Revolutionary technology. Motor Magnetar

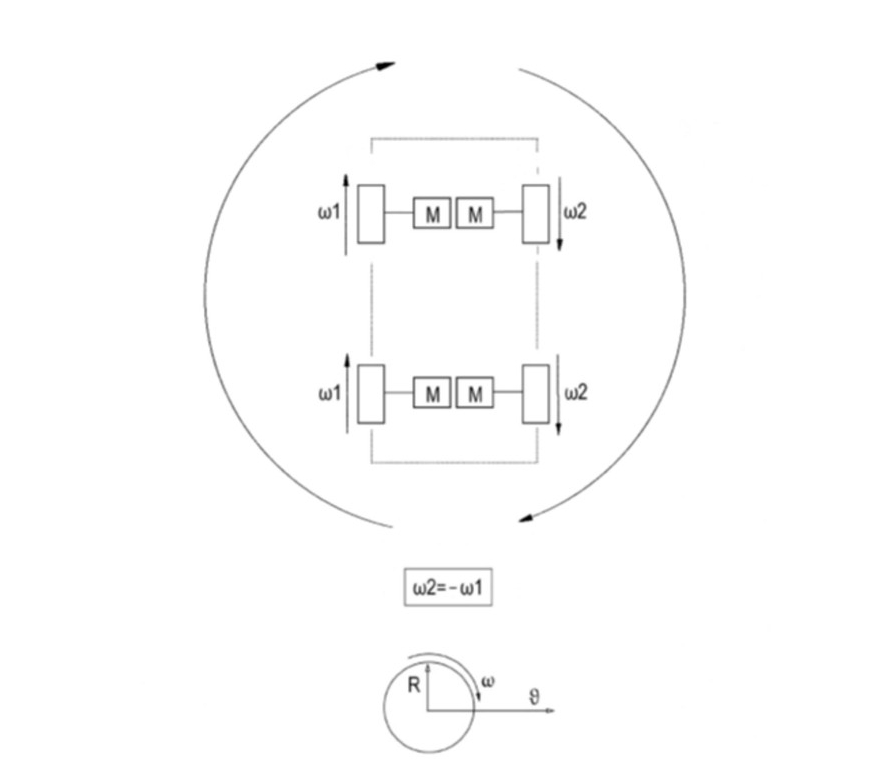

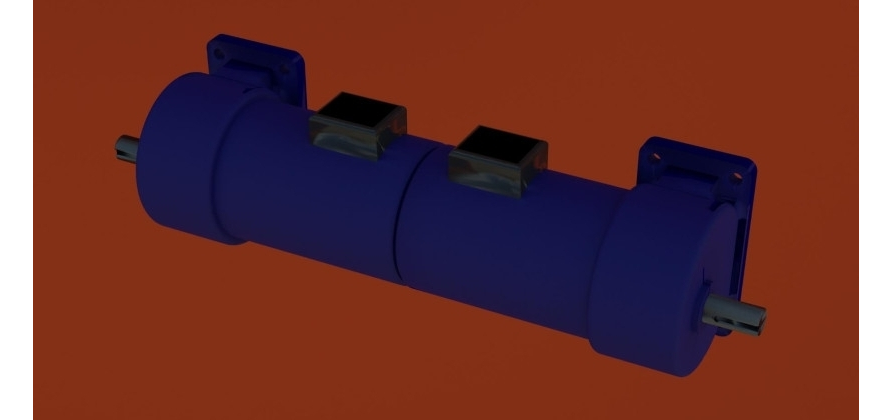

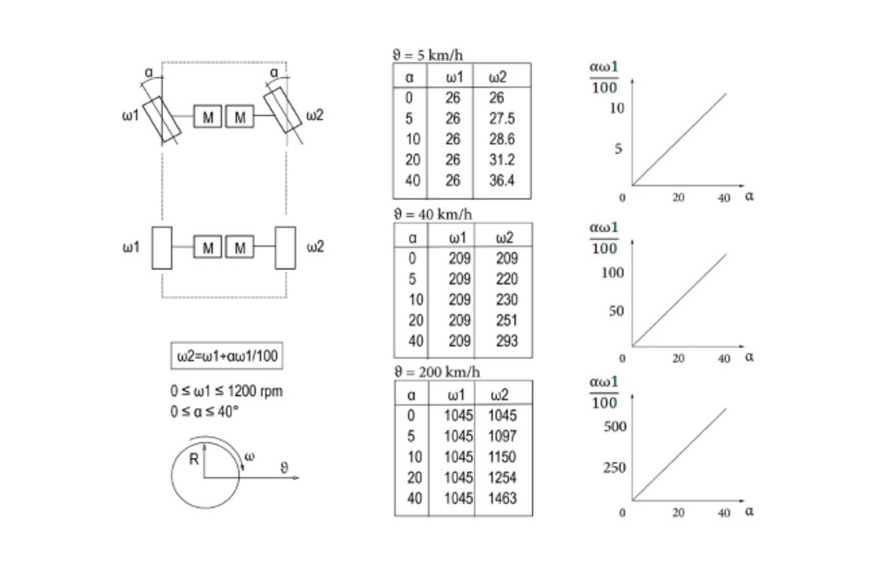

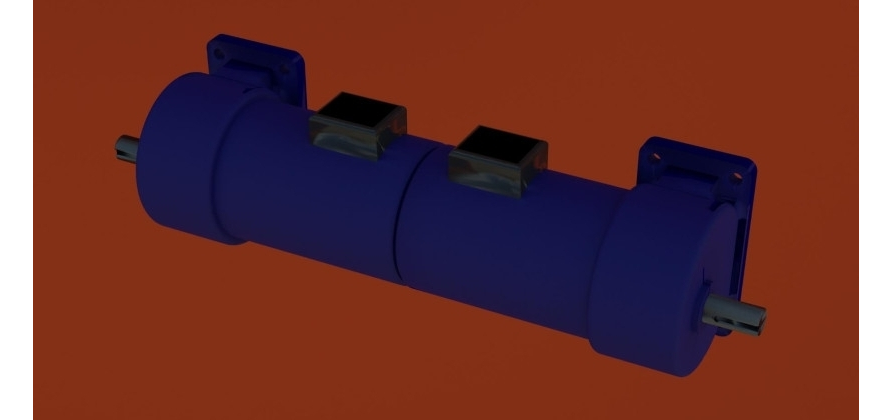

Power plant consisting of two Magnetar motors.

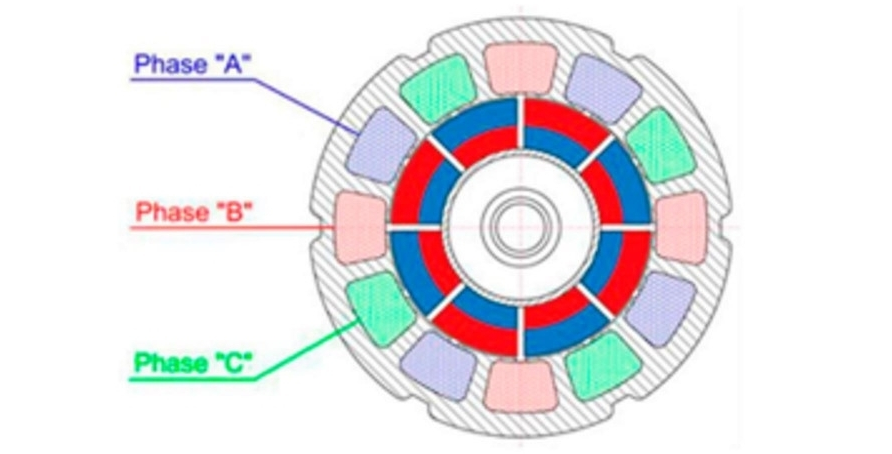

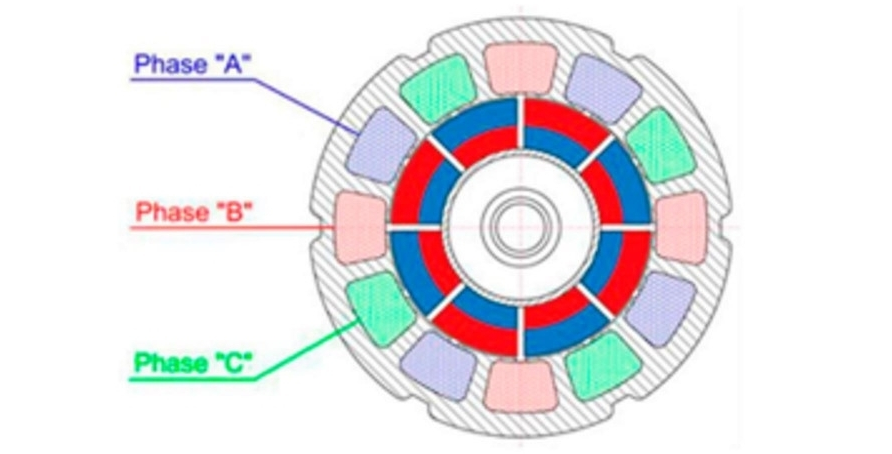

DUBINA EVO is equipped with a power plant consisting of four Magnetar electric motors. Two motors are located at the front and rear of the cockpit. There is one motor for each wheel. Car has four-wheel drive. An all-wheel drive vehicle accelerates faster and handles better. The electric powertrain is the heart of the car. It converts electrical energy into mechanical energy. The Magnetar electric motor is powerful, lightweight and quiet. Motor Magnetar is a reversible brushless multi-pole electric motor. The brushless motor has a multi-pole neodymium permanent magnet in the rotor and electrically powered magnets in the stator. This feature structurally distinguishes the brushless electric motor from other similar devices. The brushless electric motor rotates due to the consumption of direct electric current. The main difference and advantage is that the engine does not have a manifold. This significantly reduces costs and time for maintenance, and reduces power consumption. Previously, due to the wear of the brushes of the collector electric motor, an increase in its current consumption could occur without a concomitant increase in power. Sparks generated on the brushes when the motor is running create radio interference. The design of the brushless motor makes its design simple and compact, as well as economical and reliable. With the advent of neodymium production technology magnets, the power of brushless motors has increased, but the size, on the contrary, has decreased several times. But, unlike others, the brushless motor has a complex and expensive electronic control unit. The indisputable advantage of having such a control unit is the ability to change the number of revolutions of the running electric motor. The control unit is responsible for timely switching the voltage supply to the windings corresponding to the rotation of the rotor. The voltage supply is switched by the rotor position sensors. The voltage is applied to the motor windings depending on the position of the rotor. The electronics detect the position of the motor rotor. For this, position sensors based on the Hall effect (SS41) are used. Thanks to such sensors, the electronic control unit always knows what position the rotor is in and which windings to apply voltage at each moment of time. The electric motor requires a quick change in the value and direction of the speed of movement. It is known from the physics course that the acceleration E during the rotational motion of any material body (in this case, the rotor of the engine) is directly proportional to the moment M acting on this body, and inversely proportional to the moment of inertia J of this body relative to the axis of rotation:

E = M / J

It follows from the above formula that to obtain large accelerations (decelerations), it is necessary that the engine develop a significant torque M, and its rotor has a small moment of inertia J.

Three-phase motor winding.

The expression for the maximum value of the motor torque Mmax in accordance with the formula can be written as follows:

Мmax = ВIS = 2ВILR

L is the length of the frame conductors (length of the motor rotor); R is the distance from the axis of rotation of the frame 00 “to the conductors (radius of the motor rotor).

The moment of inertia J of a cylindrical body (engine rotor) relative to the axis of rotation is calculated by the formula:

J = mR2

m is the mass of the cylinder (rotor);

R is the radius of the cylinder (rotor).

Substitution of expressions in a formula leads to the following relationship:

E = 2BIL / mr

The resulting formula determines the ways to increase the speed of the engine. They are as follows:

1) Increasing the induction of the magnetic field of the motor;

2) Execution of the rotor of the engine with the lowest possible mass and with the highest possible ratio of length to radius;

3) an increase in the current in the motor windings.

To reduce the mass of the rotor (armature) of the engine, you can make it hollow.

Permanent neodymium magnets are located on the armature. The engine armature is made in the form of a thin-walled glass made of non-magnetic material.

For normal operation of a DC motor, it is necessary to change the direction of the current in the winding conductors when the position of the rotor changes. This switching in conventional DC motors is provided by a collector. The torque of a squirrel-cage induction motor varies with the rotor speed along a curve.

Torque Mvr is a measure of this effort that changes the angular speed:

ω = 2πn / 60

n — engine speed, rpm.

The following relationship exists between the engine power P (W), the angular velocity ω (rad / s), the force F (N), the pulley radius r (m), and the torque Mvr (Nm):

Мвр = Р / ω = Fr

Substituting the value of the angular velocity ω, we get:

Мвр = Р/ω = Р/2πn/60 = 60Р/2πn = 9.554Р/n

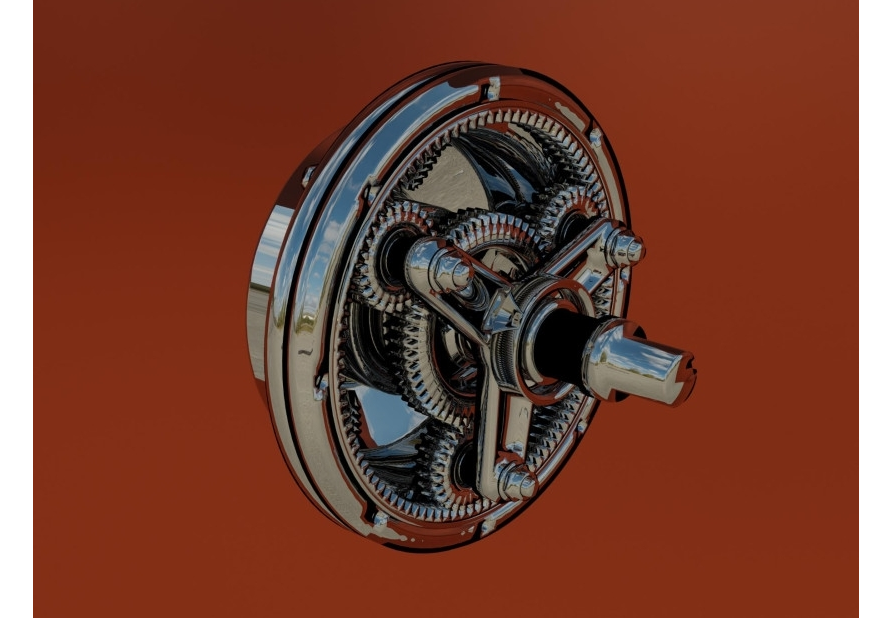

The electric motor rotates at a high frequency during operation and low torque. The torque generated by the electric motor is insufficient for the car to move. Therefore, a reduction gear is used to increase the torque. The reduction gear reduces the speed and increases torque. A planetary gearbox is used to increase the torque. With a small transverse dimension, the planetary gearbox has a large gear ratio.

Planetary reductor.

Engine braking*. A feature of the electric motor is the ability to instantly change the direction of rotation of the rotor. Thanks to this ability, it became possible in the car to perform braking by the counterflow method. When you press the brake pedal, the direction of the current in the car’s engines changes, which creates a reverse torque. This technology simplifies vehicle design. Now there are no heavy ones in the car mechanical brakes. Braking is performed at the software control level.

Recuperation. As long as the car rolls on the road without engine power or when going downhill, the engine continues to rotate. At this time, the rotor of the rotating motor works as a current generator. The generated current is returned to the battery. To prevent energy dissipation in the engine control circuit, the device turns on the engine as a generator. Such a device performs recuperation.

Hyperspeed. The electric motor can operate for a short period of time with peak current. The peak current is very strong, which gives tremendous power, but only for a short period of time. The peak current function is activated by a button located on the steering wheel.

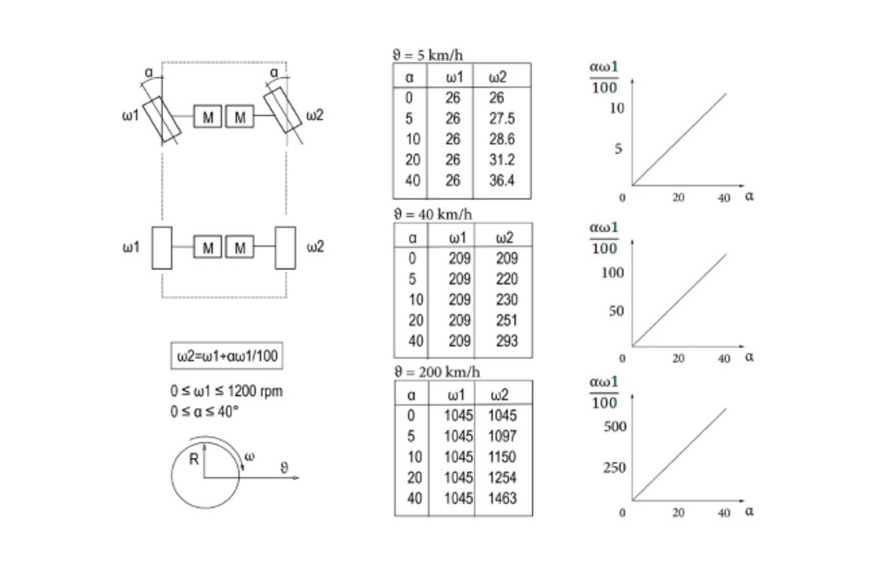

Increased agility. DUBINA EVO has four-wheel drive. There is one motor for each wheel. This design allows for increased maneuverability by changing the wheel speed depending on the steering angle. A wheel located at a larger radius when turning rotates with a frequency exceeding that of the other wheel by a percentage equal to the steering angle.

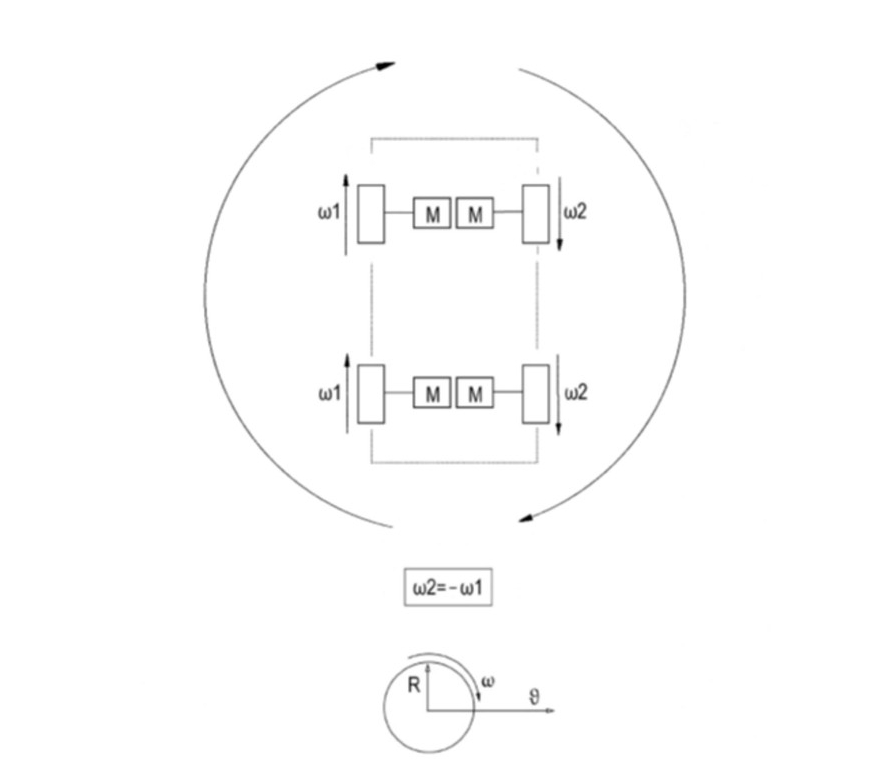

Vehicle movement around the axis. The machine can rotate around an axis. Because there is one motor for each wheel. The movement around the axis is activated by a button on the steering wheel.