manipulators. Indeed, a lot of applications do not need six DOFs. A classification proposed

by Brogardh (Brogardh, 2002) gives the necessary number of DOF for different industrial

applications. He shows that applications such as pick-and-place, assembly, cutting,

measurement, etc. just need from three up to five DOFs.

The parallel manipulator H4 can provide three translations and one rotation about a fixed

axis, which are also called Schonflies motions (Herv , 1999). SCARA robots were the first

manipulators developed to produce these movements. Due their serial architecture, these

robots involve high moving masses which are not suitable for high dynamics. Parallel

architecture can overcome this problem. Delta robot is first introduced by Clavel to execute

Schonflies motions (Clavel, 1988). This architecture is able to produce three translations and

one rotational motion is obtained using a central “telescopic” leg built with universal and

prismatic joints. This RUPUR chain suffers from a short service life, and involves a bad

stiffness of the rotation motion. Orthoglide (Chablat, 2002) is another parallel robot that can

provide Schonflies motions using linear actuators. Its particularity is to be isotropic at the

center of its workspace. The machine tool HITA STT has been proposed to produce

Schonflies motions (Thurneysen et al, 2002). The particularity of this architecture is to use

additional parts in the traveling plate in order to amplify the rotational motion. Other

Schonflies motion generators include Gross Manipulator (Angeles et al., 2000), SMG

(Angeles, 2005), Kanuk and Manta (Rolland et al., 1999) robots.

In order to avoid the central telescopic leg of the Delta robot, in 1999, the Montpellier

Laboratory of Computer Science, Robotics, and Microelectronics (LIRMM) in French

invented the parallel manipulator H4 which used the concept of articulated traveling plate.

The rotational movement is obtained using an internal mobility on the traveling plate, and a

transforming device gives the desired range of rotational motion. Because placing actuators

in a symmetrical way ( i.e. at 90° one relatively to each other) involves “internal singularities”

(Pierrot & Company, 1999), the robot has to be built using a particular arrangement of

motors. This non-symmetrical arrangement entails a non-homogeneous behavior in the

workspace and a limited stiffness of the robot (Company et al., 2005). Later, based on the

concept of H4, an improved mechanical structure called I4 is proposed by LIRMM (Krut et

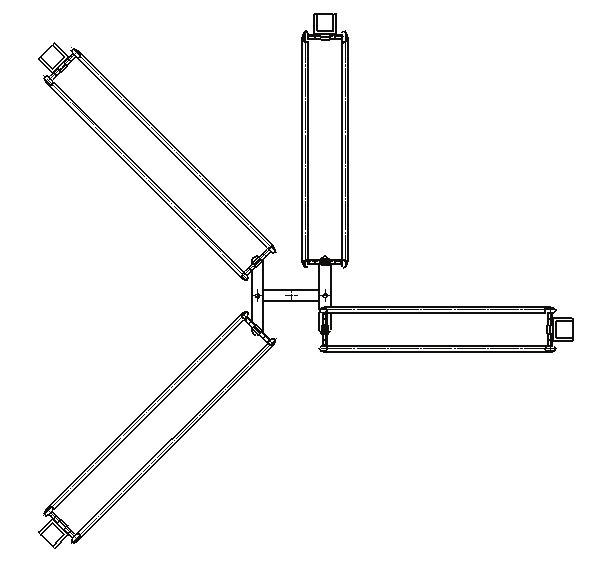

al., 2004; Krut et al., 2003). The internal mobility of I4 is obtained with a prismatic joint (Fig.

8). The advantage of this architecture is to authorize a symmetrical arrangement of the

actuators. As demonstrates by Krut (Krut et al., 2004), it is possible to place the actuators at

90° one relatively to each other. However, this architecture is more adapted to machine-tool

application than to high speed pick-and-place. Indeed, commercial prismatic joints are not

suitable for high speed and high accelerations, and have a short service life under such

conditions. This inconvenient is due to the high pressure exerted on the balls of these

elements at high acceleration conditions. Based on H4 and I4 architecture, an evolution of

these mechanisms, named Part 4, has been developed with the wish of reaching high speeds

414

Parallel Manipulators, Towards New Applications

and accelerations (Nabat et al., 2005). A paper written by Nabat (Nabat et al., 2006)

presented experimental results showing that Part 4 was able to reach an acceleration of 15G.

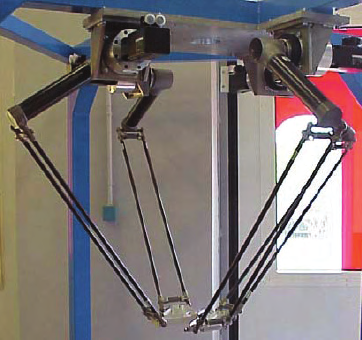

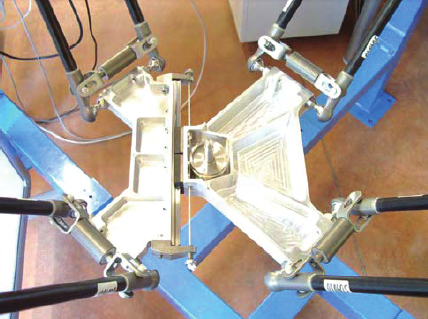

Part 4 is a parallel manipulator composed of four closed kinematic chains and an articulated

traveling plate. The kinematic chains are similar for Delta, H4 and I4, each of which is

composed of an arm and a spatial parallelogram (forearm) linked with spherical joints. The

traveling plate is composed of four parts: two main parts (1, 2) linked by two bars (3, 4) with

revolute joints (see Fig.9). Thus, its shape is a planar parallelogram and the internal mobility

of this traveling plate is a circular translation. Generally, the “natural “range of the

rotational operational motion is small, in order to make a complete turn: [-π; π], an

amplification system has to be added on the traveling plate. Several options are available for

this amplification such as gears or belt/pulleys. The prototype shown in Fig.9 (b) has been

built using belt/pulleys system, with the first pulley fixed on one half traveling plate, and

the second one is linked with a revolute joint to the second half traveling plate. Due to its

traveling plate having the shape of a planar parallelogram, Part 4 has all the advantages of

the previous robots, without their drawbacks. The traveling plate of this robot is articulated

and is exclusively realized with revolute joints. Nabat (Nabat et al., 2006) has demonstrated

that it is possible to have the same arrangements of the actuators as I4. Thus, this robot is

well suited to reach high dynamics and, at the same time, to have a good stiffness and a

homogenous behavior in the workspace.

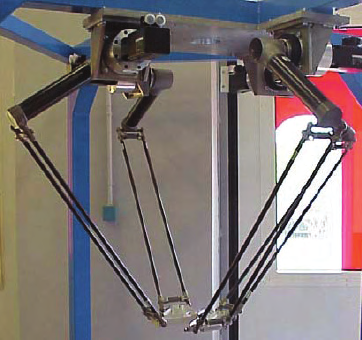

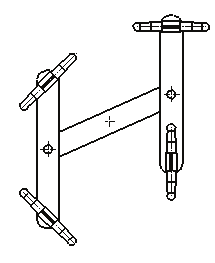

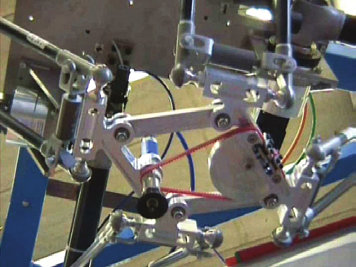

(a) Overview of I4 prototype

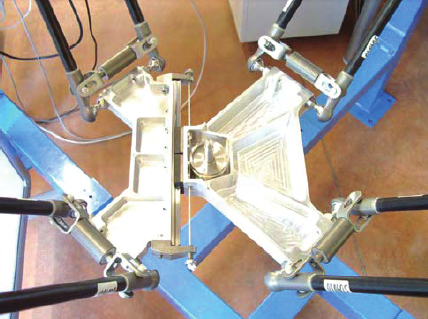

(b) Articulated traveling plate

Fig.8. I4 prototype (courtesy of LIRMM)

The use of base-mounted actuators and low-mass links allows the traveling plate to achieve

great accelerations. This makes this type of parallel manipulator a perfect candidate for pick

and place operations of light objects. Especially for semiconductor end-package equipments,

which need high-speed and high-precision pick-and-place movement, these parallel

manipulators provide a novel solution scheme.

In this chapter, only H4 is considered, because it firstly provides the most important concept

of traveling plate. Based on the analytical method of H4, other types of evolution structure

can be analyzed conveniently.

A Novel 4-DOF Parallel Manipulator H4

415

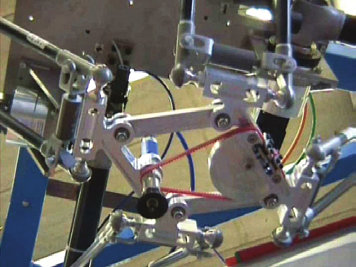

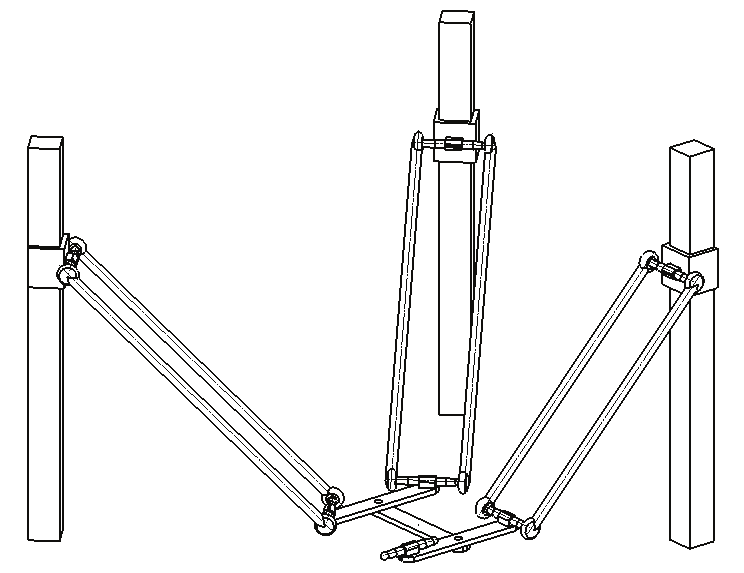

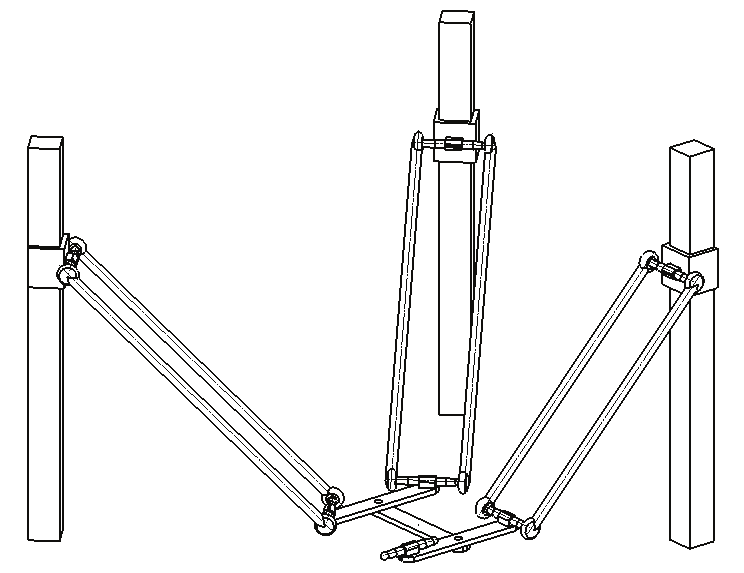

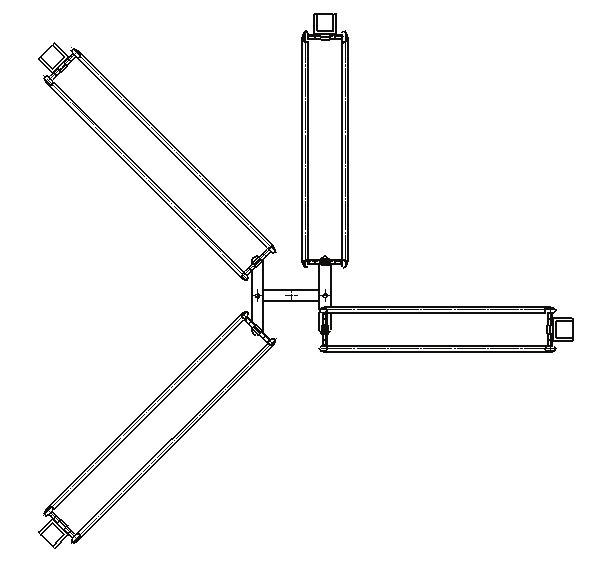

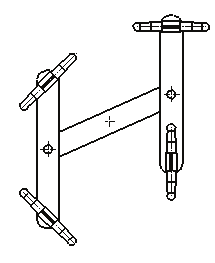

(a) Overview of Part4 prototype

(b) Articulated traveling plate

Fig.9. Part4 prototype (courtesy of LIRMM)

3. Kinematic analysis

This section will examine the relations between the actuated joint coordinates of H4 and the

nacelle (or traveling plate) pose.

3.1 Inverse kinematics

The relation giving the actuated joint coordinates for a given pose of the end-effector is

called the inverse kinematics, which is simple for parallel robots. The inverse kinematics

consists in establishing the value of the joint coordinates corresponding to the end-effector

configuration. Establishing the inverse kinematics is essential for the position control of

parallel robots. There are multiple ways to represent the pose of a rigid body through a set

of parameters X. The most classical way is to use the coordinates in a reference frame of a

given point C of the body, and three angles to represent its orientation. But there are other

ways such as kinematic mapping which maps the displacement to a 6-dimensional

hyperquadric, the Study quadric, in a seventh-dimensional projective space. The kinematic

mapping may have an interest as equations involving displacement are algebraic (and the

structure of algebraic varieties is better understood than other non-linear structures) and

may have interesting properties, for example, stating that a point submitted to a

displacement has to lie on a given sphere is easily written as a quadric equation using Study

coordinates (Merlet, 2006).

3.1.1 Analytic method

For a fully-parallel mechanism, each of the chains link the base to the moving platform. If A

represents the end of the chain that is linked to the base, and B the end of the chain that is

linked to the moving platform. By construction the coordinates of A are known in a fixed

reference frame, while the coordinates of B may be determined from the moving platform

position and orientation. Hence the vector AB is fundamental data for the inverse kinematic

problem, this is why it plays a crucial role in the solution.

In order to write the position relationship of H4, consider the robotic structure (see Fig.10,

chain #4 is not plotted for sake of simplicity). The geometrical parameters of the

manipulator at hand are defined as follows:

416

Parallel Manipulators, Towards New Applications

•

Two frames are defined, namely {A}: a reference frame fixed on the base; {B}: a

coordinate frame fixed on the nacelle ( C 1 C 2);

•

The actuators slide along guide-ways oriented along a unitary vector, k (

z

k is the

z

unity vector along z axis in the reference frame {A}), and the origin is the point iP , so

the position of each point A is given by:

,

i

A =

+

i

i

P

qiz i q is the moving distance of the

i

actuator. The number i = ,

1

,

3

,

2 4 represents each pair of kinematic chains;

•

The parameters M d

i ,

and h are the length of the rods, the offset of the revolute-joint

from the ball-joint, and the offset of each ball-joint from the center of traveling plate,

respectively;

•

The position of the end-effector, namely point B , is defined by a position vector

B = [ x y z], and a scalar θ , representing the orientation angle.

Without losing generality, in this section we consider P = a b

for simplicity, Q is the

i

( , ,0

i

i

)

z

offset of {A} from {B} along the direction of k z .

kz

z 0

y 0

q 3

A31

A

P3

x 0

A3

A32

Q z

v1

z

y

M 3

C

1

B3

B

B

31

x

B

2 h

C

32

2

2 d

Fig.10. H4 manipulator with four lines drives and (S-S)2 chains

The position of points C1 and C2 are given by:

C = B + Rot v,θ BC

C = B + Rot v,θ BC

(7)

1

( )( 1) 2

( )( 2)

A Novel 4-DOF Parallel Manipulator H4

417

Where Rot(v,θ ) denotes the rotation matrix of nacelle with respect to reference frame. The

position of each point Bi is given by:

B = C + C B

B = C + C B

1

1

1

1

2

1

1

2

(8)

B = C + C B

B = C + C B

3

2

2

3

4

2

2

4

The position relationship can then be written as:

2

2

A B

= M

(9)

i

i

i

Then for the first axis:

A B = B + Rot v,θ BC + C B − P − q z

1 1

[

( )( 1) 1 1 1] 1 1

(A B = q − 2 q d ⋅z +d

(10)

1

1 )2

2

2

1

1 1

1

1

where d = B + Rot v,θ BC + C B − P . Finally, the two solutions are given by:

1

( )( 1) 1 1 1

q = d ⋅ z ±

d ⋅ z

+ M − d

(11)

1

1

1

( 1 1)2

2

2

1

1

Similar derivations give the solution for q 2, q 3 and q 4.

3.1.2 Geometrical method

The geometrical approach to the inverse kinematics problem is to consider that the

extremities A, B of each chain have a known position in 3D space. The leg can be cut at a

point M and two different mechanisms MA, MB constituted of the chain between A, M and

the chain between B, M can be gotten. The free motion of the joints in these two chains will

be such that point M, considered as a member of MA, will lie on a variety VA, while

considered as a member of MB it will lie on a variety VB. If assume the mechanism have only

classical lower pairs, these varieties will be algebraic with dimensions dA, dB. In the 3D

space, a variety of dimension d is defined through a set of 3- d independent equations, and

hence VA, VB will be defined by 3- dA and 3- dB equations. The solutions of the inverse

kinematic problem lie at the intersection of these varieties. As the number of of solutions

must be finite (otherwise the robot cannot be controlled), the rank of the intersection variety

must be 0. In other words, in order to determine the 3 coordinates of the points, 3- dA+3- dB

should equal to 3 or dA+ dB equal to 3 (Merlet, 2006).

The key problem about the geometrical mthod rests with the choice of the cutting point. For

the H4 structure shown in Fig.10, Bi are chosen as the cutting points. Points Bi has to lie on a

sphere centered at Ai with radius Mi, while for the nacelle, the coordinates of Points Bi can

be described as (8). Hence to obtain the intersection of these 2 varieties the known distance

between A, B of should be equal to Mi: this equation will give the joint coordinates qi. The

same results can be obtained as described as (11).

3.2 Direct kinematics

Direct kinematics addresses the problem of determining the pose of the end-effector of a

parallel manipulator from its actuated joint coordinates. This relation has a clear practical

interest for the control of the pose of the manipulator, but also for the velocity control of the

end-effector.

418

Parallel Manipulators, Towards New Applications

In general, the solutions for determining the pose of the end-effector from measurements of

the minimal set of joint coordinates that are necessary for control purposes is not unique.

There are several ways of assembling a parallel manipulator with given actuated joint

coordinates, and generally the direct kinematic relationship cannot be expressed in an

analytical manner. Although various methods have been presented for finding all the

solutions for this problem and their computation times are decreasing (Faugère, 1995;

Hesselbach & Kerle, 1995; Gosselin, 1996; Merlet, 2004), it is still difficult to use these

algorithms in a real time context. Furthermore, there is no known algorithm that allows the

determination of the current pose of the platform among the set of solutions. The numerical

methods using a-priori information on the current pose are more compatible with a real-

time context, while their convergence and robustness is an important issue. As direct

kinematics is an important issue for control, it may be necessary and interesting to

investigate how to improve the computation time. Besides the progress in algorithms and

processor speed, one possible approach to solve these problem is to add sensors (i.e. to have

more than n sensors for a n-DOF manipulator) to obtain information, allowing a faster

calculation of the current pose of the platform, at the cost of more complex hardware (Bonev

et al., 2001; Chui & Perng; 2001; Parenti-Castelli, 2001). Merlet has pointed out several

unsolved problems about the parallel robot’s direct kinematics (Merlet, 2000). Especially the

algebraic geometry and computational kinematics should bring about enough attention.

The first step of solving direct kinematics is to determine a bound on its maximal number of

solution. Then, the equations are reduced for the system to obtain the solution of a

univariate polynomial whose degree should be determined in the previous analysis. Many

researchers have tried to obtained closed-form solutions of parallel robots in a univariate

polynomial equation. Especially, the 3- and 6- DOFs parallel robots, e.g., planar, Delta,

Steward platform and Hexapod robots, have been mainly considered. This section provides

a univariate polynomial equation for H4. It is shown that the solutions of the forward

kinematics yield a 16th degree polynomial in a single variable (Choi et al., 2003).

3.2.1 Forward kinematics formulation

The forward kinematics of the H4 is the problem of computing the position and orientation

of the nacelle (traveling plate) form the motor angles or the moving distance of the actuator.

To get a closed-form solution, a univariate polynomial equation needs to be solved. The

following method is extracted from the paper written by Choi (Choi et al., 2003).

The kinematic structure of H4 is shown in Fig.10 and design parameters are shown in Fig.11.

The nacelle is composed of three parts (two lateral bars and one central bar). The four points

B

A

A

1, B 2, B 3 and B 4 form a parallelogram. Let B and A represent the homogeneous

i

i

coordinates of the points Bi in {A} and Ai in {A} respectively. Then the homogeneous

coordinates of AB and A A can be written as:

i

i

⎡

x + hE cosθ

⎤ ⎡ Pi + x ⎤

i

1

i x

⎢

⎥ ⎢

⎥

+

θ +

+ +

y hE sin

dE

Pi

y Q

A

i

1

2 i

i y

i

B

⎢

⎥ ⎢

⎥

=

=

(12)

i

⎢

z

⎥ ⎢

z

⎥

⎢

⎥ ⎢

⎥

⎣

1

⎦ ⎣

1

⎦

A A = a

b

q

1

i

[ i i

] T

i

A Novel 4-DOF Parallel Manipulator H4

419

where

i = cosθ , i = sinθ , P = hE , Q = dE , E = E = 1

− , E = E = 1, E = E = 1

− ,

x

y

i