0.6125

0.5 Nrated

1

55.15

0.761

62.34

13.04

(5)

0.75

0.5 Nrated

1

60.175

0.8312

65.31

8.53

(6)

1

0.5 Nrated

1

63.54

0.8722

68.15

7.26

Table 3. Summary of the results of the two controllers

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

173

In practical system, the flux level based on PSO at different operating points (torque and

speed) is calculated and stored in a look up table (LUT). The use of look up table will enable

the system to work in real time without any delay that might be needed to calculate the

optimal point. The proposed controller would receive the operating point (torque and

speed) and get the optimum flux (λoptimal) from the look up table. It will generate the

required reference current. It is noticed that, the efficiency with the FOC based on PSO

method is higher than the efficiency with the FOC method only.

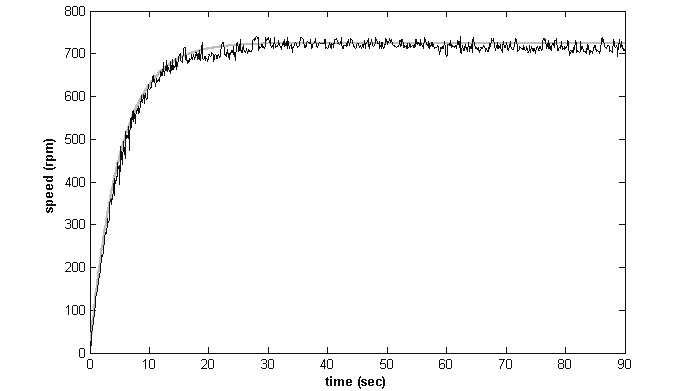

2.6 Experimental results

To verify the validity of the proposed control scheme, a laboratory prototype is built and

tested [Hegazy, 2006; Amin et al., 2006; Amin et al., 2009]. The basic elements of the

proposed experimental scheme are shown in Fig. 8 and Fig. 9. The experimental results of

the motor are achieved by coupling the motor to an eddy current dynamometer. The

experimental results are achieved using two control methods:

•

Field-Oriented Control [FOC], and

•

Field-Oriented Control [FOC] based on PSO.

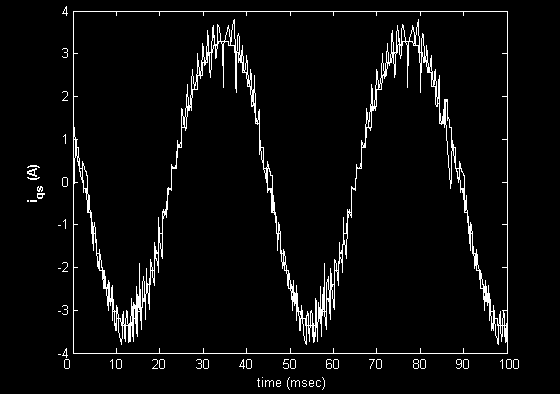

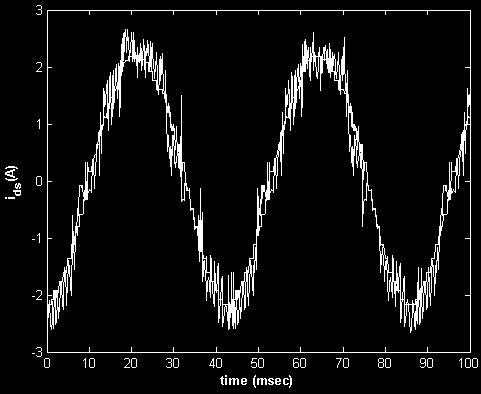

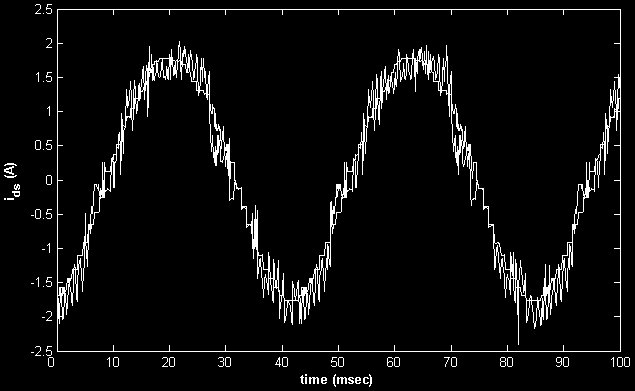

The reference and the actual motor currents are fed to the hysteresis current controller. The

switching pattern of the two-level four-switch inverter [FSI] is generated according to the

difference between the reference currents and the load currents. Figure 10 shows the

experimental results of the motor with FOC at case (1), where the motor is loaded by TL =

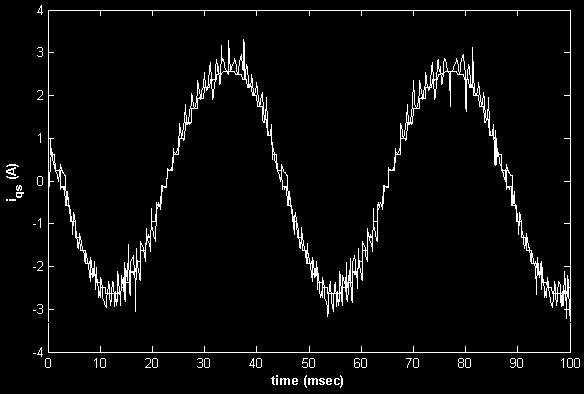

0.25 PU. Figure 11 shows the experimental result of the motor with FOC based on PSO at

case (1). The cases are summarized in Table 4.

Two dc-supply

Switching

Pattern

Inverter

4

IN

ω

isqs

Ia_ref

ref

T*e

i

+

PI

Indirect

dq-->ab

a

T

Iaact

Field-Oriented

-

E

transfor-

Hystersis

is

R

φ*

ds

me

current

I

-

b_ref

FA

controller

Rotor

ib

Ibact

PSO

CE

ωactual

Shaft

encoder

ωactual

M/c

paramaters

Tl Nr

Fig. 8. Block diagram of the proposed experimental scheme [Hegazy, 2006; Amin et al., 2009]

FOC

FOC with PSO

Cases

Improvement

λ

Power

η

λ

Power

η

(%)

(PU

Input (W)

(%)

(PU

Input (W)

(%)

(1)

1 235

32.3

0.636

169

44.92 39.07

(2)

1 323

35.2

0.690

243

47.06 33.69

Table 4. The summary of the two-cases

174

Electric Machines and Drives

D

D

Rs

Rs

S

D

1

1

S

D

2

2

Cs

C

E

G

G2

s

dc

1

S

S

iqs

D

main

E

rotor

dc

D

S

R

2

s

S

R

4

s

D3

D4

S

G2

C

G4

C

S

s

s

ids aux

Fig. 9. The power circuit of Four Switch Inverter [FSI]

(a)

(b)

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

175

(c)

Fig. 10. Experimental results of FOC method; the reference and actual speed, (b) the

reference and actual current in q-axis, (c) The reference and actual current in d-axis

(a)

(b)

Fig. 11. Experimental results of FOC method based on PSO. (a) The reference and actual

current in q-axis, the reference and actual current in d-axis

176

Electric Machines and Drives

Finally, these results demonstrate that, the FOC based on PSO method saves more energy

than conventional FOC method. Thus, the efficiency with PSO is improved than it's at FOC.

3. Maximum efficiency and minimum operating cost of induction motors

This section presents another application of PSO for losses and operating cost minimization

control in the induction motor drives. Two control strategies for induction motor speed

control are proposed. Those two strategies are based on PSO and called Maximum Efficiency

Strategy and Minimum Operating Cost Strategy [A. Hamid et al. 2006]. The proposed

technique is based on the principle that the flux level in the machine can be adjusted to give

the minimum amount of losses and minimum operating cost for a given value of speed and

load torque. The main advantages of the proposed technique are; its simple structure. It is a

straightforward maximization of induction motor efficiency and its operating cost for a given

load torque. As was demonstrated, PSO is efficient in finding the optimum operating

machine's flux level. The optimum flux level is a function of the machine operating point.

The main induction motor losses are usually split into five components: stator copper losses,

rotor copper losses, iron losses, mechanical losses, and stray losses [Kioskeridis & Margaris,

1996].

The efficiency that decreases with increasing losses can be improved by minimizing the losses.

Copper losses reduce with decreasing the stator and the rotor currents, while the core losses

essentially increase with increasing air-gap flux density. A study of the copper and core losses

components reveals that their trends conflict. When the core losses increase, the copper losses

tends to decrease. However, for a given load torque, there is an air-gap flux density at which

the total losses is minimized. Hence, electrical losses minimization process ultimately comes

down to the selection of the appropriate air-gap flux density of operation. Since the air-gap

flux density must be variable when the load is changing, control schemes in which the (rotor,

air-gap) flux linkage is constant will yield sub-optimal efficiency operation especially when the

load is light. Then to improve the motor efficiency, the flux must be reduced when it operates

under light load conditions by obtaining a balance between copper and iron losses.

The challenge to engineers, however, is to be able to predict the appropriate flux values at

any operating points over the complete torque and speed range which will minimize the

machines losses, hence maximizing the efficiency. In general, there are three different

approaches to improve the induction motor efficiency especially under light-load.

a. Losses Model Controller (LMC)

This controller depends on a motor losses model to compute the optimum flux analytically.

The main advantage of this approach is its simplicity and it does not require extra hardware.

In addition, it provides smooth and fast adaptation of the flux, and may offer optimal

performance during transient operation. However, the main problem of this approach is

that it requires the exact values of machine parameters. These parameters include the core

losses and the main inductance flux saturation, which are unknown to the users and change

considerably with temperature, saturation, and skin effect. In addition, these parameters

may vary due to changes in the operating conditions. However, with continuing

improvement of evolutionary parameter determination algorithms, the disadvantages of

motor parameters dependency are slowly disappearing.

b. Search Controller (SC)

This controller measures the input power of the machine drive regularly at fixed time

intervals and searches for the flux value, which results in minimum power input for given

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

177

values of speed and load torque. This particular method does not demand knowledge of the

machine parameters and the search procedure is simple to implement.

However, some disadvantages appear in practice, such as continuous disturbances in the

torque, slow adaptation (7sec.), difficulties in tuning the algorithm for a given application,

and the need for precise load information. In addition, the precision of the measurements

may be poor due to signal noise and disturbances. This in turn may cause the SC method to

give undesirable control performance. Moreover, nominal flux is applied in transient state

and is tuned after the system reaches steady state to an optimal value by numerous

increments, thus lengthening the optimization process. Therefore, the SC technique may be

slow in obtaining the optimal point. In addition, in real systems, it may not reach a steady

state and so cause oscillations in the air gap flux that result in undesirable torque

disturbances. For these reasons, this is not a good method in industrial drives.

c. Look Up Table Scheme

It gives the optimal flux level at different operating points. This table, however, requires

costly and time-consuming prior measurements for each motor. In this section, a new

control strategy uses the loss model controller based on PSO is proposed. This strategy is

simple in structure and has the straightforward goal of maximizing the efficiency for a given

load torque. The resulting induction motor efficiency is reasonably close to optimal. It is

well known that the presence of uncertainties, the rotor resistance, for instance makes the

result no more optimal. Digital computer simulation results are obtained to demonstrate the

effectiveness of the proposed method.

3.1 Definition of operating strategies

The following definitions are useful in subsequent analyses. Referring to the analysis of the

induction motor presented in [A. Hamid et al. 2006], the per-unit frequency is

ω

ω + ω

e

s

r

a =

=

(39)

ω

ω

b

b

The slip is defined by

ω

ω

s

s

s =

=

(40)

ω

ω + ω

b

s

r

The rotor current is given by

'

φ m

I =

(41)

r

2

'

⎛

⎞

2

⎜ r

'

r ⎟ +

⎜

⎟

Xlr

sa

⎝

⎠

The electromagnetic torque is given by

'

⎛

⎞

⎜ r ⎟

r

⎜⎜ sa ⎟⎟

⎝

⎠

(42)

=

e

T

2

φ2

'

m

⎛

⎞

2

⎜

⎟

'

rr +

⎜⎜ sa ⎟ X lr

⎟

⎝

⎠

178

Electric Machines and Drives

The stator current is related to the air gap flux and the electromagnetic torque as:

2

2

3

5

⎛

⎞

T

I = ⎜ S φ

e

+

+

⎟ +

s

1 m

S 2φ

S 2φ

CL

(43)

m

m

⎝

⎠

φ2 m

Where

x ' lr

C = + ×

L

1 2 xm

The air gap flux is related to the electromagnetic torque as:

2

'

⎛

⎞

sa ⎜ r

2

⎟

(44)

r

'

φ =

+

m

⎜

⎟

e

T

'

xlr

⎜ sa

r

⎟

r

⎝

⎠

The efficiency is defined as the output power divided by the electric power supplied to the

stator (inverter losses are included):

P

out

(

Efficiency η ) =

(45)

in

P

3.1.1 Maximum efficiency strategy

In MES (Maximum Efficiency Strategy), the slip frequency is adjusted so that the efficiency

of the induction motor drive system is maximized [A. Hamid et al. 2006].

The induction motor losses are the following:

1. Copper losses: these are due to flow of the electric current through the stator and rotor

windings and are given by:

2

2

'

'

=

+

cu

P

s

r I

(46)

s

rrIr

2. Iron losses: these are the losses due to eddy current and hysteresis, given by

2

2

P

= K (

2

+ S ) 2

1

a ϕ + K (1 +

ϕ

core

e

h

S ) a

(47)

m

m

3. Stray losses: these arise on the copper and iron of the motor and are given by:

2

2 '

=

cu

P

Cstr ω

(48)

r I r

4. Mechanical losses: these are due to the friction of the machine rotor with the bearings

and are given by:

2

=

+

fw

P

C fw ω (49)

r

5. Inverter losses: The approximate inverter loss as a function of stator current is given by:

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

179

2

=

+

(50)

inv

P

K 1 invis K 2 invis

Where: K1inv, K2inv are coefficients determined by the electrical characteristics of a switching

element where: K1inv= 3.1307e-005, K2inv=0.0250.

The total power losses are expressed by:

2

⎡

2

'

'

P

P

P

P

P

r

P

⎤

=

+

+

+

+

=

+

+

losses

cu

core

s

fw

inv

⎢ s I s rr I r ⎥

⎣

⎦

⎡ K +

ϕ ⎤ ⎡

+

+

ϕ ⎤ ⎡

⎤

+

(51)

e

⎢ (

2

1 S )

2

2

a

Kh (1 S )

2

2

2 '

a

C

⎣

⎥⎦ ⎢⎣

⎥ ⎢ str ω

⎦

I

m

m

r

r ⎥

⎣

⎦

Page 1 Page 2 Page 3 Page 4 Page 5 Page 6 Page 7 Page 8 Page 9 Page 10 Page 11 Page 12 Page 13 Page 14 Page 15 Page 16 Page 17 Page 18 Page 19 Page 20 Page 21 Page 22 Page 23 Page 24 Page 25 Page 26 Page 27 Page 28 Page 29 Page 30 Page 31