Tseng, H. F. & Li, S. S. (1972). Phys. Rev. B 6 (8): 3066.

Vincent, G., Bois, D. & Chantre, A. (1982). Photoelectric memory effect in gaas, Journal of

Applied Physics 53: 3643.

Wertheim, G. (1959). Phys. Rev. 115: 37.

Yarykin, N., Sachse, J.-U., Lemke, H. & Weber, J. (1999). Phys. Rev. B 59: 5551.

Yoffa, E. (1981). Phys. Rev. B 23 (4): 1909.

Part 6

Laser Devices and Methods

25

Electromechanical 3D Optoelectronic Scanners:

Resolution Constraints and

Possible Ways of Improvement

Oleg Sergiyenko1, Vera Tyrsa2, Luís C. Basaca-Preciado1,

Julio C. Rodríguez-Quiñones1, Wilmar Hernández4, Juan I. Nieto-Hipólito1,

Moisés Rivas Lopez1 and Oleg Starostenko3

1Autonomous University of Baja California, Mexicali-Ensenada,

2Polytechnic University of Baja California, Mexicali,

3Universidad de Las Americas, Puebla,

4Polytechnic University of Madrid,

1,2,3Mexico

4Spain

1. Introduction

Non-Contact optoelectronic 3D measurement is a rapidly growing field. Three-Dimensional

Non-Contact Measurement Technologies are very common for research due to multiple

practical applications expecting for its benefits. Many fields are using in any way 3D

measurements or shape recognition, some of them there are vision assisted assembly in

various branches of industry, autonomous mobile robots navigation, structural health

monitoring, micro surfaces inspections, precise automated surgery, etc.

In this chapter it is expedient to mention and briefly cross-compare the following emerging

technologies for 3D measurements: laser scanners, lasers based on conoscopy holography

technology and 3D cameras.

Laser scanners: Most contemporary non-contact 3D measurement devices are based on laser

range scanning. The simplest devices (Fischer, 2007) are based on the laser triangulation

technique. This is an active stereoscopic technique in which the distance of the object is

computed by means of a directional light source and a video camera. The CCD camera’s 2D

array captures the image of surface profile and digitizes all data points along the laser

disadvantage of this method is that a single camera collects only a small percentage of the

reflected energy. The amount of the collected energy can be drastically increased by

trapping the entire reflection cone, thus significantly increasing the precision and reliability

of the measurements.

Lasers based on Conoscopic Holography technology: Conoscopic Holography is a simple

implementation of a particular type of polarized light interference process based on crystal

optics. In the basic interference set-up, a point of light is projected onto a diffuse object. This

point creates a light point, which diffuses light in every direction. In a conoscopic system, a

complete solid angle of the diffused light is analyzed by the system. The measurement

550

Optoelectronic Devices and Properties

process retrieves the distance of the light point from a fixed reference plane. The problem

inherent in laser scanning is its relatively low measurement speed, though it is faster than

traditional contact Coordinate measurements machines (CMM’s).

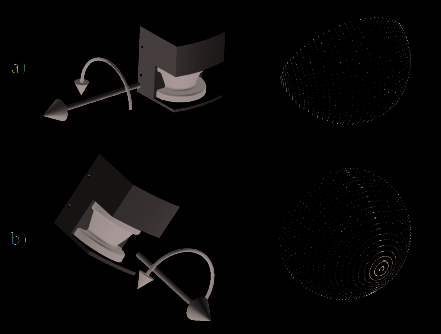

a)

b)

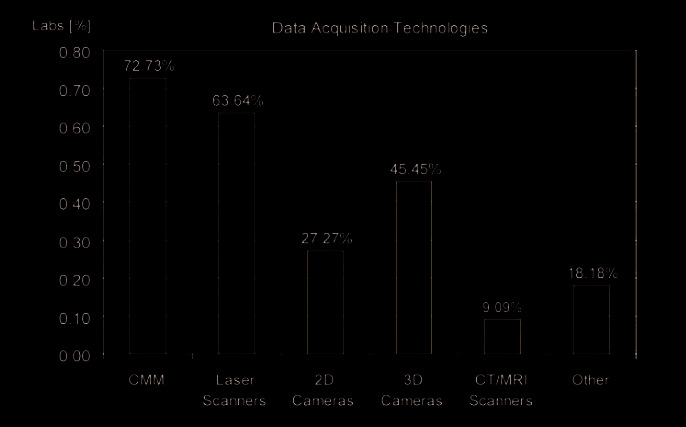

Fig. 1. A scanner laser (a) and a 3D camera (b)

3D cameras: 3D photography is based on reconstructing 3D data from 2D images, taken

from different points of view (stereo- graphic) the basic problem with this approach is the

correspondence problem. In 3D cameras a pattern is projected on the object and the same

pattern points are identified on each image. This approach is much more efficient, since it

does not require marking specific points, and it can produce a very large number of

measurements in one shot of camera.

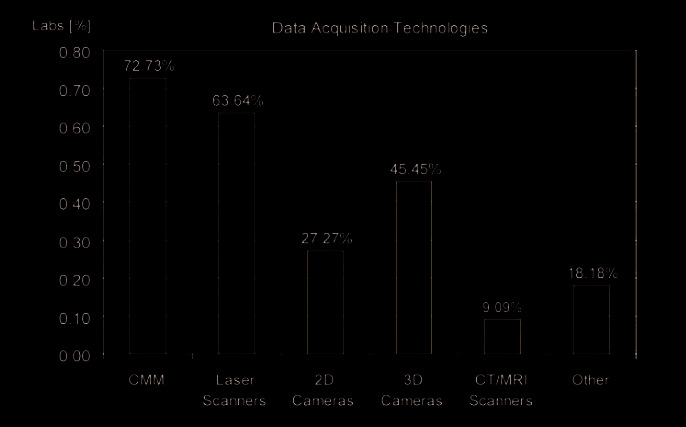

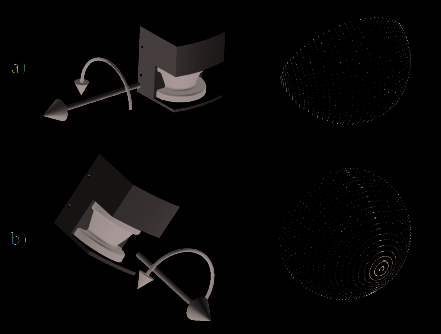

Fig. 2. Distribution of 3D scanning technologies among 23 engineering universities and

research centers across Europe according to (Fischer, 2007)

Electromechanical 3D Optoelectronic Scanners:

Resolution Constraints and Possible Ways of Improvement

551

The typical distribution of 3D scanning technologies research among engineering

universities and research centers is given on Fig.2. CMM is still numerous due to non-

innovative routines in industry with traditional investments for research. But this

technology is contact and applicable for very limited area of tasks. So, the future is for laser

scanning and 3D camera vision.

In fact, specialists already get a consensus regard to most evidences of these two branches.

Cameras are winning in a point of less energy consuming and a relatively longer range of

action. But laser scanning systems always win at resolution, accuracy and data processing

time.

Basing in this, it is easy to show that for various tasks (such as: vision assisted assembly,

robot navigation in densely cluttered environment, structural health monitoring, etc.) the

laser scanner is an optimal way to obtain quality 3D information about objects in nearest

surrounding in higher resolution.

But the majority of modern laser scanners have a certain part of rotating/moving

electromechanical components, which are closely related with such negative phenomenon

like mechanical vibrations, friction and wear, mechanical delays, etc.

Present paper scope is precisely to research what are the most prospective ways to increase

the electromechanical laser scanners resolution and robustness. With this aim let us deeper

study most typical approaches to laser scanner construction, as one of the most promising

technical vision system (TVS).

2. Typical laser scanner constructions and their constraints

According to the recent literature electromechanical laser scanners have sufficiently variety

in its constructions. At the same time, they have enough similarities and common

components in its general structure. Let will see some of the typical constructions of

electromechanical laser scanners for to have the possibility systemize such constructions and

define their common advantages and lacks.

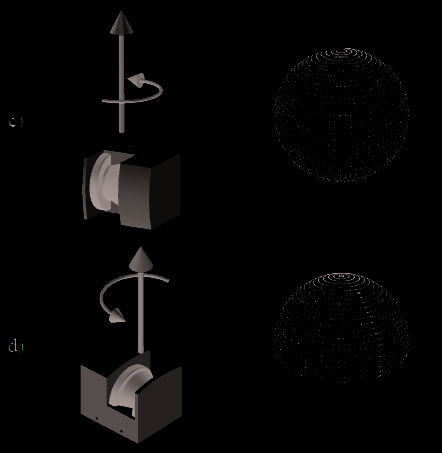

An obvious optimization of the measurement system (Wulf & Wagner, 2003) is to take the

scanning method that is most suitable for the application. However, taking a 2D laser

scanner with 180° scanning range and a servo drive it results in a number of possible

combinations of scan planes and rotation axis to get a 3D scan. This section describes four of

these combinations. We have named the scanning methods as pitching scan, rolling scan,

yawing scan and yawing scan top. The pitching scan (Fig. 3a) has a horizontal scan plane and is pitching up and down. This method is for example used in (Surmann et al., 2001) and

(Hähnel & Burgard, 2002). A method that is newly introduced here is the rolling scan (Fig.

3b). This scan is rotating around the center of the scanner, with the advantage of only one

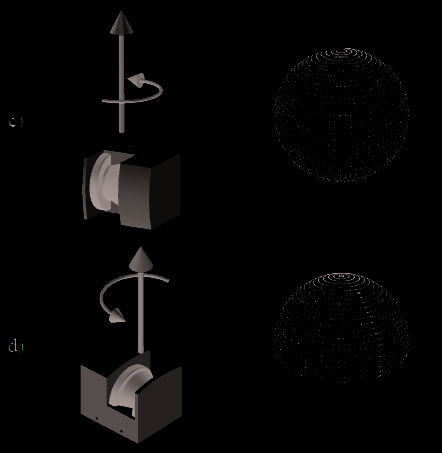

focus point in front of the sensor. The yawing scan (Fig. 3c) and the yawing scan top (Fig. 3d)

has a vertical scan plane and is rotating around the upright z-axis. This method is used e.g.

by (Wulf, O. & Wagner, B. (2003).

Let us compare constructions and advantages/disadvantages of the different laser scanner

constructions according to the next literature sources: (Son et al., 2002), (Wulf & Wagner,

2003), (Nüchter, 2007), (Nüchter, 2008), (Wulf et al., 2004), (Surmann, 2003), (Surmann et

al., 2001), (Hähnel & Burgard, 2002), (Blais et al., 1988), (Blais et al., 2000), (Beraldin et al.,

2000), (Andersen et al., 2006), (Laurin et al., 1996 ), (Blais et al., 1991), (Klöör et al., 1993),

(Vandapel et al., 2004), (Montemerlo & Thrun, 2004), (Pagnottelli et al., 2005), (Sergiyenko et

al., 2006).

552

Optoelectronic Devices and Properties

Fig. 3. The pitching scan (a), the rolling scan (b), the yawing scan (c) and the yawing scan top (d) (Wulf & Wagner, 2003)

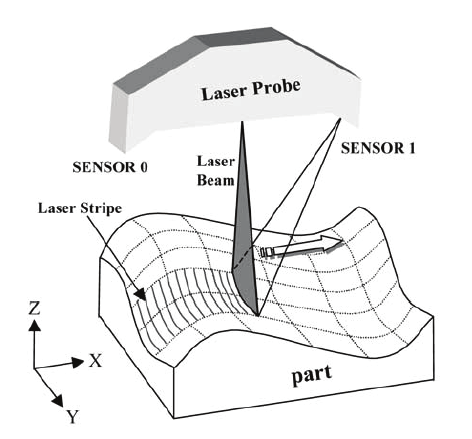

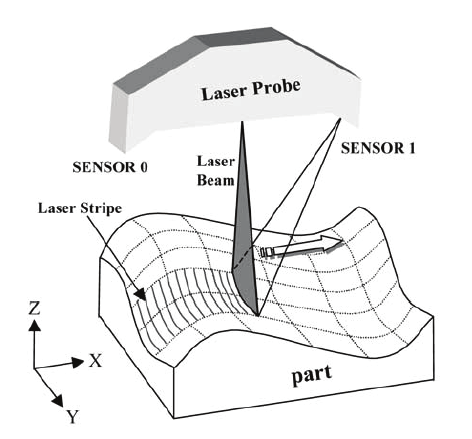

2.1 Automated laser scanning system for reverse engineering and inspection

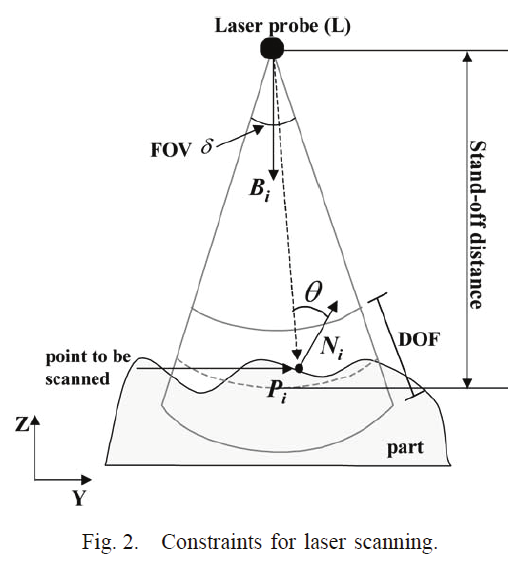

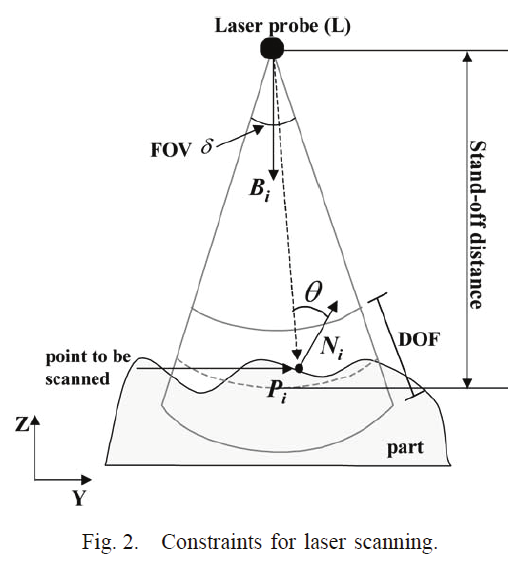

The mechanism of the 3D laser scanner used in this research (Son et al., 2002) is illustrated in

Fig. 4. A laser stripe is projected onto a surface and the reflected beam is detected by CCD

cameras. Through image processing and triangulation method, three-dimensional

coordinates are acquired. The laser probe is mounted on a three-axis transport mechanism

and moves along the scan path that consists of a series of predetermined line segments. It

also rotates in two directions.

When the laser scanner captures an image, the system automatically finds an optical focus

and keeps the standoff distance. The length of laser stripe and the stand-off distance cannot

be changed by an operator. Since a laser scanner consists of optical sensors and mechanical

moving parts, various constraints must be satisfied when measuring a certain point on a

part (Fig. 5). The goal of this section is to generate an optimal scan plan that satisfies the

following major constraints (Zussman et al., 1994):

Electromechanical 3D Optoelectronic Scanners:

Resolution Constraints and Possible Ways of Improvement

553

Fig. 4. Laser scanning mechanism

Fig. 5. Constraints for laser scanning

1. View angle: the angle between the incident laser beam and the surface normal of a point

being measured should be less than the maximum view angle γ

d • N ≥

γ (1)

i

i

cos( ),

where

L − P

i

d =

(2)

i

.

L − Pi

2. FOV: the measured point should be located within the length of a laser stripe

554

Optoelectronic Devices and Properties

⎛ δ ⎞

(− d • B ≥

(3)

i )

cos⎜ ⎟,

i

⎝ 2 ⎠

where δ is the FOV angle

3. DOF: the measured point should be within a specified range of distance from the laser

source

l

l

DOF

DOF

l

−

≤ L − P ≤ l

+

(4)

STAND

i

STAND

,

2

2

where lSTAND and lDOF denotes stand-off distance and DOF length.

4. Occlusion: the incident beam as well as the reflected beam must not interfere with the

part itself.

5. The laser probe should travel along a path that is collision-free.

6. If the part is shiny or transparent, preprocessing is required such as spraying.

2.2 Range error analysis of an integrated time-of-flight, triangulation and

photogrammetric 3D laser scanning system

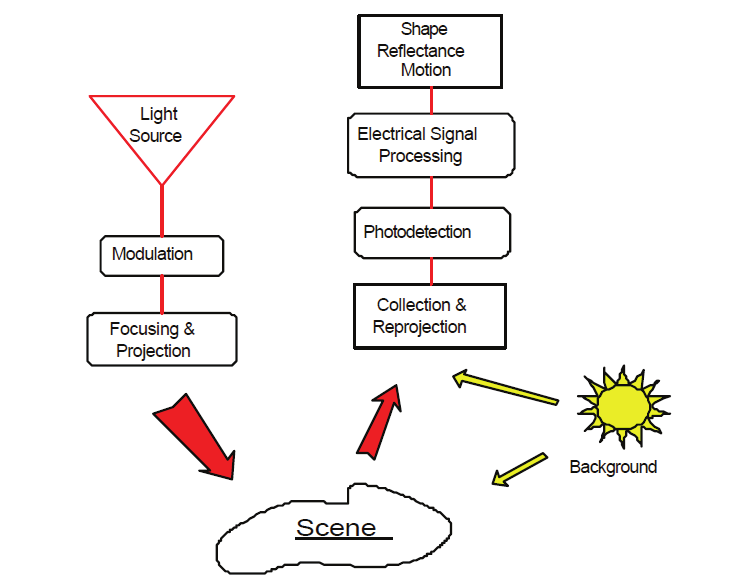

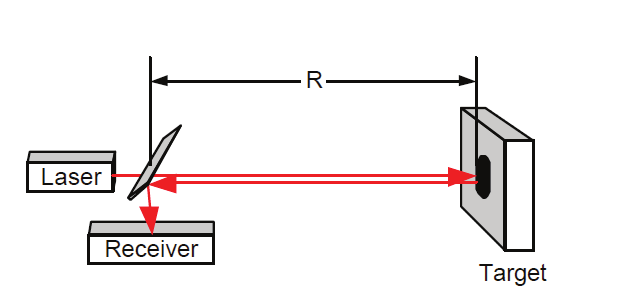

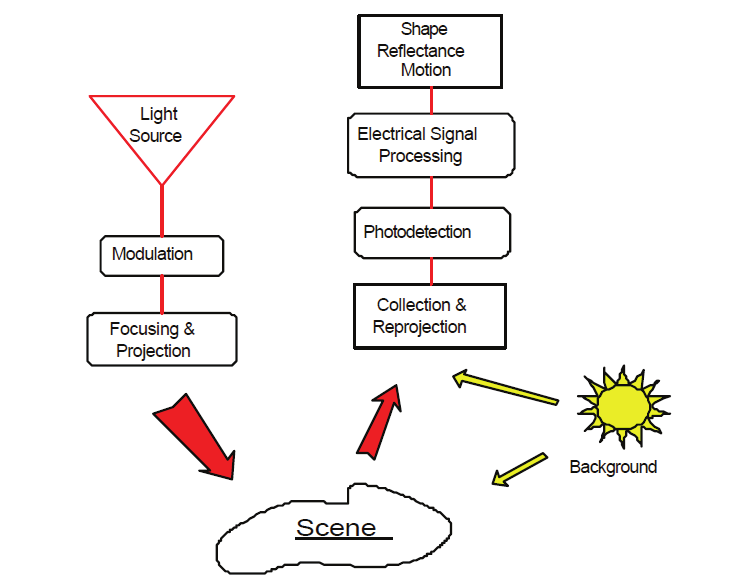

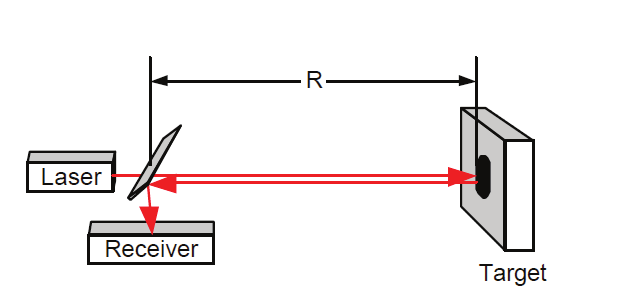

Laser scanner model (Blais et al., 2000). Models must be able to relate design parameters,

laboratory measurable, and operational performance. Figure 6 illustrates the major

subsystems of an active electro-optical system: projector sources and collimating optics,

deflection mechanism, collecting optics, detector, signal conditioning and processing, and

final output. The collecting optics images the radiation onto the detector. In the example of

Figure 7, the scanner optically moves the detector’s instantaneous field-of-view (IFOV)

across the total field-of-view (FOV) to produce an output voltage (signal) proportional to the

local scene intensity (produced by ambient light conditions) and the laser light reflected

back from a reflective surface.

Fig. 6. Generic sensor operation applied to active electro-optical systems

Electromechanical 3D Optoelectronic Scanners:

Resolution Constraints and Possible Ways of Improvement

555

The detector is at the heart of the electro-optical system because it converts the scene

radiation (reflected flux) into a measurable electrical signal. Amplification and signal

processing creates a signal in which voltage differences represent scene intensity differences

due to various objects in the field-of-view.

The majority of electro-optical quality discussions are centered on resolution and sensitivity

evaluation. System sensitivity deals with the smallest signal that can be detected. It is

usually taken as the signal that produces a signal-to-noise ratio of unity at the system

output. Sensitivity is dependent upon the light-gathering properties of the optical system,

the responsivity of the detector, the noise of the system and, for this application, the

background flux. It is independent of resolution.

In the case of metrology, resolution is not sufficient and stability and accuracy must also be

considered. Resolution has been in use so long that it is thought to be something

fundamental, which uniquely determines system performances and is often confused with

accuracy. It is often specified by a variety of sometimes-unrelated metrics such as the Airy

disk angular size, the detector subtense, or the sampling frequency. Resolution does not

usually include the effect of system noise.

Fig. 7. Schematic representation of the auto-synchronized geometry

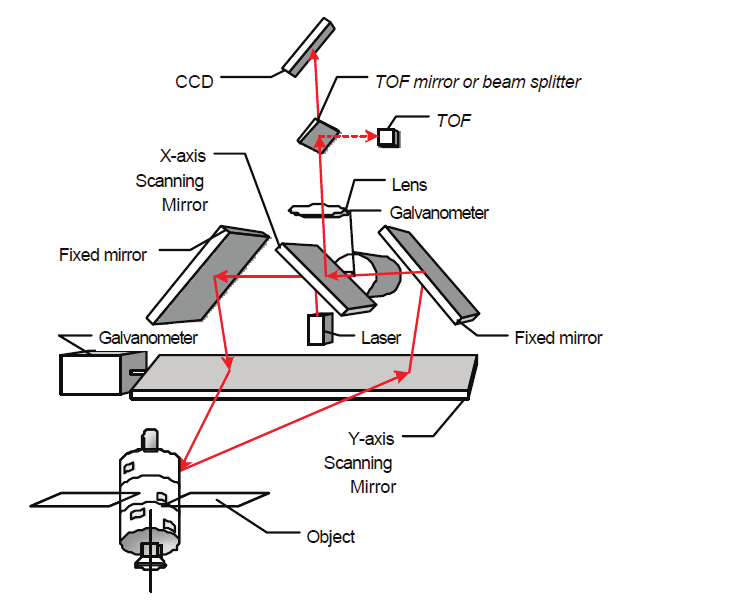

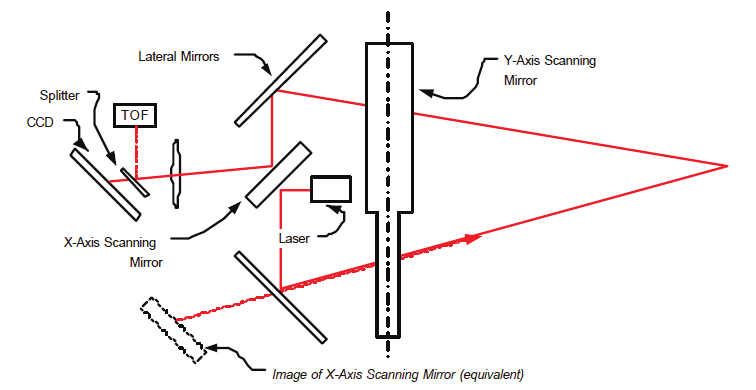

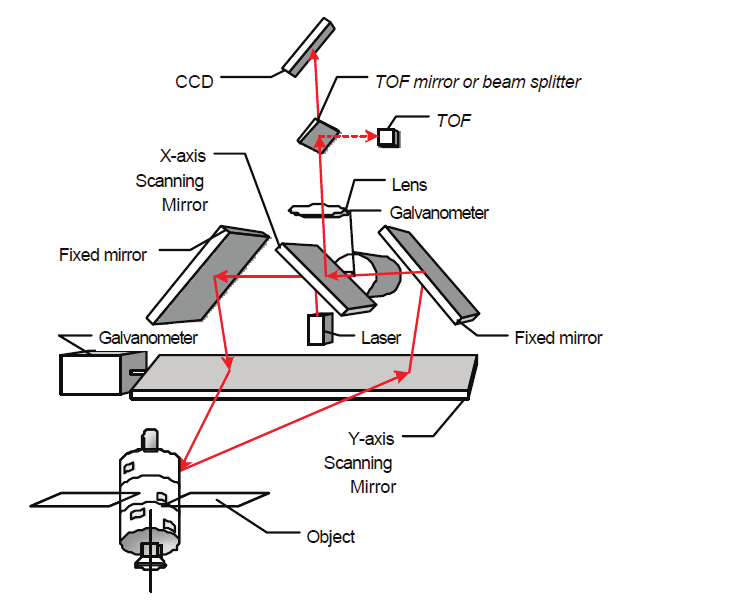

2.3 The auto-synchronized laser scanner

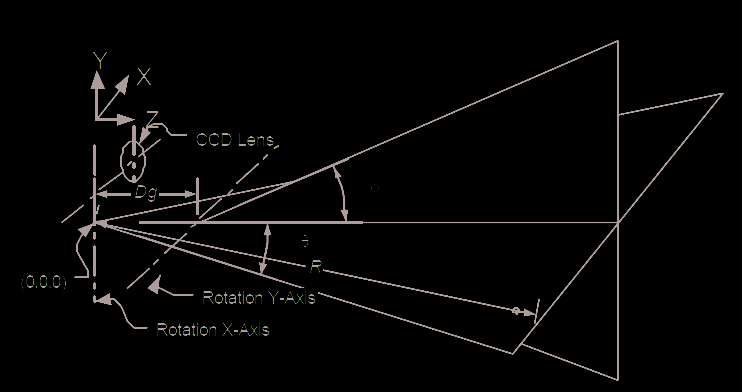

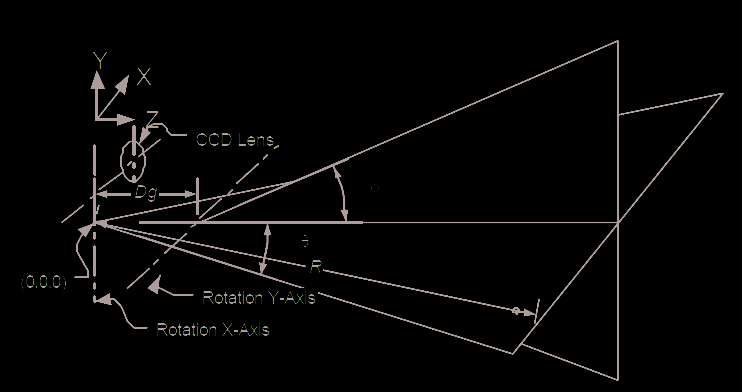

Figure 7 shows a photograph of the prototype of the auto-synchronized laser scanner

developed for this demonstration. The scanner uses a variation of the auto-synchronized

triangulation range sensor based on one galvanometer (Blais et al., 1988). The system

comprises two orthogonally mounted scanning mirrors and a linear discrete-response

photosensitive position device (e.g. linear CCD) used for short to medium range

measurement as triangulation (Beraldin et al., 2000). An optional avalanche photo-diode-

based Time-of-Flight (LIDAR) ranging module is used for longer-range measurement

556

Optoelectronic Devices and Properties

(Laurin et al., 1996). Only resolved targets using TOF are considered for this application.

Laser illumination is provided using a laser source coupled to a single-mode fiber, either

pulsed (TOF mode) or CW (triangulation mode). The laser scanner operates at a relatively

eye safe wavelength of 1.5 mm (compared to visible laser wavelengths).

The basic concept of auto-synchronization is that the projection of the light spot is

synchronized with its detection as illustrated in Figure 7. The instantaneous field of view

(IFOV) of the position sensor follows the spot as it scans the scene. Therefore, an external

optical perturbation can potentially interfere with the detection only when it intersects the

instantaneous field of view (IFOV) of the scanner. At this level, electronic signal processing

is used to filter these false readings to obtain correct 3-D measurement (Blais et al., 1991).

With synchronization, the total field of view (FOV) of the scanner is related to the scanning

angles of the galvanometers and mirrors as opposed to a conventional camera-based

triangulation. Here the field of view and image resolution are intimately linked (Blais et al.,

1988); a large field of view produces a lower pixel resolution. In summary, the instantaneous

field-of-view of the scanner plays a major role in the system sensitivity analysis.

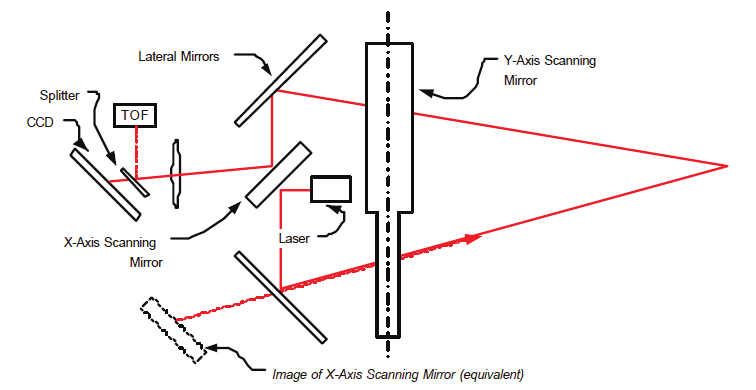

2.4 Range measurement

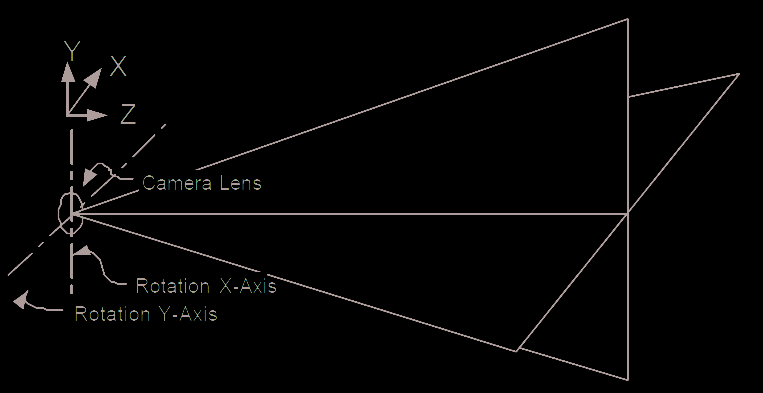

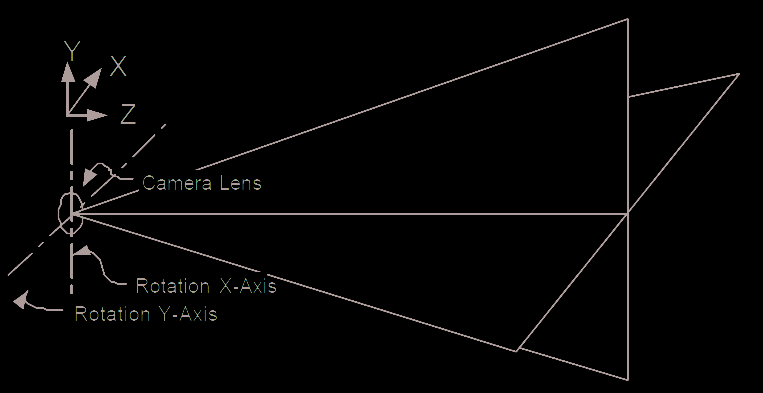

Figure 7 shows the optical geometry of the auto-synchronized laser scanner. The laser

scanner system can measure range information for each voxel (3-D pixel) in the scene

using two modes of operation: (1) triangulation as illustrated in Figure 8, and (2) time-of-

flight shown in Figure 9. It is beyond the scope of this paper to discuss the details of

operation of the scanner and the exact mathematical model. This information is available

from previous publications where the scanner is operated in imaging mode (Blais et al.,

1988; Beraldin et al., 1993; Beraldin et al., 2000). Here, we will use the simplified models

illustrated in Figure 10 to model range measurement and to associate object pose

estimation obtained using video camera models shown in Figures 10 and 11 and

techniques discussed in section 4.

Fig. 8. Simplified geometry of the laser scanner for the triangulation mode

Electromechanical 3D Optoelectronic Scanners:

Resolution Constraints and Possible Ways of Improvement

557

Fig. 9. Schematic of the time-of-flight principle

Fig. 10. Simplified geometrical model of the laser scanner showing the effect of astigmatism

between the X and Y scanning axis

Fig. 11. Simplified geometrical model of a simple camera lens system used by conventional

camera and photogrammetric methods

From (Blais et al., 1988), knowing that R=z/cos(θ), and from Figure 10, range R can be

calculated either using triangulation methods or TOF. The simplified aberrations free model

is presented here. For triangulation, range is given by

f ⋅ d

R

=

cos(θ ) + d sin θ (5)

Trian

( )

p

558

Optoelectronic Devices and Properties

where f is the focal length of the lens, d is the triangulation base, θ is the deflection angle following the x-axis, and p is the position of the imaged laser spot of the position sensor (see

(Blais et al., 1988) for details). For the TOF method of Figure 9, range is simply obtained

based on the speed of light c and the propagation delay τ of a laser pulse:

τ

R

= c (6)

TOF

2

From Figure 10, the x-y-z coordinates of a point are

⎡

⎤

⎡ x⎤

sin(θ )

⎢

⎥

⎢ y⎥ = R⋅⎢

(cos(θ)−

⎢ ⎥

ψ )sin(θ )

⎥ (7)

⎢

⎥

⎢ z⎥

⎣ ⎦

⎢(1− cos(θ ))ψ + cos(θ )cos(θ )⎥

⎣

⎦

where θ and φ are the deflection angles, and ψ=Dg/R where Dg is the separation between the two scanning axis shown in Figure 10. Range R is obtained using either RTrian or RTOF

depending on the operating mode of the scanner. Because Dg<<R, error propagation

calculations (in triangulation mode) can be approximated by

2

R

R

Δ

≈

p

Δ (8)

Trian

f ⋅ d

2

⎡Δ x⎤

⎡

sin(θ )

2

⎤

2

⎢

⎥

⎢

⎥ ⎛ R

⎞

Δ y = cos

⎢

⎥

⎢

(θ )⋅sin(ϕ)

2

⎥ ⎜

p

Δ ⎟ +

⎜ f d ⎟

⋅

⎢ z

Δ ⎥

⎢ cos

⎣

⎦

⎣

(θ )cos(ϕ) ⎥ ⎝

⎠

⎦

(9)

⎡

cos(θ )

2

2

⎤

⎡

0

⎤

⎢

⎥

⎢

⎥

+ −sin(θ ) ⋅ sin(ϕ)

2

2

R ⋅ Δθ + cos(ϕ )

2

2

R cos (θ )

2

⋅ Δ

⎢

⎥

⎢

⎥

ϕ

⎢ −sin

⎣

(θ )cos(ϕ) ⎥

⎢−sin

⎦

⎣

(ϕ)⎥⎦

where Δ p is the uncertainty associated with the laser spot measurement.

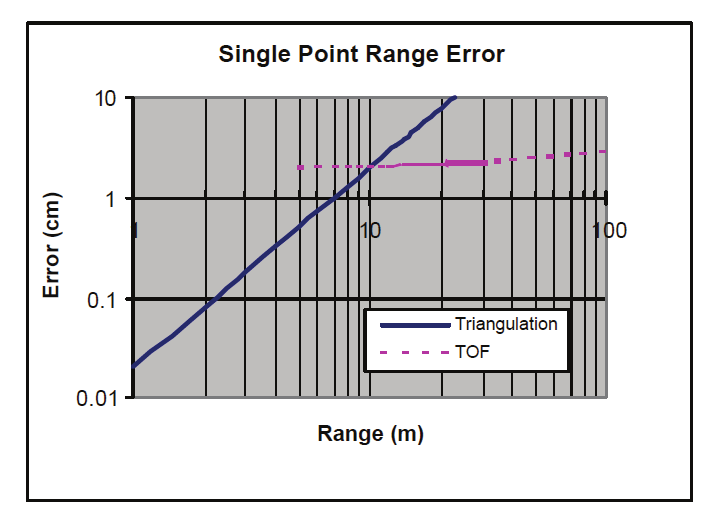

Fig. 12. Range error accuracy of the Laser Scanner System

Electromechanical 3D Optoelectronic Scanners:

Resolution Constraints and Possible Ways of Improvement

559

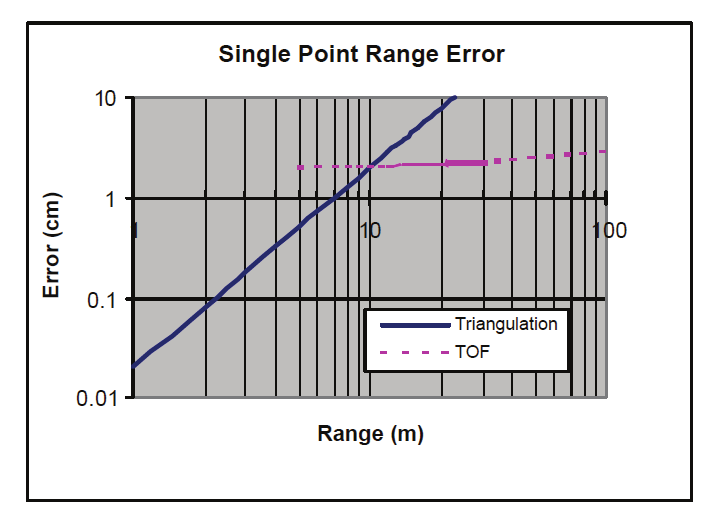

Figure 12 shows range error measured with the scanner in triangulation (notice the R2

dependence of the error), and from the manufacturer specifications for the TOF mode of

operation (notice the almost flat error over range). Other typical system parameters for the

prototype used in Figure 7 are maximum deflection angles of 0.5 rad (30 deg) and angular

errors of 50-100 µrad, depending on the target array. From equation 9 and Figure 12, the

total system error, for medium to long range, is