1 0 1 0 1 0

(73)

x

2

x 3

x 4

and

1

T 0

(74)

x

1

142

Applications of Nonlinear Control

From this we see that the function 1

T should be a function of x 1 alone. Therefore, we take

the simplest solution

y

1

1

T

x 1

(75)

and compute

y

2

2

T

d 1

T , f

x 2

(76)

MgL

k

y

3

3

T

d 2

T , f

sin( x 1)

( x 1 x 3)

(77)

I

I

MgL

k

y

4

4

T

d 3

T , f

cos( x 1) x 2

( x 2 x 4)

(78)

I

I

The feedback linearizing control input u is found from the condition

1

u

( v d

4

T , f )

dT , g

4

(79)

IJ

( v (

a x)) ( x) v ( x)

k

where

MgL

MgL

k

k

k k MgL

2

( x) :

sin( x

1 )( x 2

cos( x 1)

)

( x 1 x 3)(

cos( x 1)) (80)

I

I

I

I

I

J

I

Therefore in the coordinates y 1,, y 4 with the control law (79) the system becomes

y

1

y 2 y 2 y 3

y

3

y 4 y 4 v

or, in matrix form,

y Ay bv

(81)

where

0 1 0 0

0

0 0 1 0

0

A

b

0 0 0 1

0

0 0 0 0

1

The transformed variables y 1,, y 4 are themselves physically meaningful. We see that

y

1

x 1 =link position

Predictive Function Control of the Single-Link Manipulator with Flexible Joint

143

y

2

x 2 =link velocity

y

3

y 2 =link acceleration

y

4

y 3 =link jerk

Since the motion trajectory of the link is typically specified in terms of these quantities they

are natural variables to use for feedback.

For given a linear system in state space form, such as (81), a state feedback control law is an

input v of the form

4

T

v k y r k

iyi

r

(82)

i1

where ki are constants and r is a reference input. If we substitute the control law (82) into

(81), we obtain

(

T

y

A bk ) y br

(83)

Thus we see that the linear feedback control has the effect of changing the poles of the

system from those determined by A to those determined by

T

A bk

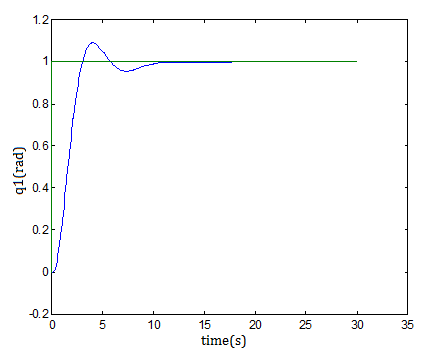

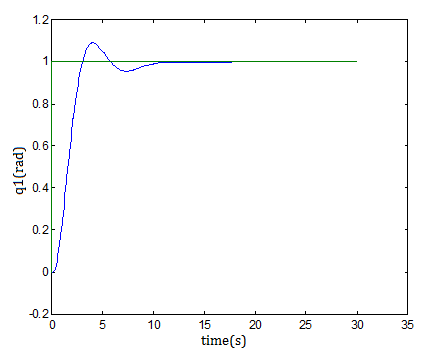

When the parameters are chosen k

1

62.5 , k

2

213.6 , k

3

204.2 k

4

54 , we can get step

responses in Figure 4. where k1, k2, k3 and k4 are linear feedback coefficients to place the

eigenvalues of A in a desired location.

y1 0

1

0

0 y 1 0

y

0

0

1

0 y 0

2

2

r

(84)

y

3

0

0

0

1

y 3

0

y

4 62.5

213.8

204.2

54 y 4 1

y 1

y

y 1 0 0 0 2

(85)

y

3

y 4

The internal model parameter: K 0.016

M

,

3

M

T , 8

d , and the coincidence point H=10.

Response time of reference trajectory is 0.01, and sample time is 0.01.

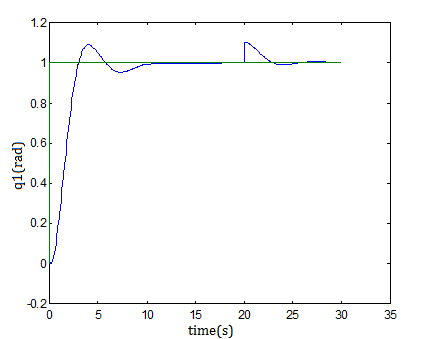

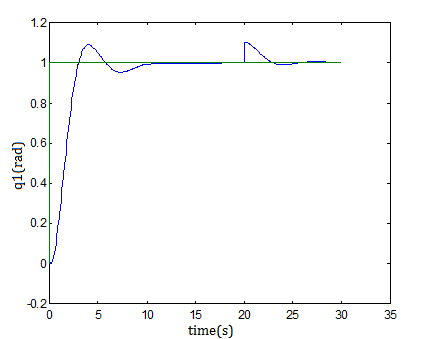

For the uncertainty , the system (38) can be written in matrix form as

(

T

y

A bk ) y {

b r ( y, v)}

then use predictive function control strategy to reduce or overcome uncertainty of nonlinear

feedback error ( y, v) ,and simulation result is shown in Figure 5 for ( y, v) 10% yr .

144

Applications of Nonlinear Control

Fig. 4. link position output

Predictive Function Control of the Single-Link Manipulator with Flexible Joint

145

Fig. 5. link position output with uncertainty rejection

146

Applications of Nonlinear Control

6. Conclusion

A new three stage design method is presented for the single link manipulator with flexible

joint. The first is feedback linearization; the second is to use pole placement to satisfy

performance, and the third is to develop predictive function control to compensate

uncertainty. Finally, for the same uncertainty, robustness is better than traditional method.

7. References

Khorasani, K. (1990). Nonlinear feedback control of flexible joint manipulators: a single link

case study. IEEE Transactions on Automatic Control, Vol. 35, No. 10, pp. 1145-1149,

ISSN 0018-9286

Richalet, J.; Rault, A.; Testud, J. L.; Papon, J.(1978). Model predictive heuristic control:

Applications to industrial processes. Automatica, Vol. 14, No. 5, pp. 413-428, ISSN

0005-1098

Spong, M.W.; Khorasani, K. & Kokotovic P.V. (1987). An integral manifold approach to the

feedback control of flexible joint robots. IEEE Journal of Robotics and Automation, Vol.

RA-3, No. 4, pp. 291-300, ISSN 0882-4967

Spong, M.W.(1987). Modeling and control of elastic joint robots. Journal of Dyn. Sys. Meas.

and Cont. , Vol. 109, pp.310-319, ISSN 0022-0434

Spong, M.W. (1989). On the force control problem for flexible joint manipulator. IEEE

Transactions on Automatic Control, Vol. 34, No. 1, pp. 107-111, ISSN 0018-9286

E. F. Camacho, Carlos Bordons(2004). Model predictive control. Springer-Verlag London Berlin

Limited. ISBN 1-85233-694-3

9

On Optimization Techniques for a Class

of Hybrid Mechanical Systems

Vadim Azhmyakov and Arturo Enrique Gil García

Department of Control Automation, CINVESTAV, A.P. 14-740, Mexico D.F.,

Mexico

1. Introduction

Several classes of general hybrid and switched dynamic systems have been extensively

studied, both in theory and practice [3,4,7,11,14,17,19,26,27,30].

In particular, driven by

engineering requirements, there has been increasing interest in optimal design for hybrid

control systems [3,4,7,8,13,17,23,26,27]. In this paper, we investigate some specific types of

hybrid systems, namely hybrid systems of mechanical nature, and study the corresponding

hybrid OCPs. The class of dynamic models to be discussed in this work concerns hybrid

systems where discrete transitions are being triggered by the continuous dynamics. The

control objective (control design) is to minimize a cost functional, where the control

parameters are the conventional control inputs.

Recently, there has been considerable effort to develop theoretical and computational

frameworks for complex control problems. Of particular importance is the ability to operate

such systems in an optimal manner. In many real-world applications a controlled mechanical

system presents the main modeling framework and can be specified as a strongly nonlinear

dynamic system of high order [9,10,22]. Moreover, the majority of applied OCPs governed

by sophisticated real-world mechanical systems are optimization problems of the hybrid

nature. The most real-world mechanical control problems are becoming too complex to allow

analytical solution. Thus, computational algorithms are inevitable in solving these problems.

There is a number of results scattered in the literature on numerical methods for optimal

control problems. One can find a fairly complete review in [3,4,8,24,25,29]. The main idea

of our investigations is to use the variational structure of the solution to the specific two point

boundary-value problem for the controllable hybrid-type mechanical systems in the form of

Euler-Lagrange or Hamilton equation and to propose a new computational algorithm for the

associated OCP. We consider an OCP in mechanics in a general setting and reduce the initial

problem to a constrained multiobjective programming. This auxiliary optimization approach

provides a basis for a possible numerical treatment of the original problem.

The outline of our paper is as follows.

Section 2 contains some necessary basic facts

related to the conventional and hybrid mechanical models.

In Section 3 we formulate

and study our main optimization problem for hybrid mechanical systems. Section 4 deals

with the variational analysis of the OCP under consideration. We also briefly discuss the

148

2

Will-be-set-by-IN-TECH

Applications of Nonlinear Control

computational aspect of the proposed approach. In Section 5 we study a numerical example

that constitutes an implementable hybrid mechanical system. Section 6 summarizes our

contribution.

2. Preliminaries and some basic facts

Let us consider the following variational problem for a hybrid mechanical system that is

characterized by a family of Lagrange functions { ˜ Lp }, p

i

i ∈ P

1 r

minimize

∑ β[

(

t

t, q( t), ˙ q( t)) dt

0

i− 1, ti ) ( t) ˜

Lpi

i=1

(1)

subject to q(0) = c 0, q(1) = c 1,

where P is a finite set of indices (locations) and q( ·) ( q( t) ∈ R n) is a continuously differentiable function. Here β[ ti− 1, ti)( ·) are characteristic functions of the time intervals [ ti− 1, ti), i = 1, ..., r associated with locations. Note that a full time interval [0, 1] is assumed to be separated into

disjunct sub-intervals of the above type for a sequence of switching times:

τ := {t 0 = 0, t 1, ..., tr = 1 }.

We refer to [3,4,7,8,13,17,23,26,27] for some concrete examples of hybrid systems with the

above dynamic structure.

Consider a class of hybrid mechanical systems that can be

represented by n generalized configuration coordinates q 1, ..., qn. The components ˙ qλ( t), λ =

1, ..., n of ˙ q( t) are the so-called generalized velocities. Moreover, we assume that ˜ Lp ( t, ·, ·) i

are twice continuously differentiable convex functions. It is well known that the formal

necessary optimality conditions for the given variational problem (1) describe the dynamics of

the mechanical system under consideration. This description can be given for every particular

location and finally, for the complete hybrid system. In this contribution, we study the hybrid

dynamic models that free from the possible external influences (uncertainties) or forces. The

optimality conditions for mentioned above can be rewritten in the form of the second-order

Euler-Lagrange equations (see [1])

d ∂ ˜ Lp ( t, q, ˙ q)

∂ ˜ L ( t, q, ˙ q)

i

−

pi

= 0, λ = 1, ..., n ,

dt

∂ ˙ qλ

∂qλ

(2)

q(0) = c 0, q(1) = c 1,

for all pi ∈ P. The celebrated Hamilton Principle (see e.g., [1]) gives an equivalent variational

characterization of the solution to the two-point boundary-value problem (2).

For the controllable hybrid mechanical systems with the parametrized (control inputs)

Lagrangians Lp ( t, q, ˙ q, u), p

i

i ∈ P we also can introduce the corresponding equations of

motion

d ∂Lp ( t, q, ˙ q, u)

∂L ( t, q, ˙ q, u)

i

−

pi

= 0,

dt

∂ ˙ qλ

∂qλ

(3)

q(0) = c 0, q(1) = c 1,

On Optimization Techniques for a Class of Hybrid Mechanical Systems

149

On Optimization Techniques for a Class of Hybrid Mechanical Systems

3

where u( ·) ∈ U is a control function from the set of admissible controls U . Let

U := {u ∈ R m : b 1, ν ≤ uν ≤ b 2, ν, ν = 1, ..., m},

U := {v( ·) ∈ L2 m([0, 1]) : v( t) ∈ U a.e. on [0, 1] }, where b 1, ν, b 2, ν, ν = 1, ..., m are constants. The introduced set U provides a standard example of an admissible control set. In this specific case we deal with the following set of admissible

controls U

C1 m(0, 1). Note that Lp depends directly on the control function u( ·). Let us

i

assume that functions Lp ( t, ·, ·, u) are twice continuously differentiable functions and every i

Lp ( t, q, ˙ q, ·) is a continuously differentiable function. For a fixed admissible control u( ·) we i

obtain for all pi ∈ P the above hybrid mechanical system with ˜ Lp ( t, q, ˙ q) ≡ L ( t, q, ˙ q, u( t)).

i

pi

It is also assumed that Lp ( t, q, ·, u) are strongly convex functions, i.e., for any

i

( t, q, ˙ q, u) ∈ R × R n × R n × R m, ξ ∈ R n the following inequality

n

n

∑ ∂ 2 Lp ( t, q, ˙ q, u)

i

ξλξθ ≥ α ∑ ξ 2 λ, α > 0

λ