straightforward. When the three detachable branches form a three-fingered gripper, the

problem falls into that of grasping kinematics (Montana, 1998). Furthermore, the proposed

system provides an additional advantage in that the detachable tripod can be coordinated

with the fixed tripod to perform auxiliary tasks such as performing a tool change on the

moving platform, or using a sensor to scan a part. Again, this adds another level of

flexibility into the system.

6. Workspace analysis

With the kinematics established, the position workspace volume and boundary of the robot

can be calculated. In each case, a grid of the independent variables as defined in Table 7. is

searched. The finer the independent variable grid spacing, the closer the estimated

workspace volume and boundary is to the true workspace volume and boundary. However

this comes at a computational cost especially with the 5 and 6-DOF cases. At a preliminary

architecture design phase, accuracy can be traded for low computational cost and faster

computational time of the robot workspace. As the design evolves to the detailed design

phase, accuracy is much more important and longer computations are required to achieve

an accurate workspace volume and boundary.

6.1 Physical parameters

The shape and size of a robot's workspace is dependent on its physical parameters such as

link lengths, joint limits, etc. These parameters may or may not be known at the architecture

Architecture Design and Optimization of an On-the-Fly Reconfigurable Parallel Robot

399

design phase depending on the requirements of the system. In order to evaluate the various

configurations, the physical parameters for the base and moving platform are uniform

throughout. The radius of the base, bi, is 100 mm and the radius of the moving platform, r, is

50 mm. In the 6-DOF case, the branches are spaced at 60° intervals. The spacing increases as

necessary when the detachable branches are disconnected from the moving platform. The

physical constraints for each branch configuration are described in Table 8.

Branch

Configuration

Variable Symbol

Value

Lower arm length

l1i

125 mm

RTUS and U*RTS

Upper arm length

l2i

125 mm

Fixed Branches1

Joint variable range

θi

0° - 180°

Guide way inclination

ηi

45°

PFUS and PFU*S

Arm length

li

100 mm

Fixed Branches

Joint variable range

si

0 mm – 100 mm

UPVS and U*PVS

Fixed Branches

Joint variable range

si

125mm – 200 mm

Guide way inclination

θi

135°

CPVS Fixed

Joint variable range

si

125 mm – 200 mm

Branches

Cylindrical joint linear range

li

0 mm – 150 mm

Arm length

l2i

150 mm

R

Cylindrical joint inclination angle

γi

90°

TCS Fixed

Branches

Joint variable range

θi

0° - 180°

Cylindrical joint linear range

li

0 mm – 150 mm

Lower arm length

l1i

150 mm

Detachable

Upper arm length

l2i

150 mm

Branches1, 2

Joint variable range

θi

0° - 180°

Table 8. Branch physical constraints

Finally, we ignore the physical constraint that would be imposed due to the presence of the

spherical joints. In reality, contact between the edge of the socket and the extension of the

ball would impede further motion and thus affect the shape of the workspace. The

1 To avoid singularities, the z-coordinate of the ith middle joint must be less than the z-

coordinate of the ith d i vector.

2 The lengths of the detachable branch arms are consistent for all fixed branch

configurations except the RTCS configuration in which both arms lengths are 250 mm. The

change in length was to provide and an acceptable workspace boundary.

400

Parallel Manipulators, Towards New Applications

alignment of the spherical joints is left to the detailed design phase, as careful design and

alignment can alleviate this impedance.

6.2 Workspace

With the kinematic equations established and the physical parameters defined, the position

workspace can finally be calculated. Table 9. shows the summary of workspace.

Fixed Branch

Robot Workspace Volume [mm3]

Configuration

3-DOF 4-DOF 5-DOF 6-DOF

RTUS and U*RTS

7549

13, 778

15, 595

29, 463

PFUS and PFU*S

15, 368

18, 224

14, 309

17, 265

UPVS and U*PVS

13, 263

9386

6275

6813

CPVS

9619 4634 1898 2244

RTPVS

43 161 2928

6021

Table 9. Workspace volume of the reconfigurable parallel robot

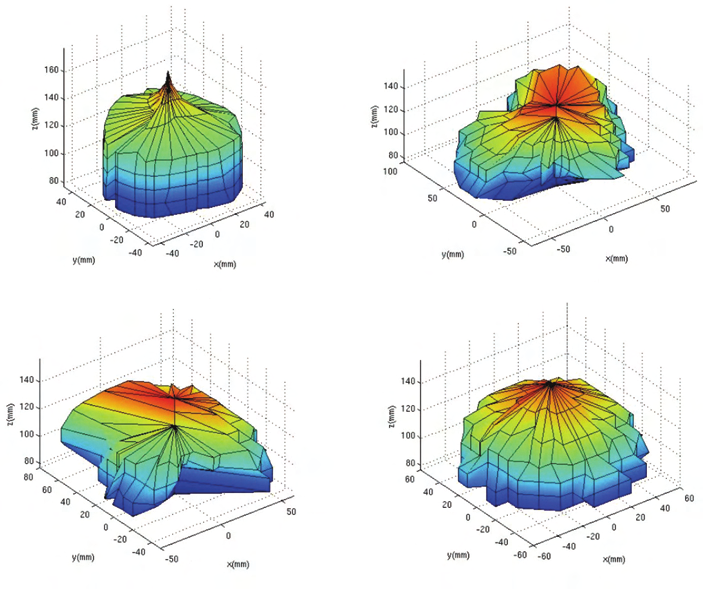

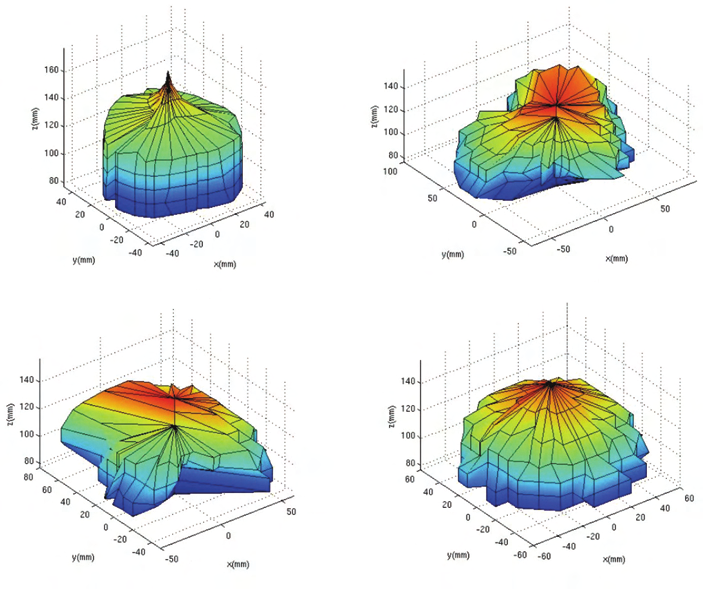

(a)

(b)

(c)

(d)

Fig. 10. Workspace boundaries of the PFUS and PFU*S fixed branch configuration: (a) 3-DOF,

(b) 4-DOF, (c) 5-DOF, (d) 6-DOF

Architecture Design and Optimization of an On-the-Fly Reconfigurable Parallel Robot

401

Note than the increase in DOF does not necessarily result in an increase in workspace

volume. This is due to the constraints of the branches and not the kinematic constraints of

the position and orientation of the moving platform. Also, in the 4 and 5 DOF cases, the

spacing of the branches is not uniform and results in very odd shaped workspace

boundaries. An example of the PFUS and PFU*S workspace is shown in Fig. 10.

7. Optimal configuration

The optimal configuration depends heavily on the type of task the robot is required to

perform. Some examples for parallel robotics include:

•

Flight simulation test beds use 6-DOF hydraulically actuated UPVS branches.

•

Machining tool applications use the PFUS branch configuration due to their structural

stiffness.

•

Pick and place automation use planar Delta robots (specialized RTUS branches).

We further note that the optimization here is not the optimization of a continuous system.

Here, there are five discrete systems that require some form of comparison to evaluate their

strengths and weaknesses. There are many methods of evaluating the merits of discrete

systems. These usually include some for of design decision matrix and there are many

works available that covers this topic. All of these methods require a certain degree of

designer input and different designers will form their decision matrices different. Once an

architecture is chosen, then continuous optimization algorithms can be used.

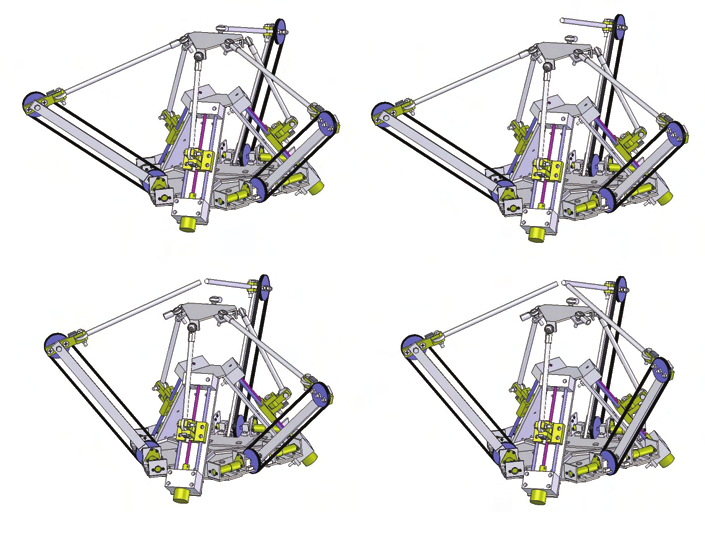

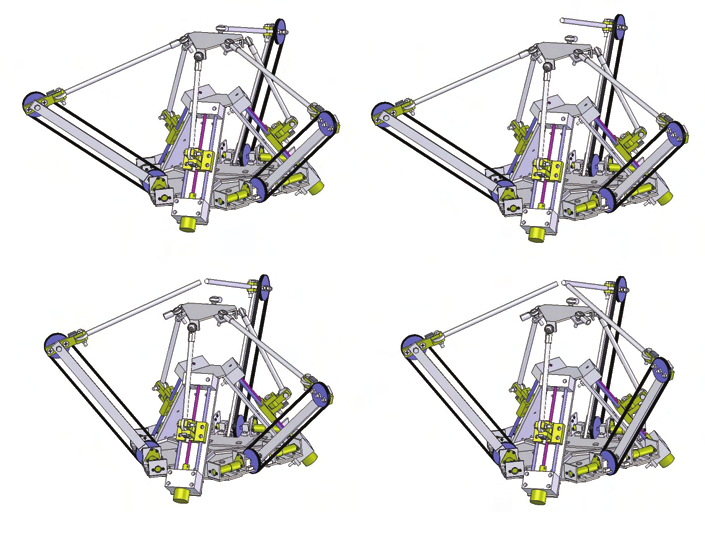

(a)

(b)

(c)

(d)

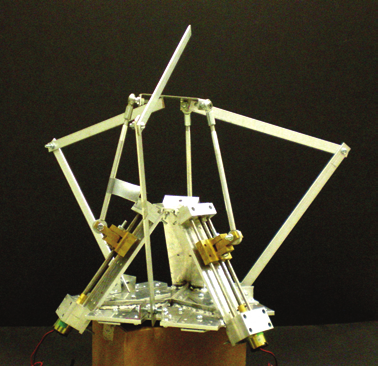

Fig. 11. Reconfigurable parallel robot currently being developed at Ryerson University:

(a) 6-DOF, (b) 5-DOF, (c)4-DOF, (d) 3-DOF

402

Parallel Manipulators, Towards New Applications

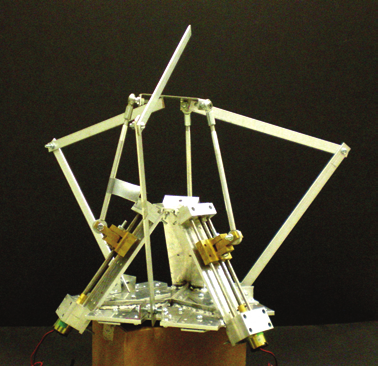

A very simple a pair-wise comparison of the discrete systems against each of for the

specified functional requirements is used to arrive at the optimal configuration (Salustri,

2008). Using this design decision method, the optimal architecture of the parallel robot is the

PFUS configuration. This robot configuration is currently being developed at Ryerson

University and is shown in Fig. 11 and the actual prototype is shown in Fig. 12. Also in

development, is a universal joint capable of locking one DOF in order to satisfy the branch

constraint requirements previously described.

Fig. 12. The prototype of the proposed reconfigurable parallel robot

8. Conclusion

A novel method for the architecture design of a reconfigurable parallel robot is presented

based on common actuation devices. System design techniques are used to classify parallel

robot modules and enumeration rules are established to determine the feasible robot

architectures. Branch kinematics are developed and a workspace analysis is performed. An

optimal design is selected from the remaining discrete robot configurations. The final design

is a self-reconfigurable parallel robot that has the ability to perform on-the-fly

reconfiguration. The proposed reconfigurable parallel robot not only provides innovation in

reconfigurable system design but also stimulates new research into parallel robot

kinematics.

9. References

Chen, I.-M. (2001). Rapid response manufacturing through a rapidly re-configurable robot

workcell. Robotics and Computer-Integrated Manufacturing, 17, 3, (June 2001) pp. 199-

213, 0736-5845.

Chen, L., Xi, F., Macwan, A. (2005). Optimal module selection for designing reconfigurable

machining systems. ASME Journal of Manufacturing Science and Engineering, 127, 1,

(February 2005) pp. 104-115, 1087-1357.

Architecture Design and Optimization of an On-the-Fly Reconfigurable Parallel Robot

403

Dash, A.K., Chen, I.-M., Yeo, S.H., Yang, G. (2005). Task-oriented configuration design for

reconfigurable parallel manipulator systems. International Journal of Computer

Integrated Manufacturing, 18, 7, (October-November 2005) pp. 615-634, 0951-192X.

Hafez, M., Lichter, M.D., Dubowsky, S. (2003). Optimized binary modular reconfigurable

robotic devices . IEEE/ASME Transaction on Mechatronics, 8, 1, (March 2003) pp. 18-

25, 1083-4435.

Hamlin, G.J., Sanderson, A.C. (1997). TETRABOT: a modular approach to parallel robotics.

IEEE Robotics and Automation Magazine, 4, 1, (March 1997) pp. 42-50, 1070-9932.

Horner, C.G., (1990). Adaptive truss structure. US/Japan Workshop on Smart/Intelligent

Materials and Systems, Honolulu, March 1990, 19-23.

Salustri, Filipo A., (2008) http://deseng.ryerson.ca/xiki/Learning/Main:Web_home

Koren, Y., Heisel, U., Jovane, F., Moriwaki, T., Pristchow, G., Ulsoy, G., Van Brussel, H.

(1999). Reconfigurable manufacturing systems. Annals of the CIRP, 48, 2, pp. 527-

540, 0007-8506.

Michael, J. (1995). Fractal shape changing robot construction theory and application note .

Robodyne Cybernetics Ltd.

Montana, D.J. (1998). The kinematics of contact and grasp. International Journal of Robotics

Research, 7, 3, (June 1998) pp. 17-32, 0278-3649.

Onoda, J., Fu, D.-Y., Minesugi, K. (1996). Two-dimensional deployable hexapod truss .

Journal of Spacecraft and Rockets, 33, 3 (May-June 1996) pp. 416-421, 0022-4650.

Sabater, J.M., Saltarén, R.J, Aracil, R. (2005). Design, modelling and implementation of a 6

URS parallel haptic device . Robotics and Autonomous Systems, 47, 1, pp. 1-10, 0921-

8890.

Schenker, P., Pirjanian, P., Huntsberger, T., Aghazarian, H., Baumgartner, E., Iagnemma, K.,

Rzepniewski, A. (2000). Reconfigurable robots for all-terrain exploration .

Proceedings of the SPIE Symposium on Sensor Fusion and Decentralized Control in

Robotic Systems, pp. 454-468, 0277-786X, Boston, September 2000, Society of Photo-

Optical Instrumentation Engineers, Bellingham, WA, USA.

Suh, N.P. (1990). The principles of design . Oxford University Press, New York.

Tomita, K., Murata, S., Yoshida, E., Kurokawa, H., Kokaji, S. (1996). Reconfiguration method

for a distributed mechanical system , In: Distributed Autonomous Robotic Systems 2.

Asama, H., Fukuda, T., Arai, T., Endo, I. (Ed), pp. 17-25, Springer-Verlang New

York Inc., 4431701907, Secaucus, NJ, USA.

Tsai, Lung-Wen. (1998). Systematic enumeration of parallel manipulators . Department of

Mechanical Engineering and Institute for Systems Research, Technical Report, pp. 1-11.

Unsal, C., Kiliccote, H., Patton, M., Khosla, P. (2000). Motion planning for a modular self-

reconfiguring robotic system . Distributed Autonomous Robotic Systems, 4, pp. 1-10.

Xi, F., Verner, M., Ross, A. (2000). A reconfigurable hexapod system—preliminary results .

Proceedings of the 2000 Japan-USA Symposium, Special Session on Modular and

Reconfigurable Controller for Flexible Automation, University of Michigan, July 2000.

Xi, Fengeng, Xu, Yuonan, Xiong, Guolian. (2006). Design and analysis of a re-configurable

parallel robot . Mechanisms and Machine Theory, 41, 2, (February 2006) pp. 191-211,

0094-114X.

404

Parallel Manipulators, Towards New Applications

Yim, M. (1994). Locomotion with a unit-modular re-configurable robot . Ph.D. Thesis,

Stanford University.

Yim, M., Zhang, Y., Duff, D. (2002). Modular robots . IEEE Spectrum, 39, 4 (February 2002)

pp. 30-34, 0018-9235.

19

A Novel 4-DOF Parallel Manipulator H4

Jinbo Wu1 and Zhouping Yin2

1 Traffic Science & Engineering College

2State Key Laboratory of Digital Manufacturing Equipment and Technology

Huazhong University of Science & Technology

China

1. Introduction

Parallel manipulators have the advantages of high stiffness and low inertia compared to

serial mechanisms. Based on the Steward-Gough platform architecture, a lot of 6-DOF

mechanical devices have been proposed. The 6-DOF parallel manipulators suffer from a

small workspace, complex mechanical design, and difficult motion generation and control

due to their complex kinematic analysis. To overcome these shortcomings, the limited-DOF

manipulator, which has fewer than 6 DOFs, can be found in many production lines. It is clear

today that most attention has been paid to 3-DOF family among the limited-DOF parallel

manipulators (Carretero, 2000). However, in many industrial situations, there is a need for

equipment providing more than 3-DOFs. For example, for most pick-and-place applications

in semiconductor manufacturing, at least 4 DOFs are required (3 translation to move the

carried die from one point to the other, 1 rotation to adjust the orientation in its final

location). A new family of 4-dof parallel manipulators called H4 that could be useful for

high-speed pick-and-place applications is proposed by Pierrot and Company (Pierrot, 1999).

The H4 manipulator offers 3 DOFs in translation and 1 DOF in rotation about a given axis.

The H4 manipulator is useful for high-speed handling in robotics and milling in machine-

tool industry since it is a fully-parallel mechanism with no passive chain and able to provide

high performance in terms of speed and acceleration.

This chapter discusses the kinematic analysis of the H4 manipulator. In section 2, synthesis

methods for designing H4 are presented, and various possible mechanical architectures of

the parallel manipulator are exposed. Section 3 discusses the inverse and forward

kinematics problem of H4. Section 4 deals with singularity analysis of H4 utilizing line

geometry tools and screw theory. Section 5 concludes this chapter by providing the

development tendency of the parallel manipulators.

2. Structural synthesis and architectures

2.1 General concept of H4

Parallel manipulators are constituted of a moving platform that is connected to a fixed base

by several chains (limbs). Generally, the number of limbs is equal to the degrees of freedom

(DOF) of the moving platform such that each limb is driven by no more than one actuator

and all actuators can be mounted on or near the fixed base. By acting on the limbs the

406

Parallel Manipulators, Towards New Applications

platform pose (position and orientation) is controlled. Moreover, if the actuators are locked,

the manipulator will become an isostatic structure in which all the legs carry the external

loads applied to the platform. This feature makes the parallel manipulators with high

stiffness possible throughout the whole space. From the first ideas proposed by Gough

(Gough, 1956) or Steward (Steward, 1965), a lot of interesting mechanical devices or design

methods have been extensively studied. In the beginning, many structures were based on

the ingenuity of the researchers and not on a systematic approach. Subsequently, a new

research domain called structure (or type) synthesis was proposed, in which vaious

methodologies were tried to generate all the structures that have a desired kinematic

performance. The most widely used synthesis approaches (and their variants) are graph

theory, group theory and screw theory (Merlet, 2006). In this section, we will not discuss these

theoretical problems, but focus on the structure generation of H4.

The 6-DOF parallel manipulators generally suffer from a small workspace, complex

mechanical design and difficult motion generation and control due to their complex

kinematic anslysis. To overcome these shortcomings, new structures for parallel

manipulators having less than 6-DOF (which are called limited-DOF manipulators in this

chapter, although many of these new structures were known well before) are explored.

There is an overriding motivation behind such efforts: limited-DOF manipulators may be

needed for many applications. For example, parallel wrists need only three rotational DOFs.

It is clear today that most attention has been paid to 3-DOF family among the limited-DOF

parallel manipulators (Gosselin & Angeles, 1989; Agrawal et al., 1995; Gosselin & St-Pierre,

1997; Fattah & Kasaei, 2000; Gregorio, 2001). However, in many industrial situations, there is

a need for equipment providing more than 3 DOFs arranged in parallel and based on

simpler arrangements than 6-DOF strctures. The reference (Cheung et al., 2002) developed a

4-DOF parallel manipulator E4 which could be used in a semiconductor packaging system.

It is in the early 80’s when Reymond Clavel comes up with the brilliant idea of using

parallelograms to build a parallel robot with three translational and one rotational degree of

freedom (Bonev, 2001). Contrary to opinions published elsewhere, his inspiration was truly

original and does not come from any parallel mechanism patents. Professor Clavel called

his creation the Delta robot. The new family of 4-DOF parallel manipulators called H4 that

could be useful for high-speed pick-and-place applications is just based on the idea of Delta

structure (Pierrot & Company, 1999; Company & Pierrot, 1999). The prototype built in the

Robotics Department of LIRMM can reach 10g accelerations and velocities higher than 5m/s

(Robotics Department of LIRMM).

2.1.1 Delta structure

Even if an incredibly large number of different structures have been proposed by academic

researchers in the last 30 years, most of these that are used widely in industry can be

classfied into two basic types: the Delta structure and the so-called “hexapod“ with 6 U-P-S

chains in parallel (U-P-S: Universal-Prismatic-Spherical). This may be a result of either the

exceptional simplicity of the Delta 3-DOF solution, or the enormous research effort

dedicated to “hexapod“ (Company, 1999).

The basic idea behind the Delta parallel robot design is the use of parallelograms. A

parallelogram allows an output link to remain at a fixed orientation with respect to an input

link. The use of three such parallelograms restrain completely the orientation of the mobile

platform which remains only with three purely translational degrees of freedom. The input

A Novel 4-DOF Parallel Manipulator H4

407

links of the three parallelograms are mounted on rotating levers via revolute joints. The

revolute joints of the rotating levers are actuated in two different ways: with rotational (DC

or AC servo) motors or with linear actuators. Finally, a fouth leg is used to transmit rotary

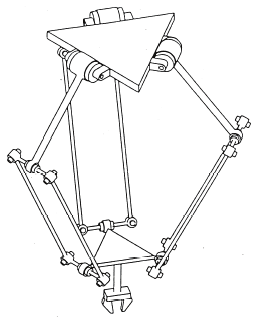

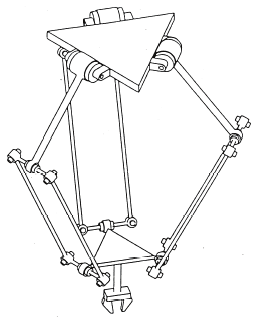

motion from the base to an end-effector mounted on the mobile platform. Fig.1 shows the

most famous Delta robot with three translation degrees of freedom, which was initially

developed at École Polytechnique from Lausanne by Clavel (Clavel, 1988). All the kinematic

chains of this robot are of the RRPaR type: a motor makes a revolute joint rotate about an

axis w. On this joint is a lever, at the end of which another joint of the R type is set, with axis

parallel to w. A parallelogram Pa is fixed to this joint, and allows translation in the direction

parallel to w. At the end of this parallelogram is a joint of the R type, with axis parallel to w,

and which is linked to the end effector.

Fig.1. The Delta structure proposed by Prof. Clavel and one of its industrial version, the

CE33 (courtesy of SIG Pack Systems)

The Delta robot is firstly marked by the two Swiss brothers Marc-Olivier and Pascal

Demaurex who created the Demaurex company (Bonev, 2001). The joint-and-loop graph of

the Delta robot and one of its equivalent structures are shown in Fig.2, where P, R and S

represent prismatic, revolute and spherical joint respectively. The displacement of the end-

effector of the Delta robot is the result of the movement of the three articulated arms

mounted on the base, each of which are connected to a pair of parallel rods. The three

orientat