Conditions: q

+ q

< b q

> b + q

q

> b + q

1 min

2 min

, 1 max

2 min ,

2 max

1 min

Fig. 22. The workspace of the planar 2 DOF Parallel Kinematics Machine is shown as the

shading region.

Case VI:

Conditions: q

+ q

> b q

> b + q

q

> b + q

1 min

2 min

, 1 max

2 min ,

2 max

1 min

Fig. 23. The workspace of the planar 2 DOF Parallel Kinematics Machine is shown as the

shading region.

Case VII:

Conditions:

q

< b

q

<

q

<

q

<

q

+ q

<

1 min

,

b

1 max

,

b

2 min

,

b

2 max

,

b

1 min

2 min

,

q

+ q

> b

1 max

2 max

Fig. 24. The workspace of the planar 2 DOF Parallel Kinematics Machine is shown as the

shading region.

312

Parallel Manipulators, Towards New Applications

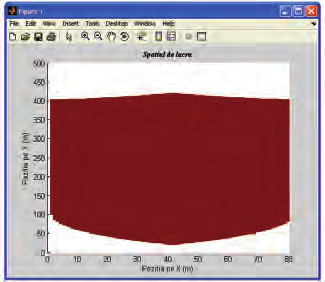

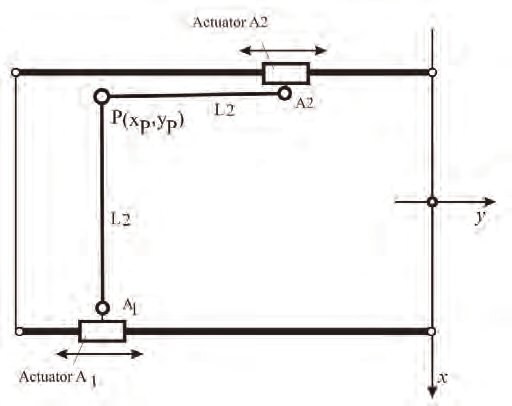

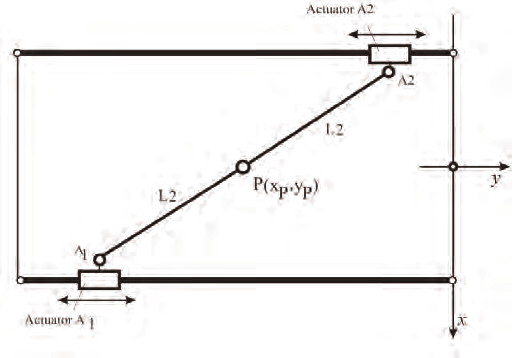

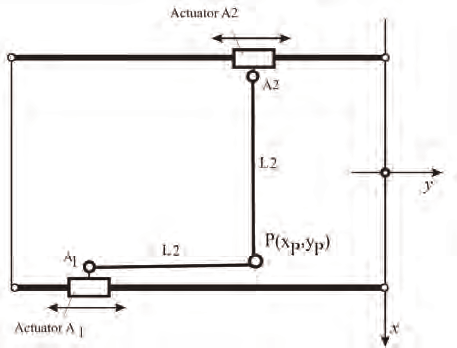

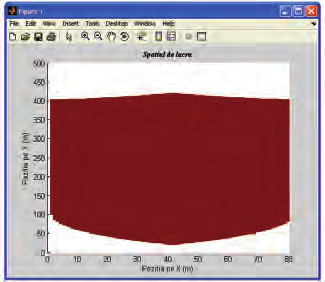

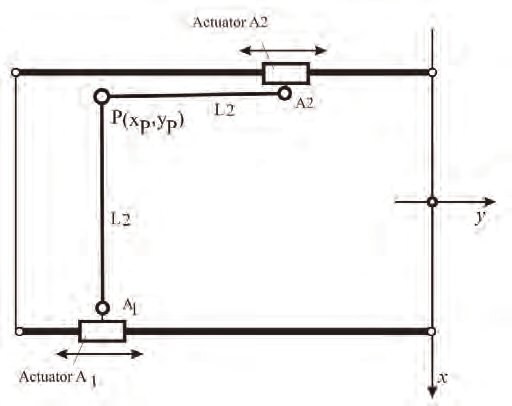

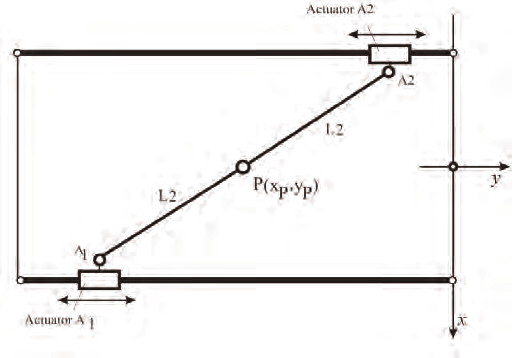

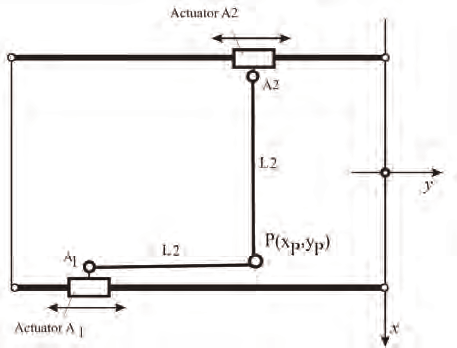

In the followings is presented the workspace analysis of 2 DOF Biglide Parallel Kinematics

Machine.

a) Workspace for the planar 2 DOF Parallel Kinematics Machine, case

q

= q

=100 mm

1 max

2 max

b) Workspace for the planar 2 DOF Parallel Kinematics Machine, case

q

= q

= 200 mm

1 max

2 max

c) Workspace for the planar 2 DOF Parallel Kinematics Machine, case

q

= q

= 400 mm

1 max

2 max

Fig. 25. Different regions of workspace for Biglide PKM for different lengths of stroke of

actuators

Optimal Design of Parallel Kinematics Machines with 2 Degrees of Freedom

313

4.2 Singularity analysis of the Biglide Parallel Kinematics Machine

Because singularity leads to a loss of the controllability and degradation of the natural

stiffness of manipulators, the analysis of parallel manipulators has drawn considerable

attention. Most parallel robots suffer from the presence of singular configurations in their

workspace that limit the machine performances. Based on the forward and inverse Jacobian

matrix, three cases of singularities of parallel manipulators can be obtained. Singular

configurations should be avoided.

In the followings are presented the singular configurations of 2 DOF Biglide Parallel

Kinematic Machine.

Fig. 26. Singular configuration for the planar 2 DOF Biglide Parallel Kinematic Machine

Fig. 27. Singular configuration for the planar 2 DOF Biglide Parallel Kinematic Machine

314

Parallel Manipulators, Towards New Applications

Fig. 28. Singular configuration for the planar 2 DOF Biglide Parallel Kinematic Machine

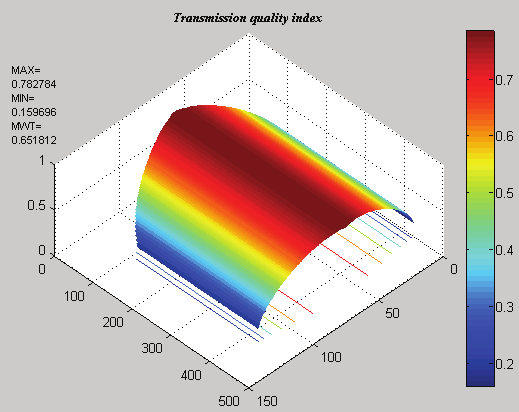

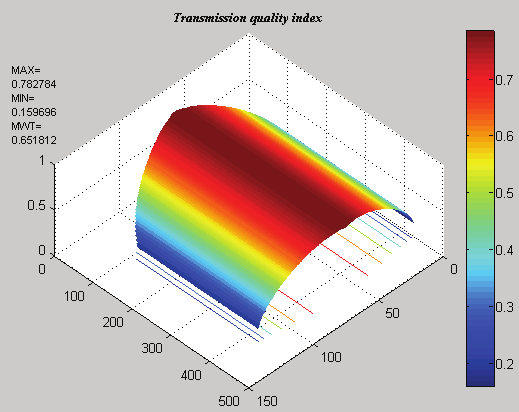

4.2 Performance evaluation

Beside workspace which is an important design criterion, transmission quality index is

another important criterion. The transmission quality index couples velocity and force

transmission properties of a parallel robot, i.e. power features (Hesselbach et al., 2004). Its

definition runs:

2

I

T =

(9)

1

−

J ⋅ J

where I is the unity matrix. T is between 0<T<1; T=0 characterizes a singular pose, the

optimal value is T=1 which at the same time stands for isotropy (Stan, 2003).

MAX=

Übertragungsgüte

0.658553

MIN=

0.427955

0.64

MWT=

0.62

0.8 0.503084

0.6

0.7

0.58

0.56

0.6

0.54

0.5

0.52

0.5

0.4

0

0.48

0

50

0.46

50

100

100

0.44

150 150

Fig. 29. Transmission quality index for RPRPR Bipod Parallel Kinematic Machine

Optimal Design of Parallel Kinematics Machines with 2 Degrees of Freedom

315

Fig. 30. Transmission quality index for PRRRP Biglide Parallel Kinematic Machine

As it can be seen from the Fig. 30, the performances of the PRRRP Biglide Parallel Kinematic

Machine are constant along y-axis. On every y section of such workspace, the performance

of the robot can be the same.

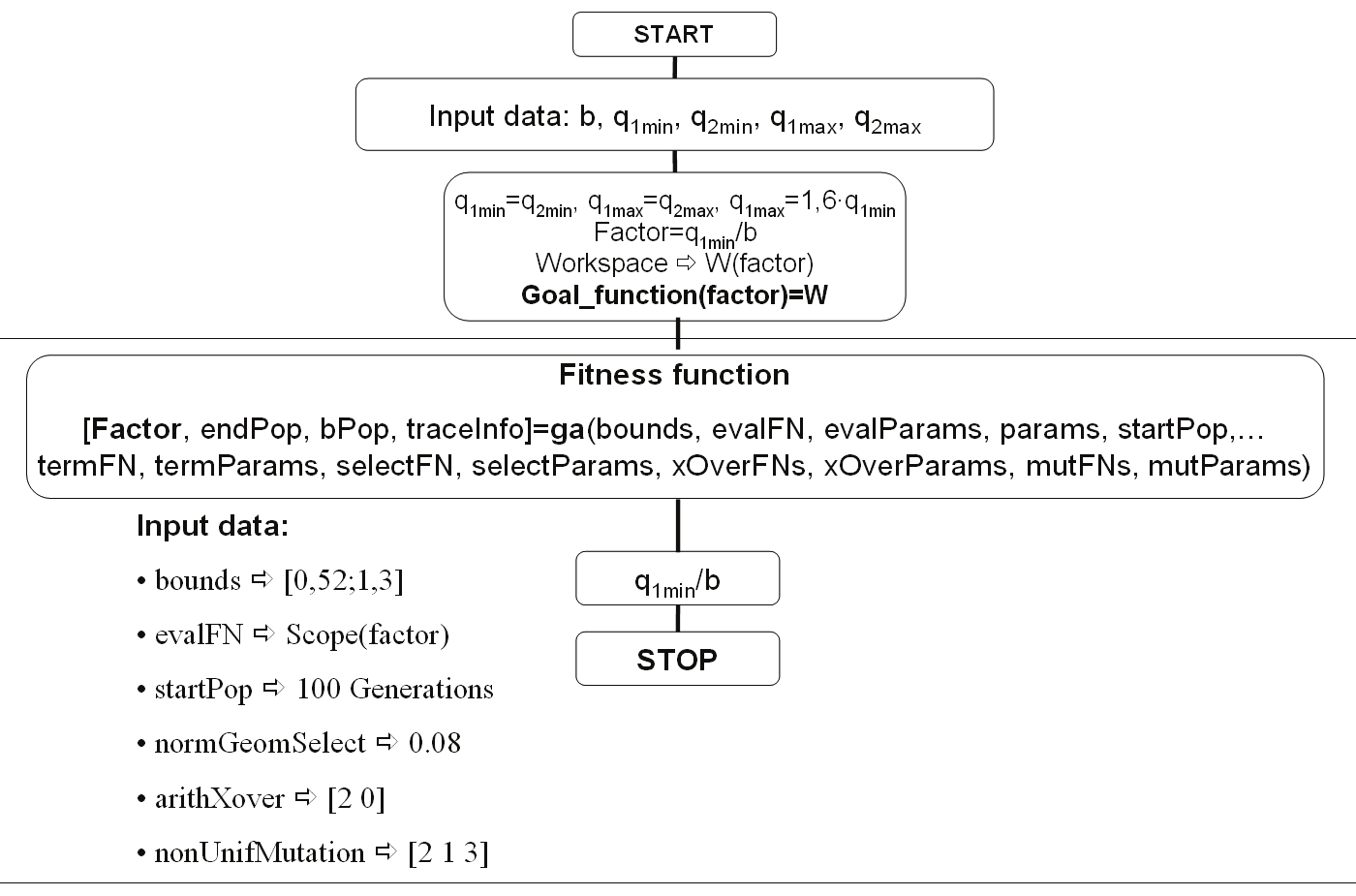

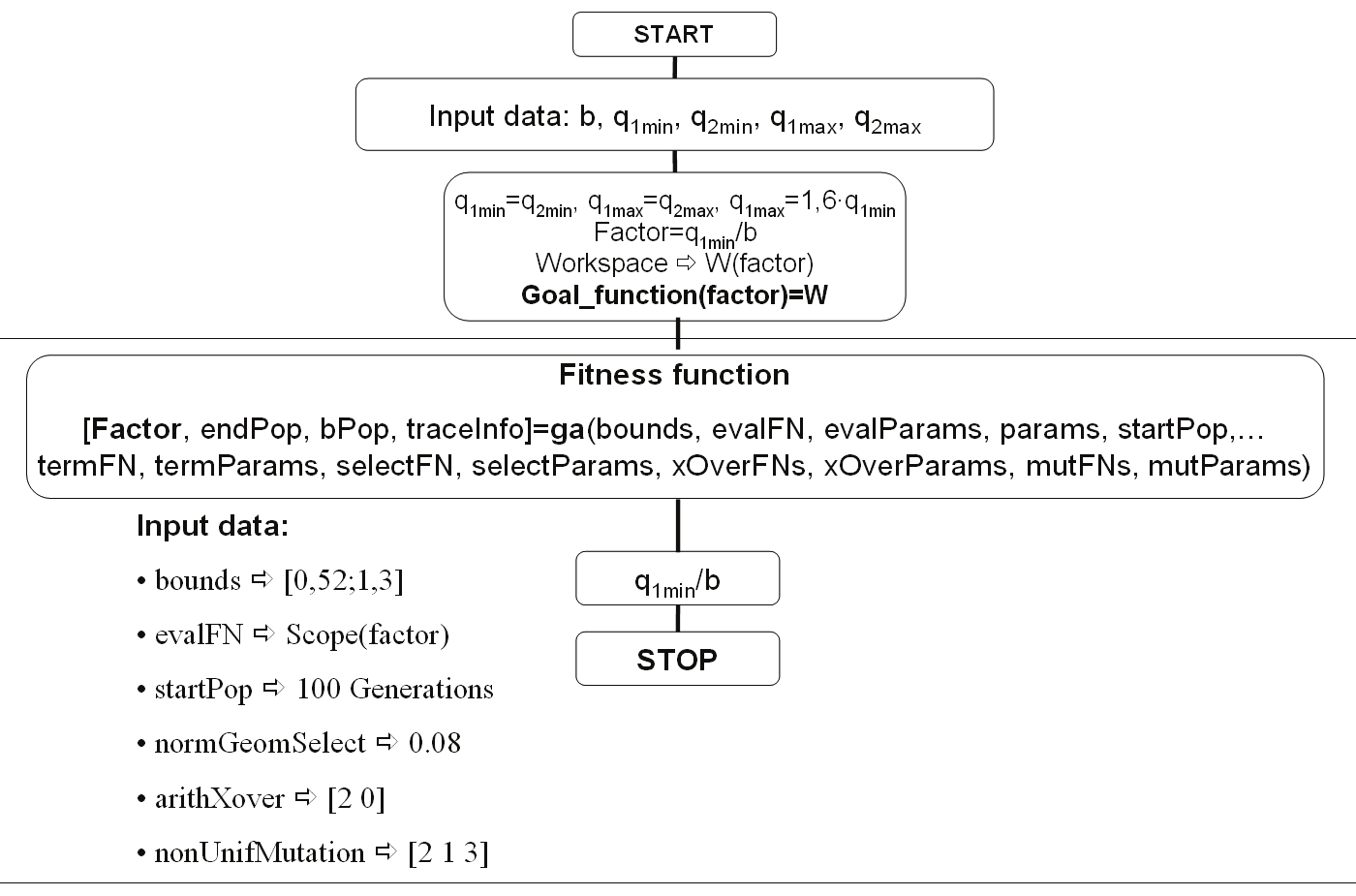

5. Optimal design of 2 DOF Parallel Kinematics Machines

5.1 Optimization results for RPRPR Parallel Kinematic Machine

The design of the PKM can be made based on any particular criterion. The chapter presents

a genetic algorithm approach for workspace optimization of Bipod Parallel Kinematic

Machine. For simplicity of the optimization calculus a symmetric design of the structure was

chosen.

In order to choose the PKM’s dimensions b, q1min, q1max, q2min, q2max, we need to define a performance index to be maximized. The chosen performance index is W (workspace) and T

(transmission quality index).

An objective function is defined and used in optimization. It is noted as in Eq. (8), and

corresponds to the optimal workspace and transmission quality index. We can formalize our

design optimization problem as the following:

ObjFun=W+T

(10)

Optimization problem is formulated as follows: the objective is to evaluate optimal link

lengths which maximize Eq. (10). The design variables or the optimization factor is the ratios

of the minimum link lengths to the base link length b, and they are defined by:

q1min/b

(11)

316

Parallel Manipulators, Towards New Applications

Constraints to the design variables are:

0,52<q1min/b<1,35

(12)

q1min=q2min, q1max=q2max, q1max=1,6q1min, q2max=1,6q2min

(13)

Fig. 31. Flowchart of the optimization Algorithm with GAOT (Genetic Algorithm

Optimization Toolbox)

For this example the lower limit of the constraint was chosen to fulfill the condition q1min≥b/2

that means the minimum stroke of the actuators to have a value greater than the half of the

distance between them in order to have a workspace only in the upper region. For simplicity

of the optimization calculus the upper bound was chosen q1min≤1,35b.

During optimization process using genetic algorithm it was used the following GA

parameters, presented in Table 1.

Generations 100

Crossover rate

0.08

Mutation rate

0.005

Population 50

Table 1. GA Parameters

Researchers have used genetic algorithms, based on the evolutionary principle of natural

chromosomes, in attempting to optimize the design parallel kinematics. Kirchner and

Neugebaur (Kirchner & Neugebaur, 2000), emphasize that a parallel manipulator machine

tool cannot be optimized by considering a single performance criterion. Also, using a

Optimal Design of Parallel Kinematics Machines with 2 Degrees of Freedom

317

genetic algorithm, they consider a multiple design criteria, such as the “velocity

relationship” between the moving platform and the actuator legs, the influence of actuator

leg errors on the accuracy of the moving platform, actuator forces, stiffness, as well as a

singularity-free workspace.

A genetic algorithm (GA) is used because its robustness and good convergence properties.

The genetic algorithms optimization approach has the clear advantage over conventional

optimization approaches in that it allows a number of solutions to be examined in a single

design cycle.

The traditional methods searches optimal points from point to point, and are easy to fall into

local optimal point. Using a population size of 50, the GA was run for 100 generations. A list

of the best 50 individuals was continually maintained during the execution of the GA,

allowing the final selection of solution to be made from the best structures found by the GA

over all generations.

We performed a kinematic optimization in such a way to maximize the objective function. It

is noticed that optimization result for Bipod when the maximum workspace of the 2 DOF

planar PKM is obtained for q

/ b

1

=1,35. The used dimensions for the 2 DOF parallel

min

PKM were: q1min=80 mm, q1max=130 mm, q2min=80 mm, q2max=130 mm, b=60 mm. Maximum

workspace of the Parallel Kinematics Machine with 2 degrees of freedom was found to be

W= 4693,33 mm2.

If an elitist GA is used, the best individual of the previous generation is kept and compared

to the best individual of the new one. If the performance of the previous generation’s best

individual is found to be superior, it is passed on to the next generation instead of the

current best individual.

There have been obtained different values of the parameter optimization ( q1/b) for different

objective functions. The following table presents the results of optimization for different

goal functions. W1 and W2 are the weight factors.

Method

GAOT Toolbox MATLAB

Z=W1·T+W2·W, W1=0,7

q

and W

1/b = 0.92

2=0,3

Z=W1·T+W2·W, W1=0,3

q

Goal functions

and W

1/b= 1.13

2=0,7

Z= W1·T,

q

W

1/b=0.71

1=1 and W2=0

Z=W2·W,

q

W

1/b= 1.3

1=0 and W2=1

Table 2. Results of Optimization for Different Goal Functions

The results show that GA can determine the architectural parameters of the robot that

provide an optimized workspace. Since the workspace of a parallel robot is far from being

intuitive, the method developed should be very useful as a design tool.

However, in practice, optimization of the robot geometrical parameters should not be

performed only in terms of workspace maximization. Some parts of the workspace are more

useful considering a specific application. Indeed, the advantage of a bigger workspace can

318

Parallel Manipulators, Towards New Applications

be completely lost if it leads to new collision in parts of it which are absolutely needed in the

application. However, it’s not the case of the presented structure.

5.2 Optimization results for PRRRP Parallel Kinematic Machine

An objective function is defined and used in optimization. Objective function contains

workspace and transmission quality index. Optimization parameter was chosen as the link

length L2. The constraints was established as 1<L2<1.2. After performing the optimization

the following results were obtained:

Method

GAOT Toolbox MATLAB

Z=W1·T+W2·W, W1=0,7

L

and W

2 = 1.1

2=0,3

Z=W1·T+W2·W, W1=0,3

L

and W

2= 1.1556

2=0,7

Goal functions

Z= W1·T,

L

W

2=1

1=1 and W2=0

Z=W2·W,

L

W

2=1.2

1=0 and W2=1

Table 3. Results of Optimization for Different Goal Functions

Based on the presented optimization methodology we can conclude that the optimum

design and performance evaluation of the Parallel Kinematics Machines is the key issue for

an efficient use of Parallel Kinematics Machines. This is a very complex task and in this

paper was proposed a framework for the optimum design considering basic characteristics

of workspace, singularities and isotropy.

6. Conclusion

The fundamental guidelines for genetic algorithm to optimal design of micro parallel robots

have been introduced. It is concluded that with three basic generators selection, crossover

and mutation genetic algorithm could search the optimum solution or near-optimal solution

to a complex optimization problem of micro parallel robots. In the paper, design

optimization is implemented with Genetic Algorithms (GA) for optimization considering

transmission quality index, design space and workspace. Genetic algorithms (GA) are so far

generally the best and most robust kind of evolutionary algorithms. A GA has a number of

advantages. It can quickly scan a vast solution set. Bad proposals do not affect the end

solution negatively as they are simply discarded. The obtained results have shown that the

use of GA in such kind of optimization problem enhances the quality of the optimization

outcome, providing a better and more realistic support for the decision maker.

7. References

Agrawal, S. K., (1990). Workspace boundaries of in-parallel manipulator systems. Int. J.

Robotics Automat. 1990, 6(3) 281-290.

Optimal Design of Parallel Kinematics Machines with 2 Degrees of Freedom

319

Cecarelli, M., (1995). A synthesis algorithm for three-revolute manipulators by using an

algebraic formulation of workspace boundary. ASME J. Mech. Des. ; 117(2(A)): 298-

302.

Ceccarelli, M., G. Carbone, E. Ottaviano, (2005). An Optimization Problem Approach For

Designing Both Serial And Parallel Manipulators, In: Proc. of MUSME 2005, the

International Symposiom on Multibody Systems and Mechatronics, Uberlandia, Brazil, 6-

9 March 2005.

Ceccarelli, M., (2004). Fundamentals of Mechanics of Robotic Manipulation, Dordrecht,

Kluwer/Springer.

Cleary, K. and Arai, T. (1991). A prototype parallel manipulator: Kinematics, construction,

software, workspace results, and singularity analysis. In: Proceedings of International

Conference on Robotics and Automation, pages 566–571, Sacramento, California, USA,

April 1991.

Davidson, J. K. and Hunt, K. H., (1987). Rigid body location and robot workspace: some

alternative manipulator forms. ASME Journal of Mech. Transmissions Automat Des,

109(2); 224-232.

Du Plessis L.J. and J.A. Snyman, (2001). A numerical method for the determination of

dextrous workspaces of Gough-Stewart platforms. Int. Journal for Numerical Methods

in Engineering, 52:345–369.

Ferraresi, C., Montacchini, G. and M. Sorli, (1995). Workspace and dexterity evaluation of 6

d.o.f. spatial mechanisms, In: Proceedings of the ninth World Congress on the theory of

Machines and Mechanism, pages 57–61, Milan, August 1995.

Gogu, G., (2004), Structural synthesis of fully-isotropic translational parallel robots via

theory of linear transformations, European Journal of Mechanics, A/Solids, vol. 23, pp.

1021-1039.

Gosselin, C. (1990). Determination of the workspace of 6-d.o.f. parallel manipulators. ASME

Journal of Mechanical Design, 112:331–336.

Gosselin, C., and Angeles J. (1990). Singularities analysis of closed loop kinematic chains.

IEEE Trans Robotics Automat; 6(3) 281-290.

Gupta, K. C. (1986). On the nature of robot workspaces, International Journal of Robotics

Research. 5(2): 112-121.

Gupta, K. G. and Roth B., (1982). Design considerations for manipulator workspace. ASME J.

Mech. Des. , 104(4), 704-711.

Hesselbach, J., H. Kerle, M. Krefft, N. Plitea, (2004). The Assesment of Parallel Mechanical

Structures for Machines Taking Account of their Operational Purposes. In:

Proceedings of the 11th World Congress in Mechanism and Machine Science-IFToMM 11,

Tianjin, China, 2004.

Kirchner, J., and Neugebauer, R., (2000). How to Optimize Parallel Link Mechanisms –

Proposal of a New Strategy. In: Proceedings Year 2000 Parallel Kinematics Machines

International Conference, September 13-15, 2000, Ann Arbor, Mi. USA, [Orlandea, N.

et al. (eds.)], pp. 307-315.

Kumar, A. and Waldron, (1981). K.J. The workspace of mechanical manipulators. ASME J.

Mech. Des.; 103:665-672.

Masory, O. and Wang J. (1995). Workspace evaluation of Stewart platforms.

Advanced robotics, 9(4):443-461.

320

Parallel Manipulators, Towards New Applications

Merlet, J. P., (1995). Determination of the orientation workspace of parallel manipulators.

Journal of intelligent and robotic systems, 13:143–160.

Pernkopf, F. and Husty, M., (2005). Reachable Workspace and Manufacturing Errors of

Stewart-Gough Manipulators, Proc. of MUSME 2005, the Int. Sym. on Multibody

Systems and Mechatronics Brazil, p. 293-304.

Schoenherr, J., (1998). Bemessen Bewerten und Optimieren von Parallelstrukturen, In: Proc.

1st Chemnitzer Parallelstruktur Seminar, Chemnitz, Germany, 85-96.

Snyman, J. A., L.J. du Plessis, and J. Duffy. (2000). An optimization approach to the

determination of the boundaries of manipulator workspaces. Journal of Mechanical

Design, 122:447–455.

Stan, S., (2003). Analyse und Optimierung der strukturellen Abmessungen von

Werkzeugmaschinen mit Parallelstruktur, Diplomarbeit, IWF-TU Braunschweig,

Germany.

Stan, S., (2006). Workspace optimization of a two degree of freedom mini parallel robot,

IEEE-TTTC International Conference on Automation, Quality and Testing, Robotics –

AQTR 2006 (THETA 15), May 25-28 2006, Cluj-Napoca, Romania, IEEE Catalog

number: 06EX1370, ISBN: 1-4244-0360-X, pp. 278-283.

Stan, S. and Lăpuşan, C., (2006). Workspace analysis of a 2 dof mini parallel robot, The 8th

National Symposium with International Participation COMPUTER AIDED DESIGN -

PRASIC'06, Braşov, 9 - 10th November 2006, pag. 175-180, ISBN (10)973-653-824-0;

(13)978-973-635-824-1.

Stan, S., Vistrian M., Balan, R. (2007). Optimal Design of a 2 DOF Micro Parallel Robot Using

Genetic Algorithms, Proceedings of the 2007 IEEE-ICIT 2007, IEEE International

Conference on Integration Technology, March 20 - 24, 2007, Shenzhen, China, 1-4244-

1092-4/07, p. 719-724, IEEE Catalog Number: 07EX1735, ISBN: 1-4244-1091-6, ISBN:

1-4244-1092-4.

Stan, S., Balan, R., Vistrian M., (2007). Multi-objective Design Optimization of Mini Parallel

Robots Using Genetic Algorithms, IEEE-ISIE 2007 2007 IEEE International

Symposium on Industrial Electronics, June 4-7, 2007, Caixanova - Vigo, Spain, IEEE

Catalog Number: 07TH8928C, ISBN: 1-4244-0755-9, Library of Congress:

2006935487, pag. 1-4244-0755-9/07/ IEEE 2173-2178.

Stan, S., Maties, V., Balan, R., (2007). Optimization of 2 DOF Micro Parallel Robots Using

Genetic Algorithms, IEEE-ICM 2007, IEEE - International Conference on Mechatronics

2007, 8-10 May, 2007, Kumamoto, Japan, ISBN: 1-4244-1184-X

IEEE Catalog Number of CD proceedings: 07EX1768C, ISBN of CD