7. Diagram 5 7.1. The designer’s Logbook

Engineers usually apply similar solutions in many variations for time measuring devices. Almost all of them are based on relatively few schematic diagrams and principles. The most important issue is what kind of regulating mechanism for the stroke of the device is going to be applied. This is followed by the question of the energy supply source and the means to transfer this energy into the kind of movement that is most suitable for the purpose [6]. With mechanical devices some initial movement is usually transmitted via some complicated transmission chain and some auxiliary mechanism into the final member, which usually comprises a dial and a scale with a time indicating hand [7].

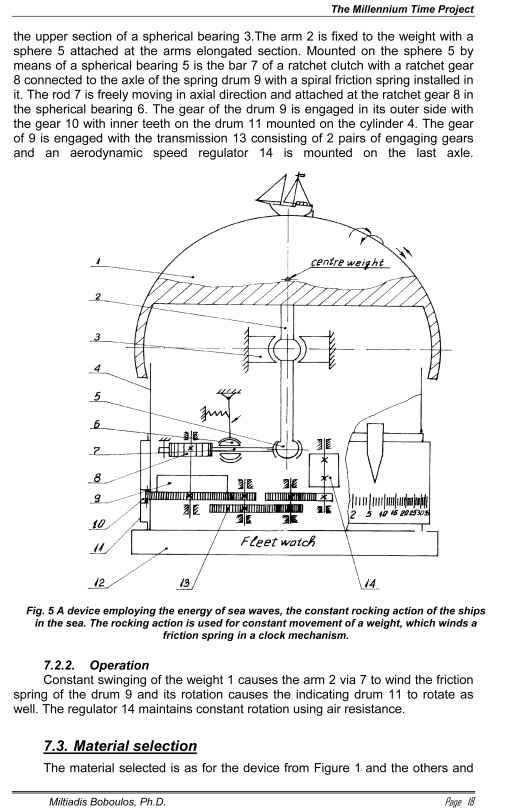

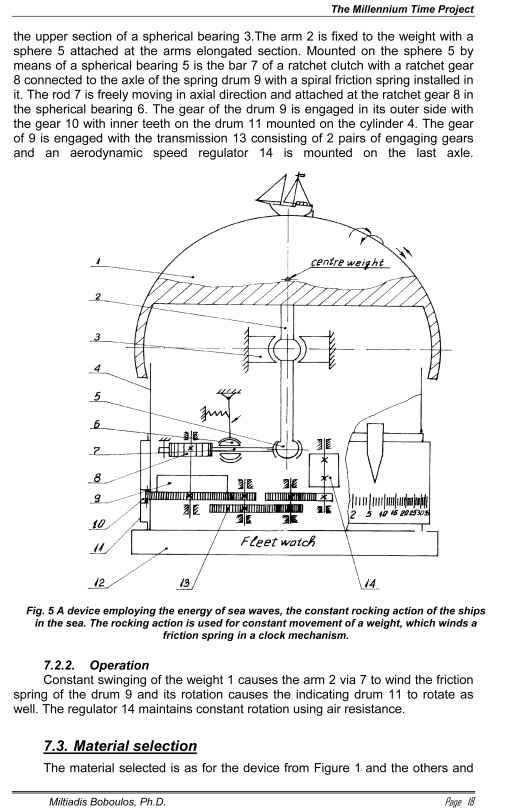

Initially, the issue of the energy source to be used has been examined. It is decided to employ natural energy that is relatively convenient for an easy application. The idea of using the energy of sea waves and wind is not new to designers. To drive such a low-power mechanism a simplified transmitting unit driven by the swinging action of sea waves could be used [6]. We decided to introduce the idea of the “sea clock” a suitable swinging weight-pendulum. It would be convenient and aesthetic to use a heavy hemisphere positioned above the device itself, which would play the pendulum role swinging in a ship with the sea waves [7].

The weight should be so positioned that the centre of gravity (CW) is higher than the point of fastening to the frame. It would be needed to have an arm coming out of the weight towards a traditionally used clock mechanism.

The end of an arm coming out of a spherical hinge is connected with an arm in a ratchet clutch. The end of the ratchet arm performs with the swinging of the spherical weight smaller or larger rectilinear for movements pressed towards the ratchet gear by an arm with a spring on the body (frame) of the device. A coil spring in a standard clock drum winds with the swinging of the device. An additional very important peculiarity arises here. This spring should slip on the drum when fully wound, se the so-called friction clock coil spring should be used. These springs are available in most modern automatic clocks [7].

the cylinder 4 is made of steel or duralumin sheet. The weight is made of stamped steel sheet filled with lead ballast or is made of concrete. It is also possible to make it of cast iron.