required delivery time, the transportation

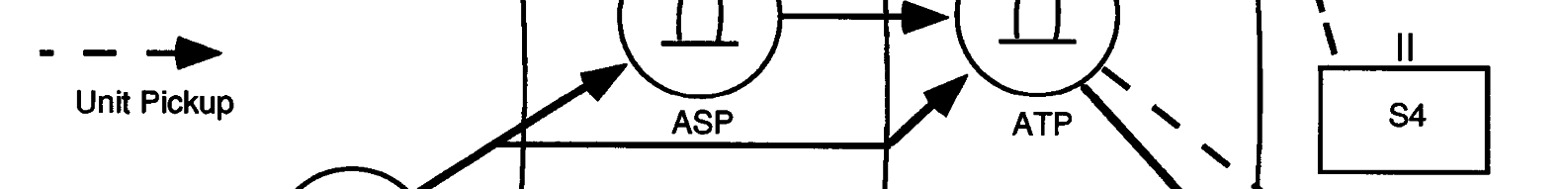

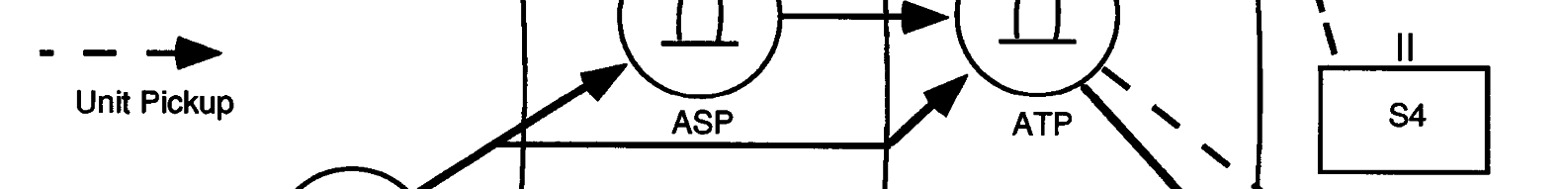

somewhat differently. The TF S4 notifies

responsibilities, and a desired location. The

the brigade S4 of Class V requirements. The

quantity includes the required quantity for

brigade S4 notifies the division ammunition

each type of obstacle. There may be several

officer (DAO) in the DMMC who authorizes

Department of Defense identification codes

Class V issue by the ammunition transfer

(DODICs) and national stock numbers

point (ATP). The DAO sends requests for

(NSNs) involved, depending on the types of

Class V to the CMMC.

obstacles required. The required delivery

time is very important to ensure an early

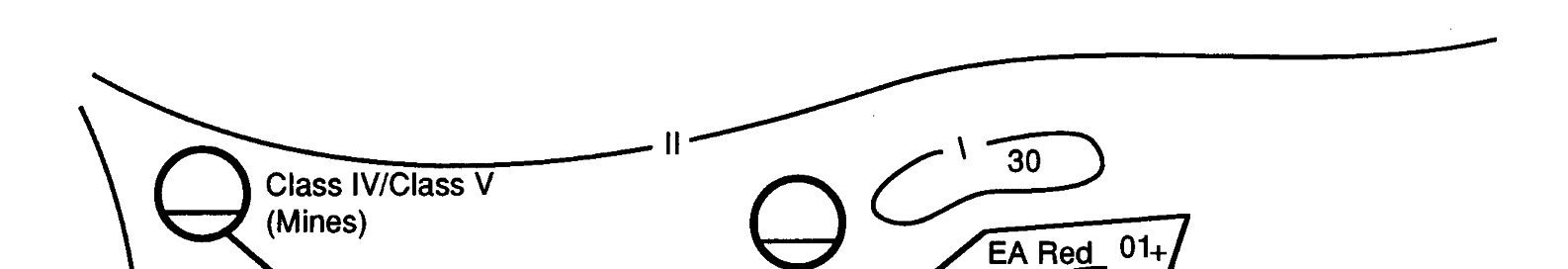

Class V obstacle material flows from the

start on the preparation of the battlefield.

corps storage area (CSA) to the ammu-

Lack of material could adversely affect the

nition storage points (ASP) to the

mission. The transportation responsibilities

ammunition transfer points (ATP) or,

must be clearly understood. MHE is

more likely, straight to the ATP. Class V

required to ensure a rapid turnaround of

obstacle material, unlike most ammunition,

haul assets.

Obstacle Resourcing and Supply Operations C-7

FM 90-7

In addition, the brigade staff identifies the

into usable packages, and then distributed

location of Class IV/Class V points in the TF

throughout the sector based on the obstacle

sectors in coordination with the TF staff.

plan. At some point in the distribution plan,

Prompt identification of the TF Class IV/

the TF turns over control of the obstacle

Class V point is required if the obstacle

material to engineers who then emplace

material is forwarded from the corps into the

them. Obstacle logistics, especially for mine

TF sector. If the material is not forwarded

warfare, at the TF level can be complex,

into the TF sector, it becomes a brigade

require prudent use of scarce haul and

responsibility to deliver the material to the

MHE, and demand positive C2.

TF.

In the case of obstacle groups developed at

At the TF level, sustaining obstacle opera-

corps, division, or brigade level, obstacle

tions is an extremely difficult task. Central-

material supply may vary slightly. The staff

ized throughput operations by the corps or

that is at the level where the obstacle group

the division stops at the TF level. Mass

is planned in detail determines the

quantities of obstacle material, especially

resources required for the obstacle. It also

mines, are centrally received, broken down

plans how the emplacing unit will get the

C-8 Obstacle Resourcing and Supply Operations

FM 90-7

materials. For example, if the corps staff

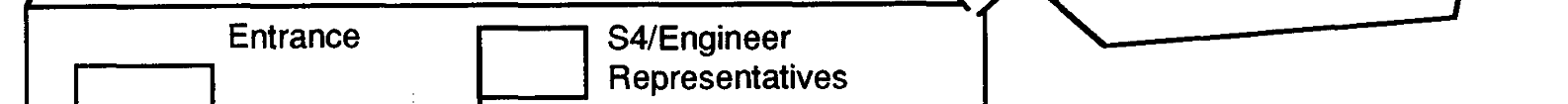

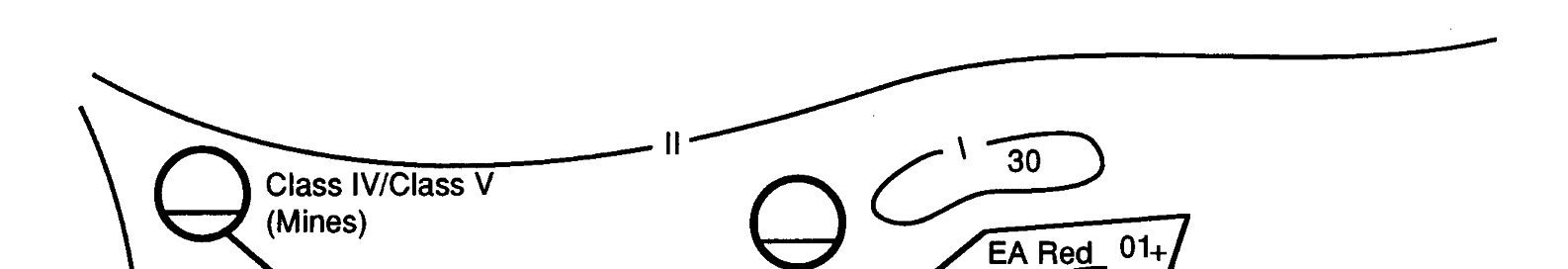

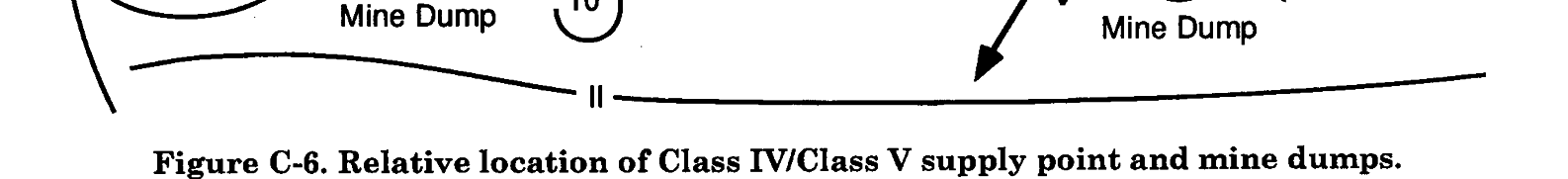

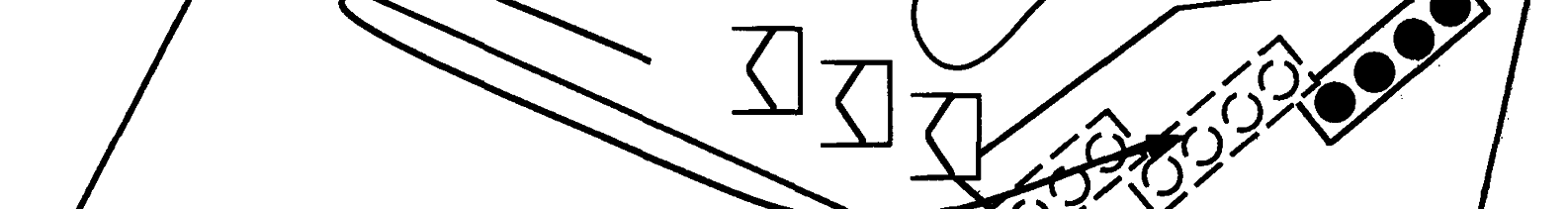

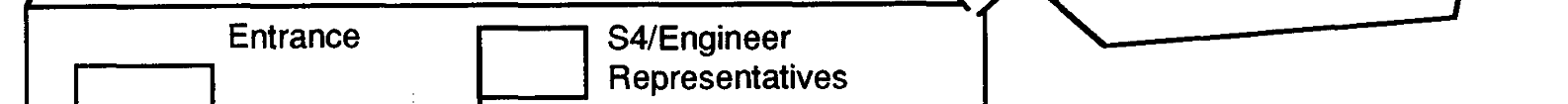

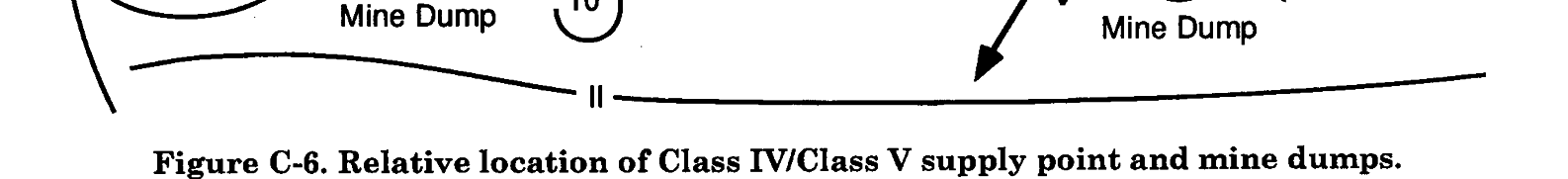

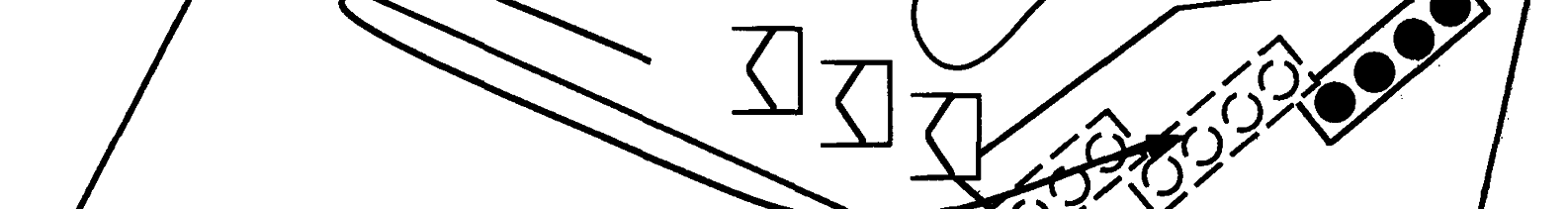

The relative location of the Class IV/Class V

plans a reserve obstacle group, but the

supply point and mine dumps are shown in

detailed planning is done at TF level, the TF

Figure C-6.

plans the resources for the obstacle group as

it would any other obstacle group. However,

if the corps staff plans the obstacle group in

Class IV/Class V Supply Point

detail, it determines the resources required.

The Class IV/Class V supply point is the cen-

In this case, the corps staff would also plan

tral receiving point of obstacle material in

for delivery of the obstacle materials to the

the TF sector. It is the point at which the TF

emplacing unit. Alternately, the corps staff receives and transfers control of obstacle could direct the emplacing unit to pick up the

material pushed forward by higher levels.

obstacle materials from a location such as

the CSA.

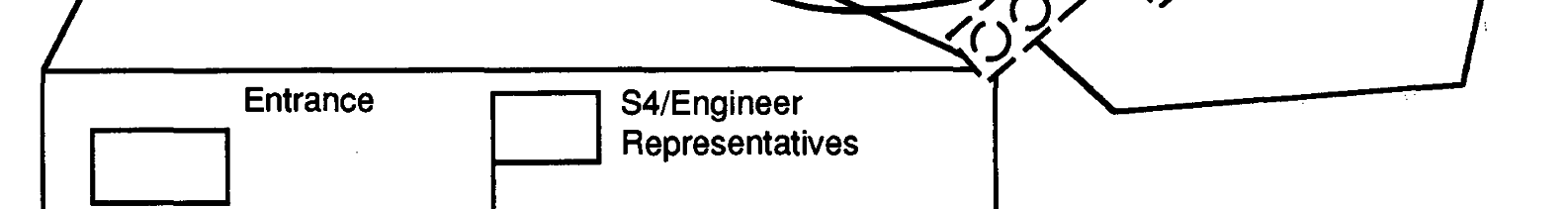

The supply point is established and operated

by the TF and is centrally located to support

all planned obstacles within the TF sector.

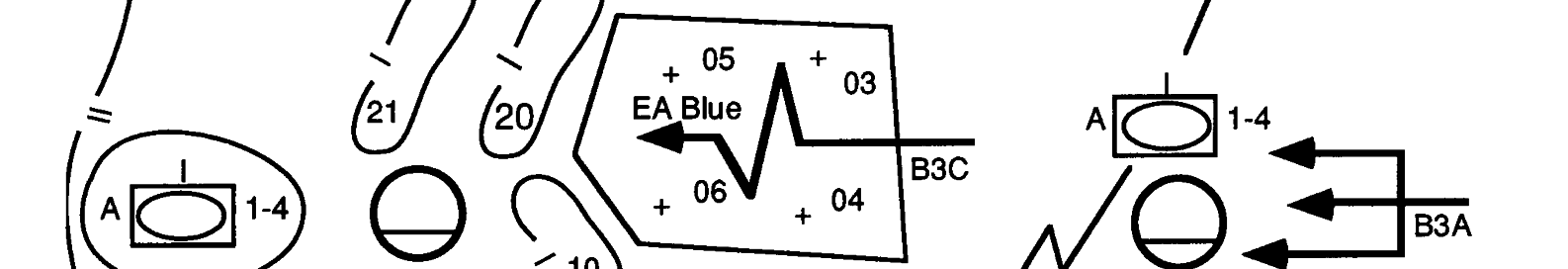

OBSTACLE RESUPPLY NODES

Where the tactical obstacle plan allows, the

There are two critical obstacle resupply

supply point should be located near the TF

nodes within the TF sector. Each of them has

combat trains to better facilitate C2 and the

a different function in the obstacle resupply

availability of equipment.

process if the material is not delivered

directly to the emplacement site. They are

The main purpose of the Class IV/Class V

the—

supply-point operation is to receive obstacle

Class IV/Class V supply point.

materials and then reconfigure them based

Mine dump.

on the requirements for each obstacle group.

Obstacle Resourcing and Supply Operations C-9

FM 90-7

This requires that the supply point must

is not always used; it depends on the

have a dedicated S4 representative to track

method of minefield resupply. These tech-

the flow of obstacle material in and out of

niques are discussed in more detail below.

the supply point. The supply point should

When used, one mine dump supports a

have dedicated MHE to off-load the bulk

single obstacle group. It is activated or

quantities of obstacle material and reconfig-

deactivated upon initiation and comple-

ure them into obstacle packages, if required.

tion of emplacing the obstacle group. Mine

Obstacle materials are normally broken

dump operations are primarily an engineer

down into obstacle packages if the materials

company or platoon responsibility. However,

are not already delivered in combat config-

it is a good technique to augment mine

ured loads. This may require a dedicated

dump operations with personnel from the

engineer representative to ensure that the

company team overmatching the obstacle

obstacle materials are configured properly.

group being emplaced. The mine dump may

The most labor-intensive task at the Class

be located either in the vicinity of the com-

IV/Class V supply point is uncrating the

pany team position or nearer to the obstacle

mines. This requires dedicated manpower

group.

equipped with tools to break shipping bands

There are three critical tasks that must be

and uncrate the mines from their containers.

accomplished at the mine dump.

Another important aspect of uncrating

mines is tracking fuzes and booster charges.

As minefield packages are transported

As the mines are uncrated, fuzes and booster

to the mine dump, they are further

charges are separated; however, the same

task organized into strip packages,

number and type of fuzes and boosters must

complete with the right number, type,

be task organized with minefield packages.

and mix of fuzes and boosters. For

This requires strict supervision because mis-

example, if the platoon is emplacing a

takes can quickly lead to confusion and a

standard disrupt row minefield, mines

waste of emplacement time.

are task organized into three packages.

As the engineer platoon moves to the

Because of the assets involved in the Class

mine dump to resupply, each emplac-

IV/Class V supply point, a TF is normally

ing vehicle loads a designated package.

capable of operating only one supply point at

The mines are prepared for emplace-

any given time.

If the TF sector is

ment. They are not fuzed at the mine

extremely wide or deep, several supply

dump. Preparation includes loosening

points may be planned; however, only one

and greasing fuze and booster wells

can be operated at a time, based on the com-

and checking to ensure proper func-

mander’s priorities for obstacle emplace-

tioning.

ment.

The mines are loaded onto the emplac-

ing vehicles or delivery system.

Mine Dump

Transportation of mines from the Class IV/

The mine dump is the most forward mine

Class V supply point to the mine dump is a

resupply node. It is the point at which

supported TF responsibility; however, it is

mines are task organized into mine strip

usually shared between the engineer com-

packages and inspected, prepared, and

pany and the TF since neither one has the

loaded onto the emplacing vehicle. It is

haul capability to simultaneously service all

not a permanent supply point. A mine dump

active mine dumps.

C-10 Obstacle Resourcing and Supply Operations

FM 90-7

OBSTACLE RESUPPLY RULES

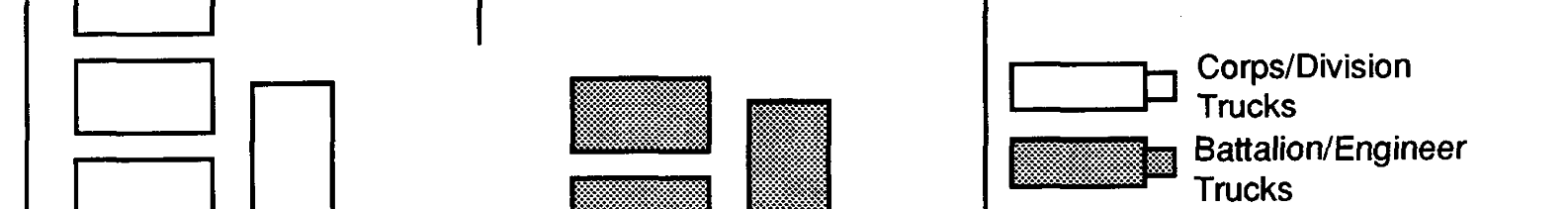

Traffic Circuit

The following rules govern obstacle material

Vehicles must be able to enter, load, unload,

resupply:

and exit without interfering with the load-

Uncrate mines at the Class IV/Class V

ing and unloading of other vehicles.

supply point to preserve transportation

assets going forward.

Camouflage and Cover

Task organize obstacle material into

Protection from observation and thermal

type packages at the Class IV/Class V

imaging is desired. Protection from artillery

supply points.

and air attack should be considered. Residue

Transport materials from the Class IV/

must be removed.

Class V supply point to the mine dump

(a shared engineer and maneuver unit

responsibility) when a mine dump is

Defense

used.

The site must be organized for defense

Inspect and prepare mines at the last

against enemy patrols and saboteurs.

supply node (Class IV/Class V supply

point or mine dump) before loading

Time

them onto the emplacing vehicle or dis-

pensing system.

Time factors to handle the obstacle

material—to include all unloading, uncrat-

Set up Class IV/Class V supply points

ing, inspecting, and loading—must be con-

using authorized ammunition proce-

sidered. Use of soldiers other than engineers

dures and distance requirements.

to perform these functions can have a signif-

icant impact on obstacle capability.

OBSTACLE SUPPLY LOCATIONS

Considerations for selecting a location for

Operators

the Class IV/Class V supply point and/or

Leaders and soldiers must be specifically

mine dump are—

allocated to operate mine dumps. They will

Carrying capacity.

probably remain there until the task is com-

Traffic circuit.

plete. The supply node may have to be collo-

Camouflage and cover.

cated with or be near a source of manpower.

Defense.

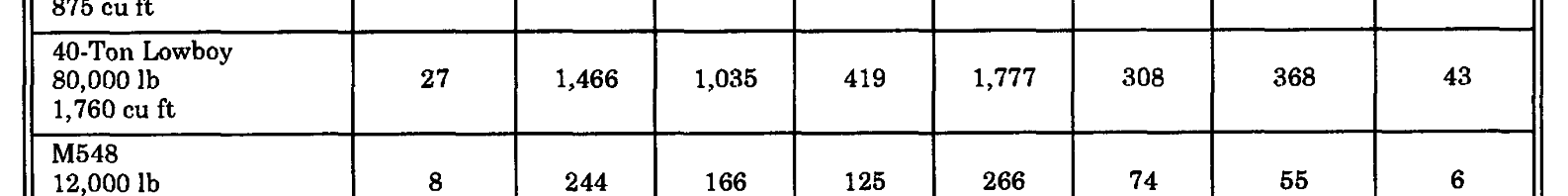

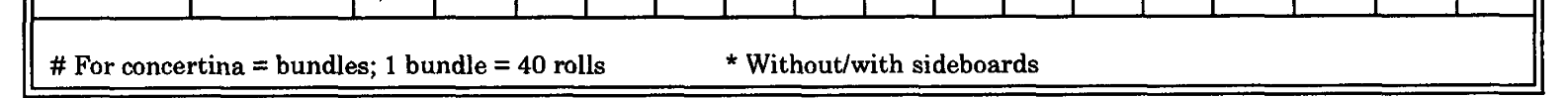

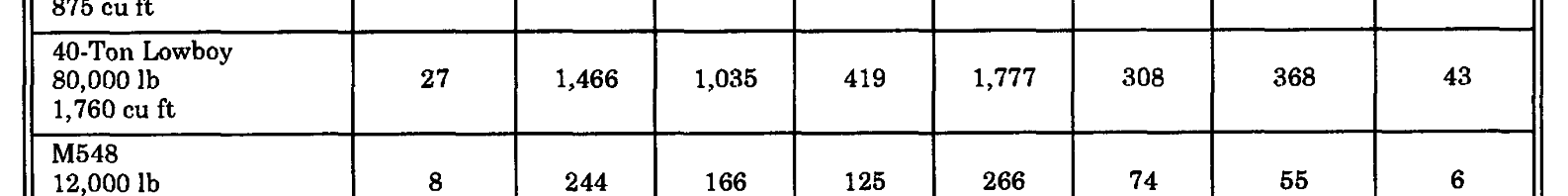

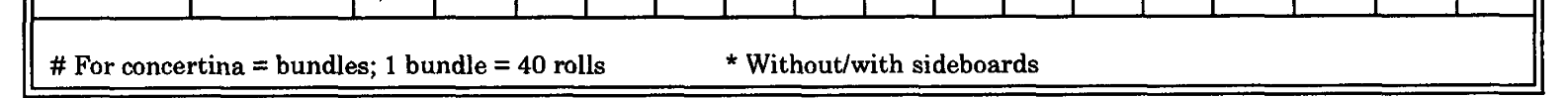

Table C-4, page C-12, provides general guidance on how much manpower is required to

Time.

sustain mine resupply operations.

Operators.

OBSTACLE MATERIAL RESUPPLY

Carrying Capacity

METHODS

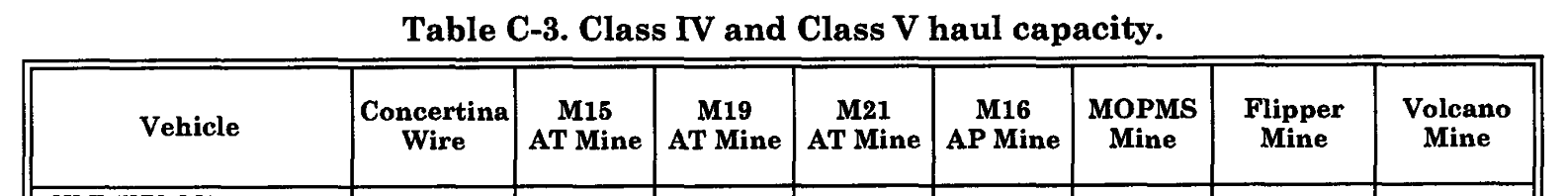

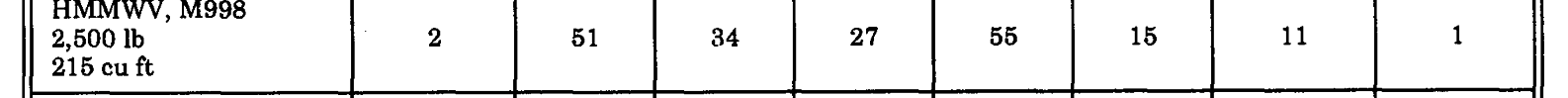

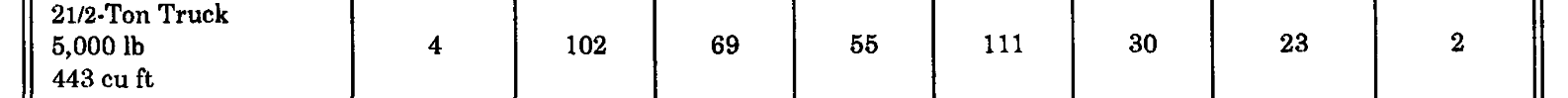

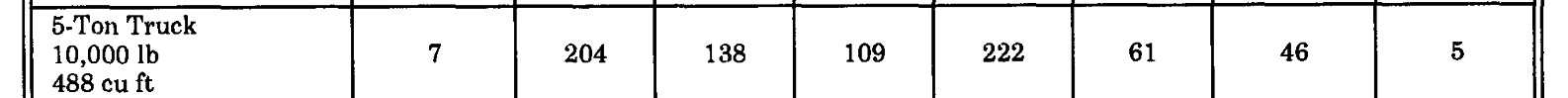

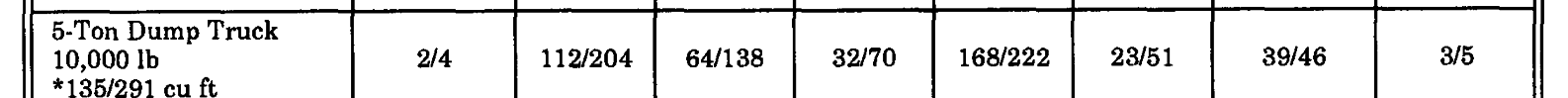

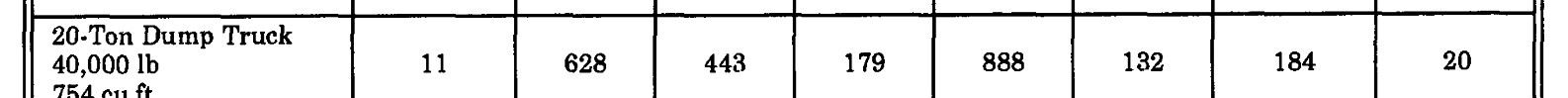

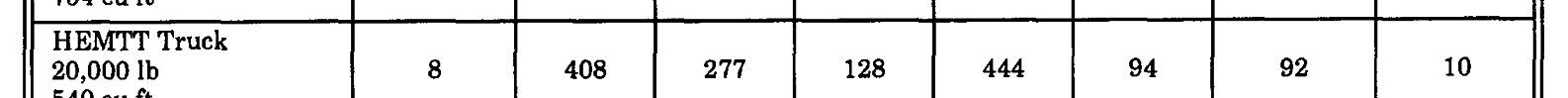

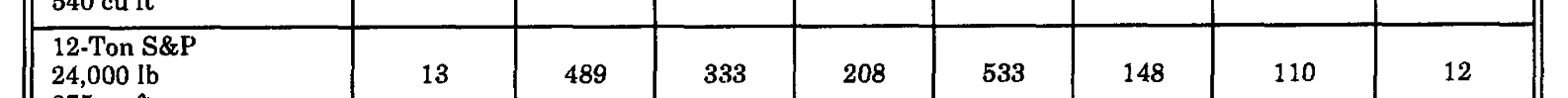

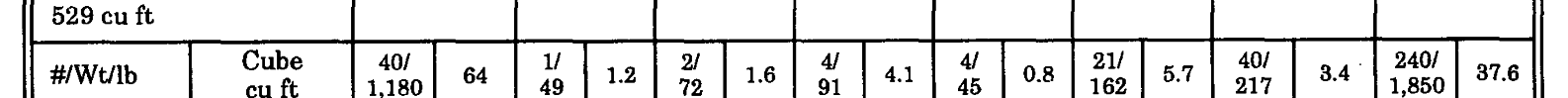

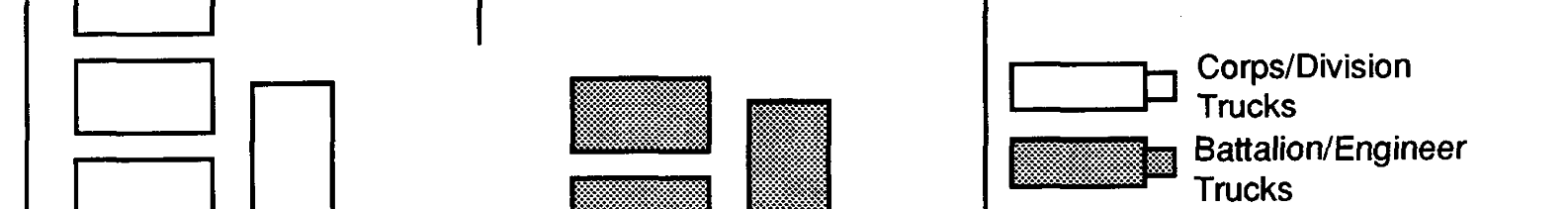

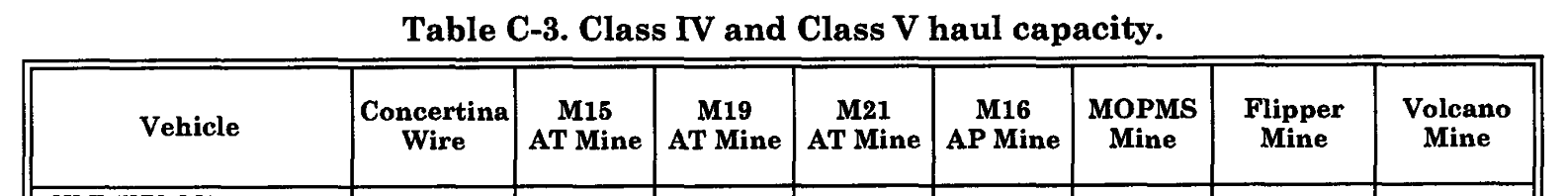

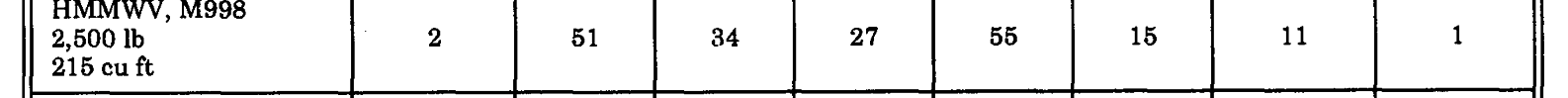

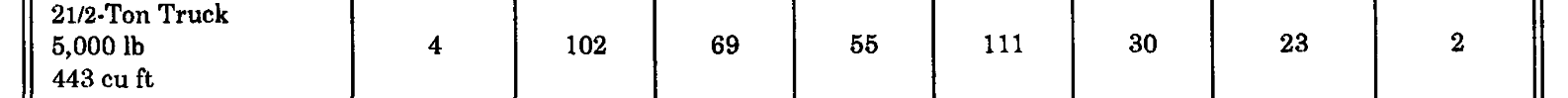

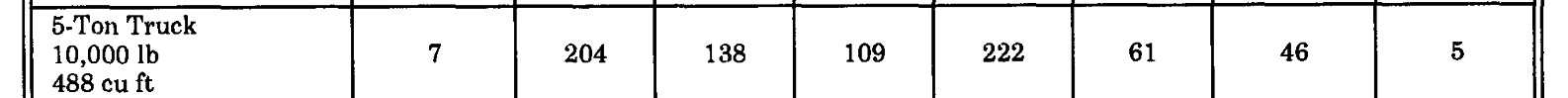

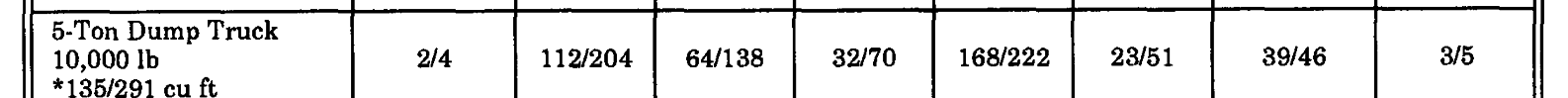

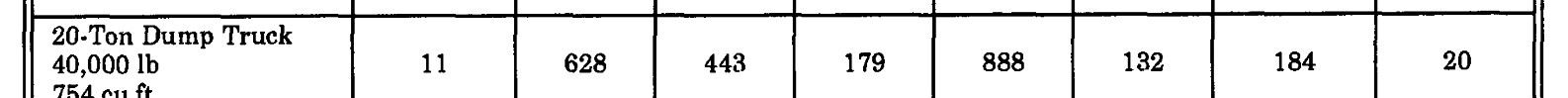

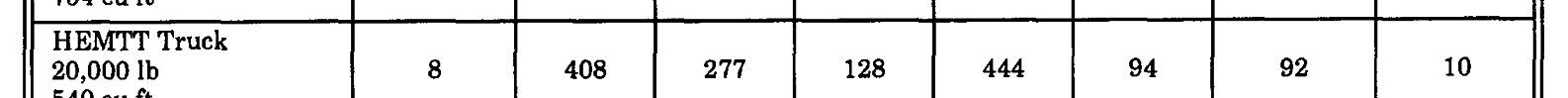

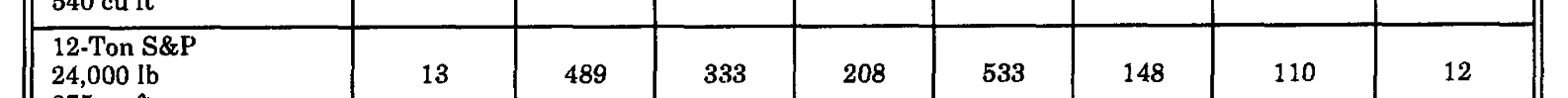

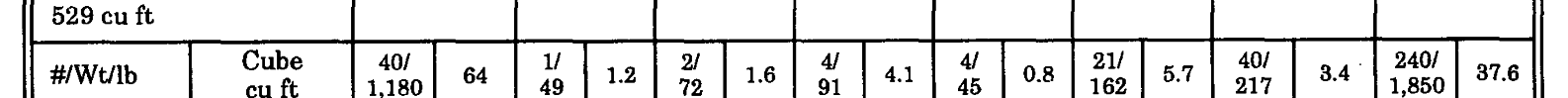

The location of key supply nodes depends in

The methods for obstacle material resupply

part on the type, amount, and availability of

are—

haul assets. The carrying capacity plays a

Supply point.

large role. In short, the more material a

Service station.

vehicle can carry, the more turn-around

time you can afford. Table C-3, page C-12, Tailgate.

provides the Class IV and Class V haul

In each method, corps or division transport

capacity for various types of vehicles.

delivers Class IV/Class V supplies forward

Obstacle Resourcing and Supply Operations C-11

FM 90-7

C-12 Obstacle Resourcing and Supply Operations

FM 90-7

to a designated Class IV/Class V point in

May disrupt the emplacement of indi-

each TF sector. The primary differences in

vidual obstacles when emplacing vehi-

each method are how the material is deliv-

cles cannot carry enough material to

ered from the Class IV/Class V point to the

start and complete the obstacle. This

obstacle location and whether or not a mine

causes emplacing vehicles to stop work,

dump is activated in the resupply chain.

reload, and pick up where they left off.

Requires a larger Class IV/Class V sup-

ply point capable of receiving mass

Supply Point

quantities of obstacle material and

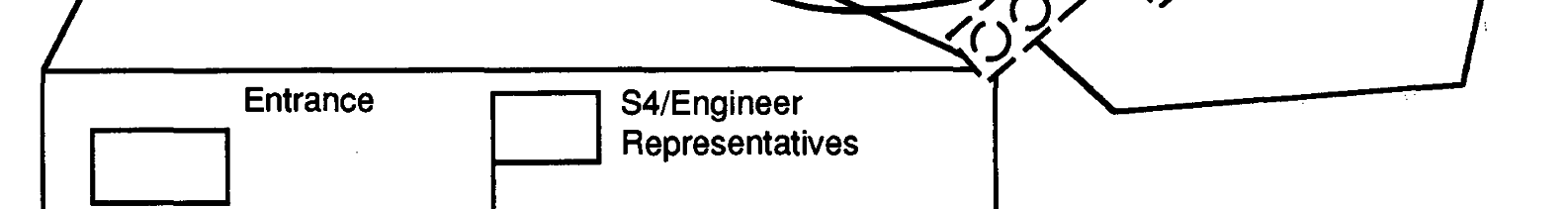

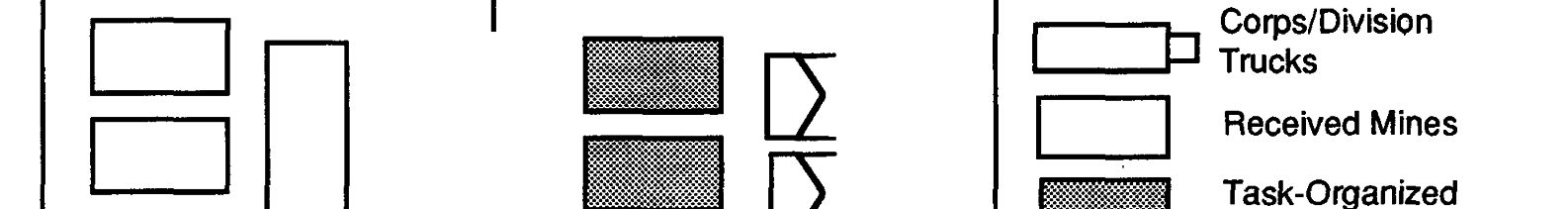

The supply-point technique requires that the

loading platoons simultaneously.

emplacing engineer platoon return to the

Does not afford an opportunity to task

Class IV/Class V supply point each time it

organize obstacle packages.

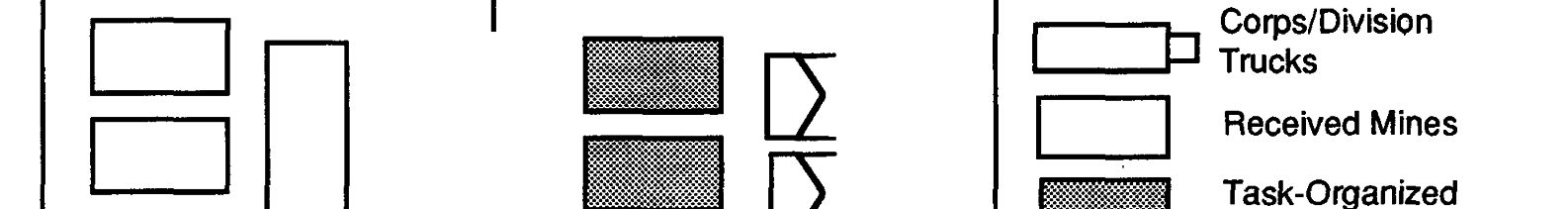

must resupply. Figure C- 7, page C-14, illustrates the supply point method of resupply.

The supply-point technique does not activate

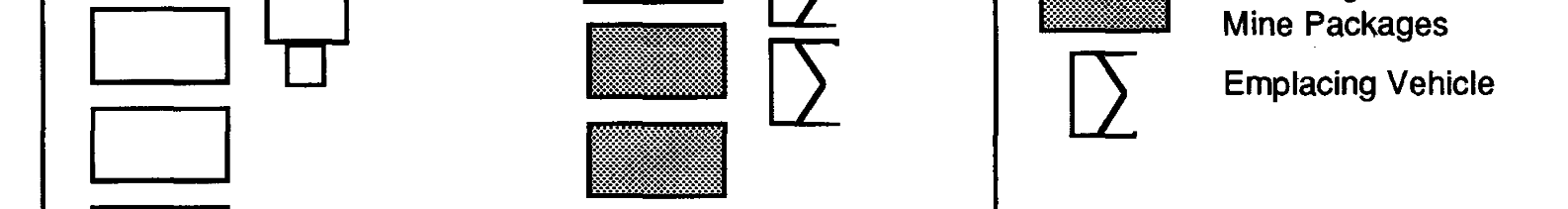

Service Station

a separate mine dump. In effect, it moves the

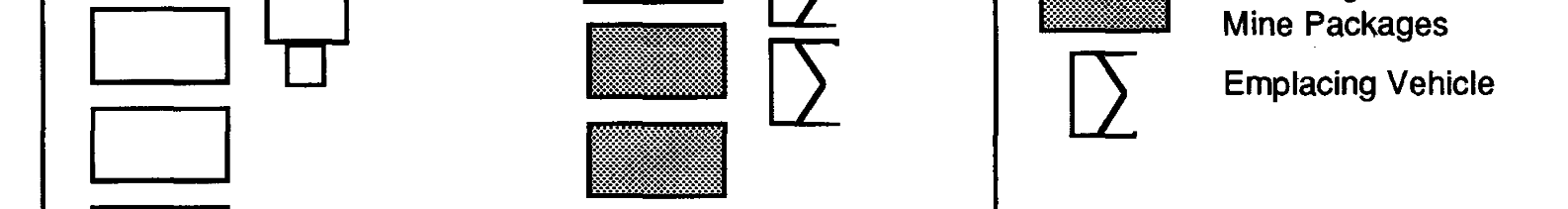

The service-station technique centers on the

normal tasks associated with a mine dump

activation of a mine/obstacle dump forward

to the supply point. Mines are prepared and

of the Class IV/Class V supply point (see

inspected at the supply point as they are

Figure C-8, page C-15). In the service-sta-loaded onto the emplacing vehicle or dis-

tion method, mines/material are transported

penser.

to a mine/obstacle dump using a combina-

Several considerations may affect the use of

tion of engineer and TF haul assets that are

supply point resupply. First, if there are no

normally under the control of the emplacing

additional haul assets to transport obstacle

engineer. At the mine/obstacle dump, mate-

material forward from the Class IV/Class V

rial is stockpiled and prepared by the

supply point, the supply-point method may

mine/obstacle dump party. Obstacle mate-

be the only viable technique. Second, the

rial is further task organized into packages.

obstacle may be close enough to the supply

The emplacing platoon moves to the mine/

point that any other method is less efficient.

obstacle dump to resupply emplacing vehi-

cles or dispensers. Once the obstacle group

Advantages. The advantages to a supply is emplaced, the mine/obstacle dump is

point are that it—

deactivated or moved to support another

Minimizes unloading and loading of

obstacle group.

material.

Requires minimal augmentation of

There are several considerations for using

haul assets.

the service-station resupply method:

Allows manpower and equipment to be

It is used when the obstacle group is

massed at a single supply point.

located too far from the Class IV/Class

Streamlines C2 of material.

V supply point to allow efficient turn-

around.

Disadvantages. The disadvantages to a It is used when available haul assets

supply point are that it—

have a relatively small capacity. This

Requires more movement of the pla-

requires frequent short-duration

toon, which may take away from

resupply trips and stocking mines to

emplacement time.

keep pace with emplacement.

Requires that the platoon move in and

It streamlines emplacement since

out of the area.

there is an opportunity to task organize

Obstacle Resourcing and Supply Operations C-13

FM 90-7

the mines into strip packages based

Minimizes the distance and time the

on the emplacement method and type of

emplacing platoon must travel to

minefield.

reload.

Allows for obstacle packages.

While it still requires the emplacing

May provide additional manpower and

platoon to stop laying and resupply, it

minimizes the distance and time the

security if it is located near a company

team.

platoon must travel to reload. This

requires that a small party be left at the

Disadvantages. The disadvantages to the minefield to assist in picking up where

service-station resupply method are that it—

emplacement stopped.

Requires additional loading and

unloading of obstacle material.

Advantages. The advantages to the service-May require augmentation with haul

station resupply method are that it—

assets.

Allows for prestockage of obstacle mate-

Disrupts emplacement by requiring the

rial to keep pace with emplacement.

emplacing platoon to stop obstacle

C-14 Obstacle Resourcing and Supply Operations

FM 90-7

Obstacle Resourcing and Supply Operations C-15