The research presented in this chapter establishes the CPM as a viable robotic device for

three degrees of freedom manipulation. The manipulator offers the advantages associated

with other parallel manipulators, such as light weight construction; while avoiding some of

the traditional disadvantages of parallel manipulators such as the extensive use of spherical

joints and coupling of the platform orientation and position. The CPM employs only

revolute and prismatic joints to achieve translational motion of the moving platform. The

main advantages of this parallel manipulator are that all of the actuators can be attached

directly to the base, closed-form solutions are available for the forward and inverse

kinematics, and the moving platform maintains the same orientation throughout the entire

workspace. From simulations done in this research, performance of various motion

controllers are studied and compared. Although the simple PD controller with only position

and velocity reference is easy to implement and no knowledge of the system is needed to

develop this type of controller, the tracking ability is very poor compared to the rest of the

controllers used in this thesis. At the next step, when partial dynamic modeling information

is incorporated into the controller, the PD controller with gravity compensation is

implemented. The simulation results show a significant improvement in tracking ability

from a simple PD controller. Next, the verification is needed to determine if complete

mathematical modeling knowledge is needed to give the controller complete advantage in

motion control. Hence, the PD controller with full dynamic feedforward terms and

computed torque controller are implemented and put to the test. The model based

controllers such as computed torque and PD control with full dynamic feedforward terms

can generate force commands more intelligently and accurately than simple non-model

based controllers. Hence, the need for studying dynamics of robot manipulator as well as

having a good understanding of various basic motion controller theories are important in

designing and controlling motion of the robot to achieve the highest quality and quantity of

work. The simulation results show that the computed torque controller gives the best

292

Parallel Manipulators, Towards New Applications

performance. This is a result of the computed torques canceling the nonlinear components

of the controlled system. From the observations seen in this work, one can see the

motivation for engineers to develop more advanced controllers that not only know the

dynamic model of the manipulator, but can also detect if the dynamic is changed and can

tune itself accordingly (i.e. adaptive control).

7. Future work

1. The effect of some unknown parameters such as the friction and the nonlinear factors

introduced by the motors and the gear boxes which may be obtained by experimental

measurements and through the identification methods can be studied.

2. The performance of model based control relies on an accurate model of a system.

However, identifying the accurate dynamic model of a system is very difficult.

Therefore, effective controllers for the versatile application of parallel robots should be

developed. Adaptive control has the potential to improve the tracking accuracy because

it updates the unknown parameters online. Adaptive control algorithm is too

complicated to be utilized in high speed applications. In such applications, robust

independent joint control is a prospective method to improve the performance of

simple PD control.

3. Adaptive Neuro Fuzzy Inference System ( ANFIS) controller can be used for each active

joint to generate the required control system, then its performance is compared with the

conventional controllers. Although many of model based methods have been found and

they provide satisfactory solutions, these solutions have been subordinated to the

development of the mathematical theories that deal with over idealized problems

bearing little relation to practice.

8. Acknowledgment

The authors would like to thank Prof. Han Sung Kim for his valuable suggestions and his

kind assistance during this work.

9. References

Carricato, M., and Parenti-Castelli, V., (2001), “A Family of 3-DOF Translational Parallel

Manipulators”, Proceedings of the 2001 ASME Design Engineering Technical

Conferences, Pittsburgh, PA, DAC-21035.

Ceccarelli, M., (1997), “A New 3 D.O.F. Spatial Parallel Mechanism”, Mechanism and

Machine Theory, Vol. 32, No. 8, pp. 895-902.

Clavel, R., (1988), “Delta, A Fast Robot with Parallel Geometry”, Proceedings of the 18th

International Symposium on Industrial Robots, pp. 91-100.

Di Gregorio, R., (2001), “A New Parallel Wrist Using only Revolute Pairs: The 3 RUU Wrist”,

Robotica, Vol. 19, No. 3, pp. 305-9.

Di Gregorio, R. and Parenti-Castelli, V., (1998), “A Translational 3-DOF Parallel

Manipulator”, in Advances in Robot Kinematics, Edited by J. Lenarcic and M. L.

Husty, Kluwer Academic Publishers, London, pp. 49-58.

Cartesian Parallel Manipulator Modeling, Control and Simulation

293

Fang, Y. and Tsai, L. W., 2002, “Enumeration of 3-DOF Translational Parallel Manipulators

Using the Theory of Reciprocal Screws”, accepted for publication in ASME Journal

of Mechanical Design.

Gosselin, C. and Angeles, J., 1989, “The Optimum Kinematic Design of a Spherical Three-

Degree-of-Freedom Parallel Manipulator”, ASME Journal of Mechanisms,

Transmissions, and Automation in Design, Vol. 111, No. 2, pp. 202-7.

Griffiths, J.D., An. C.H., Atkeson, C.G. and Hollerbach, J.M., 1989, “Experimental evaluation

of feedback and computed torque control”, International Journal of Robotics and

Automation, 5(3):368–373, June.

Gullayanon R., 2005, “Motion Control of 3 Degree-of-Freedom Direct-Drive Robot.", A

master thesis presented to the School of Electrical and Computer Engineering,

Georgia Institute of Technology.

Karouia, M., and Herve, J. M., 2000, “A Three-DOF Tripod for Generating Spherical

Rotation”, in Advances in Robot Kinematics, Edited by J. Lenarcic and V. Parenti-

Castelli, Kluwer Academic Publishers, pp. 395-402.

Kim H.S., and Tsai L.W., 2002, “Design optimization of a Cartesian parallel manipulator”,

Department of Mechanical Engineering, Bourns College of Engineering, University

of California.

Lewis, F., Abdallah, C. and Dawson, D., 1993, “Control of Robot Manipulators”, MacMillan

Publishing Company.

Pierrot, F., Reynaud, C. and Fournier, A., 1990, “Delta: A Simple and Efficient Parallel

Robot”, Robotica, Vol. 6, pp. 105-109.

Sciavicco, L., Chiacchio, P. and Siciliano, B., 1990, “The potential of model-based control

algorithms for improving industrial robot tracking performance”, IEEE

International Workshop on Intelligent Motion Control, pp. 831–836, August.

Spong, M. W., 1996, “Motion Control of Robot Manipulators”, University of Illinois at

Urbana-Champaign.

Spong, M.W. and Vidyasagar, M., 1989, “Robot dynamics and control”, John Wiley & Sons.

Stewart, D., 1965, “A Platform with Six Degrees of Freedom”, Proceedings Institute of

Mechanical Engineering, Vol. 180, pp. 371-386.

Tsai, L. W., and Joshi, S., 2002, “Kinematic Analysis of 3-DOF Position Mechanism for Use in

Hybrid Kinematic Machines", ASME Journal of Mechanical Design, Vol. 124, No. 2,

pp. 245-253.

Tsai, L. W., 1999, “Robot Analysis: the mechanics of serial and parallel manipulators”, John

Wiley & Sons.

Tsai, L. W., 1996, “Kinematics of a Three-DOF Platform Manipulator with Three Extensible

Limbs”, in Advances in Robot Kinematics, Edited by J. Lenarcic and V. Parenti-

Castelli, Kluwer Academic Publishers, pp. 401-410.

Tsai, L. W., Walsh, G. C. and Stamper, R., 1996, “Kinematics of a Novel Three DOF

Translational Platform”, IEEE International Conference on Robotics and

Automation, Minneapolis, MN, pp. 3446-3451.

294

Parallel Manipulators, Towards New Applications

Vischer, P. and Clavel, R., 2000, “Argos: a Novel 3-DOF Parallel Wrist Mechanism”, The

International Journal of Robotics Research, Vol. 19, No. 1, pp. 5-11.

14

Optimal Design of Parallel Kinematics

Machines with 2 Degrees of Freedom

Sergiu-Dan Stan, Vistrian Mătieş and Radu Bălan

Technical University of Cluj-Napoca

Romania

1. Introduction

The mechanical structure of today’s machine tools is based on serial kinematics in the

overwhelming majority of cases. Parallel kinematics with closed kinematics chains offer

many potential benefits for machine tools but they also cause many drawbacks in the design

process and higher efforts for numerical control and calibration.

The Parallel Kinematics Machine (PKM) is a new type of machine tool which was firstly

showed at the 1994 International Manufacturing Technology in Chicago by two American

machine tool companies, Giddings & Lewis and Ingersoll.

Parallel Kinematics Machines seem capable of answering the increase needs of industry in

terms of automation. The nature of their architecture tends to reduce absolute positioning

and orienting errors (Stan et al., 2006). Their closed kinematics structure allows them

obtaining high structural stiffness and performing high-speed motions. The inertia of its

mobile parts is reduced, since the actuators of a parallel robot are often fixed to its base and

the end-effector can perform movements with higher accelerations. One drawback with

respect to open-chain manipulators, though, is a typically reduced workspace and a poor

ratio of working envelope to robot size.

In theory, parallel kinematics offer for example higher stiffness and at the same time higher

acceleration performance than serial structures. In reality, these and other properties are

highly dependent on the chosen structure, the chosen configuration for a structure and the

position of the tool centre point (TCP) within the workspace. There is a strong and complex

link between the type of robot’s geometrical parameters and its performance. It’s very

difficult to choose the geometrical parameters intuitively in such a way as to optimize the

performance. The configuration of parallel kinematics is more complex due to the high

sensitivity to variations of design parameters. For this reason the design process is of key

importance to the overall performance of a Parallel Kinematics Machines. For the

optimization of Parallel Kinematics Machines an application-oriented approach is necessary.

In this chapter an approach is presented that includes the definition of specific objective

functions as well as an optimization algorithm. The presented algorithm provides the basis

for an overall multiobjective optimization of several kinematics structures.

An important objective of this chapter is also to propose an optimization method for planar

Parallel Kinematics Machines that combines performance evaluation criteria related to the

following robot characteristics: workspace, design space and transmission quality index.

296

Parallel Manipulators, Towards New Applications

Furthermore, a genetic algorithm is proposed as the principle optimization tool. The success

of this type of algorithm for parallel robots optimization has been demonstrated in various

papers (Stan et al., 2006).

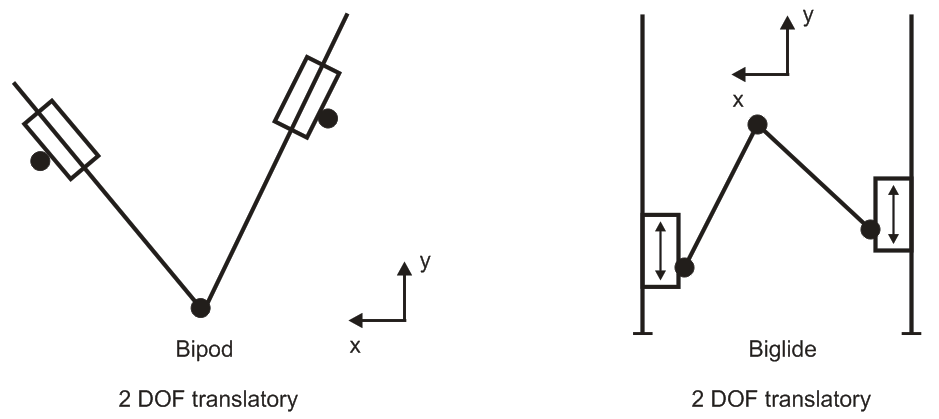

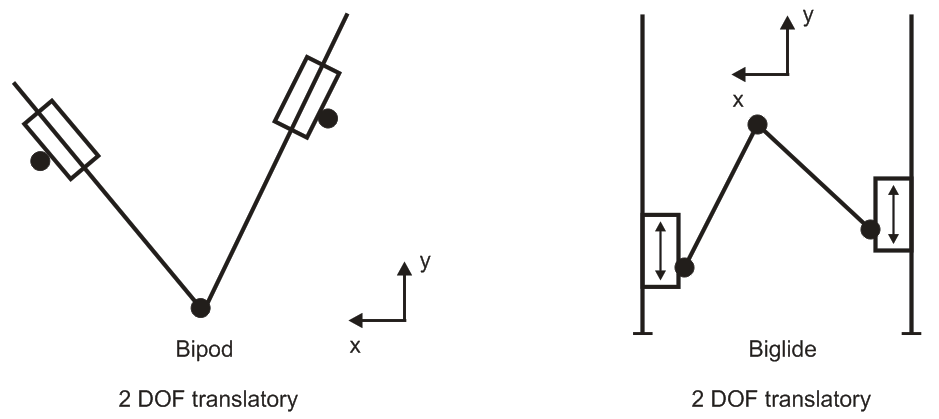

Fig. 1. Parallel kinematics for milling machines

For parallel kinematics machines with reduced number of degrees of freedom kinematics

and singularity analyses can be solved to obtain algebraic expressions, which are well suited

for an implementation in optimum design problems.

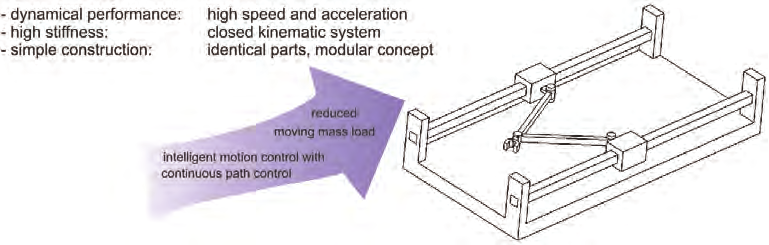

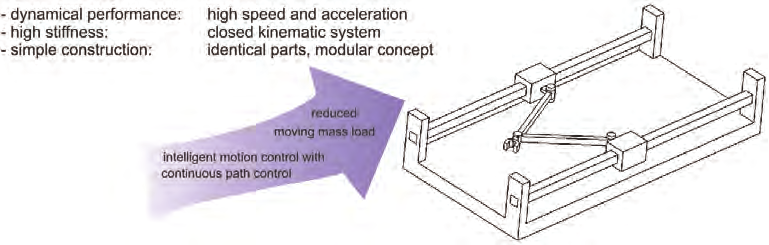

Fig. 2. Benefits of Parallel Kinematics Machines

High dynamical performance is achieved due to the low moved masses. Due to the closed

kinematics the movements of parallel kinematics machines are vibration free for which the

accuracy is improved. Finally, the modular concept allows a cost-effective production of the

mechanical parts.

In this chapter, the optimization workspace index is defined as the measure to evaluate the

performance of two degree of freedom Parallel Kinematics Machines. Another important

contribution is the optimal dimensioning of the two degree-of-freedom Parallel Kinematics

Machines of type Bipod and Biglide for the largest workspace using optimization based on

Genetic Algorithms.

Optimal Design of Parallel Kinematics Machines with 2 Degrees of Freedom

297

2. Objective functions used for optimization of machine tools with parallel

kinematics

One of the main influential factors on the performance of a machine tool with parallel

kinematics is its structural configuration. The performance of a machine tool with parallel

kinematics can be evaluated by its kinematic, static and dynamic properties. Optimal design

is one of the most important issues in the development of a parallel machine tool. Two

issues are involved in the optimal design: performance evaluation and dimensional

synthesis. The latter one is one of the most difficult issues in this field. In the optimum

design process, several criteria could be involved for a design purpose, such as workspace,

singularity, dexterity, accuracy, stiffness, and conditioning index.

After its choice, the next step on the machine tool with parallel kinematics design should be

to establish its dimensions. Usually this dimensioning task involves the choice of a set of

parameters that define the mechanical structure of the machine tool. The parameter values

should be chosen in a way to optimize some performance criteria, dependent upon the

foreseen application.

The optimization of machine tools with parallel kinematics can be based on the following

objectives functions:

•

workspace,

•

the overall size of the machine tool,

•

kinematic transmission of forces and velocities,

•

stiffness,

•

acceleration capabilities,

•

dexterity,

•

accuracy,

•

the singular configurations,

•

isotropy.

In the design process we want to determine the design parameters so that the parallel

kinematics machine fulfills a set of constraints. These constraints may be extremely different

but we can mention:

•

workspace requirement,

•

maximum accuracy over the workspace for a given accuracy of the sensors,

•

maximal stiffness of the Parallel Kinematics Machines in some direction,

•

minimum articular forces for a given load,

•

maximum velocities or accelerations for given actuator velocities and accelerations.

Determination of the architecture and size of a mechanism is an important issue in the

mechanism design. Several objectives are contradictory to each other. An optimization with

only one objective runs into unusable solutions for all other objectives. Unfortunately, any

change that improves one performance will usually deteriorate the other. This trade-off

occurs with almost every design and this inevitable generates the problem of design

optimization. Only a multiobjective approach will result in practical solutions for machine

tool applications.

The classical methods of design optimization, such as iterative methods, suffer from

difficulties in dealing with this problem. Firstly, optimization problems can take many

iterations to converge and can be sensitive to numerical problems such as truncation and

round-off error in the calculation. Secondly, most optimization problems depend on initial

298

Parallel Manipulators, Towards New Applications

guesses, and identification of the global minimum is not guaranteed. Therefore, the relation

between the design parameters and objective function is difficult to know, thus making it

hard to obtain the most optimal design parameters of the mechanism. Also, it’s rather

difficult to investigate the relations between performance criteria and link lengths of all

mechanisms. So, it’s important to develop a useful optimization approach that can express

the relations between performance criteria and link lengths.

2.1 Workspace

The workspace of a robot is defined as the set of all end-effector configurations which can be

reached by some choice of joint coordinates. As the reachable locations of an end-effector are

dependent on its orientation, a complete representation of the workspace should be

embedded in a 6-dimensional workspace for which there is no possible graphical

illustration; only subsets of the workspace may therefore be represented.

There are different types of workspaces namely constant orientation workspace, maximal

workspace or reachable workspace, inclusive orientation workspace, total orientation

workspace, and dextrous workspace. The constant orientation workspace is the set of

locations of the moving platform that may be reached when the orientation is fixed. The

maximal workspace or reachable workspace is defined as the set of locations of the end-

effector that may be reached with at least one orientation of the platform. The inclusive

orientation workspace is the set of locations that may be reached with at least one

orientation among a set defined by ranges on the orientation parameters. The set of locations

of the end-effector that may be reached with all the orientations among a set defined by

ranges on the orientations on the orientation parameters constitute the total orientation

workspace. The dextrous workspace is defined as the set of locations for which all

orientations are possible. The dextrous workspace is a special case of the total orientation

workspace, the ranges for the rotation angles (the three angles that define the orientation of

the end-effector) being [0,2π].

In the literature, various methods to determine workspace of a parallel robot have been

proposed using geometric or numerical approaches. Early investigations of robot workspace

were reported by (Gosselin, 1990), (Merlet, 1005), (Kumar & Waldron, 1981), (Tsai and Soni,

1981), (Gupta & Roth, 1982), (Sugimoto & Duffy, 1982), (Gupta, 1986), and (Davidson &

Hunt, 1987). The consideration of joint limits in the study of the robot workspaces was

presented by (Delmas & Bidard, 1995). Other works that have dealt with robot workspace

are reported by (Agrawal, 1990), (Gosselin & Angeles, 1990), (Cecarelli, 1995). (Agrawal,

1991) determined the workspace of in-parallel manipulator system using a different concept

namely, when a point is at its workspace boundary, it does not have a velocity component

along the outward normal to the boundary. Configurations are determined in which the

velocity of the end-effector satisfies this property. (Pernkopf & Husty, 2005) presented an

algorithm to compute the reachable workspace of a spatial Stewart Gough-Platform with

planar base and platform (SGPP) taking into account active and passive joint limits. Stan

(Stan, 2003) presented a genetic algorithm approach for multi-criteria optimization of PKM

(Parallel Kinematics Machines). Most of the numerical methods to determine workspace of

parallel manipulators rest on the discretization of the pose parameters in order to determine

the workspace boundary (Cleary & Arai, 1991), (Ferraresi et al., 1995). In the discretization

approach, the workspace is covered by a regularly arranged grid in either Cartesian or polar

form of nodes. Each node is then examined to see whether it belongs to the workspace. The

accuracy of the boundary depends upon the sampling step that is used to create the grid.

Optimal Design of Parallel Kinematics Machines with 2 Degrees of Freedom

299

The computation time grows exponentially with the sampling step. Hence it puts a limit on

the accuracy. Moreover, problems may occur when the workspace possesses singular

configurations. Other authors proposed to determine the workspace by using optimization

methods (Stan, 2003). Numerical methods for determining the workspace of the parallel

robots have been developed in the recent years. Exact computation of the workspace and its

boundary is of significant importance because of its impact on robot design, robot placement

in an environment, and robot dexterity.

Masory, who used the discretisation method (Masory & Wang, 1995), presented interesting

results for the Stewart-Gough type parallel manipulator:

•

The mechanical limits on the passive joints play an important role on the volume of

the workspace. For ball and socket joints with given rotation ability, the volume of

the workspace is maximal if the main axes of the joints have the same directions as

the links when the robot is in its nominal position.

•

The workspace volume is roughly proportional to the cube of the stroke of the

actuators.

•

The workspace volume is not very sensitive to the layout of the joints on the

platforms, even though it is maximal when the two platforms have the same

dimension (in this case, the robot is in a singular configuration in its nominal

position).

Even though powerful three-dimensional Computer Aided Design and Dynamic Analysis

software packages such as Pro/ENGINEER, IDEAS, ADAMS and Working Model 3-D are

now being used, they cannot provide important visual and realistic workspace information

for the proposed design of a parallel robot. In addition, there is a great need for developing

methodologies and techniques that will allow fast determination of workspace of a parallel

robot. A general numerical evaluation of the workspace can be deduced by formulating a

suitable binary representation of a cross-section in the taskspace. A cross-section can be

obtained with a suitable scan of the computed reachable positions and orientations p, once

the forward kinematic problem has been solved to give p as function of the kinematic input

joint variables q. A binary matrix P ij can be defined in the cross-section plane for a

crosssection of the workspace as follows: if the ( i, j) grid pixel includes a reachable point,

then P ij = 1; otherwise P ij = 0, as shown in Fig. 3. Equations (1)-(4) for determining the

workspace of a robot by discretization method can be found in Ref. (Ottaviano et al., 2002).

Then is computed i and j:

⎡ x + Δ x ⎤

⎡ y + Δ y ⎤

i = ⎢

⎥ j = ⎢

⎥

x

⎣ y ⎦

⎣

⎦

(1)

where i and j are computed as integer numbers. Therefore, the binary mapping for a

workspace cross-section can be given as:

⎧0 if P ∉ W ( H )

P = ⎨

ij

ij

1 if P ∈ W ( H )

⎩

ij

(2)

where W( H) indicates workspace region; ∈stands for “belonging to” and ∉is for “not

belonging t