.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . .

. . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.

. . . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

i

.

.

.

.

.

.

.

.

.

.

.

.

. a

.

.

.

.

.

.

.

.

.

.

.

. . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.

. . . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.

. . . .

. . . .

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

1) [THS720P].CH1 100 V 2 mS

1) [THS720P]

. .CH1 10. 0 V 5 m. S

.

.

.

.

.

2) [THS720P].CH2 5 A 2 mS

2) [THS720P].CH2 1 A 5 mS

(a) (b)

Fig. 17. Voltage and current for: a) uncompensated motor; b) compensated motor

6. Comments

This study proved that direct injecting capacitance reactance through auxiliary winding

does improve the power factor of the induction motor; it also increases the ratio torque over

current. What is also very interesting is this method achieves a “flat” variation of power

factor with respect of load variation. This is a very important improvement given the fact

that majority of induction motors do not work at constant full load where the classic design

produces maximum performances.

However, this method introduces extra copper losses reducing the overall efficiency and

increasing the operation temperature.

This study did not intended to elucidate the full effect of the method upon the torque

especially the existence of the influence produced by the current flowing through auxiliary

windings. The only aspect clearly noticed was the torque ripple introduced by the “single-

phase” auxiliary winding connection.

Further more, the same method was applied to a synchronous reluctance motor

(Ogunjuyigbe et al, 2010). The same type of stator winded similarly as above was used with

a salient milled rotor obtained from the corresponding squirrel cage induction motor. The

experimental results show an improvement of the power factor from 0.41-0.69 to 0.93-0.97

for the entire loading range.

40

Electric Machines and Drives

The economic benefits are related with the savings on demand especially for places where a

large number of three-phase induction motors are used under variable loading.

7. References

M. A El-Sharkawi, S. S Venkata, T. J Williams, and N. G Butler, “An adaptive Power Factor

Controller for Three-Phase Induction Generators”, Paper 84 SM 672-2 presented at

the IEEE/PES Summer Meeting, Seattle, Washington, July 15-20, 1984.

Fuchs, E.F. Hanna, W.J.; “Measured efficiency improvements of induction motors with

thyristor/triac controllers”, , IEEE Transaction on Energy Conversion, Volume 17,

Issue 4, Dec. 2002 pp. 437 – 444

Suciu, C.; Dafinca, L.; Kansara, M.; Margineanu, I.; “Switched capacitor fuzzy control for power

factor correction in inductive circuits”, IEEE 31st Annual Power Electronics Specialists Conference, 2000. Vol. 2, pp. 773 - 777

C. Suciu, M. Kansara, P. Holmes and W. Szabo, “Performance Enhancement of an Induction

Motor by Secondary Impedance Control, IEEE Trans. On Energy Conversion, Vol. 17,

No. 2, June 2002

J. Reinert, M.J. Parsley, ‘‘Controlling the speed of 8×1 induction motor by resonating the

rotor &wit,” in IEEE Transactions on Industry Applications, Vol. 31, No. 4,

July/August 1995, pp. 887-891.

E. Muljadi, T.A. Lipo, D.W. Novotny, "Power Factor Enhancement of Induction Machines by

Means of Solid State Excitation," IEEE Trans. on Power Electronics, Vol. 4, No. 4, pp.

409418, Oct. 1989.

I. M Tamrakan and O.P Malik, “Power Factor Correction of Induction motors Using PWM

Inverter Fed Auxiliary Stator Winding”, IEEE Transaction on Energy Conversion, Vol.

14, No.3, Sept, 1999, pp. 426-432

J. B. Medarametla, M. D. Cos, and Baghzouz, “Calculations and measurement of unity plus

three-phase induction motor,” IEEE Transactions on Energy Conversion, vol. 7, no. 4,

pp. 732-738, 1992.

S. D. Umans, and H. L. Hess, “Modelling and analysis of a the Wanlass three-phase

induction motor configuration,” IEEE Transaction on Power Apparatus and Systems,

vol. 102, no. 9, pp. 2912-2916, 1983.

R. Spée and A. Wanllace, “Comparative Evaluation Of Power-Factor Improvement

Techniques For Squirrel cage Induction Motors”, Industry Applications Society

Annual Meeting, 1990.

A.A. Jimoh and D.V. Nicolae, “Performance Analysis of a Three-Phase Induction Motor with

Capacitance Injection”, OPTIM’06, 10th International Conference on Optimization of

Electrical and Electronic Equipments, Brasov, Romania, May 17-20, 2006

D.V. Nicolae and A.A. Jimoh, “Three-Phase Induction Motor with Power Electronic

Controlled Single-Phase Auxiliary Stator Winding”, PESC’07, The 38th IEEE Power

Electronics Specialists Conference, Orlando, USA, June 17-21, 2007

A.S.O. Ogunjuyigbe, A.A. Jimoh, D.V. Nicolae and E.S. Obe, “Analysis of Synchronous

Reluctance Machine with Magnetically Coupled Three Phase Windings and Reactive

Power compensation”, IET Electric Power Applications, 2010, Vol. 4, Iss. 4, pp 291-303

3

Magnetic Reluctance Method for Dynamical

Modeling of Squirrel Cage Induction Machines

Jalal Nazarzadeh and Vahid Naeini

Faculty of Engineering

Shahed University, Tehran

Iran

1. Introduction

Nowadays, induction machines play important role in electromechanical energy conversion in

industry. These machines are often operated in critical conditions where can cause unexpected

failures and outages. Generally, stator and bearing faults, broken rotor bar and end-rings,

air-gap irregularities are some of the major faults in an induction machine (Al-Shahrani, 2005;

Sprooten, 2007) which may be situated the induction machines in out of service (Siddique

et al., 2005). Fourier analysis for stator currents (Bellini et al., 2001; Benbouzid, 2000; Jung

et al., 2006), torque and rotor speed, acoustic noise and temperature analysis (Siddique et

al., 2005) are some classical techniques which introduced for identification and diagnosis of

induction machines faults. Additionally, other heuristic methods were proposed to monitor

of the induction machines for fault detection. For instance, neural network modelling were

applied to monitor an induction machine for fault detection (Su & Chong, 2007). Also, space

vector of rotor magnetic field (Mirafzal & Demerdash, 2004) based on artificial intelligent

approaches and pendulous oscillation of the rotor magnetic field were proposed. Recently,

a new technique based on the analysis of three-phase stator current envelopes was presented

(Mirafzalet & Demerdash, 2008). In all monitoring and fault detection techniques, we need

to tune up the monitoring systems based on response of induction machines for proper

operations. However, experimental set up for testing any arbitrary fault conditions are not

practical. Thus, an accuracy dynamic and steady state models of induction machines are very

important for this propose.

Also, for dynamical modelling of induction machines, space harmonic distribution, core

saturation and loss are often neglected in abc quantitative and two-axis methods (Krause et

al., 1995). Thus, these approaches do not have an efficient accuracy for modelling of induction

machines in asymmetrical and non-linear conditions. For considering distribution rotor bars,

coupled magnetic circuit method (Muñoz & Lipo, 1999), abc quantitative based on rotor bar

currents (Alemi & Nazarzadeh, 1996) can be utilized. Furthermore, winding function method

may be used to include the stator winding distribution effect in the air gap flux (Luos et al.,

1995). However, in all mentioned methods, the core saturation, stator and rotor teeth effects

and distributions of the rotor and stator windings can not be investigated, simultaneously.

Also, Finite Element Method (FEM) is a professional technique for analysis of any

electromagnetic systems, which needs to magnetic and geometry details of the systems (Faiz

42

Electric Machines and Drives

et al., 2002). This method is very accurate and flexible, but due to complexity, the dynamical

modelling of an induction machine is quite complicated. Contrary to FEM, the Magnetic

Equivalent Circuit Method (MECM) can apply to analysis of the electro magnetics problems

with lower complexity. Magnetic saturation, space harmonics in stator and rotor teeth, stator

windings and distributed structure of a squirrel-cage rotor can be considered by MECM for

modelling and analysis of any induction machines (Jeong et al., 2003; Ostovic, 1989). In this

approach, the non-linear reluctances of flux paths use to configure magnetic equivalent circuit.

This method has less complexity than FEM for dynamical modelling of induction machines.

Therefore, developing an exact details model of induction machine for analysis of transient,

sensitivity and fault diagnosis in the asymmetrical conditions are very essential.

The present chapter introduces methodology of MECM for modelling and analysis of

asymmetrical non-linear systems in transient and steady state conditions. MECM is very

suitable method for finding a generalized accurate dynamical model of squirrel cage induction

machines with asymmetrical conditions. For evaluation of the method, several simulations

in linear and non-linear conditions are made. Also, some simulations results for induction

machines with broken bar faults and core saturation conditions are included to illustrate

capability of the method in asymmetrical conditions.

2. Electric and magnetic based model of squirrel cage induction machines

For detailed modelling of any electromagnetic systems, we have to find a correlation between

electric and magnetic variables of the system. Generally, a set of non-linear differential

equations presents dynamical model of a electromagnetic system that by using numerical

analysis, transient response of the electrical variables can be obtained. In addition, non-linear

algebraic equations illustrate non-linear relations between electrical and magnetic variables.

MECM provides an augmented model of the electromagnetic systems, in which we can

achieve all variables of the systems in transient and steady state, simultaneously. Also, the

main advantages of MECM for modelling of induction machines are; simple algorithm for

including distribution winding, stator and rotor teeth effects and magnetic core saturation

phenomena. Global non-linear model of squirrel cage induction machines can be offered

in algebraical (magnetic) and differential (electric) equations which will be presented in the

following sections.

3. Magnetic equivalent circuit of induction machines

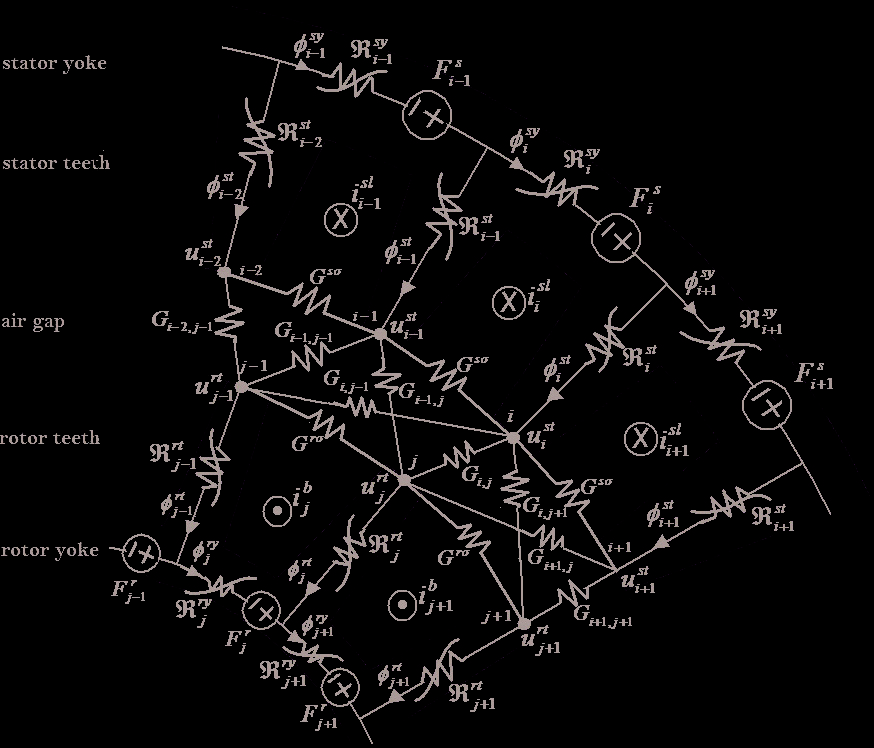

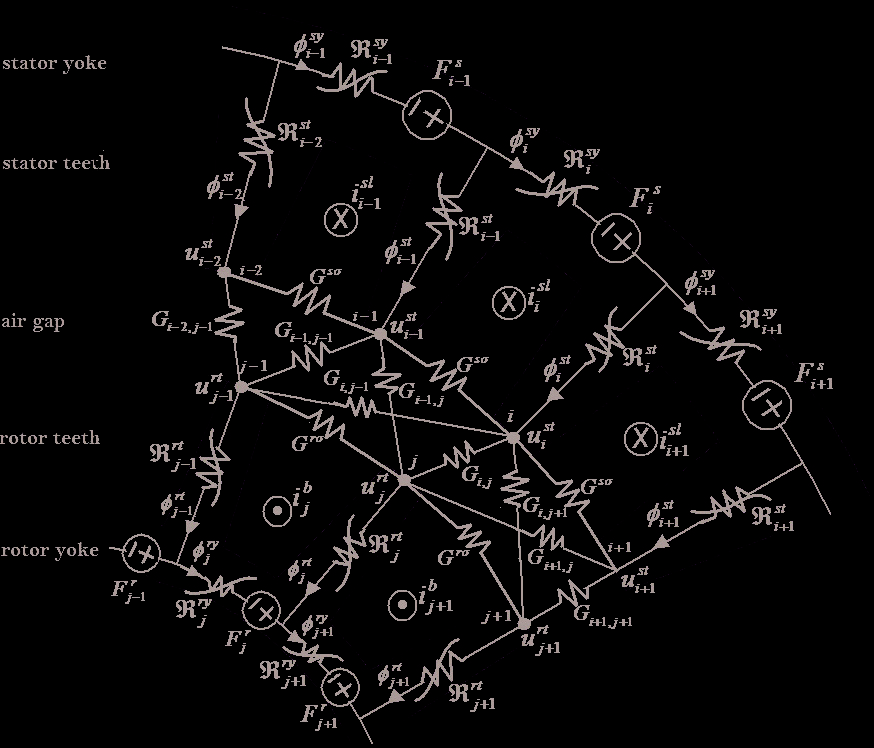

Fig. 1 shows a part of rotor and stator structures for a typical squirrel cage induction

machine that magnetic circuit elements are presented for rotor and stator teeth and yoke.

Numbers of rotor and stator teeth are considered by h and l, respectively. Also in this figure, magnetic mutual permeances of rotor and stator teeth in air gap are shown. Due to non-linear

characteristics of flux and magnetic current in iron core, permeances of the rotor and stator in

the magnetic cores are illustrated as non-linear elements. Gi, j is linear permeance of flux path between ith stator and jth rotor teeth in the air gap.

3.1 Magnetic node equations

Due to the fact that magnetic permeances of each stator and rotor teeth make several magnetic

loops in the air gap, we apply node magnetic potential equations to the each air gap nodes for

Magnetic Reluctance Method for Dynamical Modeling of Squirrel Cage Induction Machines

43

Rotor Axis

J t

Stator Axis

Fig. 1. Magnetic equivalent circuit of induction machine

simplicity in algebraic magnetic equations. For instance, sum of magnetic fluxes in ith air gap

node (stator tooth) have to be zero; thus we can write:

us −

−

− )

− )

i

usi+1 Gsσ + usi usi− 1 Gsσ + ( usi ur 1 Gi 1 + · · · + ( usi url Gil = φsti (1)

where us, ur and φst are magnetic potential of stator, rotor and flux of ith stator tooth and i

i

i

Gsσ and Gi, j are permeances of stator neighbour slots and mutual permance between ith stator with jth rotor teeth, respectively.

Similar Eq. (1), continuity principle in the teeth fluxes at ith rotor node yields as:

ur −

−

− )

− )

i

uri+1 Grσ + uri uri− 1 Grσ + ( uri us 1 Gi 1 + · · · + ( uri ush Gih = −φrti (2)

In Eq. (2), φst and Grσ are flux of ith rotor tooth and permeance of rotor slot, respectively.

i

Consequently, node potential equations for equivalent circuit of Fig. 1 along the air gap can

be written as:

A ssU st + A srU rt = Ψ st

(3)

A rsU ss + A rrU rt = −Ψ rt

(4)

44

Electric Machines and Drives

where A ss ∈ R h×hâ ˘

Ać, A rr ∈ R l×l and A sr ∈ R h×l are air gap permeance coefficients matrices that we can written as:

⎡

⎤

l

⎢ 2 Gsσ+ ∑ G

⎢

1, j

−Gsσ

0

· · · 0

0

−Gsσ

⎥

⎢

j=1

⎥

⎢

⎥

l

⎢

⎥

⎢

−Gsσ

2 Gsσ+ ∑ G 2, j

−Gsσ · · · 0

0

0

⎥

⎥

A ss = ⎢

j=1

⎢

⎥

(5)

⎢

.

.

.

.

.

.

.

⎥

⎢

.

.

.

.

⎥

.

.

.

.

⎢

.

.

.

.

.

.

⎥

⎣

⎥

l

−

⎦

Gsσ

0

0

· · · 0 −Gsσ 2 Gsσ+ ∑ Gh, j

j=1

⎡

⎤

h

⎢ 2 Grσ+ ∑ G

⎢

i,1

−Grσ

0

· · · 0

0

−Grσ

⎥

⎢

i=1

⎥

⎢

h

⎥

⎢

−

⎥

Grσ

2 Grσ+ ∑ Gi,2

−Grσ · · · 0

0

0

⎥

A

⎢

⎥

rr = ⎢

i=1

(6)

⎢

⎥

.

.

.

.

.

.

⎢

.

.

.

. .

.

.

.

⎥

⎢

.

.

.

.

.

.

.

⎥

⎣

⎥

h

⎦

−Grσ

0

0

· · · 0 −Grσ 2 Grσ+ ∑ Gi, l

i=1

⎡

⎤

G 1,1

G 1,2

· · · G 1, l

⎢

⎢ G