture, %

0.8

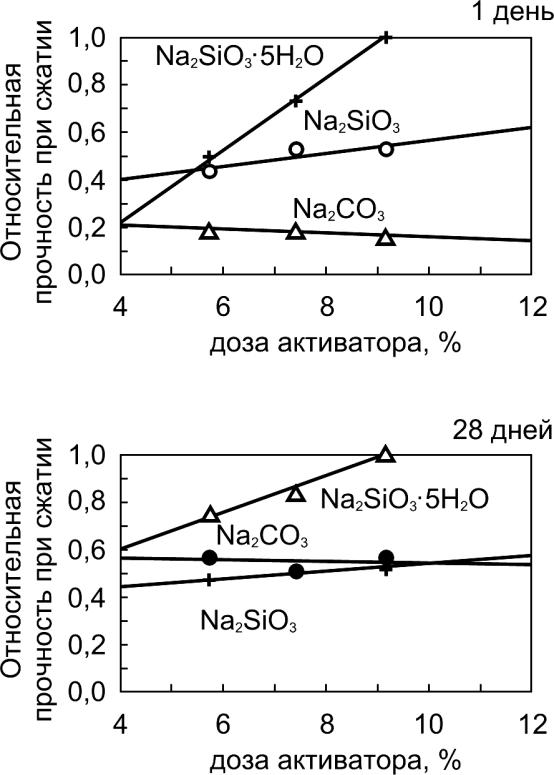

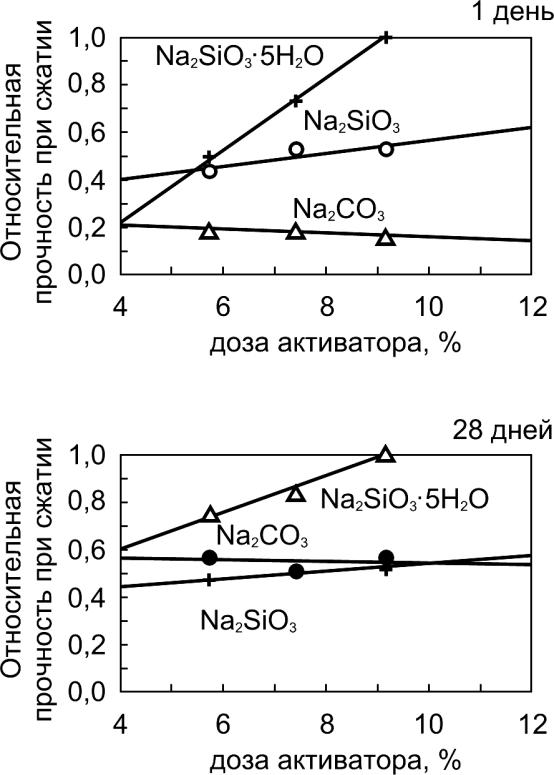

Fig. 10.3. Relationship between slag alkaline

ressiv

0.6

concrete compressive strength (R

gth

c), humidity of

mixture and weight part of clayey particles in the

comp

0.4

aggregate:

stren 0.2

1 – weight part of clayey particles in the aggregate 1.2 %;

0.0

2 – idem 5.2 %; 3 – idem 6.4 %; 4 – idem 8.8 %

Relative

(according to G.Skurchinskaya data)

Activator dosage, %

Fig.10.4. Relative strength of alkaline

slag binder depending on type and

content of activator

(from I.Blackmeyer data)

194

10.4. Gypsum concrete

Gypsum concrete is concrete produced on the basis of gypsum binders. Building

blocks, masonry blocks, panels, assigned particularly for internal walls and

crosswalls are produced from gypsum concrete. Application area of such

concrete is limited mostly because of their insufficient water resistance.

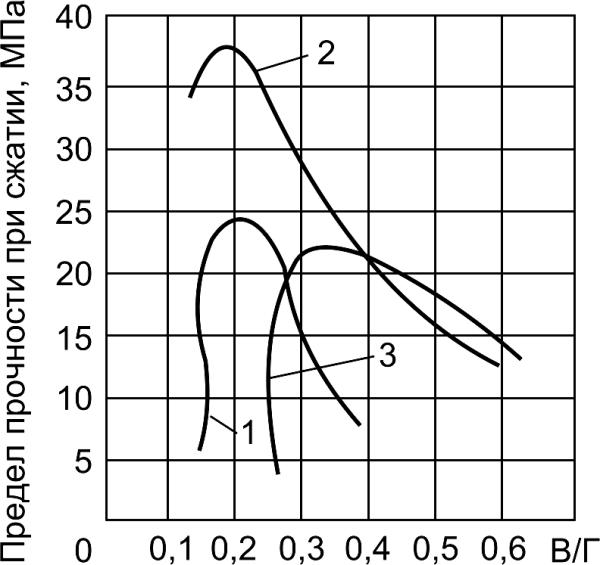

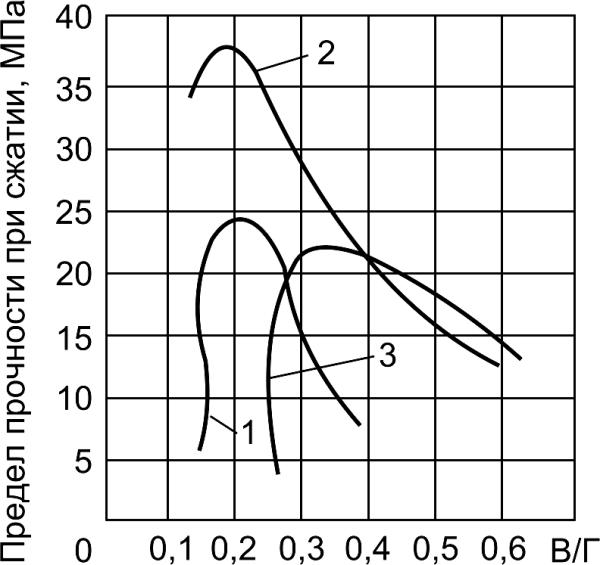

According to data obtained by

A.Volgensky and А.Ferronskaya, the

effect of water-gypsum ratio (W/G) on

th, MPa

gypsum concrete strength is similar to

ng

effect of water-cement ratio on cement

stre

concrete strength (Fig.10.5).

ssivere

mp

Co

0.1 0.2 0.3 0.4 0.5 0.6 W/G

Fig.10.5. Influence of water-gypsum

ratio (W/G) on gypsum strength:

2-α-hemihydrate gypsum;

1, 3 - β-hemihydrate gypsum.

195

Water-gypsum ratio depends on gypsum binder type, temperature of mixing

water and method of forming of elements.

There are obtained concrete with strength 5-10 MPa on the basis of gypsum

binder. Application of high-strength gypsum, anhydrous gypsum and estrich

gypsum permits to increase strength up to 20 MPа. Concrete strength at

application of composite gypsum-cement-pozzolanic and gypsum-slag-cementpozzolanic binders on the basis of alabaster is 7.5-20 MPa, on the basis of alpha

gypsum is 15-40 MPa.

Quality and nature of aggregates make significant influence on strength of

gypsum concrete.

10.5 Mortars

Lime, gypsum, cement and composite (cement-lime, cement-clay) mortars are

the most common in construction.

Basic properties of mortars are workability and water-retaining capacity.

Providing of required workability of mortar mixtures without segregation can be

reached by adding of plastizing admixtures and fillers.

196

Water-retaining capacity prevents segregation of mortar mixture. In view there,

are reduced water-binder ratio (due to right proportion), ultra-fine mineral fillers,

plastizing and special water-retaining admixtures.

For strength forecasting of cement-lime mortars are widely used N.Popov

formula. At pouring on dense basement, mortars strength (R ) is calculated by

m

formula:

Rm=0.25Rcem(C/W-0.4), (10.5)

Where R

– strength of cement, MPa; C/W – cement-water ratio.

cem

At water drawoff by porous base in the mortars with different C/W,

strength of mortars (R ) can be calculated as follows:

m

Rm=KRcem(C-0.05)+4, (10.6)

where К - coefficient of sand quality: for coarse sand К=2.2; medium sand

К=1.8; fine sand К=1.4; C - cement content.

197

Composites of mortars are selected by tables or calculation and specified by

experimental way in the context of specific materials.

Strength increase of masonry mortars at cold-weather construction can be

provided by adding of a series of chemical admixture.

10.6 Dry pack mixes

Modern construction industry is characterized by more wide application of dry

pack mixes, accurately batched and mixed in plant conditions mortars and

concrete mixes, with adding water at building site.

At construction work effectiveness of dry pack mixes is demonstrated in high

level of mechanization, significant reduction of construction terms, decreasing

labour content and working costs, providing high quality.

Dry pack mixes are classified by:

- main purpose (type of work);

- type of binder in the mixture;

- modification level of the mixture by admixtures;

- the most significant feature in hardened state;

- conditions of application.

198

There are identified different mixes by purpose: masonry, facing, jointing,

stopping, plastering, gluing, sealing mixes etc.; by type of basic binder –

gypsum, anhydrate, lime, magnesium, cement, cement-lime, polymer etc.; by

modification level – cost-effective, standard, high-quality; by characteristic

feature in hardened state - adhesive, weather-proof, fast-hardening, waterproof,

frostproof, high-strength, self-leveling, elastic etc.; by application conditions –

hand and machine coating, for porous materials etc.

The same mix can be often used at different construction.

Adjustment of technological and performance properties of dry pack mixes is

reached by adding different chemical admixtures

Thickening, dispersing, foaming, defoaming, water-repelling, conservative

agents etc. are included into the complex of special chemical admixtures.

199