2

3

4

5

6

7

Time in s

Fig. 13c. Results – min torque priority

256

New Approaches in Automation and Robotics

By changing the weighting factors it is also possible to shift the focus more towards other

attributes. For instance one can achieve a reduction of the waste gas emission by a setpoint

for corresponding λ=1 and increasing the weighting factors of the lambda path.

The results are shown in figure 13c for the same setpoint and load steps as in the example

above. It is visible that the torque adjustment is (compared to figure 13a) slower and the

controller output for the fuel path is used only marginally.

6

5

4

m

3

rque in N

Torque setpoint

To 2

Torque

1

0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3

Time in s

30

20

m

Torque (fresh air)

Torque (exhaust gas)

10

Torque (ignition angle)

rque in N

Torque (lambda)

To

0

-10

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

3

Time in s

Fig. 13d. Results – min torque priority

As mentioned in section 2 the described control approach allows to switch smoothly

between torque, speed or acceleration control. This can be simply achieved by the model

extension (described in section 2, equation 3) and appropriate weighting parameters for the

MPC. Only by shifting the weighting factors one can switch from speed control to torque

control and back.

The plots in figure 14 demonstrate how this control mode works. In this example we used

only the fresh air and the ignition path for torque control. Up to 3 seconds the controller

should work as a speed controller. From then it should work as a torque controller. At

approximately 6 seconds the weighting factors where switched back to speed control mode

values. Equation 21 represents the linear model which is used internally by the MPC for this

example.

⎛

Torque

Engine

⎞ ⎛ G ( s) G ( s)

11

12

⎞

⎜

⎟

⎜

⎟ ⎛ Torque

Setpoint

Air

Fresh

⎞

⎜

Speed

Engine

⎟ = ⎜ G ( s) G ( s)

(21)

21

22

⎟ ⋅⎜⎜

⎟⎟

⎜

⎟ ⎜

⎟ ⎝Δ TorqueI

⎠

⎝Δ

Setpoint

Angle

gnition

Torque

0

G ( s)

Angle

Ignition

⎠ ⎝

32

⎠

Advanced Torque Control

257

Switching between speed and torque control can simply be realized by changing some

weighting factors. The behaviour of the MPC changes automatically. This is a very

convenient way to change for instance to the idle speed control mode and back to torque

control.

In figure 14 first the speed control is active. The speed follows the desired characteristic

whereas the torque is different from the corresponding setpoint. After changing the

weighting factors the torque will be adjusted to the setpoint and the engine speed is only

marginally considered by the controller.

Time period in

Active

Torque weighting

Speed weighting

s

Control

factor

factor

0 … 2.5

Speed control

0

1

Torque

2.5 …6

1 0

control

6 … 8.5

Speed control

0

1

Table 1. Enabled control

m 1100

p

r 1000

Speed Setpoint

in

900

Speed

eed

800

p

0

1

2

3

4

5

6

7

8

S

Time in s

m N

20

in -2

-4

Torque Setpoint

-6

que

Torque

-8 0

1

2

3

4

5

6

7

8

Tor

Time in s

m 30

N

Torque about Fresh Air

20

in

Torque about Ignition Angle

10

que

0 0

1

2

3

4

5

6

7

8

Tor

Time in s

m 6

N

4

Load Torque

in 2

que 0 0

1

2

3

4

5

6

7

8

Tor

Time in s

Fig. 14. Speed and Torque Control

258

New Approaches in Automation and Robotics

At approximately 6 seconds the engine speed control mode was activated again. The speed

should decrease here from the current value smoothly along a given trajectory. It is visible

in figure 14 that the controller solves the differing control tasks properly. In the third plot

(from the top) one can see also that the ignition path control variable is used transient by the

controller. Stationary the setpoint is adjusted.

5. Conclusion

In the chapter we discussed a control approach for torque control of gasoline engines.

Because of several actuating variables and control requirements the process to be controlled

is multivariable. The actuating variables are usually bounded and the effects on the engine

torque are nonlinear. Hence direct use of the actuator variables for torque control generally

produces plenty of problems.

The two layer approach described in the chapter allows the application of standard control

methods. The main idea of the control structure is to compensate or alleviate the

nonlinearity behaviour by subordinate control circuits. All the physical actuating variables

are substituted by setpoints of the subordinate systems. The torque controller so can be

designed on base of linear models. Additionally only bounds of some control variables have

to be considered.

An appropriate standard control concept for the superordinate torque controller is the

model predictive control principle. For the implementation we used a state space approach.

The optimization problem is solved by the active set algorithm. For lower computation

effort a solution with constant parameters was introduced. But this solution doesn't consider

constraints and loss performance can occur.

The three examples in section 4 show the capability of the control concept. The extension of

the control structure is possible simply by completing the model and appropriate weighting

parameters. In this way the controller should be able to handle more actuating variables or

other requirements.

The control quality depends on the quality of the model. Although the subordinate control

circuits contribute to the linearization of the process behaviour the dynamic parameters may

be dependent on engine speed or load. For that case a set of linear models could be useful.

The control approach described in this chapter demonstrates that modern control

approaches have considerable potential to improve the performance of embedded control

systems. In addition to better performance also the variability of the systems and the ability

to handle different control requirements could improve.

6. References

Auckenthaler, T.S. (2005). Modelling and Control of Three-Way Catalytic Converters,

Institute of Technology, Zürich, Dissertation

Back, M. (2005). Prädiktive Antriebsregelung zum energieoptimalen Betrieb von

Hybridfahrzeugen, Institut für Regeluns- und Steuerungssysteme Universität

Karlsruhe, Dissertation

Bauer, H. (2003): Ottomotor-Management: Systeme und Komponenten, Friedr. Vieweg &

Sohn Verlagsgesellschaft mbH

Advanced Torque Control

259

Brand, D. (2005). Control-Oriented Modeling of NO Emissions of SI Engines, Institute of

Technology, Zürich, Dissertation

Basshuysen, R. van; Schäfer, F. (2002): Handbuch Verbrennungsmotor – Grundlagen,

Komponenten, Systeme und Perspektiven, Vieweg und Sohn Verlagsgesellschaft

mbH, Braunschweig/Wiesbaden

Dittmar, R.; Pfeiffer, B. (2004). Modellbasierte prädiktive Regelung, Oldenbourg Verlag

München, Wien

Dünow, H.-P. (2004). Anwendung Modellprädiktiver Regelungen, Forschungsbericht,

Hochschule Wismar, Fachhochschule für Technik, Wirtschaft und Gestaltung –

Fachbereich Elektrotechnik und Informatik

Dünow, H.-P.; Lekhadia, K.N.; Köller, M.; Jeinsch, T. (2005). Model based predictive control

of spark ignition engine, Proceedings of MMAR

Fletscher, R.R (1987). Practical Methods of Optimization, Wiley, 2nd edition

Fritzsche, C.; Dünow, H.-P.; Lampe, B.; Schultalbers, M. (2007). Torque Coordination of

Spark Ignition Engines based on Predictive Control, Proceedings of MMAR,

Szczecin, Poland

Gill, P.E.; Murray, W.; Wright, M.H. (1991). Numerical Linear Algebra and Optimization,

Volume 1, Addison Wesley

Grimble, M.J. (2001). Industrial Control Systems Design, John Willey & Sons, LDT

Chichester, New York, Weinheim, Brisbane, Singapore and Toronto

Grohe, Heinz (1990). Otto- und Dieselmotoren, Vogel Fachbuchverlag, Auflage 9,

Würzburg, Germany

Guzella, L. and Onder, C.H. (2004). Introduction to Modeling and Control of Internal

Combustion Engine Systems, Springer Verlag Berlin, Heidelberg, Germany

Johansen, T.A. (1994). Operating Regime based Process Modelling and Identification, PhD

Thesis, Department of Engineering Cybernetics – The Norwegian Institute of

Technology – University of Trondheim

Johansen, T.A.; Murray-Smith, R. (1997). Multiple Model Approaches to Modelling and

Control, Taylor & Francis London

Kristoffersson, I. (2006). Model Predictive Control of a Turbocharged Engine, School of

Electrical Engineering and Information Technology, Stockholm

Lekhadia, K.N.; Dünow, H.-P.; Jeinsch, T. (2004). Active Set Method Approach for Real Time

Model Predictive Engine Control, In: Modellierung, Regelung und Diagnose von

Verbrennungsmotorprozessen, 2. ASIM Workshop Wismar

Lekhadia, K.N. (2004a). Development of OP Algorithms for Real-Time Predictive Control

Systems, Master Thesis, FH Darmstadt

Maciejowski, J.M. (2002). Predictive Control with constraints, Prentice Hall

Pulkrabek, Willard (2004). Engineering Fundamentals of the Internal Combustion Engine,

Prentice Hall

Rückert, J.; Richert, F.; Schlosser, A.; Abel, D.; Herrmann, O.; Pfeifer, A.; Pischinger, S.

(2003). Konzepte zur Regelung von Ladedruck und AGR-Rate beim Nutzfahrzeug-

Dieselmotor, GMA-Kongress – VDI-Berichte 1756, VDI-Verlag Düsseldorf

260

New Approaches in Automation and Robotics

Salgado, M.E.; Godwin, G.C.; Greabe, S.F. (2001). Control System Design, Prentice Hall

London

Urlaub, Alfred (1995). Verbrennungsmotoren – Grundlagen, Verfahrenstheorie,

Konstruktion, Springer Verlag Berlin, Heidelberg, Germany

15

Design, Simulation and Development of

Software Modules for the Control of Concrete

Elements Production Plant

Georgia Garani and George K. Adam

Technological Educational Institute of Larissa

Dept. of Informatics and Telecommunications

41110 Larissa

Greece

1. Introduction

Manufacturing and control procedures for automation require many different technologies.

The last decade has seen computer technology applied widely in industrial production,

particularly in manufacturing processes not generally associated with high technology. The

technology used in the automated production of moulded concrete elements for the

architectural and building industry has changed dramatically in recent years. The

introduction of Computer Integrated Manufacturing (CIM) between 1960 and 1980 (Trybula

& Goodman, 1989), e.g., numerically controlled machines, followed in the 1980 to 1990

developments in robotics, e.g., advanced robotics (Shell & Hall, 2000) had a significant

impact on automating the production of moulded concrete elements.

The types of system that produce concrete elements are mainly machines using hydraulic

compression and extraction. This is the most common method used to form the complex

product shapes required by the architectural and building industry. These machines can be

either stationary, or they can be mobile, with automated mobile machines being the machine

of preference these days. Other relevant ancillary equipment used in the automated

production of concrete elements are aggregate mixers, material storage silos and conveyors.

The concrete elements required by architects and builders often include complex geometric

shapes; it is for this reason that the central process in their production is the hydraulic press.

Complex geometric shapes in concrete and their quality control can only produced using

automated compression machinery (Isayev, 1987; Reinhart, 1987). The various phases of this

process are (1) material mixture; aggregates of variable form tightly compressed into a

mould and (2) compression to form and extract the desired product.

The application of computer aided systems to hydraulic press machines has increased the

range and variety of concrete elements that these machines can produce for the architectural

and building industry (e.g., ZENITH, KNAUER, BESSER, etc.). The consistency and quality

control of landscape and architectural products, such as concrete blocks, curb stones,

palisades, paving stones, etc., has improved through introducing computer aided systems.

Computer-control systems, teleoperation and automation technology, modelling and

simulation tools are some of the technologies and techniques used to acquire the desired

262

New Approaches in Automation and Robotics

functionality in operation control and quality in production (Chryssolouris, 1992; Gutta &

Sinha, 1996; Marvel & Bloemer, 2000).

However, quite often various problems arise during the attempt of systems modelling and

control, in most cases due to insufficient structuring of the system in the real world. In these

cases, usually artificial intelligence techniques are being applied (Fishwick & Luker, 1991;

Hwang et. al., 1995). For this reason, the design and control of automated production system

requires an effective development system that enables the design specifications to be

implemented and tested prior to the actual implementation and control of the production

system. The generation and implementation of such systems has become essential to the

development of automated production systems (Rao et al., 1993; Nise, 1995; Shetty & Kolk,

1997; Srovnal & Pavliska, 2002).

Qualitative modelling approaches have been applied for a long period of time with quite

successful results in most of the cases (Forbus, 1984; Groumpos & Krauth, 1997; de Kleer &

Brown, 1984; Trave-Massuyes, 1992; Garani & Adam, 2007). One of the aims of this research

was to accomplish an adequate control structure for a synchronised co-operation of the

plant machines. Previous work on applications of qualitative modelling techniques (Adiga

& Gadre, 1990; Lamperti & Zanella, 2003; Mak et. al., 1999; Zhang et. al., 1990) shows that

there is still further need of work to be carried out for the development of highly intelligent

qualitative modelling approaches.

This chapter presents the application of design, simulation and software development

techniques for the operation and control of a concrete elements production plant and

particularly, an automated mobile press machine (RoboPress). Teleoperation is required in

operating the mobile press machine for performing the actual production procedures. The

plant is consisted of various machines such as a press machine for concrete elements

production, a mixing machine for aggregates mixing, aggregates storage silos, transport

buckets and conveyors, etc. The design, operation and control of a concrete mixer machine

and an autonomous mobile hydraulic press machine are discussed in detail. The whole

system automates the production of moulded concrete elements for architectural and

building projects. The research work demonstrates how the design of a state-of-the-art

industrial plant can be optimised by using qualitative modelling and simulation from

artificial intelligence and other engineering software tools. Further on, it shows how an

efficient control algorithm for operating the group of machines can be derived from a

qualitative modelling approach.

The rest of this chapter is structured as follows: the following section describes the

application environment of this research; in section 3 a detailed description of the overall

plant control system is provided; section 4 provides details of the modelling and simulation

techniques used for the development and verification of the overall system’s operation and

control algorithm prior to its implementation; in section 5 details are given for the system

performance evaluation and implementation procedures of the software control modules

and algorithms. The chapter is concluded in section 6, which presents the outcomes and

future research work.

2. Application environment

The concrete plant under investigation and control is consisted of a group of machines

including a mobile press machine for the concrete elements production, an aggregates’

mixing machine, aggregates’ storage silos, a forklift loader, feeding conveyors, etc. Other

Design, Simulation and Development of Software Modules for the Control of

Concrete Elements Production Plant

263

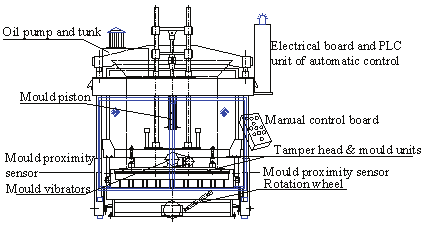

basic machine components include the electronic control board based on a Hitachi EC series

programmable logic controller of type EC-60HRP. That unit offers up to 60 I/O points,

direct PC connection (RS232) and monitoring. A number of solid state inductive proximity

sensors of Telemecanique type XS7C40NC440 for industrial applications and PLC

compatible are employed, in perfect compatibility with the electronic automated system for

presence detection. The overall control is based on a closed-loop control system, with the

PLC unit to control real-time processes, under the operator’s control. The driving force

behind the above control system is the control software, the creation of which is based on

the construction and execution of descriptive qualitative models.

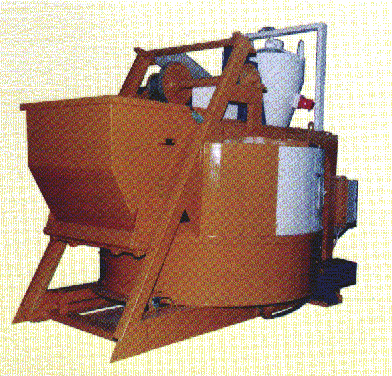

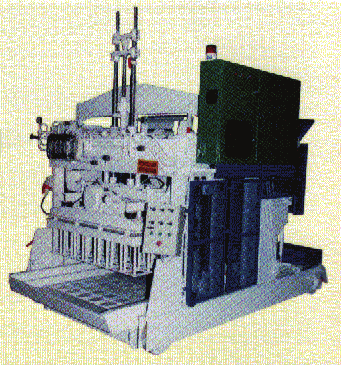

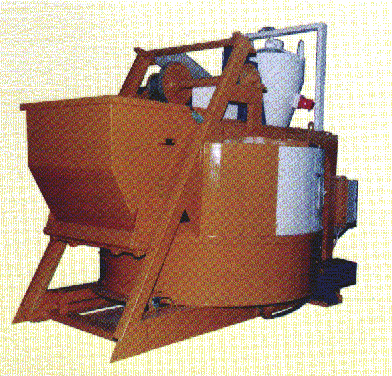

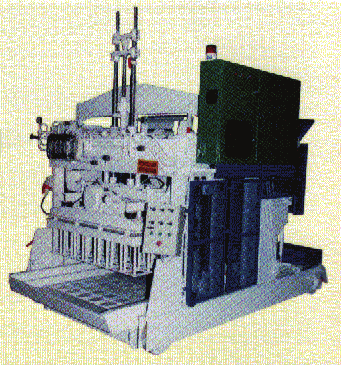

The concrete elements production of the plant varies from 6000 blocks per day (8hours) up

to 14000. Two of the main machines of interest, press and mixer machine, are shown in Fig.

1 while an overall configuration of the concrete plant is shown schematically in Fig. 2.

Fig. 1. Press and mixer machines

cement silo mixer

press

machine

machine

forklift

aggregates silos

concrete elements

mixer loader

conveyor

Fig. 2. Concrete plant configuration

The press and mixer machines are constructed mainly of mechanical and electrical parts and

devices, incorporating electrical boards, PLC units and other electronic equipment.

Basically, the plant operates as follows: aggregates from the storage silos are being supplied

through a feeding conveyor into the mixer machine and the wet concrete produced is

transported by a forklift loader into the press machine for the actual production of the

concrete elements. A simplified functional diagram of plant’s overall operation cycle is

shown in Fig. 3.

264

New Approaches in Automation and Robotics

press

concrete

blocks

out

forklift

loader

aggregates silos

in

mixer

Fig. 3. Plant’s operation cycle

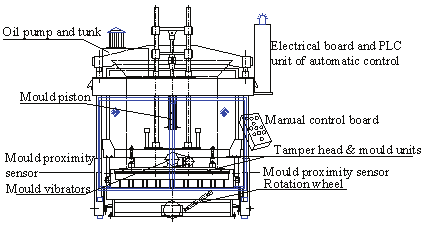

2.1 The mobile press machine

The press machine is one of the most important production units of the concrete plant (Fig.

4). The machine produces a variety of concrete products such as blocks, curbs, paving

stones, etc. It is consisted mainly of mechanical and electrical parts and devices, the

electrical board and the electronic control system based on a PLC unit (Hitachi EC series)

and other electronic equipment. The machine is mobile, based on a four wheels metallic

base. Other basi