3.1. The Environmental Impact of the Manufacturing of Seminconductors*

"This module was developed as part of a Rice University Class called "Nanotechnology: Content and Context"initially funded by the National Science Foundation under Grant No. EEC-0407237. It was conceived, researched, written and edited by students in the Fall 2005 version of the class, and reviewed by participating professors."

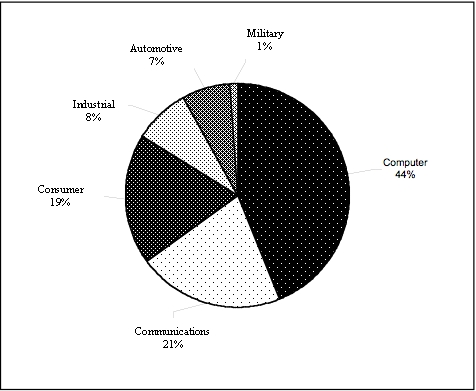

The semiconductor industry is one of the

fastest growing manufacturing sectors in not only the United States

but also in the world. According to the American Electronics

Association, the domestic sales of electronic components have

skyrocketed, jumping from $127 billion to $306 billion over the

course of the 1980’s. In the first three quarters of the 2003

fiscal year alone, the export of technology goods from the United

States increased by $19 billion [1].

The word “semiconductor” technically refers

to any member of a class of solid, crystalline materials that is

characterized by an electrical conductivity better than that of

insulators (e.g., plastic) but less than that of good conductors

(e.g., copper) [2]. Semiconductors are particularly useful

as a base material in the manufacturing of computer chips, and the

term semiconductor has actually come to be synonymous with the

computer chips, themselves. However, semiconductors are not only used in

computers. Computers only make up 44% of entire industry

consumption (see Figure 3.1). Semiconductors are also used for military, automotive,

industrial, communications, and other consumer purposes.

Semiconductors seem to be anywhere and

everywhere throughout our everyday lives, yet it is surprising how

little most people know about how they actually work or about the

potentially devastating effects their manufacturing can have on the

environment and human health.

Why is nanotechnology important to the semiconductor industry?

Much of the study of nanotechnology has been centered on the manufacturing of semiconductors. Though there are a number of

highly anticipated applications for nanotechnology in other fields,

notably in medicine and in biotechnology, the most tangible results

thus far can be argued to have been achieved in the semiconductor

industry.

For example, Intel recently unveiled its

first products based on a generation of 90-nanometer process

technology, and its researches and engineers have built and tested

prototype transistors all the way down to the 22-nanometer range.

Currently, Intel scientists and engineers are working on

identifying new materials such as carbon nanotubes and nanowires to

replace current transistors, and in particular they hope to develop

a “tri-gate” transistor approach that would enable chip designers

to build transistors below the 22-nanometer range [4].

With the advent of nanotechnology, these

transistors are becoming even faster and more powerful, and in

accordance with the law of accelerating returns, the industry has

been producing smaller transistors at lower costs with each and

every passing year. As these semiconductors become smaller and

smaller, they are quickly and surely pushing towards the limits of

the nano-realm.

These innovations, however, do not come

without their fair share of challenges. Physical issues that are

not problematic at the micron scale arise at the nano-scale due to

the emergence of quantum effects, and in much the same way that

optical microscopy cannot be utilized at the nano-scale, the

semiconductor industry is fast approaching a similar diffraction

limit. Optical lithography, for instance, a process that uses the

properties of light to etch transistors onto wafers of silicon,

will soon reach its limit.

At its most basic level, nanotechnology

involves pushing individual atoms together one by one. Since

approximately 1.7 billion transistors are required for a single

chip, this is obviously not a realistic method for mass production.

Unless an alternative method for production or a solution to this

problem is found, the development and manufacturing of transistors

are expected to hit a proverbial brick wall by the year 2015. This

is the reason that research in nanotechnology is so important for

the world and future of semiconductors.

How are semiconductors manufactured?

Today’s semiconductors are usually composed

of silicon, and they are manufactured in a procedure that combines

the familiar with the bizarre; some steps that are involved in the

process are as everyday as developing a roll of photographic film

while others seem as if they would be better suited to take place

on a spaceship.

These semiconductors appear to the naked eye

as being small and flat, but they are actually three-dimensional

“sandwiches” that are ten to twenty layers thick. It can take more

than two dozen steps and up to two full months to produce a single

one of these silicon sandwiches. Some of the basic and more

essential steps involved in the manufacturing process of silicon

chips are briefly detailed below.

First, silicon crystals are melted in a vat

and purified to 99.9999% purity. The molten silicon is drawn into

long, heavy, cylindrical ingots, which are then cut into thin

slices called wafersabout the thickness of a business card.

One side of each wafer must be polished

absolutely smooth. This process is called chemical-mechanical

polishing, and it involves bathing the wafers in special abrasive

chemicals. After chemical-mechanical polishing, imperfections

cannot be detected on the wafers even with the aid of a laboratory

microscope.

After a wafer is polished, layers of material

must be stacked on top of the silicon wafer base. Insulating layers

are laid down in alternation with conducting layers in a process

called deposition. This is often achieved by spraying the chemicals

directly onto the surface of the wafer through chemical vapor

deposition. Following deposition, the wafer is coated with another

layer of chemicals called a photoresist that is sensitive to

light.

Next, a machine called a stepper (Figure 3.3) is calibrated to project

an extremely fine and focused image through a special type of

reticle film in a manner similar to that of a simple slide

projector. The light that is transmitted through the reticle is

projected onto the photoresist layer, which reacts to the light and

begins to harden. All of the parts of the wafer exposed to this

light harden into a tough crust while the parts in shadow remain

soft. This particular step is known by the name of

photoelectrochemical etching because it achieves an etching effect,

resulting in a chip.

Hundreds of copies of the chip are etched onto the wafer until the entire

surface has been exposed. Once this process is complete, the entire

wafer is submerged into an etching bath, which washes away any

parts of the photoresist that remain unexposed along with the

insulating chemicals underneath. The hardened areas of the

photoresist, however, remain and protect the layers of material

underneath them. This process of depositing chemicals, coating with

a photoresist, exposure to light over a film mask, and etching and

washing away is repeated more than a dozen times. The result is an

elaborate, three-dimensional construction of interlocking silicon

wires.

This product is then coated with another

insulating layer and is plated with a thin layer of metal, usually

either aluminum or copper. Yet another photoresist is laid down on

top of this metal plating, and after the wafer is exposed in a

stepper, the process repeats with another layer of metal. After

this step has been repeated several more times, a final wash step

is performed, and a finished semiconductor product rolls off the

assembly line, at last.

A typical semiconductor fabrication facility, or “fab” in

industry jargon, looks like a normal two- or three-story office

building from the outside, and most of the interior space is

devoted to one or more “clean rooms,” in which the semiconductors

are actually made. A clean room is designed with a fanatical

attention to detail aimed towards keeping the room immaculate and

dust-free (Figure 3.4).

Most if not all surfaces inside these clean

rooms are composed of stainless steel, and these surfaces are

sloped whenever possible or perforated by grating to avoid giving

dust a place to settle. The air is filtered through both the

ceiling and the floor to remove particles that are down to 1/100

the width of a human hair. Lighting is characteristically bright

and slightly yellowish to prevent mildew from forming behind

equipment or in recessed corners, and even the workers in a clean

room must be absolutely spotless.

Workers in these rooms must be covered from

head to toe in “bunny suits” that completely seal the body in a

bulky suit, helmet, battery pack, gloves, and boots. Once sealed in

these suits, the workers often look more like space explorers in a

science fiction movie than computer chip employees, but in order to

even enter the stainless steel locker room to suit up to begin

with, they must first pass through a series of air lock doors,

stand under a number of “air showers” that actually blow dust off

of clothing, and walk across a sticky floor matting that removes

grime from the bottom of shoes.

Semiconductor-manufacturing companies often

portray their fabrication facilities as being clean,

environmentally friendly, and conspicuously free of the black,

billowing smokestacks that have come to be associated with the

plants and factories of other major industries. These facilities

produce no visible pollution and certainly do not appear to pose

any health or environmental risks.

In truth, the term “clean room,” itself is

more than just a bit of an understatement. Industry executives

often boast that their clean rooms are from 1,000 times to 10,000

times cleaner and more sanitary than any hospital operating

room.

What are the health risks involved in the

semiconductor industry?

The use of sterile techniques and the

fastidious attention devoted to cleanliness in the semiconductor

industry may perpetuate the illusion that the manufacturing of

semiconductors is a safe and sterile process. However, as a rapidly

growing body of evidence continues to suggest, hardly anything

could be further from the truth (Figure 3.5). The question of worker safety and

chemical contamination at chip-making plants has received an

increasing amount of attention over the course of the past

decade.

The devices being built at semiconductor fabrication

facilities are super-sensitive to environmental contaminants.

Because each chip takes dozens of trained personnel several weeks

to complete, an enormous amount of time and effort is expended to

produce a single wafer. The industry may pride itself on its

perfectly immaculate laboratories and its bunny-suited workers, but

it should be noted that the bunny suits are not designed to protect

their wearers from hazardous materials but rather to protect the

actual semiconductor products from coming into contact with dirt,

hair, flakes of skin, and other contaminants that can be shed from

human bodies. They protect the silicon wafers from the people, not

the people from the chemicals.

Lee Neal, the head of safety, health, and

environmental affairs for the Semiconductor Industry Association,

has been quoted as saying, “This is an environment that is cleaner

than an operating room at a hospital.” However, this boast is

currently being challenged by industry workers, government

scientists, and occupational-health experts across the country and

worldwide.

Industrial hygiene has always been an issue

in the semiconductor industry. Many of the chemicals involved in

the manufacturing process of semiconductors are known human

carcinogens or pose some other serious health risk if not contained

properly. Table 3.1 lists ten of the hazardous chemicals

most commonly used in manufacturing semiconductors along with their

known effects on human health.

Table 3.1. Chemicals of concern in the semiconductor industry [5].| Chemical name | Role in manufacturing process | Health problems linked to exposure |

| Acetone | Chemical-mechanical polishing of silicon wafers | Nose, throat, lung, and eye irritation, damage to the skin,

confusion, unconsciousness, possible coma |

| Arsenic | Increases conductivity of semiconductor material | Nausea, delirium, vomiting, dyspepsia, diarrhea, decrease in

erythrocyte and leukocyte production, abnormal heart rhythm, blood

vessel damage, extensive tissue damage to nerves, stomach,

intestine, and skin, known human carcinogen for lung cancer |

| Arsine | Chemical vapor deposition | Headache, malaise, weakness, vertigo, dyspnea, nausea,

abdominal and back pain, jaundice, peripheral neuropathy,

anemia |

| Benzene | Photoelectrochemical etching | Damage to bone marrow, anemia, excessive bleeding, immune

system effects, increased chance of infection, reproductive

effects, known human carcinogen for leukemia |

| Cadmium | Creates “holes” in silicon lattice to create effect of

positive charge | Damage to lungs, renal dysfunction, immediate hepatic

injury, bone defects, hypertension, reproductive toxicity,

teratogenicity, known human carcinogen for lung and prostate

cancer |

| Hydrochloric acid | Photoelectrochemical etching | Highly corrosive, severe eye and skin burns, conjunctivitis,

dermatitis, respiratory irritation |

| Lead | Electroplated soldering | Damage to renal, reproductive, and immune systems,

spontaneous abortion, premature birth, low birth weight, learning

deficits in children, anemia, memory effects, dementia, decreased

reaction time, decreased mental ability |

| Methyl chloroform | Washing | Headache, central nervous system depression, poor

equilibrium, eye, nose, throat, and skin irritation, cardiac

arrhythmia |

| Toluene | Chemical vapor deposition | Weakness, confusion, memory loss, nausea, permanent damage

to brain, speech, vision, and hearing problems, loss of muscle

control, poor balance, neurological problems and retardation of

growth in children, suspected human carcinogen for lung and liver

cancer |

| Trichloroethylene | Washing | Irritation of skin, eyes, and respiratory tract, dizziness,

drowsiness, speech and hearing impairment, kidney disease, blood

disorders, stroke, diabetes, suspected human carcinogen for renal

cancer |

Several semiconductor manufacturers including

National Semiconductor and IBM have been cited in the past for

holes in their safety procedures and have been ordered to tighten

their handling of carcinogenic and toxic materials.

In 1996, 117 former employees of IBM and the

families of 11 workers who had died of cancer filed suit against

the chemical manufacturers Eastman Kodak Company, Union Carbide

Corporation, J. T. Baker, and KTI Chemicals, claiming that they had

suffered adverse health effects as a result of exposure to

hazardous chemicals on the job in the semiconductor industry [5]. The lawsuit was filed in New York, which prevented the employees

from suing IBM directly. A separate group of former IBM workers who

had developed cancer filed suit against the company in California,

alleging that they had been exposed to unhealthy doses of

carcinogenic chemicals over the past three decades. Witnesses who

testified in depositions in the New York state court in Westchester

County described how monitors that were supposed to warn workers of

toxic leaks often did not function because of corrosion from acids

and water. They also alleged that supervisors sometimes shut down

monitors to maintain production rates. When they lodged complaints

with senior officials in the company, they claim to have been told

not to “make waves” [6]. Meanwhile, 70 female workers in

Scotland sued National Semiconductor Corporation, another

U.S.-based company, claiming that they, too, were exposed to

carcinogens on the job.

These lawsuits and the resulting publicity

prompted a groundbreaking study by the Health and Safety Executive,

which commissioned a committee to investigate these

allegations [7]. The committee found that there were indeed unusually high levels of breast and other kinds of cancer among workers at National

Semiconductor’s fabrication facility in Greenock, Scotland. The

committee concluded that the company had failed to ensure that the

local exhaust ventilation systems adequately controlled the

potential exposure of employees to hydrofluoric acid and sulphuric

acid fumes and to arsenic dust. These findings proved to be

extremely embarrassing for the company and for the industry.

According to an official statement released by Ira Leighton, acting

regional administrator of the New England branch of the U.S.

Environmental Protection Agency,

“National Semiconductor is a big business

that uses a large amount of harmful chemicals and other materials. Our hazardous waste regulations were created to properly monitor dangerous chemicals and prevent spills. In order for it to work, it is important businesses to comply with all of the regulations. When

companies fail to do this they are potentially putting people – their employees and neighbors – at risk [8]. ”

Moreover, a study of fifteen semiconductor manufacturers

published in the December 1995 issue of the American Journal of

Independent Medicine showed that women working in the so-called

clean rooms of the semiconductor fabs suffered from a 14%

miscarriage rate.

The main problem in prosecution is that the industry does not have a single overarching and definitive process for manufacturing,

and it is difficult to pinpoint one particular compound as causing

a certain health problem because some plants use as many as 300

chemicals. Also, many of the manufacturing processes take place in

closed systems, so exposure to harmful substances is often

difficult to detect unless monitored on a daily basis.

Executives and spokespeople for the

semiconductor industry maintain that any chip workers’ cancers and

other medical problems are more likely due to factors unrelated to

the job, such as family history, drinking, smoking, or eating

habits. They also say that over the years, as awareness of chemical

hazards has grown, they have made efforts to phase out toxic

chemicals and to lower exposure to others. They insist that they

use state-of-the-art process equipment and chemical transfer

systems that limit or prevent physical exposure to chemicals and

point out that the substances used in the semiconductor industry

are used in other industries without a major health or safety

problem.

What environmental risks are involved?

In theory, attention to cleanliness is in the

manufacturer’s best interest not only from a health perspective but

also from an economic. Many chemicals used in the production

process are not expensive in and of themselves; however, the cost

of maintaining these materials in an ultra-clean state can be quite

high. This encourages the close monitoring of usage, the

minimization of consumption, and the development of recycling and

reprocessing techniques. Also, the rising costs of chemical

disposal are prompting companies to conduct research into

alternatives that use more environmentally friendly methods and

materials. Individual companies and worldwide trade associations

were active in reducing the use and emission of greenhouse gases

during the 1990’s, and the industry as a whole has substantially

reduced emissions over the last twenty years.

Nonetheless, there has been a history of

environmental problems linked to the industry in Silicon Valley and

other technology centers. To begin with, a tremendous amount of raw

materials is invested in the manufacturing of semiconductors every

year.

Moreover, a typical facility producing

semiconductors on six-inch wafers reportedly uses not only 240,000

kilowatt hours of electricity but also over 2 million gallons of

water every day [9]. Newer facilities that produce eight-inch and twelve-inch wafers

consume even more, with some estimates going as high as five

million gallons of water daily. While recycling and reusing of

water does occur, extensive chemical treatment is required for

remediation, and in dry or desert areas such as Albuquerque, New

Mexico, home to plants for Motorola, Philips Semiconductor, Allied

Signal and Signetics, Intel, and other high-tech firms, the high

consumption of water necessary for the manufacturing of

semiconductors can pose an especially significant drain on an

already scarce natural resource [10]. The existence of economic mainstays including the mining industry

and the established presences of Sandia National Laboratories and

the Los Alamos National Laboratory make New Mexico an attractive

location for high-tech tenants. However, the opening of fabrication

facilities in the state leaves its farmers and ranchers in constant

competition with the corporations for rights to water consumption.

On average, the manufacturing of just 1/8-inch of a silicon wafer

requires about 3,787 gallons of wastewater, not to mention 27

pounds of chemicals and 29 cubic feet of hazardous

gases [11].