circuit of three-phase squirrel-cage induction motors using two-dimensional

finite-elements technique. IEEE Transactions on Energy Conversion, Vol. 17, No. 3,

(Spet. 2002), 363-367

Gautschi W. (1964). Error function and Fresnel integrals, Handbook of Mathematical Functions, NBS

Appl. Math. Series, Vol. 55, U.S. Government Printing Office, Washington, D.C.

Jeong, J. H.; Lee E. W. & Cho, H. K. (2003). Analysis of transient state of the squirrel cage

induction motor by using magnetic equivalent circuit method, Sixth International

Conference on Electrical Machines and Systems, Vol. 2, 720-723, 2003

Jung, J. H.; Lee, J. J. & Kwon, B. H. (2006). Online diagnosis of induction motors using MCSA.

IEEE Transactions on Industry Electronics, Vol. 53, No. 6, (Dec 2006), 1842-1852

Krause, P. C.; Wasynczuk, O. & Sudhoff, S. D. (2002). Analysis of Electric Machinery and Drive

Systems (2nd Edition), Wiley-IEEE Press, ISBN 047114326X, New York.

Luos, X.; Liao, Y.; Toliyaty, H.; El-Antably, A. & Lipos, T. A. (1995). Multiple coupled circuit

modeling of induction machines. IEEE Transactions on Industry Applications, Vol. 31,

No.2, (Mar./Apr. 1995), 311-318

Mirafzal, B.& Demerdash, N. A. O. (2004). Induction machine broken-bar fault diagnosis

using the rotor magnetic field space-vector orientation. IEEE Transactions on Industry

Applications, Vol. 40, No. 2, (Mar./Apr. 2004), 534-542

Mirafzal, B.& Demerdash, N. A. O. (2008). Induction machine broken bar and stator

short-circuit fault diagnostics based on three-phase stator current envelopes. IEEE

Transactions on Industry Applications, Vol. 55, No. 3, (March 2008), 1310-1318

Muñoz, A. R. & Lipo, T. A. (1999). Complex vector model of the squirrel-cage induction

machine including instantaneous rotor bar currents. IEEE Transactions on Industry

Applications, Vol. 35, No. 6, (Nov./Dec. 1999), 1332-1340

Ostovic, V. (1989). A novel method for evaluation of transient states in saturated electric

machine. IEEE Transactions on Industry Applications, Vol. 25, No. 1, (Feb. 1989), 96-1000

Ostovic, V. (1989). Dynamics of Saturated Machines, Springer-Verlag, ISBN 0387970797, New

York

Siddique, A.; Yadava, G. S. & Singh, B. (2005). A review of stator fault monitoring techniques

of induction motors. IEEE Transactions on Energy Conversion, Vol. 20, No. 1, (March

2005), 106-114

Sprooten, J. (2007). Finite element and electrical circuit modeling of faulty induction machines study of internal effects and fault detection techniques. Ph.D. thesis, Department of Bio, Electro

and Mechanical Systems (BEAMS), University Libre de Bruxelles

60

Electric Machines and Drives

Su, H. & Chong, K. T. (2007). Induction machine condition monitoring using neural network

modelling. IEEE Transactions on Industry Applications, Vol. 54, No. 1, (Feb. 2007),

241-249

4

Minimization of Losses in Converter-

Fed Induction Motors – Optimal Flux Solution

Waldiberto de Lima Pires, Hugo Gustavo Gomez Mello,

Sebastião Lauro Nau and Alexandre Postól Sobrinho

WEG Equipamentos Eletricos S.A. – Motores

Research and Development of Product Department

Av. Pref. Waldemar Grubba, 3000 – malote 41

Jaraguá do Sul, SC - 89256-900

Brazil

1. Introduction

When a TEFC induction motor fed by static frequency converter drives a load which

demands constant torque throughout the operation range, the low speeds are thermally

critical, because the motor losses (heat sources) do not vary much as a function of the speed,

but the ventilation efficiency decreases as the operation speed falls down, since the fan is

installed on the very motor shaft. In such cases, when operating at low speeds, the

temperature rise often exceeds the limits of the motor thermal class due to the lack of

cooling. In order to prevent this problem the industry has traditionally adopted one of the

following solutions: independent ventilation (a small auxiliary motor is used to exclusively

drive the fan that provides the main motor cooling) or oversizing (the motor used in the

application provides a higher torque than the rated load demand). However, neither one

nor the other of these two options are attractive, as both, besides increasing the space

required for the installation, still increase the motor price [1].

Frequency converters usually apply to the motor a constant voltage/frequency ratio

throughout the operation range, so that no loss control is provided. But the study on the

motor losses composition and its relation with voltage, frequency, magnetic flux and

current, allied with the study on the influence of the ventilation on the temperature rise of

the motor, has led to an optimal voltage/frequency ratio, which minimizes the total motor

losses at each speed [2]. This way, by implementing the automatic control of the

voltage/frequency ratio in the converter, the motor loss minimization can be automatically

obtained throughout the frequency range, so that the motor temperature rise is kept within

the thermal class limits even at low speeds with reduced ventilation.

2. Determination of losses

The fast growth of the number of industrial applications using static frequency converters

recently observed in variable speed drives has encouraged the meticulous study of losses in

magnetic materials under PWM supply by several researchers [3, 4, 5, 6, 7, 8]. They have

62

Electric Machines and Drives

shown that such losses depend on a number of control parameters, such as the modulation

index, the number of levels and pulses of the frequency converter and the duration of PWM

signal pulses. On the other hand, Boglietti et alli have concluded that the flux waveforms

resulting from PWM supply differ from those resulting from sinusoidal supply just except

for a small ripple, which depends on the switching frequency, and that above approximately

5 kHz the iron losses can be considered independent of this parameter [9]. Such studies

represent the first step towards the understanding of the losses behavior in electric motors

under PWM supply, that involves a higher degree of complexity and is not restricted

exclusively to the magnetic materials issue, but includes also additional losses in the

conductors and due to the cooling system and depends, besides the control parameters, on

some machine design parameters, such as the flux density, the lamination geometry and the

connection of windings [3, 10, 11, 12], as well as on other variables inherent to the

manufacturing process [13].

For the purposes of this study, however, the analysis of the motor losses can be simplified,

so that it is enough to separate the total motor losses in three key components:

P = Pfe + Pj + Pmec (1)

where:

Pfe – Iron losses, which depend on the flux density (or magnetic induction), the frequency

and the quality of the magnetic material.

Pj – Losses by Joule effect, which depend on the currents flowing through the stator

windings and the rotor bars.

Pmec – Mechanical losses due to cooling system (fan coupled to the shaft) and friction,

which depend on the speed.

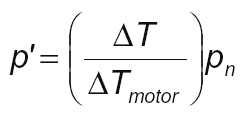

The iron losses are classically considered as being composed of two portions: Hysteresis losses

(pH) and induced eddy current (Foucault) losses (pF). For a lamination sample tested in

Epstein Frame with sinusoidal supply, the hysteresis losses are directly proportional to the

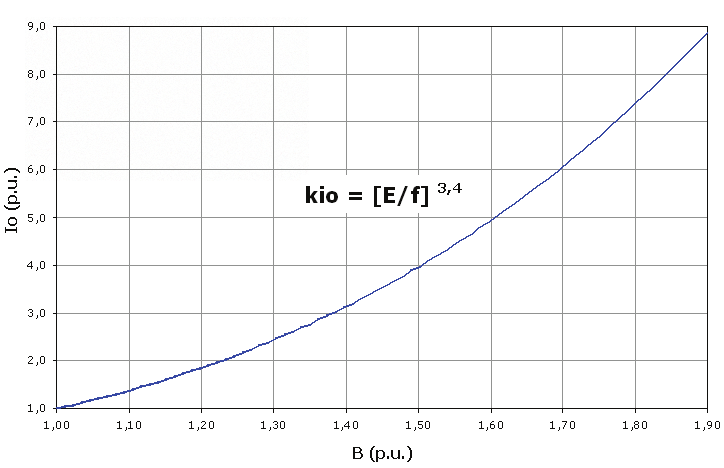

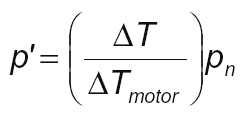

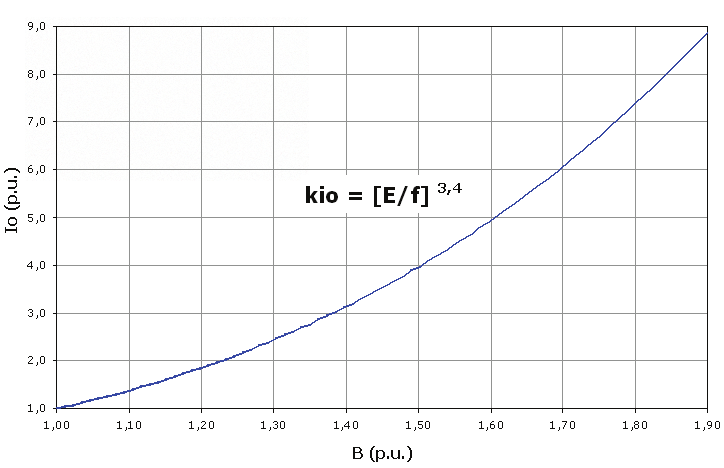

frequency ( f) and to the square of the magnetic induction ( B2), while the eddy current losses are proportional to the square of both the frequency ( f2) and the magnetic induction ( B2), especially for induction values above one Tesla (1 T). However, in the induction motor the iron

losses present a much more induction-dependent behavior than the quadratic ratio obtained

with normalized samples of the magnetic material in Epstein Frame tests. In low-voltage three-

phase induction motors manufactured with fully processed steel laminations tested under

different saturation levels, iron losses presented a dependance on the induction close to B4 for

inductions above 1,2 T (usual value for industrial motors), as presented in Fig. 1.

The fundamental theory of the electric machines shows that the torque provided by the

induction motor is directly proportional to the product between the magnetic flux and the

electric current [14, 15]. Then in order to keep a constant torque, if the flux increases the

current can decrease (and vice-versa). As the Joule losses are directly proportional to the

square of the current, these losses can be considered as inversely proportional to the square

of the magnetic flux. From the Faraday-Lenz law of induction, one can easily demonstrate

that the magnetic flux in the motor is directly proportional to the ratio between the

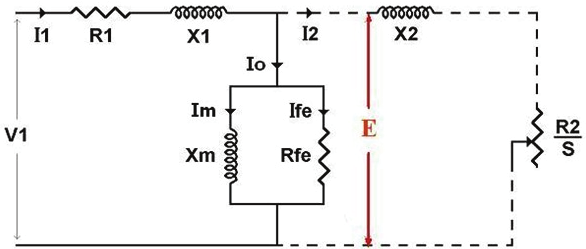

electromotive force ( E) and the frequency. Considering the steady-state model of equivalent

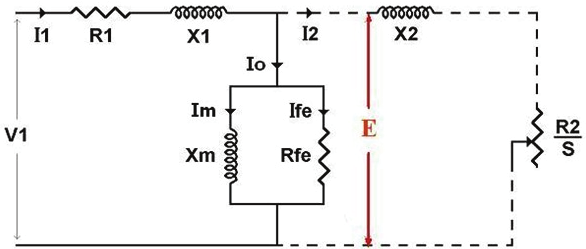

circuit of the induction motor per-phase (Fig. 2), it can be noted that at the base frequency

the voltage drop in the primary impedance has little significance, so that the flux can be

considered as proportional to the V1/f (voltage/frequency) ratio.

Minimization of Losses in Converter-Fed Induction Motors – Optimal Flux Solution

63

3,25

Motor 30kW IV poles 400V 50Hz

3,00

2,75

2,50

.).u 2,25

p

pfe = (E/f)4

(e 2,00

pf 1,75

1,50

1,25

1,00

1,00

1,05

1,10

1,15

1,20

1,25

1,30

E/f (p.u.)

Fig. 1. Iron losses x Magnetic induction for an industrial three-phase induction motor

Fig. 2. Steady state equivalent circuit of the induction motor per-phase

For low operating frequencies, however, in which the input voltage is reduced, the voltage

drop in the primary resistance becomes important and can be no longer despised. By

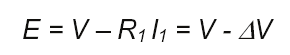

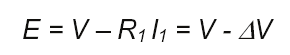

neglecting the influence of the primary reactance, electromotive force E is given by

(2)

The voltage drop at the stator branch (Δ V) then depends directly on the stator current ( I1).

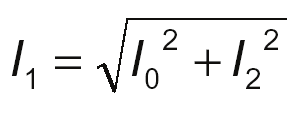

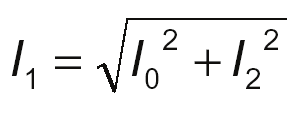

As Fig. 2 shows, the motor current can be decomposed into two components: one

concerning magnetization and the other concerning torque production.

(3)

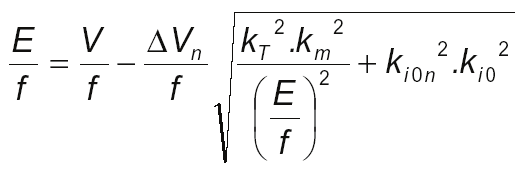

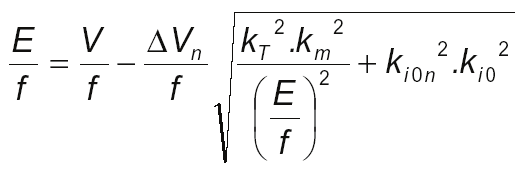

Taking rated voltage as the base, E/f ratio per unit can be written as:

64

Electric Machines and Drives

(4)

where:

Δ Vn - Voltage drop per unit with rated frequency and load.

f – Motor operating frequency per unit, considering rated frequency fn as the base.

In (4), the square root results in a correction factor, which is function of the motor current

and whose terms are explained in the following paragraphs.

It should be taken into account that, as the frequency (and consequently, the rotation) is

reduced, the mechanical losses decrease in a nearly cubic proportion to it ( f3). The

mechanical losses do not affect the iron losses, but they act as an additional load to the

motor, therefore they must be considered as a torque to be added to the rated torque

available on the shaft. Its reduction implies current reduction and so reduction of Joule

losses in the conductors ( Pj).

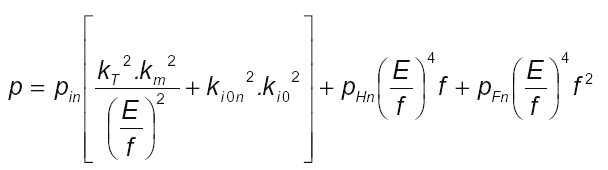

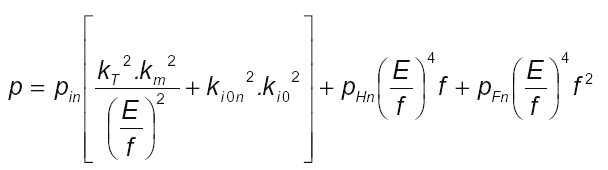

Thus it is possible to rewrite the induction motor total losses per unit p, for operation with variable voltage and frequency, as follows:

(5)

where:

pin – Total Joule losses with the motor operating at rated conditions of load, voltage and

frequency.

pHn – Total hysteresis losses with the motor operating at rated conditions of load, voltage

and frequency.

pFn – Total eddy current losses with the motor operating at rated conditions of load, voltage

and frequency.

Motors manufactured with low loss magnetic core (fully processed silicon steel) operating at

rated conditions typically present values of 80%, 12% and 8%, for parameters pin, pHn and

pFn, respectively. The remaining parameters of (5) will be opportunely explained ahead.

The term of (5) in brackets refers to the motor Joule losses and depends on the total motor

current. The second and third terms refer to the motor iron losses for hysteresis and eddy

currents, respectively. The magnetic induction was conveniently replaced by the E/f ratio.

There is no explicit term for the motor total mechanical losses in the equation, because they

are embedded in the first term, in accordance with what was mentioned before, by means of

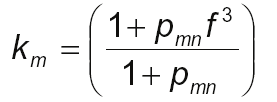

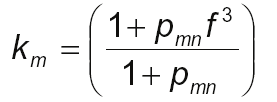

the factor km defined below:

(6)

where pmn is the mechanical losses at rated speed referred to the rated output power Pn.

The aim of this study is to minimize the motor losses, in order to reduce its temperature rise,

so that the need of both the torque reduction (oversizing) and the use of independent

ventilation can be prevented. In (5), this is considered by means of the derating factor kT,

Minimization of Losses in Converter-Fed Induction Motors – Optimal Flux Solution

65

which will be addressed later on this paper. It should be noted that the torque affects only

the current-dependent losses, not influencing the iron losses. Therefore, km and kT are torque correction factors required to compensate for the effects of the speed variation, which

influences the portion of losses related to the load current.

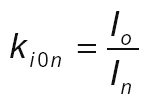

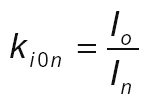

Ki0n is the no-load current factor, defined by (7).

(7)

where:

Io – No-load current under rated voltage and frequency.

In – Full-load current under rated voltage and frequency.

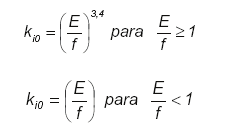

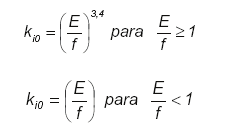

Due to the non-linearity of the magnetization curve of the laminations, the E/f ratio increase

causes the no-load current to increase according to (8). This peculiar behavior of the no-load

current was observed experimentally (Fig. 3), and is taken into account in (5) by means of

the factor ki0.

(8)

Fig. 3. Magnetizing current x E/f

66

Electric Machines and Drives

3. Minimization of losses

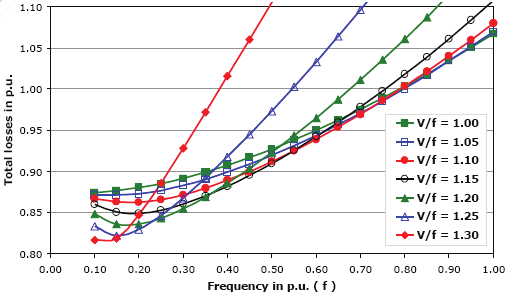

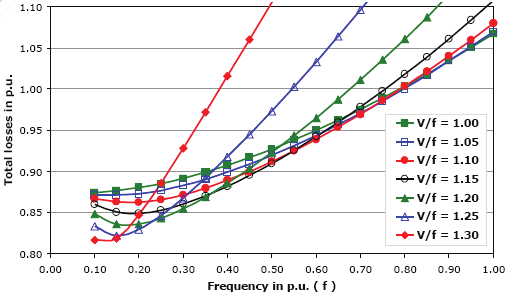

The analysis of (5) shows that the induction motor global losses depend on both the

operation frequency and the induction (or magnetic flux). Then the values of V/f that

minimize the motor global losses change with the operation frequency, so that it is necessary

to find the minimum losses at each frequency, with different values of V/f. Fig. 4 shows the

total losses calculated as function of the frequency for various values of the V/f ratio.

Fig. 4. Total losses x frequency curve for several V/f ratios at rated torque

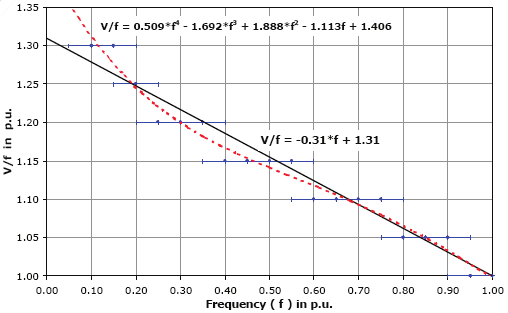

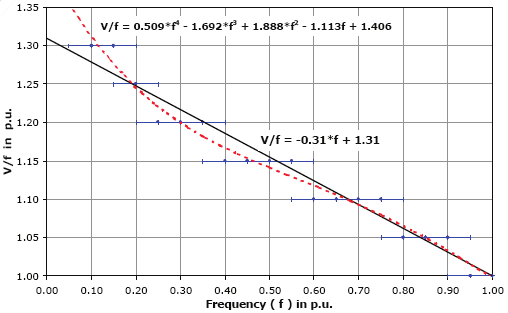

Fig. 5 derives from the family of curves above and represents the V/f ratios theoretically

obtained, which minimize the total losses of the motor at each operation frequency.

Fig. 5. V/f x frequency curve for minimization of total losses

Minimization of Losses in Converter-Fed Induction Motors – Optimal Flux Solution

67

4. Influence of ventilation reduction

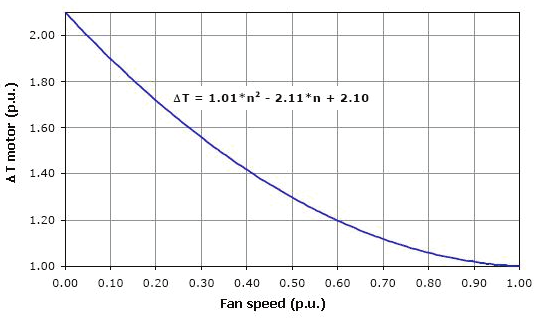

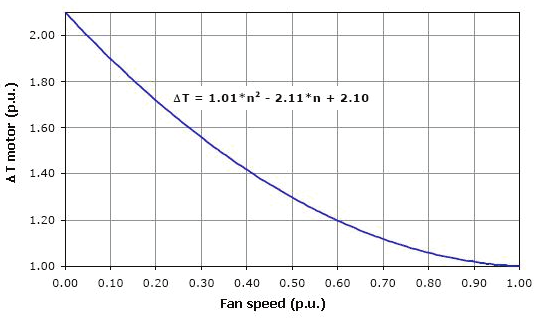

Thermal calculations implemented for a number of motors of distinct frame sizes and power

ratings considering speed variation, combined with experiments and tests performed with

several motors at rated load, varying separately the fan speed from zero to base speed, led

to the conclusion that TEFC three-phase motors of a wide output range present a similar

thermal behavior. Fig. 6 represents the temperature rise per unit of low-voltage 4-pole cage

induction motors manufactured with die cast iron frame as a function of the fan speed per

unit.

Fig. 6. Temperature rise x fan speed at rated load

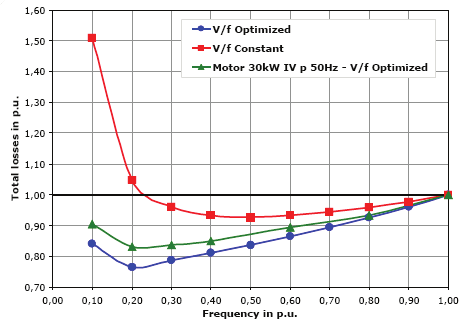

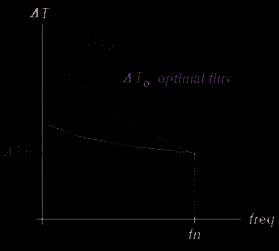

In this approach, for each desired value of frequency and for each value of V/f ratio

according to Fig. 5, the total losses p are calculated according to (5). Fig. 6 determines the

influence of the ventilation reduction on the motor temperature rise (Δ Tmotor). So in order for the required motor temperature rise to be assured, it is necessary to calculate a new

value of p, henceforth referred to as p’, according to (9).

(9)

where:

p’ – total motor losses for the required temperature rise, considering the ventilation

reduction.

pn - total motor losses at rated conditions.

If, for instance, the maximum required temperature rise is the limit of the insulation system

thermal class, then Δ T = Δ Tclass. If, otherwise, the maximum required temperature rise is

Δ Tn, then Δ T=1.

68

Electric Machines and Drives

Once known the total losses p’ that will cause the required temperature rise in the motor with

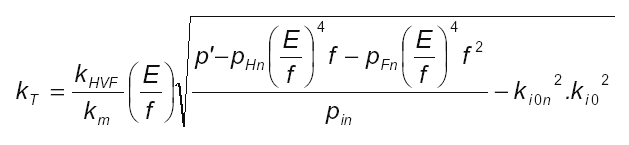

reduced ventilation, then it is possible to calculate the convenient derating factor using (10):

(10)

where kHVF is the harmonic voltage factor as defined by NEMA [16]. It was placed in the

equation originally conceived as (5) for the influence of the PWM supply voltage harmonics

to be also considered on the motor temperature rise. For most of the modern static

frequency converters kHVF is 0.95.

As a consequence of the cooling reduction, kT is usually lower than 1. However, if the

minimized total losses are such that reduce the motor temperature rise even with poor

ventilation, kT can be higher than 1. Similarly, if kT is calculated for an insulation class temperature rise, it will be normally higher than 1 if the rated motor temperature rise is

much below the insulation class temperature rise limit.

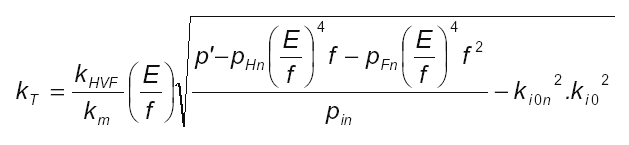

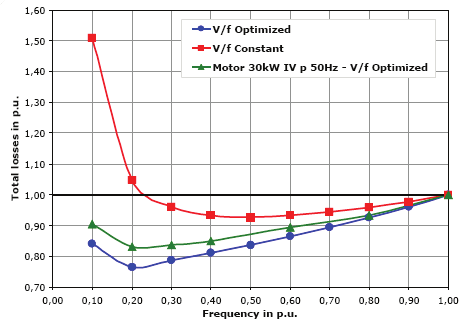

Fig. 7 presents an example of loss reduction achieved with the proposed method. A three-

phase, 30 kW, 4-pole induction motor was tested at constant rated torque within the

frequency range from 0.1 to 1.0 (p.u.). The results are presented for three different situations:

calculation with constant flux, calculation with optimal flux and testing with optimal flux.

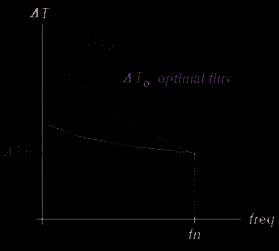

The loss reduction obtained with the proposed technique, as shown in Fig. 7, results in a

better thermal performance of the motors operating with optimal flux. Comparing the motor

temperature rises when operating at constant flux condition to those when operating at

optimal flux condition, it is remarkable a behavior similar to that outlined in Fig. 8, as can be

checked in the experimental results presented in section VI.

Fig. 7. Total losses (p.u.) x frequency (p.u.)

Minimization of Losses in Converter-Fed Induction Motors – Optimal Flux Solution

69

ΔTn: temperature of thermal stabilization of the motor fed by sinusoidal supply (mains)

ΔT0: temperature of thermal stabilization of the motor fed by converter supply

fn: operation base frequency of the motor

Fig. 8. Temperature rise x operation frequency, sketch of the motor performance under

different flux conditions

5. Validation and implementation of the optimal flux curve

To validate the proposed technique, temperature rise tests with speed/ventilation variation

were accomplished for a wide range of industrial motor ratings. This way, it was possible to

compare the thermal performances of converter-fed motors when under constant flux (rated

losses) and optimal flux (minimum losses) conditions.

Before the implementation of the automatic function for optimal flux selection by the

converter, drives with suitably modified softwares were used, so that specific flux values

could be manually adjusted. This allowed the practical correction of the curve obtained by

means of mathematical calculations and the finding of the actual optimal flux curve that was

implemented in the converters used in the tests, into which were incorporated the automatic

function for the optimal flux setting.

As the sensorless vector control enables the magnetic flux of the motor to be directly altered,

this was the control type employed in all tests with converter. The switching frequency used

in all tests with converter was 2.5 kHz.

A. NEMA High Efficiency (NHE) Motors

The motors to be tested were selected considering the worst horsepower/frame size ratios

criteria. The following machines were used in the tests, all of them 4-pole (predominant

polarity in low-voltage industrial applications) and all of them with class F insulation: 5 hp

(NEMA 184T); 20 hp (NEMA 256T); 50 hp (NEMA 326T) and 150 hp (NEMA 444T).

Occasionally, for investigation of specific issues, tests were also realized with motors that

are not related above.

70

Electric Machines and Drives

It should be noted that the loss minimization technique was conceived and devel