the valve element. A poppet-type valve is usually hydraulically operated. A rotary-spool

type may be manually (lever or plunger action), mechanically (cam or trip action), or electrically (solenoid action) operated. A sliding-spool type may be manually, mechanically, electrically, or hydraulically operated, or it may be operated in combination.

Directional-control valves may also be classified according to the number of positions of

the valve elements or the total number of flow paths provided in the extreme position. For

example, a three-position, four-way valve has two extreme positions and a center or neutral

position. In each of the two extreme positions, there are two flow paths, making a total of

four flow paths.

Spool valves (see Figure 5-11) are popular on modern hydraulic systems because they—

•

Can be precision-ground for fine-oil metering.

•

Can be made to handle flows in many directions by adding extra lands and oil

ports.

•

Stack easily into one compact control package, which is important on mobile sys-

tems.

Spool valves, however, require good

maintenance. Dirty oil will damage the

mating surfaces of the valve lands, causing

them to lose their accuracy. Dirt will cause

these valves to stick or work erratically.

Also, spool valves must be accurately

machined and fitted to their bores.

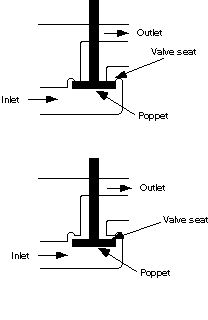

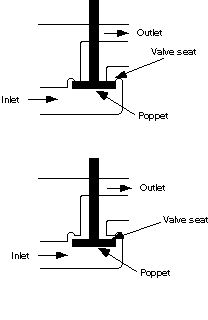

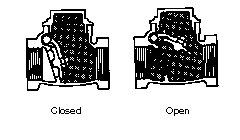

a. Poppet Valve. Figure 5-12, page 5-10,

shows a simple poppet valve. It consists

primarily of a movable poppet that closes

against a valve seat. Pressure from the

inlet tends to hold the valve tightly closed.

A slight force applied to the poppet stem

opens the poppet. The action is similar to

the valves of an automobile engine. The

poppet stem usually has an O-ring seal to

prevent leakage. In some valves, the pop-

pets are held in the seated position by

springs. The number of poppets in a valve

depends on the purpose of the valve.

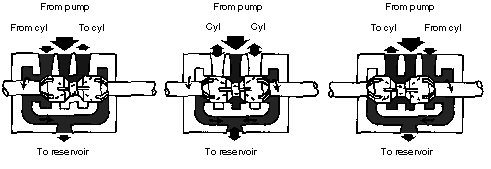

Figure 5-11. Spool valve

Valves

5-9

FM 5-499

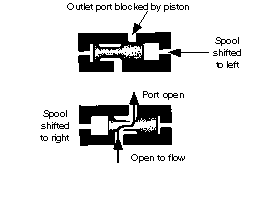

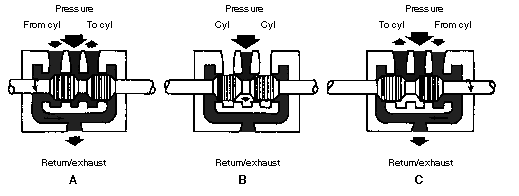

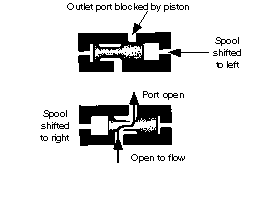

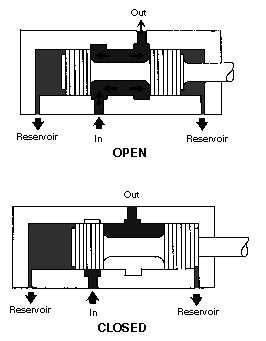

b. Sliding-Spool Valve. Figure 5-13 shows a

sliding-spool valve. The valve element slides back

and forth to block and uncover ports in the housing.

Sometimes called a piston type, the sliding-spool

valve has a piston of which the inner areas are equal.

Pressure from the inlet ports acts equally on both

inner piston areas regardless of the position of the

spool. Sealing is done by a machine fit between the

spool and valve body or sleeve.

Figure 5-12. Operation of a sim-

Figure 5-13. Operation of sliding-spool,

ple poppet valve

directional-control valve

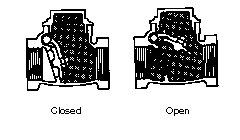

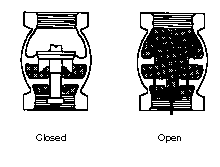

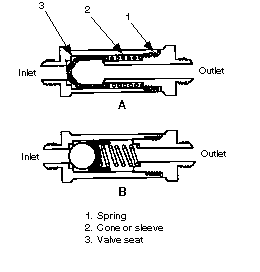

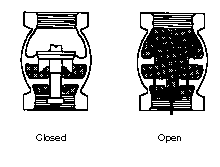

c. Check Valves. Check valves are the most commonly used in fluid-powered systems.

They allow flow in one direction and prevent flow in the other direction. They may be

installed independently in a line, or they may be incorporated as an integral part of a

sequence, counterbalance, or pressure-reducing valve. The valve element may be a sleeve,

cone, ball, poppet, piston, spool, or disc. Force of the moving fluid opens a check valve; back-flow, a spring, or gravity closes the valve. Figures 5-14, 5-15 and 5-16 show various types of check valves.

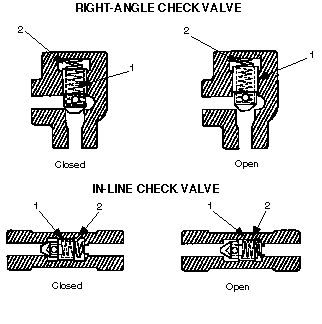

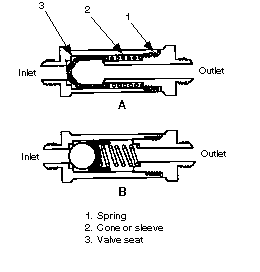

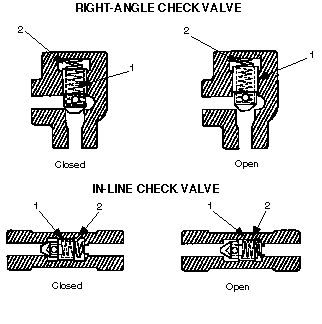

(1) Standard Type (Figure 5-17, page 5-12). This valve may be a right-angle or an in-

line type, depending on the relative location of the ports. Both types operate on the same

principle. The valve consists essentially of a poppet or ball 1 held on a seat by the force of spring 2. Flow directed to the inlet port acts against spring 2 to unseat poppet 1 and open

the valve for through flow (see Figure 5-17, diagram B, for both valve types). Flow entering the valve through the outlet port combines with spring action to hold poppet 1 on its seat to check reverse flow.

These valves are available with various cracking pressures. Conventional applications

usually use the light spring because it ensures reseating the poppet regardless of the valve's 5-10

Valves

FM 5-499

mounting position. Heavy

spring units are generally used

to ensure the availability of at

least the minimum pressure

required for pilot operations.

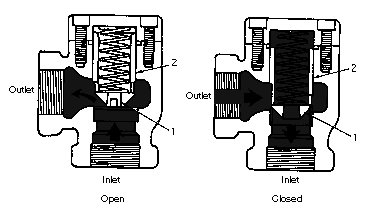

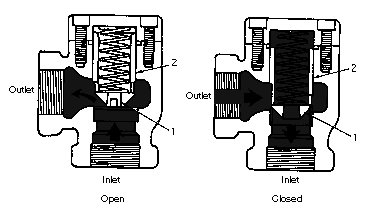

(2) Restriction Type (Fig-

ure 5-18, page 5-12). This

valve has orifice plug 1 in the

nose of poppet 2, which makes

it different from a conven-

tional, right-angle check valve.

Flow directed to the inlet port

opens the valve, allowing free

Figure 5-14. Swing-type check valve

flow through the valve.

Reverse flow directed in through

the outlet port seats poppet 2.

Flow is restricted to the amount

of oil, which can be altered, to

allow a suitable bleed when the

poppet is closed. Uses of a

restriction check valve can be to

control the lowering speed of a

down-moving piston and the

rate of decompression in large

presses.

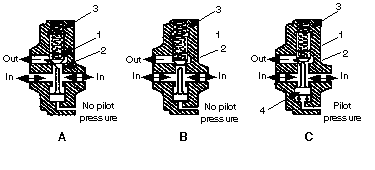

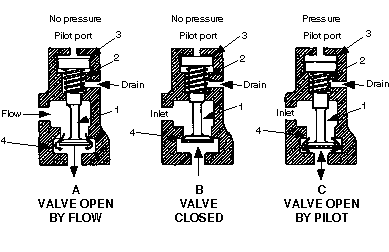

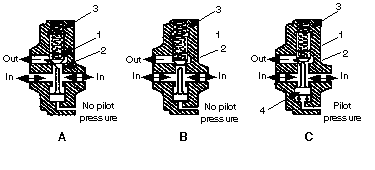

(3) Pilot-Operated Type

(Figure 5-19, page 5-13). In dia-

gram A, the valve has poppet 1

Figure 5-15. Vertical check valve

seated on stationary sleeve 2 by

spring 3. This valve opens the same as a

conventional check valve. Pressure at the

inlet ports must be sufficient to overcome

the combined forces of any pressure at the

outlet port and the light thrust of spring 3

so that poppet 1 raises and allows flow

from the inlet ports through the outlet

port. In this situation, there is no pressure

required at the pilot port.

In diagram B, the valve is closed to

prevent reverse flow. Pressure at the out-

let port and the thrust of spring 3 hold pop-

pet 1 on its seat to block the flow. In this

case, the pilot port has no pressure.

In diagram C, pressure applied at the

pilot port is sufficient to overcome the

thrust of spring 3. The net forces exerted

Figure 5-16. Spring-loaded check valve

Valves

5-11

FM 5-499

A

B

Figure 5-17. Standard check valve

Figure 5-18. Restriction check valve

5-12

Valves

FM 5-499

Figure 5-19. Pilot-operated check valve

by pressures at the other ports raise piston 4 to unseat poppet 1 and allow controlled flow

from the outlet to the inlet ports. With no pressure at the inlet ports, pilot pressure must exceed 40 percent of that imposed at outlet to open the poppet.

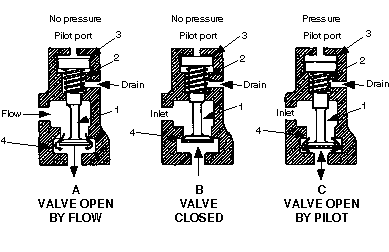

Figure 5-20 shows another pilot-operated check valve. This valve consists of poppet 1

secured to piston 3. Poppet 1 is held against seat 4 by the action of spring 2 on piston 3. In diagram A, the valve is in the free-flow position. Pressure at the inlet port, acting downward against poppet 1, is sufficient to overcome the combined forces of spring 2 against piston 3

and the pressure, if any, at the outlet port. (The pressure at the outlet port is exerted over a greater effective area than that at the inlet because of the poppet stem.) The drain post is open to the tank, and there is no pressure at the pilot port. Diagram B shows the valve in a position to prevent reverse flow, with no pressure at the pilot port and the drain opening to the tank.

Figure 5-20. Pilot-operated check valve, second type

Valves

5-13

FM 5-499

Diagram C shows the pilot operation of the valve. When sufficient pressure is applied at

the pilot port to overcome the thrust of spring 2 plus the net effect of pressure at the other ports, poppet 1 is unseated to allow reverse flow. Pilot pressure must be equal to about 80

percent of that imposed at the outlet port to open the valve and allow reverse flow.

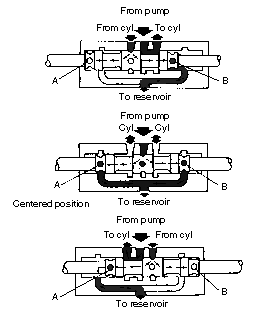

d. Two-Way Valve. A two-way valve is generally used to control the direction of fluid flow in a hydraulic circuit and is a sliding-spool type. Figure 5-21 shows a two-way, sliding-spool, directional-control valve. As the spool moves back and forth, it either allows or prevents fluid flow through the valve. In either shifted position in a two-way valve, a pressure port is open to one cylinder port, but the opposite cylinder port is not open to a tank. A tank port on this valve is used primarily for draining.

e. Four-Way Valves. Four-way, directional-control valves are used to control the direction of fluid flow in a hydraulic circuit, which controls the direction of movement of a work cylinder or the rotation of a fluid motor. These valves are usually the sliding-spool type. A typical four-way, directional-control valve has four ports:

•

One pressure port is connected to a pressure line.

•

One return or exhaust port is connected to a reservoir.

•

Two working ports are connected, by lines, to an actuating unit.

Four-way valves consist of a rectan-

gular cast body, a sliding spool, and a way

to position a spool. A spool is precision-

fitted to a bore through the longitudinal

axis of a valve’s body. The lands of a spool

divide this bore into a series of separate

chambers. Ports in a valve’s body lead

into a chamber so that a spool's position

determines which ports are open to each

other and which ones are sealed off from

each other. Ports that are sealed off from

each other in one position may be inter-

connected in another position. Spool posi-

tioning is accomplished manually,

mechanically, electrically, or hydrauli-

cally or by combing any of the four.

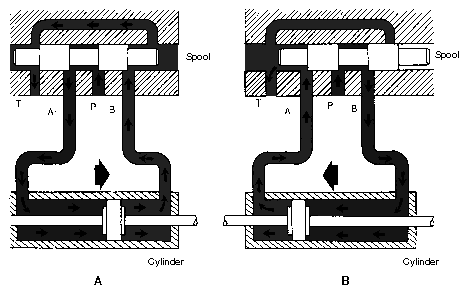

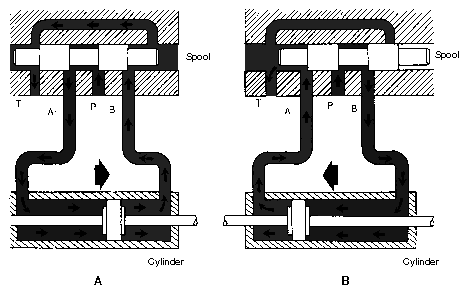

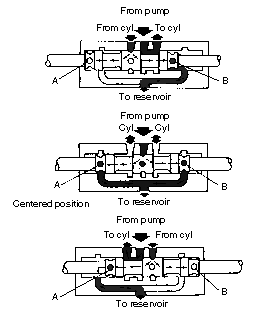

Figure 5-22 shows how the spool posi-

tion determines the possible flow condi-

tions in the circuit. The four ports are

marked P, T, A, and B: P is connected to

the flow source; T to the tank; and A and

B to the respective ports of the work cylin-

der, hydraulic motor, or some other valve

in the circuit. In diagram A, the spool is

in such a position that port P is open to

port A, and port B is open to port T. Ports

Figure 5-21. Two-way valve

A and B are connected to the ports of the

cylinder, flow through port P, and cause

5-14

Valves

FM 5-499

Figure 5-22. Flow conditions in a circuit

the piston of the cylinder to move to the right. Return flow from the cylinder passes through ports B and T. In diagram B, port P is open to port B, and the piston moves to the left.

Return flow from the cylinder passes through ports A and T.

Table 5-1, page 5-16, lists some of the classifications of directional-control valves. These valves could be identified according to the—

•

Number of spool positions.

•

Number of flow paths in the extreme positions.

•

Flow pattern in the center or crossover position.

•

Method of shifting a spool.

•

Method of providing spool return.

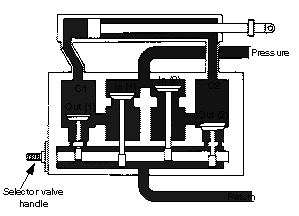

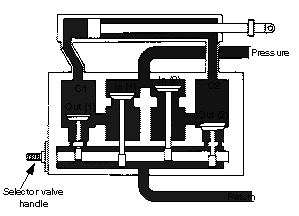

(1) Poppet-Type Valve. Figure 5-23, page 5-16, shows a typical four-way, poppet-type,

directional-control valve. It is a manually operated valve and consists of a group of conventional spring-loaded poppets. The poppets are enclosed in a common housing and are inter-

connected by ducts so as to direct the fluid flow in the desired direction.

The poppets are actuated by cams on the camshaft. They are arranged so that the

shaft, which is rotated by its controlling lever, will open the correct poppet combinations to direct the fluid flow through the desired line to the actuating unit. At the same time, fluid will be directed from the opposite line of the actuating unit through the valve and back to the reservoir or exhausted to the atmosphere.

Valves

5-15

FM 5-499

Table 5-1. Classifications of directional-control valves

Classification

Description

Path-of-flow type

Two way

Allows a total of two possible flow paths in two

extreme spool positions

Four way

Allows a total of four possible flow paths in two

extreme spool positions

Control type

Manual operated

Hand lever is used to shift the spool.

Pilot operated

Hydraulic pressure is used to shift the spool.

Solenoid action is used to shift the spool.

Solenoid operated

Solenoid action is used to shift the integral pilot

Solenoid controlled, pilot oper-

spool, which directs the pilot flow to shift the main

ated

spool.

Position type

Two position

Spool has two extreme positions of dwell.

Spool has two extreme positions plus one interme-

Three position

diate or center position.

Spring type

Spring offset

Spring action automatically returns the spool to the

normal offset position as soon as shifter force is

released. (Spring offset is always a two-way

No spring

valve.)

Spool is not spring-loaded; it is moved only by

shifter force, and it remains where it is shifted (may

be two- or three-position type, but three-position

Spring centered

type uses detent).

Spring action automatically returns the spool to the

center position as soon as the shifter force is

released. (Spring-centered is always a three-

position valve.)

Spool type

Open center

These are five of the more common spool types.

Closed center

They refer to the flow pattern allowed when the

Tandem center

spool is in the center position (three-position

Partially closed center

valves) or in the cross-over position (two-position

Semi-open center

valves).

Springs hold the poppets to their

seats. A camshaft unseats them to

allow fluid flow through the valve.

The camshaft is controlled by moving

the handle. The valve is operated by

moving the handle manually or by

connecting the handle, by mechanical

linkage, to a control handle. On the

camshaft are three O-ring packings

to prevent internal and external leak-

age. The camshaft has two lobes

(raised portions). The contour

(shape) of these lobes is such that

when the shaft is placed in the neu-

tral position, the lobes will not touch

any of the poppets.

Figure 5-23. Working view of poppet-type, four-

way valve

5-16

Valves

FM 5-499

One cam lobe operates the two pressure poppets; the other lobe operates the two return/

exhaust poppets. To stop the rotating camshaft at the exact position, a stop pin is secured to the body and extended through a cutout section of the camshaft flange. This stop pin prevents overtravel by ensuring that the cam lobes stop rotating when the poppets have

unseated as high as they can go.

Figure 5-23 shows a working view of a poppet-type, four-way valve. The camshaft

rotates by moving the control handle in either direction from neutral. The lobes rotate,

unseating one pressure poppet and one return/exhaust poppet. The valve is now in a work-

ing position. Pressure fluid, entering the pressure port, travels through the vertical fluid passages in both pressure poppet seats. Since only one pressure poppet is unseated by the

cam lobe, the fluid flows past the open poppet to the inside of the poppet seat. It then flows out one working port and to the actuating unit. Return fluid from the actuating unit enters

the other working port. It then flows through the diagonal fluid passages, past the unseated return poppet, through the vertical fluid passages, and out the return/exhaust port. By

rotating the camshaft in the opposite direction until the stop pin hits, the opposite pressure and return poppets are unseated, and the fluid flow is reversed. This causes the actuating

unit to move in the opposite direction.

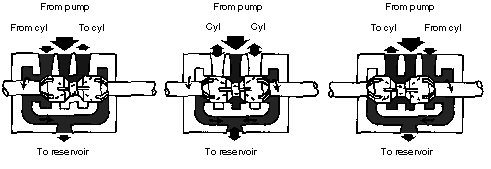

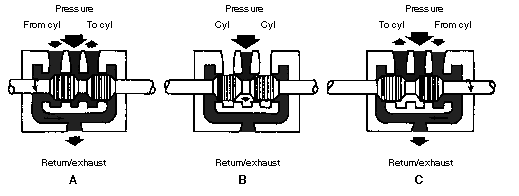

(2) Sliding-Spool Valve. The four-way, sliding-spool, directional-control valve is simple

in operation principle and is probably the most durable and trouble free of all four-way,

directional-control valves in current use. Figure 5-24 shows a typical four-way, sliding-

spool, directional-control valve. The valve body contains four fluid ports: pressure, return/

exhaust, and two working ports (referred to as cylinder ports). A hollow steel sleeve fits into the main bore of the body. Around the outside diameter of the sleeve are O-ring gaskets.

These O-rings form a seal between the sleeve and the body.

In Figure 5-24, diagram A, the valve is at the far right in its cylinder. Liquid from the

pump flows to the right end of the cylinder port, while liquid from the left end returns to the reservoir. In diagram C, the situation is reverse. The piston is to the far left in its cylinder.

Liquid from the pump flows to the left end of the cylinder port, while liquid from the right

end returns to the reservoir. In diagram B, the piston is in an intermediate position. Flow through the valve from the pump is shut off, and both ends of the cylinder can drain to the

Figure 5-24. Schematic of a four-way, directional-control, sliding-spool valve

Valves

5-17

FM 5-499

reservoir unless other valves are set to control the flow.

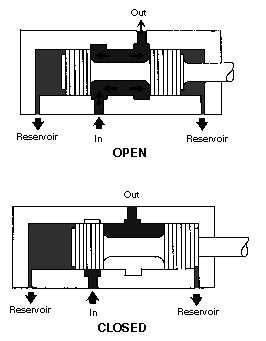

In a closed-center spool valve, a piston is solid, and all passages through a valve are blocked when a piston is centered in its cylinder (see Figure 5-24, diagram B). A closed-center valve is used when a single pump or an accumulator performs more than one operation and where

there must be no pressure loss in shifting a stroke direction at a work point.

In an open-center spool valve, the spools on a piston are slotted or channeled so that all

Figure 5-25. Closed-center spool valve

passages are open to each other

when a piston is centered (see Figure

5-25). In some open-center valves,

passages to a cylinder port are

blocked when a valve is centered and

liquid from a pump is carried

through a piston and out the other

side of a valve to a reservoir (see Fig-

ure 5-26). Liquid must be carried to

both ends of a piston of a directional

valve to keep it balanced. Instead of

discharging into a reservoir when a

valve is centered, liquid may be

directed to other valves so that a set

of operations is performed in

sequence.

Open-center valves are used

when a work cylinder does not have

to be held in position by pressure and

where power is used to perform a sin-

gle operation. These valves also

avoid shock to a system when a valve

spool is moved from one position to

another, since in the intermediate

Figure 5-26. Open-center spool valve

5-18

Valves

FM 5-499

position, pressure is temporarily relieved by liquid passing from a pump directly to the res-

ervoir.

(3). Manually Operated Four-Way Valve. This valve is used to control the flow direction

manually. A spool is shifted by operating a hand lever (Figure 5-27, page 5-20). In a spring-offset model, a spool is normally in an extreme out position and is shifted to an extreme in

position by moving a lever toward a valve. Spring action automatically returns both spool

and lever to the normal out position when a lever is released. In a two-position, no-spring

model, a spool is shifted back to its original position. (Figure 5-27 does not show this valve.) In a three-position no-spring model, a detent (a devise which locks the movement) retains a

spool in any one of the three selected positions after lever force is released. In a three-position, spring-centered model, a lever is used to shift a spool to either extreme position away from the center. Spring action automatically returns a spool to the center position when a

lever is released.

(4) Pilot-Operated, Four-Way Valve. This type of valve is used to control the flow direc-

tion by using a pilot pressure. Figure 5-28, page 5-21, shows two units in which the spool is shifted by applying the pilot pressure at either end of the spool. In the spring-offset model, the spool is held in its normal offset position by spring thrust and shifted to its other position by applying pilot pressure to the free end of the spool. Removing pilot pressure shifts the

spool back to its normal offset position. A detent does not hold this valve, so pilot pressure should be maintained as long as the valve is in the shifted position.

(5) Solenoid-Operated, Two- and Four-Way Valves. These valves are used to control the

direction of hydraulic flow by electrical means. A spool is shifted by energizing a solenoid that is located at one or both ends of the spool. When a solenoid is energized, it forces a push rod against the end of a spool. A spool shifts away from the solenoid and toward the opposite end of the valve body (see Figure 5-29, page 5-21). In a spring-offset model, a single solenoid shifts a spring-loaded spool. When a solenoid is deenergized, a spring returns a spool to its original position.

5-3. Flow-Control Valves. Flow-control valves are used to control an actuator’s speed by metering flow. Metering is measuring or regulating the flow rate to or from an actuator. A

water faucet is an example of a flow-control valve. Flow rate varies as a faucet handle is

turned clockwise or counterclockwise. In a closed position, flow stops. Many flow-control

valves used in fluid-powered systems are similar in design and operation to a water faucet’s.

In hydraulic circuits, flow-control valves are generally used to control the speed of

hydraulic motors and work spindles and the travel rates of tool heads or slides. Flow-control valves incorporate an integral pressure compensator, which causes the flow rate to remain

substantially uniform regardless of changes in workload. A nonpressure, compensated flow

control, such as a needle valve or fixed restriction, allows changes in the flow rate when

pressure drop through it changes.

Variations of the basic flow-control valves are the flow-control-and-check valves and the

flow-control-and-overload relief valves. Models in the flow-control-and-check-valve series

incorporate an integral check valve to allow reverse free