•

Perform repairs, taking time to do the job well.

a. Causes of Improper Operations. If improper operation does occur, the cause can generally be traced to one of the following:

•

Use of the wrong oil viscosity or type.

•

Insufficient fluid in the system.

•

Presence of air in the system.

•

Mechanical damage or structural failure.

•

Internal or external leakage.

•

Dirt, decomposed packing, water, sludge, rust, and other foreign matter in the

system.

•

Improper adjustments.

•

Heat exchanger that is plugged, dirty, or leaking.

b. Testing a Hydraulic Circuit. To test complete or individual parts of a hydraulic circuit, use a hydraulic circuit tester (see para-

graph 2-8, page 2-18). The best tester to use is

a compact portable unit that can check flow,

pressure, and temperature.

c. Comparing Test Results with Specifica-

Steering column

tions. Hydraulic-powered systems are power-

transmission systems. The only purpose of the

components and the circuit is the controlled

transfer of power from the motor shaft to the

point of effective work.

fp

HP = --------

1, 714

Steering valve

Steering gear

where—

HP = hydraulic horsepower

f = flow, in GPM

Figure 6-24. Semi-integral power-

p = pressure, in psi

steering system

Circuit Diagrams and Troubleshooting

6-13

FM 5-499

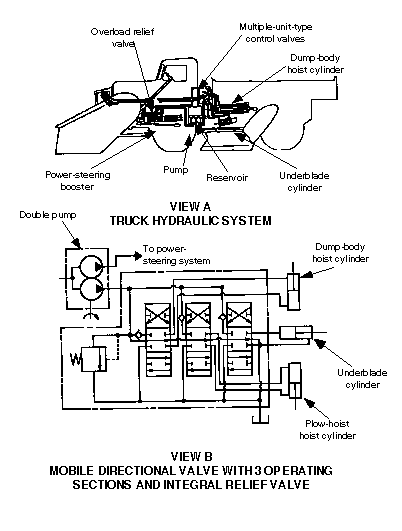

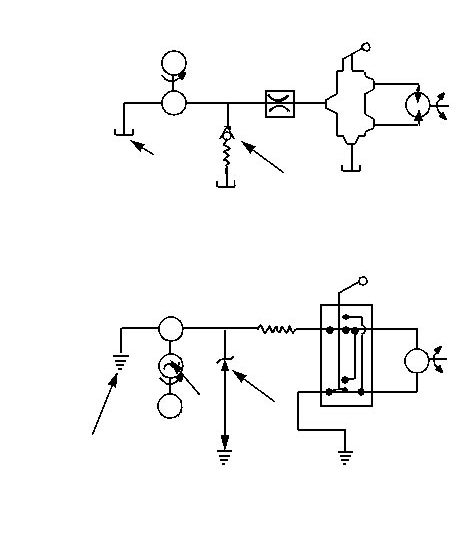

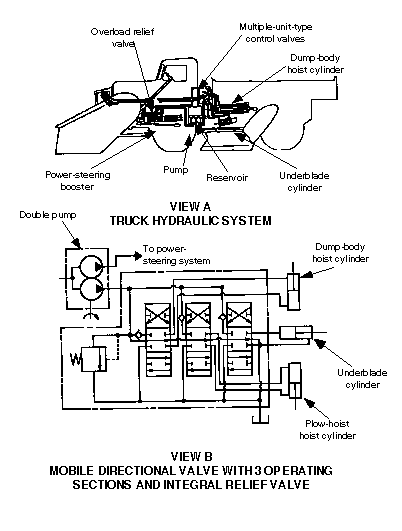

Figure 6-25. Hydraulic circuit diagram for a road-patrol truck

6-14

Circuit Diagrams and Troubleshooting

FM 5-499

By measuring those two factors at the same time, it is possible to read the effective out-

put at any point. Comparing test results with specifications will give the necessary fault-

finding facts.

d. Slippage. All hydraulic systems have some slippage (see paragraph 3-4, page, page 3-3) even when new. As wear increases, slippage at wear points increases, causing a

decrease in GPM. However, system pressure is maintained. In time, wear can be so great

that all flow is lost. Only at a complete breakdown will a pressure gauge show where the

trouble is. Conducting a flow, pressure, and temperature (FPT) test would have indicated

such a problem and avoided a complete breakdown.

NOTE: At low oil temperature and low pressure (or light loads) the

machine will continue to operate but at less speed.

e. Flow and Pressure. Always test flow and pressure together. Connect a hydraulic

tester into the hydraulic circuit at various points to isolate and check components (pumps,

valves, or cylinders) for efficiency. Figure 6-26 shows a hydraulic tester, connected to the pump's output, checking the flow at various pressures that, in turn, checks the pump's performance against the recommended specification. When isolating and testing individual

components with a hydraulic tester, direct the return fluid to the reservoir. If the fluid

returns to the reservoir through the system's piping, you will not get a correct reading

because of buildup of back pressure.

Test the

whole circuit as

TROUBLESHOOTING A HYDRAULIC SYSTEM

described, and

then isolate por-

tions and test

Isolate and check the following:

for a complete

analysis of the

• Directional-control valves

system. If a test

for leakage, efficiency.

on a full circuit

• System’s relief valves

indicates a mal-

for leakage, proper settings.

function, isolate

• Pump’s GPM flow at

a portion and

various pressures.

test the remain-

• Cylinder’s efficiency.

ing portions

until you find

the malfunction-

ing part. Gener-

ally, cylinders

Figure 6-26. Hydraulic tester connected to a pump’s output

will fail first.

Packing will

wear because of friction and loading against the cylinder walls. Therefore, isolate the cylinders first. If test results indicate that the circuit is operating properly, the cylinders have a problem. During testing, determine the setting and condition of the relief valve. If further tests are necessary, isolate the directional-control valve to check the pump's efficiency and inlet hose.

f. Other Conditions. Other problems could occur that are not directly related to nor caused by the various parts of the hydraulic system. These problems could show the same

Circuit Diagrams and Troubleshooting

6-15

FM 5-499

general malfunctions of an improperly operating system. Examples are leaking hose, pack-

ing glands, and seals, which would be visually evident; a bind in the directional-control

valve or the cylinder's piston rod; a dented or deformed hydraulic cylinder; or a crimped or

restricted pressure line, which would be harder to detect.

g. Specific Troubles, Causes, and Solutions. Tables 6-1 through 6-5, pages 6-17 through 6-21 list some possible problems and solutions in a hydraulic system.

6-16

Circuit Diagrams and Troubleshooting

FM 5-499

Table 6-1. Problems and solutions with pump operations

No Fuel Delivery

Problems

Solutions

Fluid level in the reservoir is low.

Add the recommended oil; check the level on both sides of

the tank's baffle to be certain that the pump suction is sub-

merged.

Oil intake pipe or inlet filter is plugged.

Clean the filter; otherwise, remove the obstruction.

Air leak in the inlet line prevents priming or causes

Repair the leaks.

noise and irregular action of the control circuit.

The pump shaft turns too slowly to prime itself

Check the appropriate manual's minimum speed recommen-

(vane-type pumps only).

dations.

The oil viscosity is too heavy to pick up the prime.

Use a lighter oil viscosity; follow the appropriate manual's

recommended temperatures and services.

Shaft rotates in the wrong direction.

Reverse the rotation immediately to prevent seizure and

parts from breaking due to lack of oil.

Pump shaft is broken, parts are broken inside the

See the appropriate manual for replacement instructions.

pump, or the shear pin or shear linkage is broken.

Pump has dirt in it.

Dismantle and clean the pump; flush the system.

The stroke is incorrect on variable delivery pumps.

See the appropriate manual for instructions.

No Pressure in the System

Pump does not deliver oil for any reasons given in

Follow the remedies given.

above section.

• Relief-valve setting is not high enough.

• Increase the pressure setting of the valve; check the

appropriate manual for the correct pressure.

• Relief valve leaks.

• Check the seat for score marks and reseat.

• Relief-valve spring is broken.

• Replace the spring and readjust the valve.

Vane is stuck in the rotor slots (vane-type pumps

Inspect for wedged chips; inspect the oil for excessive vis-

only).

cosity.

The head is loose (very infrequent occurrence).

Tighten the head; check the appropriate manuals before

tightening.

Oil to the tank recirculates freely through the sys-

Check to see if a return line is open due to either a direc-

tem.

tional valve set in the open-center neutral position or some

other valve is left open.

Control valves have internal leakage.

Block off various parts of the circuit to determine where the

leak is; repair when located.

Noisy Pump

Intake line, filter, or restricted intake pipe is partially

Clean out the intake or strainer, or eliminate the restrictions;

clogged.

ensure that the inlet line is open.

Circuit Diagrams and Troubleshooting

6-17

FM 5-499

Table 6-1. Problems and solutions with pump operations (continued)

Noisy Pump (continued)

Problems

Solutions

• Air leaks occur at the pump's intake piping joints.

• Pour oil on the joints while listening for a change in the

operating sounds; tighten the joints as required.

• Air leaks are present at the pump's shaft packing.

• Pour oil around the shaft while listening for a change in

the operating sounds; follow the appropriate manual

instructions when changing the packing.

• Air is drawn in through the inlet pipe openings.

• Ensure that the inlet and return lines are well below the oil

level in the reservoir; add oil to the reservoir if necessary.

Air bubbles are present in the intake oil.

Use hydraulic oil that has a foam depressant.

Reservoir's air vent is plugged.

Clean or replace the breather.

Pump is running too fast.

See the appropriate manuals for recommended maximum

speeds.

Oil viscosity is too high.

Use a lower oil viscosity; check the appropriate manuals for

the recommended temperatures and services.

Coupling is misaligned.

Realign the coupling.

Pump vane is stuck (vane-type pump).

Inspect the pump for wedged chips or sticky oil; reassemble.

Parts are worn or broken.

Replace worn or broken parts.

External Oil Leaks

Shaft packing is worn.

Replace the worn parts.

A head of oil is present on an inlet-pipe connection.

Keep all the joints tight; slight leakage may be necessary.

Excessive Wear

Abrasive matter in the hydraulic oil is being circu-

Install an adequate filter or replace the oil more often.

lated through the pump.

Oil viscosity is too low for working conditions.

Check the appropriate manual's recommendations or the

lubrication chart for information.

Sustained high pressure occurs above the maxi-

Check the relief or regular valve's maximum setting.

mum pump rating.

Drive is misaligned or belt drive is tight.

Check the parts; correct the problem.

Air recirculation is causing a chatter in the system.

Remove the air from the system.

Broken Parts Inside the Pump Housing

Excessive pressure above the maximum pump rat-

Check the relief or regulator valve's maximum setting.

ing is present.

Seizure occurs due to lack of oil.

Check the reservoir level, oil filter, and possibility of restric-

tion in the inlet line.

Solid matter is being wedged in the pump.

Install a filter in the suction line.

Head screws are too tight.

Check appropriate manual’s recommendations; adjust.

6-18

Circuit Diagrams and Troubleshooting

FM 5-499

Table 6-2. Problems and solutions with actuating mechanism

Inoperative System

Problems

Solutions

System fails because of any problem listed in

Follow recommened solution.

Tables 6-1 through 6-5.

Mechanism Creeps (Stopped in Intermediate Position)

Internal leakage occurs in the actuating cylinders or

Replace the piston packing or cylinder, if the walls are

operating valves.

scored; replace or repair the valve.

Longer Operating Times Than Specified

Air is present in the system.

Bleed the system.

Actuating cylinder or directional-control valve has

Replace the piston packing or replace the cylinder if the

an internal leak.

walls are scored; replace or repair the valve; clean the unit to

remove foreign matter; check the cam clearance.

Pump is worn.

Repair or replace the pump.

Action is sluggish on start up but less so after oper-

Check appropriate manual’s lubrication order.

ating temperatures have increased, or action slows

down after warm up. Depending on equipment and

circuit design, could indicate that the oil viscosity is

too high.

External Oil Leaks

End caps leak.

Tighten caps, if possible, or replace the gasket.

Chevron seals leak.

Adjust or replace the seals.

Abnormal Packing-Gland Wear

Cylinder is not securely fastened to the frame,

Tighten the cylinder; check it periodically.

causing it to vibrate.

Cylinder and piston-rod extension are misaligned.

Check the parts; correct the problem.

Side load occurs on the piston rod.

Check for cylinder alignment or worn pins or ball joints.

Circuit Diagrams and Troubleshooting

6-19

FM 5-499

Table 6-3. Problems and solutions with heating oil

Heating Caused by Power Unit (Reservoir, Pump, Relief Valve, Coolers)

Problems

Solutions

Relief valve is set at a higher pressure than neces-

Check manual for the correct pressure; reset the relief valve.

sary; excess oil dissipated through increased slip-

page in various parts or through the relief valve or

directional valve.

Internal oil leaks occur due to wear in the pump.

Repair or replace the pump.

Oil viscosity is too high.

Check appropriate manual for correct oil viscosity to use at

various temperatures.

Overhauled pumps may be assembled too tightly,

Follow the appropriate manuals when rebuilding a pump.

which reduces clearances and increases friction.

Pump has leaking check or relief valves.

Repair or replace the valves.

Oil cooler or coolant functions improperly in cut off.

Inspect cooler; clean inside and outside; ensure that air flow

or coolant flow around fins is not cut off.

Conditions in System Cause Excessive Heating

Lines are restricted.

Replace the lines if they are crimped; remove any obstruc-

tion if lines are partially plugged.

Large pump deliveries do not unload properly.

Ensure that the open-center valves are neutralized and that

any pressure-relieving valves are in the correct position.

(Allow only small pumps to stay at high pressures when run-

ning idle for long periods.)

Radiation is insufficient.

Use artificial cooling.

Pump has internal leaks.

Locate leaks; replace the packing.

Reservoir is too small to provide adequate cooling.

Replace unit with a larger reservoir.

Valves or piping is undersized.

Check flow velocity through the lines and valves; compare

them with the manual’s recommendations. If velocity is

excessive, install larger equipment.

6-20

Circuit Diagrams and Troubleshooting

FM 5-499

Table 6-4. Problems and solutions with fluid motors

Motor Turns in the Wrong Direction

Problems

Solutions

Conductors are crossed between the control valve

Check circuit to determine the correct conductor connection

and the motor.

between the control valve and motor.

Motor Does Not Turn or Does Not Develop Proper Speed or Torque

System’s overload-relief-valve adjustment is not set

Check system’s pressure; reset the relief valve.

high enough.

Relief valve sticks open.

Clean or replace the relief valve; adjust.

Oil to the reservoir freely recirculates through the

Check control-valve linkage; directional-control valve may be

system.

in open-center neutral.

Driven mechanism binds because of misalignment.

Check the motor shaft for alignment.

Pump does not deliver enough GPM or pressure.

Check pump’s GPM and pressure; repair or replace.

Motor yoke is not set at the proper angle.

Adjust the pump’s yoke angle.

External Oil Leak From the Motor

Seals leak (drain may not be connected from motor

Check motor for 3rd line (a drain line that must go to tank

to tank).

used on piston and vane motors).

NOTE: See Table 6-1 for improper operation of pump.

Table 6-5. Problems and solutions with accumulator operation

Sudden Drop in Accumulator Pressure (Position of Selector Valve is Changed)

Problems

Solutions

Accumulator has an internal or external leak.

Repair the leak or replace the accumulator.

No Pressure When Pump Stops Running (Normal Pressure When Pump Was Running)

Hydraulic line has a leaking gas or check valve.

Replace the check or the gas valve.

Sluggish Response for Accumulator

Oil screen in the accumulator stops.

Dismantle the accumulator; clean the screen.

Gas precharge is not sufficient.

Precharge according to recommendations in the manual;

check for gas leaks.

NOTE: Release all internal pressure before making repairs on accumulators.

Circuit Diagrams and Troubleshooting

6-21

FM 5-499

CHAPTER 7

Electrical Devices:

Troubleshooting and Safety

This chapter describes the process of locating the cause of malfunctions in electrical circuits associated with hydraulic-control systems. The information includes testing devices and types of grounding points. Also addressed in this chapter are the safety measures personnel should take when working on or around electrical circuits.

7-1. Hydraulics and Electricity. Hydraulics and electricity are often compared because the systems have similarities. A hydraulic circuit requires a power source (usually a pump), a load device (actuator), and conductors. The circuits differ mainly in the—

• Types of devices used to control, direct, and regulate the hydraulic fluid flow.

• Type and capacity of the actuators used to accomplish the work, which varies,

depending on the application.

An electrical circuit also requires a power source (battery, generator), a load device

(light, bell, motor), and proper connections. An assortment of devices also controls, directs, and regulates the flow of electrical current.

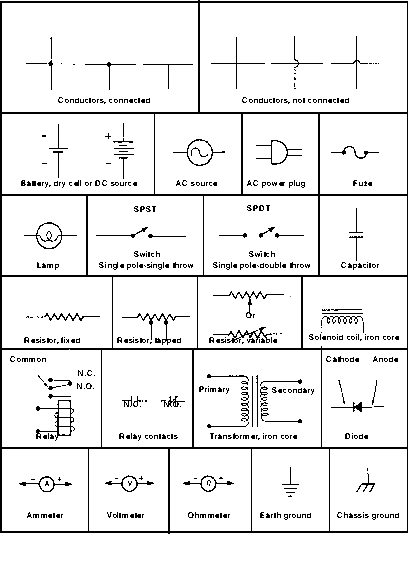

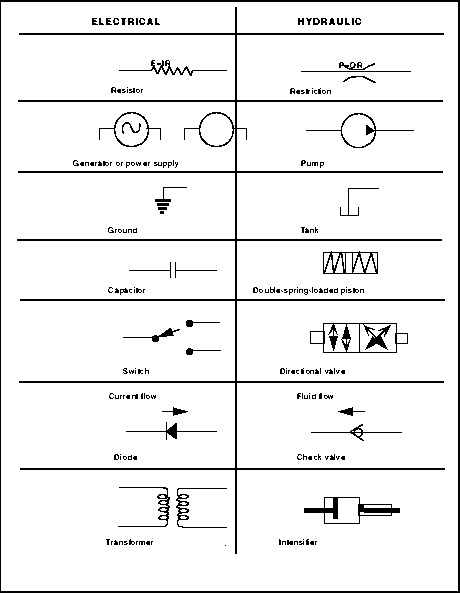

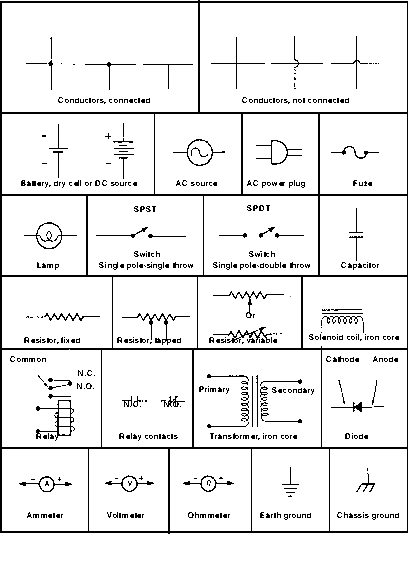

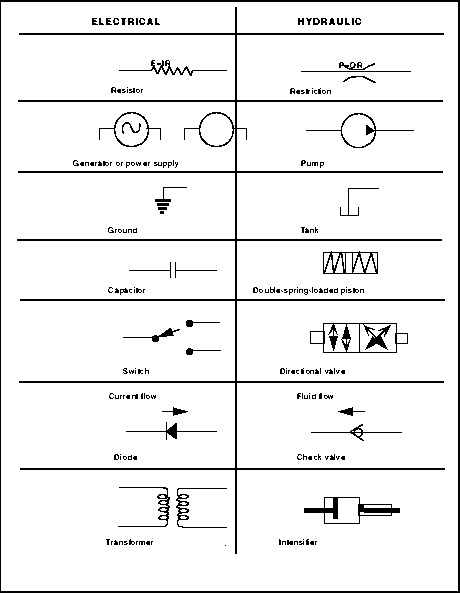

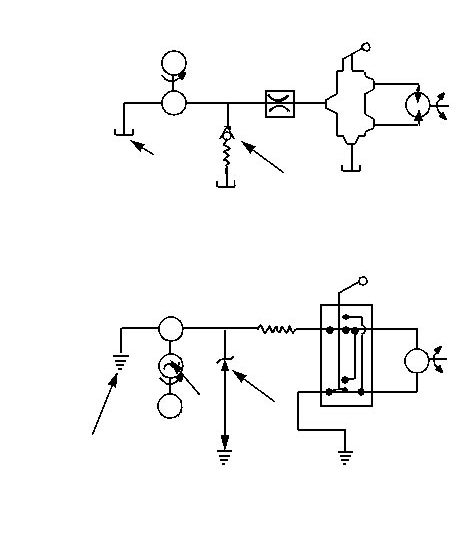

Hydraulic and electrical components are usually represented on diagrams by their own

set of standardized symbols. Electrical diagrams are often called schematics. Figure 7-1,

page 7-2, shows some of the more common symbols. Hydraulic and electrical systems and

circuits have many differences. For example, electrical current is invisible, hydraulic fluid is not; electrical current flows through solid wires, hydraulic fluid flows through hollow lines.

Figure 7-2, page 7-3, shows symbols for electrical and hydraulic components. Figure 7-3,

page 7-4, compares a hydraulic circuit and an electrical circuit.

7-2. Troubleshooting Electrical Devices. Electrical troubleshooting is the process of locating the cause of malfunctions in electrical circuits. The following paragraphs contain

some general troubleshooting information as well as specific tests for determining the status of some electrical devices. Skill in troubleshooting electrical equipment and circuits

requires—

• Knowledge of electrical principles to understand how a circuit or device should func-

tion.

• Skill in reading and interpreting electrical schematics, diagrams, product data, and

so forth.

• Skill in operating test equipment and interpreting test measurements.

• Ability to analyze problems in a logical manner.

Following systematic steps that narrow down the problem to a smaller area of the

equipment is much more efficient than trial-and-error methods. The troubleshooting

Electrical Devices: Troubleshooting and Safety

7-1

FM 5-499

Figure 7-1. Common electrical schematic symbols

7-2

Electrical Devices: Troubleshooting and Safety

FM 5-499

Figure 7-2. Comparison of electrical and hydraulic components

Electrical Devices: Troubleshooting and Safety

7-3

FM 5-499

Directional valve

Power source

M

Motor

Load

(motor)

Pressure drop

Pump

(Restriction

orifice)

Pressure reference

(tank)

Regulation

(relief valve)

HYDRAULIC CIRCUIT

Directional switch

Power source

Power supply

Voltage drop

(Resistor)

Generator

Load

(motor)

Motor

M

Regulation

(zener diode)

Voltage reference

(ground)

ELECTRICAL CIRCUIT

Figure 7-3. Comparison of electrical and hydraulic circuits

7-4

Electrical Devices: Troubleshooting and Safety

FM 5-499

procedure detailed below can be very useful in organizing the problem-solving effort and

reducing equipment downtime:

a. Procedure.