Sheepsfoot roller

A roller with spikes inserted to compact, perforate, or scarify the rolled surface.

Shoreline

The boundary area where water meets land.

Shotcrete

Shotcrete or gunite is a concrete that is pneumatically placed in layers usually from 1 to 2 inches. Water is mechanically added to the dry mixture at the

nozzle, which shoots the freshly mixed concrete (really a mortar) at the surface prepared for its reception.

Stringer

A horizontal framing member used to support a floor or deck.

Syntactic foam

A foam composed of hollow spheres in a resin matrix.

Tetrapod

A nonreinforced concrete armor unit used for riprap (see Figure 5-1).

Traprock

Fine-grained igneous rock.

Tremie

A steel tube 12 inches or greater in diameter used for depositing concrete

underwater, having at its upper end a hopper for filling.

Tribar

A reinforced concrete armor unit used for riprap (See Figure 5-1).

Glossary-7

Tuck-point

To finish the joints between masonry units with a narrow ridge (bead) of mortar.

Pointing mortars usually shrink after placement and if finished flush with the masonry units will result in a concave joint.

Turning basin

An enlarged space at the end of a canal or narrow channel to permit vessels to turn around.

Ultrasonic testing

High frequency sound readings to determine voids in landfills, flaws in welds, etc.

Vertical lift

A platform which is lowered into the water to receive a small vessel and then

elevated out of the water by hoisting equipment (see Figure 1-6).

Wale

A long, horizontal structural member of timber or steel used for bracing vertical members. Also known as "waler" or "ranger."

Weep hole

An opening in a retaining wall, canal lining foundation, or other structure to drain away accumulated water.

Wharf

An open-type marginal platform structure, usually parallel to the shoreline, that is used primarily for berthing of vessels. It is usually connected to the shore at more than one point but may also have continuous access along the shore. It

ordinarily provides berthing along the outboard face (see Figure 1-2).

Glossary-8

Appendix A

DIVER INSPECTION OF STRUCTURES

INTRODUCTION

entire structure. The preference for a raft or boat for

handling diver and inspection equipment (if both are

This appendix is a brief summary of procedures

available) depends upon the calmness of the waters and

for locating and assessing damage to underwater

the need for mobility, as well as other job requirements.

structures.

An engineer and activity representative should

Underwater inspection requires the use of diving

be present whenever underwater inspections are made.

equipment. Hardhat diving equipment provides good

They are necessary to explain to the diver exactly what

stability in flowing water and good protection from a

should be found, i.e., number and size of piles, type and

dangerous bottom, moving debris, and/or sharp fouling

depth of bulkheads, location of tiebacks, cross bracing,

organisms, but affords less freedom of movement.

etc. The engineer shall evaluate the diver's

Scuba equipment does not provide such protective

observations, determine the degree-of-hazard, and

clothing, but permits faster inspection because of

recommend repairs.

greater mobility. A hardhat diver should remain in

The following general diver equipment is

constant contact via a two-way telephone with an

necessary:

assistant topside who relays instructions and data

between the inspector and the diver and provides

• Portable flashlight

necessary diver support. A scuba diver usually surfaces

• Special sampling equipment (see Table A-1)

to communicate findings to the inspector or engineer;

• Writing slate

however, communication by radio telephone is

• Air-powered scrapers or wire brushes for

preferable. Closed-circuit underwater television

removal of fouling, rust, silt, etc.

equipment (especially with facilities for tape recording)

• Easy-to-read measuring tape

can be of great value. Underwater photography may

• Wrecking bar

also be useful for documentation.

• Probe, such as sharp ice pick

• Knife, hand scraper, and hammer

All fouling organisms, rust, and other surface

• Sounding gear for determining depth and other

contaminants must be removed before a close-up

measuring devices

inspection of underwater surfaces can be made. This is

usually done at spot locations rather than cleaning an

A-1

The activity shall provide as-built drawings

Table A-1 identifies special inspection

previous inspection reports, or other information that will

equipment, visual observations, and measurements,

assist the diver and engineer in locating critical areas or

ratings, or samplings required for inspecting structures

areas at which damage had previously been noted.

made of different construction materials.

A-2

Table A-1. Inspection of Specific Structures

Construction

Measurements, Ratings,

Special Sampling Equipment

Visual Observations

Material

or Samplings

Wooden

Calipers for determining piling

Breaking or cracking from

Piling diameter

diameter

impact or overload

Location and size of

Sonic equipment for detecting

Detection of Limnoria or

damaged areas

hollow areas in piling

teredine siphons on surface

Depth of cracks and

Increment borer for deter-

Areas of reduction of piling

other damaged areas

mining quality of preserva-

diameter from abrasion or

Rating of piling

tive or soundness of piling

marine borer attack

condition

Treated wooden plugs for

Areas of riddled or lost wood

Data from sonic

holes left after boring

Condition of pile barriers

equipment

Diameter/condition of

Wood samples or

fasteners (bolts, etc.), cables,

increment borings

wraps

Concrete

Hammer

Chipping, cracking, spalling,

Location and size of

Chipping tool

and disintegration

damaged areas

Concrete-core rotary

Rust spots

Depth of chips, cracks,

drilling equipment

Condition of exposed steel

spalls, etc.

Sonic or ultrasonic equip-

Joint conditions

Drilled concrete cores

ment for detecting voids

Bottom scouring, undermining

Sonic or ultrasonic

Power source

data

Stone

Chipping, cracking, abrasion

Location and size of

masonry b

damage

damaged areas

Settlement and horizontal

Depths of chipped,

displacement

cracked, or abraded

Erosion of soil through joints

areas

or cracks

Rubble-mound

Erosion of core material by

Location and size of

wave action

damaged areas

Erosion of small stones in riprap

Slope of structure

Stability of armor stones or

blocks

Breakage and displacement of

concrete armor elements

Washing out of substrate at the

toe of structures

continued

A-3

Table A-1. Continued.

Construction

Measurements, Ratings,

Special Sampling

Visual Observations

Equipment

Material

or Samplings

Rubble-mound

Undermining of foundation

(con't)

High water mark; overtopping

Settling of structures

Structures

Erosion of foundation or

Location and size of

involving

slopes

damaged areas

soil

Subsidence of soil because of

lost backfill through cracks or

holes in bulkheads, etc.

Steel

Scale or calipers for

Coating condition (peeling,

Metal thickness

determining thickness

blistering, erosion, etc.)

Location and size of

Ultrasonic equipment for

Condition of cathodic pro-

damaged areas

determining thickness

tection equipment (broken

Depth of pits and

Equipment for measuring

or corroded conduits, loose

extent of their

electric potentials on

wires, lost anodes, etc.)

occurrence

cathodically protected steel

Extent of corrosion

Samples of corrosion

Pit gage

Type of corrosion (density,

products or damaged

Equipment for patching holes

pitting, etc.)

coatings

cut into steel structures

Members structurally damaged

Cathodic protection

by impact

potentials

Power source

Open seams or holes in quay-

Deformation of

walls, etc

structural members

Soil subsidence because of lost

backfill through seams or holes

Inspection of welds

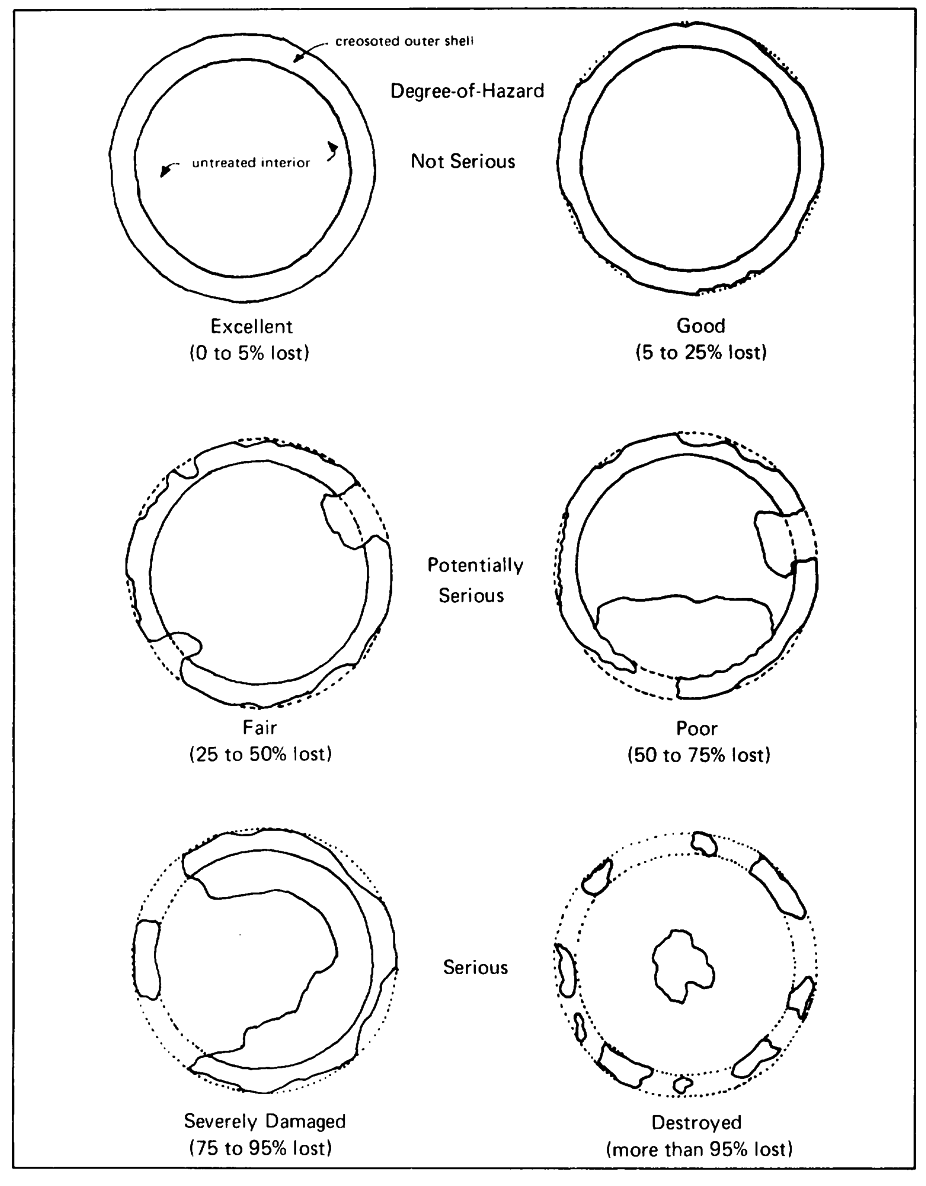

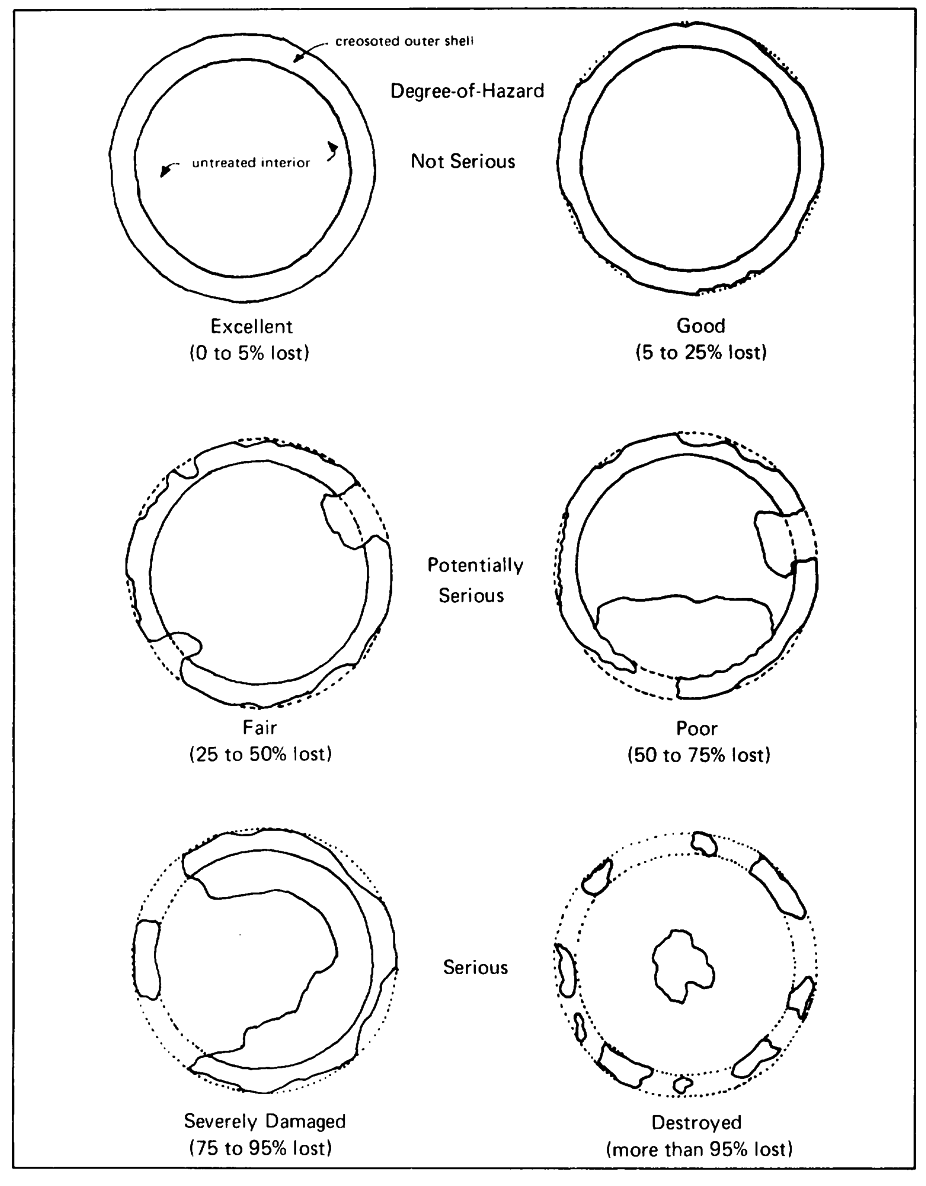

aThe diver notes the diameter loss (which is later classified as shown in Figure A-1), whether damage is general or

localized at a particular depth, and unusual conditions prevailing.

b lnteriors of graving docks are ordinarily inspected at a time when the docks are empty. Divers are required to inspect aprons or entrance settlement and condition of approaches.

A-4

Figure A-1. Cross section of piles with different damage ratings.

A-5

Appendix B

INSPECTION, DOCUMENTATION, MAINTENANCE, AND CERTIFICATION

OF GRAVING DOCKS

INTRODUCTION . Detailed information is given in this

(3)

Copies of correspondence relative to

appendix for inspecting, reporting, maintaining, and,

matters affecting the capabilities of the dock or its

specifically, certifying graving docks, because this

material readiness.

information is no longer covered in a maintenance and

(4)

Reports of machinery derangements and

operation manual.

casualties to material.

(5)

Operational logs, if any, of the dock and

SCHEDULING. It is not necessary for all parts of a

its equipment.

dock to be inspected simultaneously. Each item shall

(6)

Operation manuals for the equipment.

be inspected at least once each year, except for

(7)

A record of repairs or improvements

machinery, such as pumps and capstans (see Table B-1

effected on machinery.

for detailed scheduling). Machinery that must be

(8)

Prints or drawings of the structure and

opened for inspection should be scheduled for

utilities of the dock. Plans and as-built specifications,

inspection at a time when it will not interfere with the

when available.

docking schedule. Advantage shall be taken of routine

pumping and flooding of the dock and caisson to inspect

Each activity shall prepare a Preventive

the machinery and equipment while they are in

Maintenance (PM) Manual for the mechanical

operation.

equipment (pumps, sluice gates, valves, ventilation,

etc.) for each graving drydock. The Manual should

DOCUMENTATION . The following documents shall be

include but is not limited to the following:

made available for study and use by the inspectors:

(1)

Location of all fittings.

(1)

Previous reports of preventive

(2)

Maintenance schedule for components,

maintenance inspections and control inspections.

including description of work

(2)

Copies of correspondence relative to

(3)

Overhaul frequency for each piece of

correction of deficiencies that were initiated or received

equipment (varies between 2 and 10 years)

since the last inspection.

B-1

(4)

Type, age, and manufacturer of installed

progressive failure.

equipment

(5)

Equipment usage and reliability histories

MAINTENANCE. Preventive maintenance is primarily

(6)

Backup equipment available

concerned with items that, if disabled, would (1)

(7)

Notes on overall condition and impact of

interfere with an essential operation of the graving

failure

drydock, (2) endanger life and/or property, or (3) involve

high cost or long lead time for replacement.

INSPECTION. Table B-2 lists specific items to inspect.

Maintenance work must be scheduled to conform to the

The inspectors shall observe the following procedures

operating schedule of a drydock. Maintenance work

when making these inspections.

which does not interfere with a dock operating schedule

should be performed when necessary. The following are

(1)

Thoroughly inspect every part of the

the principal elements of maintenance for a graving

drydock and every item of machinery and equipment to

drydock:

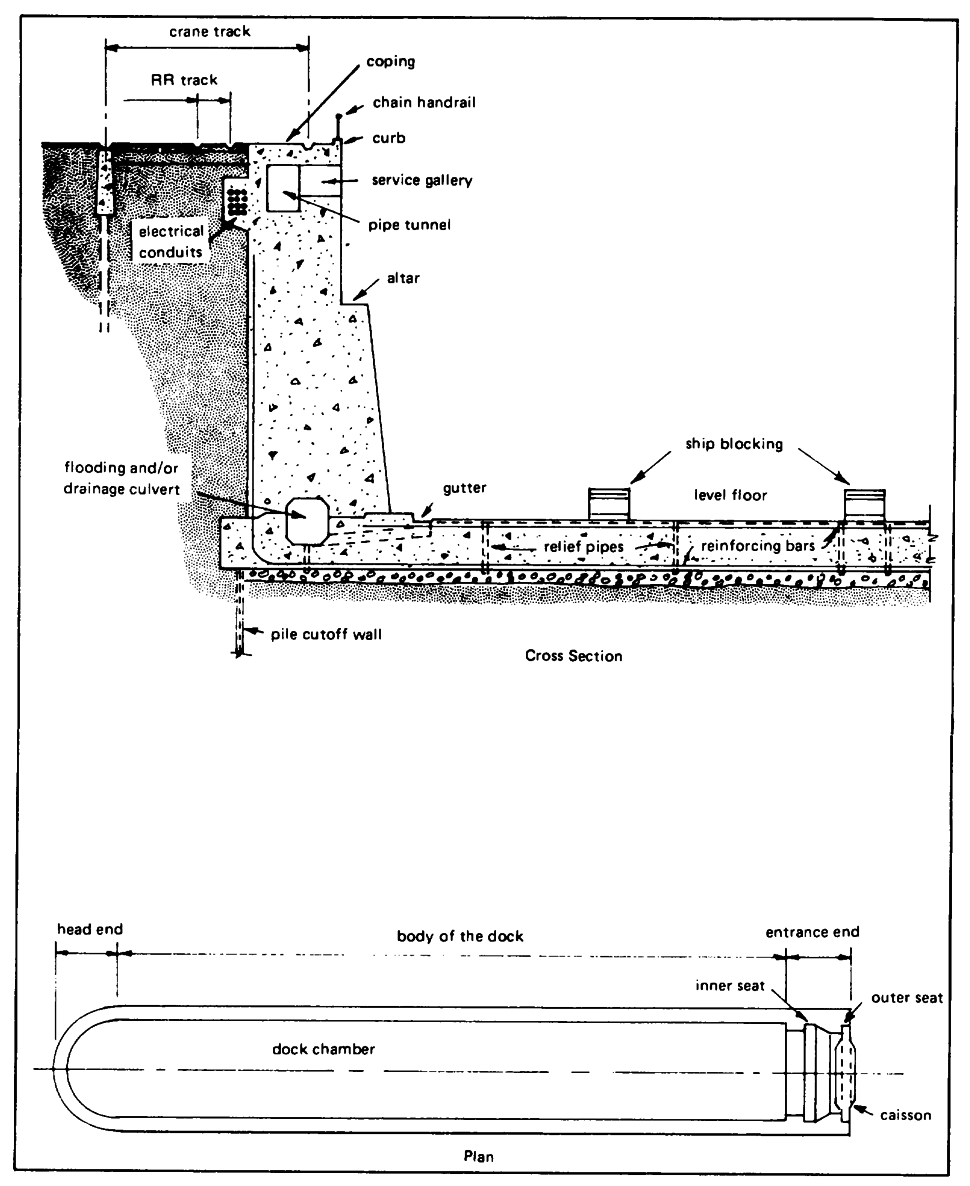

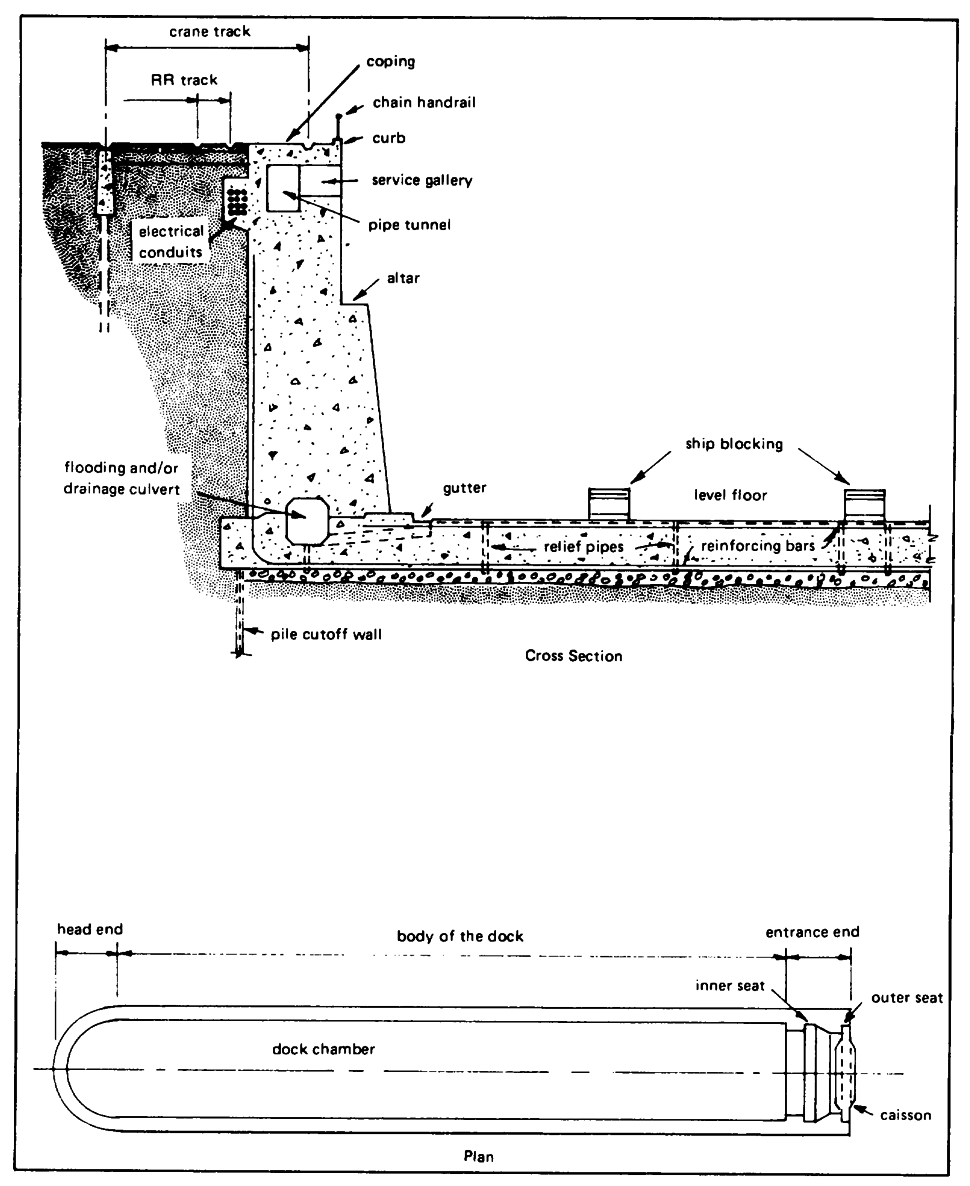

determine its condition (see Figure B-1 ).

(2)

Make free use of hammers for sounding

(1)

Patching cracks and grouting leaks in the

rivets, bolts, plates, and other parts, and of scrapers for

concrete dock body, including filling and discharge

removing paint to disclose metal surfaces. Use probes

culverts; weld repair of metal cracks and damaged

to determine the soundness of timber structures.

metal.

Hammers can be used to examine defective areas on

(2)

Cleaning, painting, and replacing metal

concrete surfaces.

guardrails, stanchions, gratings, and similar equipment.

(3)

Pay particular attention to leaks, and note

(3)

Repairing and replacing operating

if any materials are being carried in suspension.

equipment (such as motors and controls, pumps, valves,

(4)

Pay particular attention to the possibility

and sluice gates) and utility equipment (such as air,

of settlement of the drydock or adjacent land.

water, steam, electric power, and sewage).

(5)

Take soundings outboard of entrances to

(4)

Renewal of blocking.

determine whether there are any large holes or raised

(5)

Cleaning and painting of the drydock

areas that might indicate movement of earth from or

entrance closures and seats, and repair and

development of water-ways under the drydock floor.

replacement of its operating equipment.

(6)

Note any evidence of undue stress in

caisson structure, such as sprung plates, leaky rivets, or

The coating systems recommended for

bent frames, caused by unequal drydock settlement.

maintenance painting of drydock components are listed

in Table B-3. The methods for surface preparation and

If feasible, cracks and other similar faults should

their application are described in Chapter 7 of this

be repaired or photographed to determine the rate of

manual and in much greater detail in Reference 7-3 and

B-2

B-1. The latter gives detailed instruction for use of MIL-

shown to be effective by audit.

P-24441 listed in Table B-3.

Facility certification shall be terminated as a result of the

CERTIFICATION . The objective of facility certification

following:

is to assure the safety of ships and personnel during

docking and undocking operations and the safety of

(1)

Major overhaul or repair.

ships while in dock. This certification does not cover

(2)

Broaching of the scope of the facility

other requirements of the facility, such as compressed

certification.

air, steam, electrical, and sewage services. Normally,

(3)

Expiration of tenure of facility certification.

the facility shall be certified for its maximum designed

(4)

Recognition of the existence of an unsafe

capacity. If the facility is certified for a loading of less

condition.

than this amount, the reason for choosing this value

shall be explained. The maximum designed capacity,

After certification, the facility must remain in the "as

unless otherwise stated, shall be based on a typical ship

certified" condition with full consideration being given to

loading.

normal wear and tear for the period of certification.

When required certification shall be submitted to

The general requirements for certification are:

the major Command with a copy to the appropriate

headquarters for each facility every five years. In the

(1)

Provide a description of the graving dock.

event major changes are made to the facility within this

The description must be based on the dock design as

five-year period, a revised certification application shall

presently constructed, including modification to date.

be submitted. As an option, a maintenance program

Provide data such as core borings and foundation data;

providing for a continuous certification without frequent

description of foundation, longitudinal and transverse

or regular resubmittals, except when significant changes

sections with appropriate elevations, and entrance

are made, can be implemented, with the stipulation that:

closure; information on the performance and adequacy

of the drydock pressure relief system; the effectiveness

(1)

A formalized and implemented

of the drainage features (blankets, filters, and

maintenance program exists and can be shown to be

underdrain); and irregularities which may indicate

effective by audit.

normal concentration of flow or subsurface erosion.

(2)

Operating procedures are maintained in

Original historical data would only be provided when

current and self-correcting accuracy as shown by in-

relevant to the present configuration.

process audit.

(2)

Provide a history of the successful

(3)

Control of design and other system

operation of the graving dock over the last five years.

changes are effected through a formalized and

(3)

Provide copies of Standard Operating

implemented Design (or change) Control Board and

Procedures for Docking and Undocking Vessels and

B-3

Standard Operating Procedures for Operating the

team must conduct a material survey. The material

Graving Docks.

survey shall include measurements for potential

(4)

Where activity disaster plans and firemain

corrosion and cathodic protection. Upon receipt of the

certification tests have already been submitted, include

survey, the conditional acceptance will be made a full

copies for information only.

acceptance.

(5)

An earthquake analysis shall be provided

A material survey by an independent team shall

in areas subject to seismic events.

be conducted at ten-year intervals. A yearly visual

survey of each facility must be conducted by in-house

On the basis of the above information, a

personnel and a report submitted. If any material

conditional certification of the facility will be given.

change occurs to the condition of the facility, the activity

Within the next three years, a professional engineer

must notify the certification organization.

B-4

Figure B-1. Designation of drydock features.

B-5

Table B-1. Inspection Frequencies

Preventive

Control or

Preventive

Control or

Component

Maintenance

Engineering

Component

Maintenance

Engineering

Inspection

Inspection

Inspection

Inspection

Electrical:

Mechanical (cont'd):

Communication equip-

Sewage and plumbing

ment and controls

SA

A

system:

Distribution:

Fixtures

M

A

Transformers

-

A

Piping

M

A

Feeder and branch

Pumps

SA

A

circuit switchgear

SA

A

Valves

SA

A