13.13

24.61

26.25

21

ISBN: 978-967-14475-3-6; eISBN: 978-967-14475-2-9 264

Biotech Sustainability (2017)

Biodiesel Production for Sustainability Meena Devi et al.

-ion hectare is classified as waste and

curcas is the most known variety; it

degraded land (Dwivedi et al., 2014).

requires little water or additional care;

therefore, it is adequate for warm regions

4.1. Typical oil crops useful for biodiesel

with little fertility. Productivity may be

production

reduced by irregular rainfall or strong

The main characteristics of typical

winds during the flowering season. Yield

oil crops that have been found useful for

depends on climate, soil, rainfall and

biodiesel production are summarized in

treatment during sowing and harvesting.

the following paragraphs.

Jatropha plants become productive after 3

or 4 years, and their lifespan is about 50

4.1.1. Castor seed

years. Oil yield depends on the method of

The castor oil plant grows in

extraction; it is 28–32% using presses and

tropical climates, with temperatures in the

up to 52% by solvent extraction. Since the

range 20–30◦C; it cannot endure frost. It

seeds are toxic, jatropha oil is nonedible.

is important to note that once the seeds

The toxicity is due to the presence of

start germinating, the temperature must

curcasin (a globulin) and jatrophic acid

not fall below 12 ◦C. The plant needs a

(as toxic as ricin).

warm and humid period in its vegetative

phase and a dry season for ripening and

4.1.4. Microalgae

harvesting. It requires plenty of sunlight

Microalgae have great potential for

and adapts well to several varieties of

biodiesel production, since the oil yield

soils. The total rainfall during the growth

(in liters per hectare) could be one to two

cycle must be in the range 700–1,400

orders of magnitude higher than that of

mm; although it is resistant to drought,

other raw materials. Oil content is usually

the castor oil plant needs at least 5 months

from 20 to 50%, although in some species

of rain during the year. Castor oil is a

it can be higher than 70%. However, it is

triglyceride, ricinolenic acid being the

important to note that not all microalgae

main constituent (about 90%). The oil is

are adequate for biodiesel production.

non-edible and toxic owing to the

High levels of CO2, water, light, nutrients

presence of 1–5% of ricin, a toxic protein

and mineral salts are necessary for the

that can be removed by cold pressing and

growth

of

microalgae.

Production

filtering. The presence of hydroxyl groups

processes take place in raceway ponds

in its molecules makes it unusually polar

and photobiological reactors.

as compared to other vegetable oils.

5. Biodiesel production techniques

4.1.2. Jojoba

Although jojoba can survive

There are different processes which

extreme drought, it requires irrigation to

can be applied to synthesize biodiesel

achieve an economically viable yield.

such as direct use and blending, micro

Jojoba needs a warm climate, but a cold

emulsion

process,

thermal

cracking

spell is necessary for the flowers to

process and the most conventional way is

mature. Rainfall must be very low during

transesterification process (Gashaw et al.,

the harvest season (summer). The plant

2015).

reaches its full productivity 10 years after

planting. The oil from jojoba is mainly

5.1.

Direct use and blending

used in the cosmetics industry; therefore,

The direct use of vegetable oils in

its market is quickly saturated.

diesel engine is not favorable and

problematic because it has many inherent

4.1.3. Jatropha

failings. Even though the vegetable oils

Jatropha is a shrub that adapts

have familiar properties as biodiesel fuel,

well to arid environments. Jatropha

it required some chemical modification

ISBN: 978-967-14475-3-6; eISBN: 978-967-14475-2-9 265

Biotech Sustainability (2017)

Biodiesel Production for Sustainability Meena Devi et al.

before can be used into the engine. It has

proportions. The equipment for thermal

only been researched extensively for the

cracking and pyrolysis is expensive for

past couple of decades, but has been

modest biodiesel production particularly

experimented with for almost hundred

in developing countries. Furthermore, the

years. Although some diesel engine can

removal of oxygen during the thermal

run pure vegetable oils, turbocharged

processing

also

removes

any

direct injection engine such as trucks are

environmental benefits of using an

prone to many problems.

oxygenated fuel. Another disadvantage of

pyrolysis is the need for separate

5.2.

Microemulsion process

distillation equipment for separation of

A micro emulsion is defined as the

the various fractions. Also the product

colloidal

equilibrium

dispersion

of

obtained is similar to gasoline containing

optically isotropic fluid microstructures

Sulphur which makes it less ecofriendly.

with dimensions generally in the range of

The pyrolyzed material can be vegetable

1–150 nm formed spontaneously from

oils, animal fats, natural fatty acids and

two normally immiscible liquids and one

methyl esters of fatty acids.

or more ionic or non-ionic. The problem

of the high viscosity of vegetable oils was

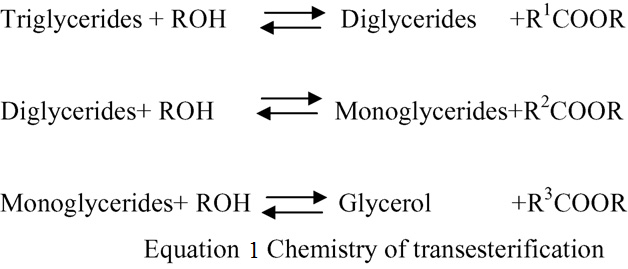

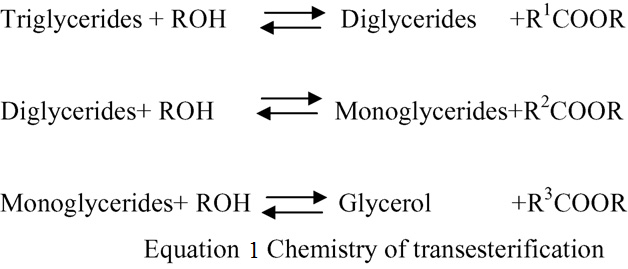

5.4. Transesterification

solved by micro-emulsions with solvents

Generally, biodiesel is produced

such as methanol, ethanol, and 1-butanol.

by

means

of

transesterification.

The components of a biodiesel micro-

Transesterification is the reaction of a

emulsion include diesel fuel, vegetable

lipid with an alcohol to form esters and a

oil, alcohol, surfactant and cetane

byproduct, glycerol. It is, in principle, the

improver

in

suitable

proportions.

action of one alcohol displacing another

Alcohols such as methanol and ethanol

from an ester, referred to as alcoholysis

are used as viscosity lowering additives,

(cleavage

by

an

alcohol).

In

higher alcohols are used as surfactants

Transesterification

mechanism,

the

and alkyl nitrates are used as cetane

carbonyl carbon of the starting ester

improvers. Microemulsions can improve

(RCOOR1) undergoes nucleophilic attack

spray

properties

by

explosive

by the incoming alkoxide (R O−) to give

2

vaporization

of

the

low

boiling

a tetrahedral intermediate, which either

constituents in the micelles. Micro-

reverts to the starting material, or

emulsion results in reduction in viscosity

proceeds to the transesterified product

increase in cetane number and good spray

(RCOOR2). Transesterification consists of

characters in the biodiesel. However,

a sequence of three consecutive reversible

continuous use of microemulsified diesel

reactions. The first step is the conversion

in engines causes problems like injector

of triglycerides to diglycerides, followed

needle sticking, carbon deposit formation

by the conversion of diglycerides to

and incomplete combustion.

monoglycerides,

and

finally

monoglycerides into glycerol, yielding

5.3. Thermal cracking (pyrolysis)

one ester molecule from each glyceride at

Pyrolysis is defined as the

each step. The reaction is represented in

conversion of one substance into another

equation 1.

by means of heat or heating with the aid

of a catalyst. Pyrolysis involves heating in

absence of air or oxygen and cleavage of

chemical bonds to yield small molecules.

The pyrolysis of vegetable oil to produce

biofuels has been studied and found to

produce alkanes, alkenes, alkadienes,

aromatics and carboxylic acids in various

ISBN: 978-967-14475-3-6; eISBN: 978-967-14475-2-9 266

Biotech Sustainability (2017)

Biodiesel Production for Sustainability Meena Devi et al.

There

are

different

acid catalyzed transesterification process,

transesterification processes that can be

which converts the FFA to esters (Leung

applied to synthesize biodiesel: (a) base-

and Guo, 2006).

catalyzed transesterification, (b) acid-

catalyzed transesterification, (c) enzyme-

5.4.3. Enzyme catalysts

catalyzed transesterification, and (d)

Lipase enzymes can also catalyze

supercritical alcohol transesterification.

methanolysis of triglycerides. The most

promising results were obtained by using

5.4.1. Catalysts: acid catalyst

immobilized Candida Antarctica lipase

The use of an acid catalyst is

(Novozym 435). Shimada et al., (1999),

observed to be more effective than alkali

found that Novozym435 was inactivated

catalysts when the concentration of free

by shaking it in a mixture containing

fatty acids is high. Also the performance

more than 1.5 M eq. of methanol to oil.

of the acid catalyst is not strongly

Above this concentration, methanol is

affected by the presence of FFAs in the

partially present as small droplets in the

feedstock. In fact, acid catalysts can

oil phase. These droplets are believed to

simultaneously

catalyze

both

cause enzyme deactivation. Therefore,

esterification

and

transesterification.

methanol was added stepwise; after the

Thus, a great advantage with acid

addition of the third methanol equivalent,

catalysts is that they can directly produce

conversion to methyl esters was almost

biodiesel from low cost lipid feedstocks,

complete. The enzyme could be reused 50

generally associated with high FFA

times without loss of activity. The

concentrations (low-cost feedstocks, such

occurrence of free fatty acids did not

as used cooking oil and greases,

affect the enzyme catalyst. Before the

commonly have FFAs levels of >6%)3.

inlet of every reactor,1 M eq. was added

However, Homogeneous acid catalyzed

to the feed. Samukawa et al. (2000)

reaction is about 4000 times slower than

reported a dramatic increase of the lipase

the homogeneous base-catalyzed reaction.

efficiency when it was pretreated by a

Acids used in the catalysis of the

consecutive incubation in methyl ester

transesterification

of

biodiesels

are

and oil prior to reaction. The use of

usually either hydrochloric acid or

Novozym435

in

methanolysis

of

sulfuric acid. Though these two acids are

triglycerides

is

also

reported

in

the most common, any Bronsted acid can

supercritical carbon dioxide at 24.1 MPa

also be used in this reaction.

and 50 ◦C. High yields (90–95%) of fatty

acid methyl esters could be obtained

5.4.2. Base catalyst

when the reaction was carried out at

Transesterification reaction can be

molar methanol/oil ratios of 25:1.

catalyzed by both homogeneous (alkalies

and acids) and heterogeneous catalysts.

5.4.4. Supercritical transesterification

The used alkali catalysts are NaOH,

Saka and Kusdiana (2001) have

CH3ONa, and KOH for producing

developed a catalyst free method for

biodiesel (Wang et al., 2007). The alkali

biodiesel fuel production by employing

catalyzed transesterification of vegetable

supercritical methanol. The supercritical

oils proceeds faster than the acid

treatment at 350 ◦C, 43 MPa, and 240 s

catalyzed. But the use of base catalyzed

with a molar ratio of 42:1 in methanol is

transesterification is only limited to oil

the

optimum

condition

for

having low water and FFA content. This

transesterification of rapeseed oil to

reaction is the most widely used process

biodiesel fuel. The great advantage of this

for production of biodiesel worldwide. To

method was that free fatty acids present in

keep check on the water and FFA content

the oil could be simultaneously esterified

of the oil, they are first pretreated with an

in the supercritical solvent. Variables such

ISBN: 978-967-14475-3-6; eISBN: 978-967-14475-2-9 267

Biotech Sustainability (2017)

Biodiesel Production for Sustainability Meena Devi et al.

as the molar ratio of alcohol to vegetable

found that reaction mixture containing

oil and reaction temperature were

65ml of methanol along with 2.4 g of

investigated during the transesterification

catalyst (KOH) took a good start in half

within this supercritical media. Increasing

an hour at30°C. In this reaction, amount

the reaction temperature within the

of glycerine removed as well as ester

supercritical regime resulted in increased

content

produced

was

considerably

ester conversion.

increased with rise in temperature of

mixture up to 70°C by extending time

6. Previous work done on production of

period (180-360 minutes). The removal of

biodiesel from edible oil

glycerine increased by two and half times

and ester content by four times,

Leung and Guo (2006) compared

respectively. When castor oil was

the transesterification reaction conditions

subjected to acid esterification, prior to

for fresh canola oil and used frying oil.

transesterification

(a

separate

Higher molar ratio (7:1, methanol/used

investigation), it was found that ester

frying oil), higher temperature (60° C)

contents up to 95% could be obtained.

and higher amount of catalyst (1.1 wt%

Hasan et al. (2013) produced biodiesel

NaOH) was maintained in used frying oil

from neem seeds, its properties were

when compared to fresh canola oil where

close to diesel. The methodology of

optimal conditions maintained were 315-

esterification process was selected and

318 K, 1.0 wt% NaOH and 6:1

carried out by 1000 ml raw neem oil,

methanol/oil molar ratio. However, less

300ml methanol and sodium hydroxide

reaction time (20 min) was observed for

on mass basis as a catalyst usually kept in

used frying oil when compared to fresh

oven to form methyl ester, and initially to

canola oil reaction time (60 min). Ying et

reach

equilibrium

condition

at

al. (2011), developed a new method

temperature 55-66°C. The ester and

catalyst,

benzyl

bromide-modified

glycerine were separated by stimulating

calcium oxide (CaO) for production of

continuously and allow settling under

biodiesel from rapeseed. The improved

gravity for 24 h. Thus the separated ester

catalytic activity was obtained by better

contains 3% to 6% methanol and soap

fat diffusion to the surface of the benzyl

agents. The methanol was removed by

bromide-modified CaO. Further, a 99.2%

vaporization. The biodiesel had some

yield of fatty acid methyl esters in 3h was

catalyst; it was removed by warm water

obtained in comparison to by better fat

mix with ester. Kinematic viscosity lay

diffusion to the surface of the benzyl

between 1.9 and 6.0 according to the

bromide-modified CaO. Wakil et al.

ASTM D6751 specification. It was

(2012), chosen Cottonseed oil, Mosna oil

reported that, 0.95 L biodiesel was

and Sesame oil for producing biodiesel.

produced from 1 L neem oil.

7. Previous work done on production of

8. Factors affecting biodiesel

biodiesel from non-edible oil

production

Mohibbe et al. ( 2005), found that

The yield of biodiesel in the

FAME of Jatropha curcas were most

process of transesterification is affected

suitable for use as bio- diesel and met the

by several process parameters which

major

specification

of

bio-diesel

include;

reaction

time,

reaction

standards of the European, Germany and

temperature, catalyst and molar ratio of

USA

Standards

Organization.

alcohol and oil and mixing intensity

Chakrabarti and Ahmad (2008) presented

(Gashaw et al., 2015).

work on extraction of oil from castor bean

and converting it into biodiesel. It was

8.1. Temperature

ISBN: 978-967-14475-3-6; eISBN: 978-967-14475-2-9 268

Biotech Sustainability (2017)

Biodiesel Production for Sustainability Meena Devi et al.

Reaction

temperature

is

the

of alcohol and 1 mole of triglyceride are

important factor that will affect the yield

required for transesterification to yield 3

of biodiesel. For example, higher reaction

moles of fatty acid methyl/ethyl esters

temperature increases the reaction rate

and 1 mole of glycerol is used. In order to

and shortened the reaction time due to the

shift the reaction to the right, it is

reduction in viscosity of oils. However,

necessary to either use excess alcohol or

<