+

+

( F

F

F

F

) * V

g

roll

AD

acc

P

=

(61)

load

η GB

F = M . g. sin(α )

g

(62)

F

= M . g. f .cos(α)

roll

r

(63)

2

F

= .

0 5 ρ . C . A . V

AD

a D F

(64)

dV

F

= M .

acc

dt

(65)

V = ω . r

w w

(66)

The total electric power required from sources can be expressed as:

Pload

P

=

(67)

req

η η

.

η

.

m Inv Conv

The parameters of the vehicle are given in Table 6. The analysis of FCHEV is performed

with two standard driving cycles:

1. The Federal Test Procedure (FTP75) Urban;

2. The New European Driving Cycle (NEDC)

Suppose that the efficiencies of the motor (ηm), inverter (ηInv), and MIPEC (ηConv= ηB= η B/B)

are 0.90, 0.94 and 0.95, respectively.

M

Vehicle mass (kg)

1450

Af

Front Area (m2)

2.13

Radius of the

fr

Rolling Resistance Coefficient

0.013

rω

0.28

wheel (m)

Aerodynamic Drag

Air density

CD

0.29

ρ

1.202

Coefficient (CD)

a

(kg/m3)

Table 6. Vehicle Parameters [Wu & Gao, 2006]

186

Electric Machines and Drives

4.2 Optimal powertrain design

The first goal of optimization algorithm, PSO, is to minimize the cost, the mass, and the

volume of the fuel cell (FC) and supercapacitor (SC). It is assumed that, the cost, the mass

and the volume of the fuel cell and supercapacitor are a function of the number of the

parallel units Nfcp and Nscp, respectively. The multi-objective criterion should be aggregated in a single objective function if the design objective is to embody a unique solution. The

objective function can be formulated as follows:

F( x) = w cos t + w mass + w volume

1

2

3

(68)

cos t = C 1. Nfcs. Nfcp + C 2. Nscs. Nscp (69)

The coefficients of the terms in F(x) were chosen to reflect the importance of minimizing the

cost, the mass and the volume. Suppose that w1, w2, and w3 are 0.35, 0.35, and 0.3,

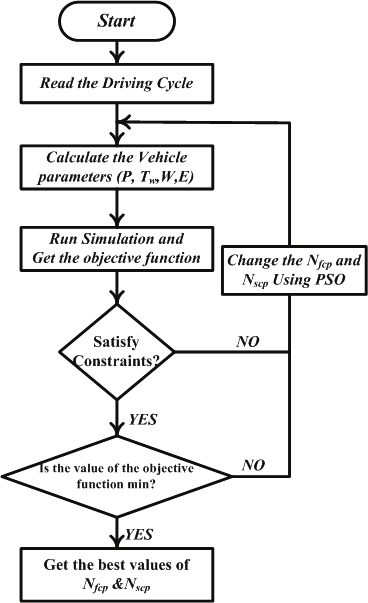

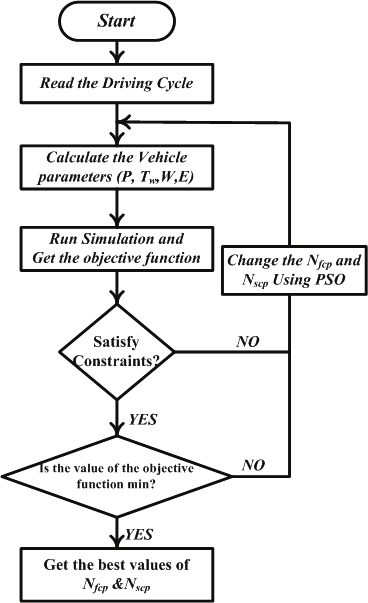

respectively. Figure 17 presents the flowchart of the execution of PSO, which evaluates the

optimal number of the FC units and the supercapacitor units by using MATLAB

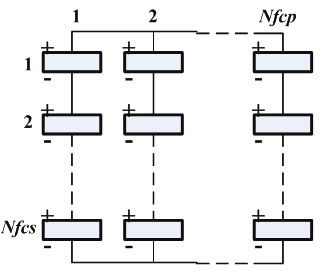

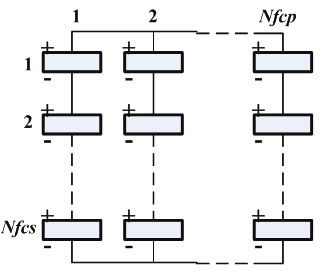

/SIMULINK. The layout of the fuel-cell stack and layout of the supercapacitor system are

shown in Fig.18 (a) and (b), respectively. The constraints of the optimization problems are

mentioned in [Hegazy & Van Mierlo, 2010].

Fig. 17. The flowchart of the execution of PSO [Hegazy et. al 2010]

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

187

(a)

(b)

Fig. 18. (a) Layout of the FC; (b) Layout of the SC

188

Electric Machines and Drives

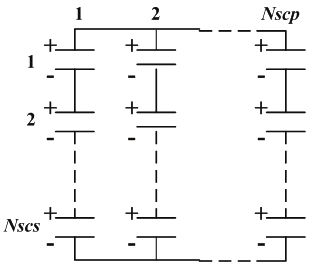

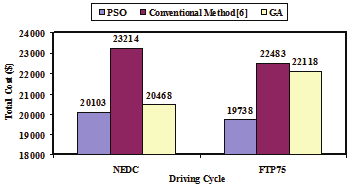

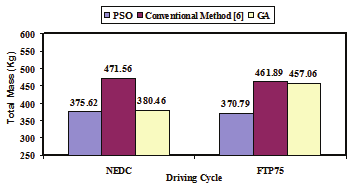

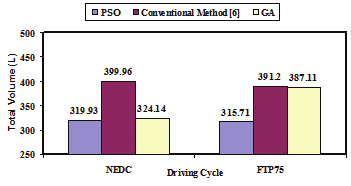

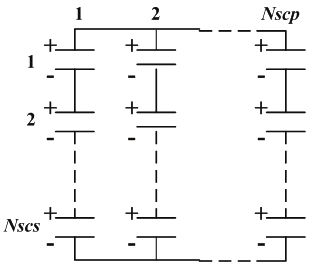

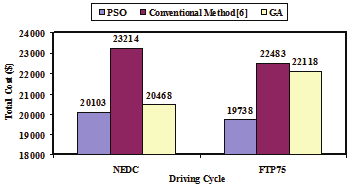

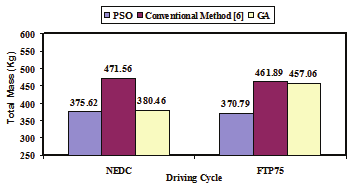

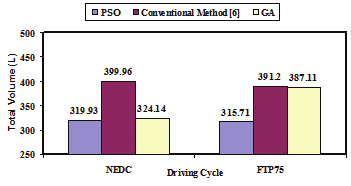

Based on minimizing the objective function F(x) in (68), the results of the optimal design and

components sizing of the FC/SC powertrain are shown in Fig.19. The analyses and

parameters of the FC and the SC are mentioned in [Hegazy & Van Mierlo, 2010].

(a) The optimal numbers of cells of FC and SC

(b) The cost of the FC/SC components

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

189

(c) The mass of the FC/SC components

(d) The mass of the FC/SC components

Fig. 19. The Comparative of the optimal design between different methods for FC/SC HEV

4.3 Optimal Power Control (OPC)

The second goal of the PSO is to minimize the vehicle fuel, hydrogen, consumption while

maintaining the supercapacitor state of charge. As a hybrid powertrain is under

consideration, a power management strategy is required to define what both the FC and SC

powers are. The global optimization algorithms, such as GA and dynamic programming

(DP), achieve an optimal power control for FC/SC hybrid electric vehicle, which leads to the

lowest hydrogen consumption and maintains the supercapacitor SOC [Sinoquet et. al 2009;

Sundstrom & Stefanopoulou 2006].

In this study, the optimal power control can be achieved by using PSO and GA for a given

driving cycle. Suppose that the degree of hybridization of the fuel cell is Kfc at time t and Ksoc, Proportional controller gain, which used to adapt the SOC during charging from the

FC. A balance equation can naturally be established, since the sum of power from both

sources has to be equal to the required power at all times:

190

Electric Machines and Drives

( t) = Pfc( t)

Psc( t) (70)

req

P

+

Pfc( t)

Kfc( t) =

(71)

( t)

req

P

The net energy consumed from the FC at time t can be computed as follows:

t

( )

(72)

Efc t

( ) =

Pfc t

∫

dt

η ( Pfc t())

0

The cost function can be expressed as follows:

N

Pfc

( k)

1

(73)

F ( x) =

∑

Opti

Δ T

2

Elow K = η ( Pfc

( k

0

Opti ))

The Optimal fuel cell power output, PfcOpti, is calculated based on the SOC of the

supercapacitor and power demand, Preq, as follows:

⎡

SOC

− SOC( k)

⎤

ref

(74)

Pfc

( k) = Kfc( k)

( k) + Ksoc( k) ( Pfc

− Pfc

) ⎢

⎥

Opti

req

P

max

min ⎢( SOC

− SOC

) / 2 ⎥

⎣

max

min

⎦

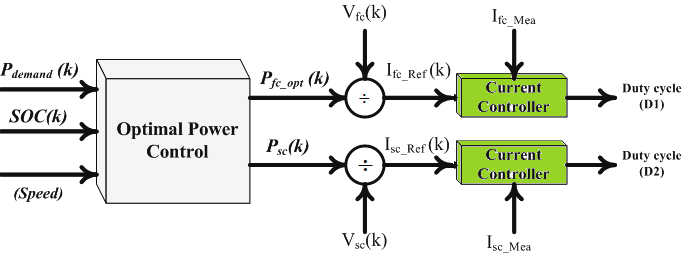

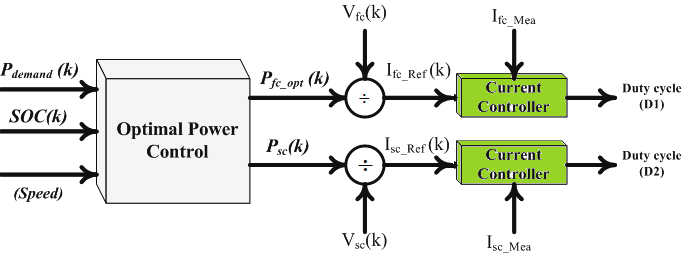

Fig. 20. The block diagram of the Optimal power Control

Where: N= T/ΔT is number of samples during the driving cycle, and ΔT=1s is the sampling

time.

The block diagram of the optimal power control based on optimization algorithm is shown

in Fig.20.

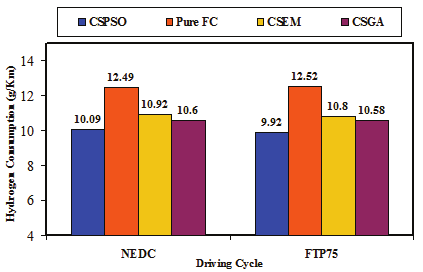

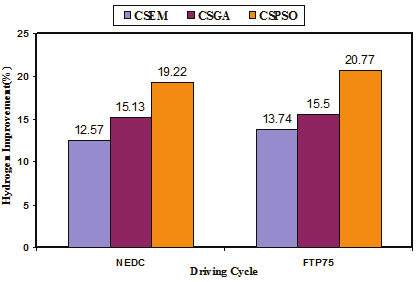

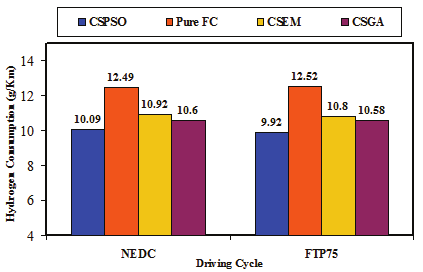

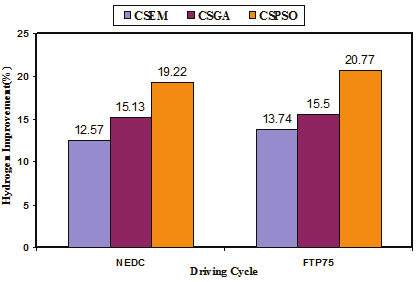

Based on minimizing the objective function F2(x) in (73), the results of the optimal power

sharing based PSO and the comparative study for the FC/SC powertrain are summarized in

Fig.21 [Hegazy et. al 2010].

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

191

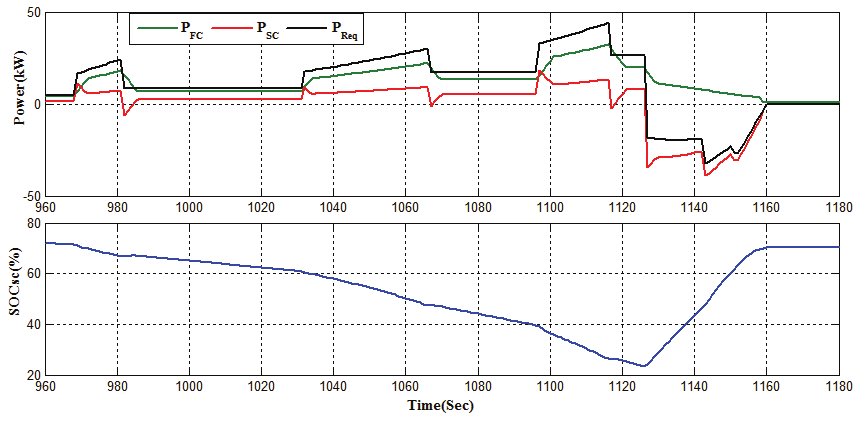

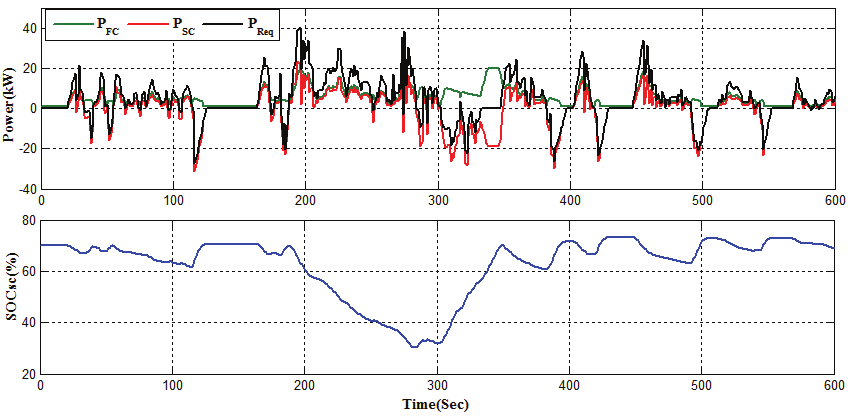

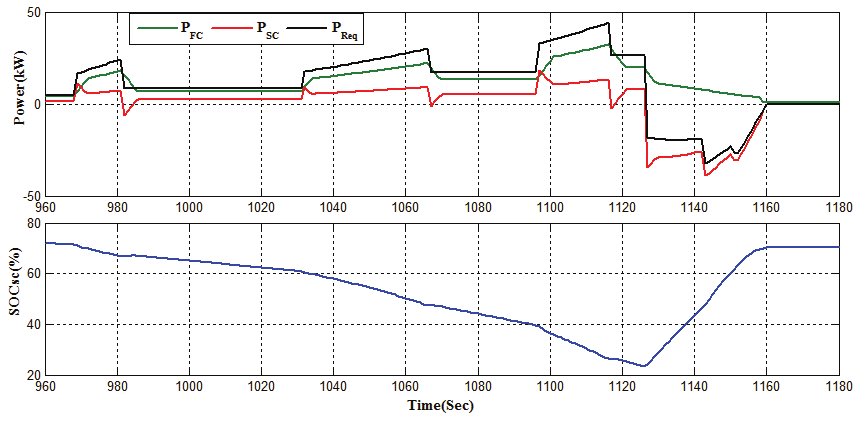

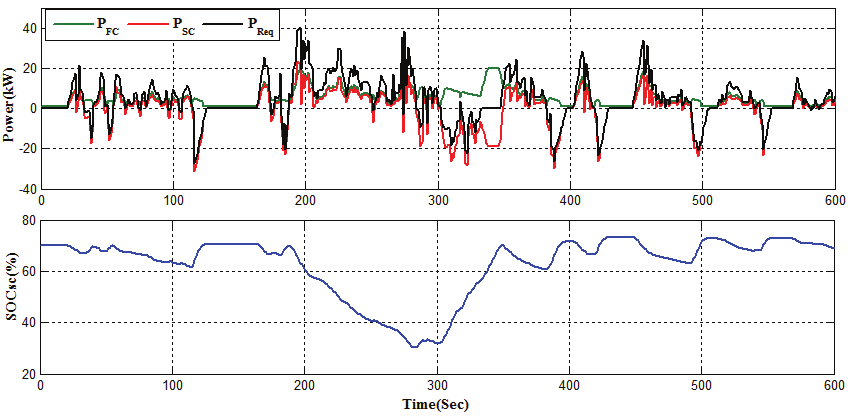

(a) The power sharing between FC and SC on NEDC driving cycle

(b) The power sharing between FC and SC on FTP75 driving cycle

192

Electric Machines and Drives

(c) The Comparative of the hydrogen consumption between control strategies

(d) The Hydrogen improvements with respect to pure fuel cell without SC

Fig. 21. The results of the optimal power Control for FC/SC

Swarm Intelligence Based Controller for

Electric Machines and Hybrid Electric Vehicles Applications

193

5. Conclusion

This chapter deals with the applicability of swarm intelligence (SI) in the form of particles

swarm optimization (PSO) used to achieve the best performance for the electric machines

and electric drives. In addition, by analyzing and comparing the results, it is shown that

control strategy based on PSO is more efficient than others control strategies to achieve the

optimal performance for fuel cell/supercapacitor hybrid electric vehicles (FCHEV).

It is very important to note that, these applications were achieved without any additional

hardware cost, because the PSO is a software scheme. Consequently, PSO has positive

promises for a wide range of variable speed drive and hybrid electric vehicles applications.

6. Index I

List of principal symbols

ωe : synchronous speed

ωr : rotor speed

p

: differential operator

rm , ra : main, auxiliary stator windings resistance

rr

: rotor winding resistance

Rfeq,d

: equivalent iron-loss resistance(d and q axis)

Llm ,Lla : main, auxiliary stator leakage inductance

Lmd ,Lm q : magnetizing inductance (d& q axis )

Llr

: rotor leakage inductance

K

: turns ratio auxiliary/main windings

Te

: electromagnetic torque

J

: inertia of motor

λds,qs

: stator flux(d and q axis)

λdr,qr

: rotor flux(d and q axis )

Vds,qs

: stator voltage (d and q axis)

ids,qs

: stator current (d and q axis)

M : mutual inductance

7. References

Amin. A. M. A., Korfally. M. I., Sayed. A. A. and Hegazy. O.T. M., (2009), Efficiency

Optimization of Two Asymmetrical Windings Induction Motor Based on Swarm

Intelligence, IEEE Transactions on Energy Conversion, Vol. 24, No. 1, March

2009

Amin. A. M. A., Korfally. M. I., Sayed. A. A. and Hegazy. O.T. M., (2006), Losses

Minimization of Two Asymmetrical Windings Induction Motor Based on Swarm

Intelligence, Proceedings of IEEE- IECON 06 , pp 1150 – 1155, Paris , France , Nov.

2006 .

Amin. A. M. A., Korfally. M. I., Sayed. A. A. and Hegazy. O.T. M., (2007), Swarm

Intelligence-Based Controller of Two-Asymmetrical Windings Induction Motor,

accepted for IEEE. EMDC07, pp 953 –958, Turkey, May 2007.

Eberhart. R, Kennedy. J, (1995), A New Optimizer Using Particles Swarm Theory, Proc.

194

Electric Machines and Drives

Sixth International Symposium on Micro Machine and Human Science (Nagoya,

Japan), IEEE Service Center, Piscataway, NJ, pp. 39-43,

A. Hamid Radwan H., Amin Amr. M. A., Ahmed Refaat S., and El-Gammal Adel A. A.

,(2006), New Technique For Maximum Efficiency And Minimum Operating Cost

Of Induction Motors Based On Particle Swarm Optimization (PSO)”, Proceedings

of IEEE- IECON 06 , pp 1029 – 1034, Paris , France , Nov. 2006.

Hegazy Omar, (2006), Losses Minimization of Two Asymmetrical Windings Induction

Motor Based on Swarm Intelligence, M.Sc., Helwan University, 2006.

Hegazy Omar, and Van Mierlo Joeri, (2010), Particle Swarm Optimization for Optimal

Powertrain Component Sizing and Design of Fuel cell Hybrid Electric Vehicle, 12th

International Conference on Optimization of Electrical and Electronic Equipment,

IEEE OPTIM 2010

Hegazy Omar, Van Mierlo Joeri, Verbrugge Bavo and Ellabban Omar, (2010), Optimal

Power Sharing and Design Optimization for Fuel Cell/Battery Hybrid Electric

Vehicles Based on Swarm Intelligence, The 25th World Battery, Hybrid and Fuel

Cell Electric Vehicle Symposium & Exhibition © EVS-25 Shenzhen, China, Nov. 5-9,

2010.

Kennedy. J and Eberhart .R, (2001), Swarm Intelligence, Morgan Kaufmann Publishers, Inc.,

San Francisco, CA

Kioskeridis, I; Margaris, N., (1996), Losses minimization in scalar-controlled induction

motor drives with search controllers" Power Electronics, IEEE Transactions,

Volume: 11, Issue: 2, March 1996 Pages: 213 – 220

Popescu. M, Navrapescu. V, (2000) ,A method of Iron Loss and Magnetizing Flux

Saturation Modeling in Stationary Frame Reference of Single and Two –Phase

Induction Machines”, IEE 2000, Conf. power Elec. & Variable Speed Drives, 140-

146

Sundstrom Olle and Stefanopoulou Anna, (2006), Optimal Power Split in Fuel Cell Hybrid

Electric Vehicle with different Battery Sizes, Drive Cycles, and Objectives,

Proceedings of the 2006 IEEE International Conference on Control Applications

Munich, Germany, October 4-6, 2006.

Van Mierlo Joeri, Cheng Yonghua, Timmermans Jean-Marc and Van den Bossche Peter,

(2006), Comparison of Fuel Cell Hybrid Propulsion Topologies with Super-

Capacitor, IEEE, EPE-PEMC 2006, Portorož, Slovenia

Wu Ying, Gao Hongwei, (2006) ,Optimization of Fuel Cell and Supercapacitor for Fuel-Cell

Electric Vehicles, IEEE Transactions On Vehicular Technology, Vol. 55, No. 6,

November 2006.

10

Operation of Active Front-End Rectifier in

Electric Drive under Unbalanced Voltage Supply

Miroslav Chomat

Institute of Thermomechanics AS CR, v.v.i.

Czech Republic

1. Introduction

Non-standard conditions in the power network such as voltage unbalance can negatively

affect operation of electric drives. The unbalance can be caused by a failure in the network

or by an unbalanced load in the electric vicinity of the affected drive. Unsymmetrical

voltages at the input of a voltage source inverter cause pulsations in the DC link voltage

when not properly taken care of. This may result in significantly reduced power capabilities

and, therefore, limited controllability of the drive. This text deals with the effects of

unbalanced voltage supply on the DC-link voltage pulsations, methods to address this

problem and the additionally imposed constraints in operating regions of the rectifier.

2. Control method

A simplified scheme of the drive under investigation is shown in Fig. 1. The front-end

controlled rectifier is connected to the mains through input filter inductors. The output

current of the rectifier supplies the DC current to the output inverter and maintains the

voltage across the DC-link capacitors constant at the same time. The value of this current

can be controlled by suitable switching of solid-state elements in the front-end stage.

i

power

input

front end

DC

DC bus

inverter

electric

network

impedance

machine

V

i

A

A

L

R

C DC

VDC

iB

VB

L

R

N

0

M

i

V

V

C

V

N

A

L

R

0

C

V

DC

DC

Fig. 1. Scheme of system under investigation.

Suitable control of the front-end AC/DC converter can be employed in order to draw

constant input power from the power network even at unbalanced voltage supply

196

Electric Machines and Drives

(Stankovic & Lipo, 2001; Lee et al., 2006; Cross et al., 1999; Song & Nam, 1999). The

switching functions for the front-end AC/DC converter are generated so that a constant

voltage across the DC bus is maintained. Series combinations of inductance and resistance

are considered at the input terminals of the inverter.

The system can be electrically described by the following set of ordinary differential

equations (Chomat & Schreier, 2005):

di

A

v − L

− Ri − v + v − v = 0

A

A

SA

N

0

, (1)

dt

di

B

v −

−

−

+

−

=

B

L

RiB

S

v B vN

0

v

0 , (2)

dt

C

di

−

−

−

+

−

= ,

(3)

C

v

L

R C

i

S