CHAPTER 7

WASTEWATER

7–1. Black water

Black water refers to latrine wastewater containing human waste and is discussed in more detail in chapter 6.

7–2. Gray water

a. Gray water refers to wastewater from nonlatrine sources such as showers, laundry, kitchen operations, vehicle washracks, and handwash devices. Management of this wastewater is mission-specific, and depends upon factors such as field conditions, the number of Soldiers (volume of gray water), and the anticipated length of stay at a given location. Gray water management develops from primitive in the initial stages to semipermanent as the camp matures.

However, the final design must be envisioned from the beginning. Some solutions (for example, lagoons or leach fields) require considerable space that may not be available after construction of other camp infrastructure. Other solutions (for example, self-provided treatment plants) need to be ordered at the beginning of deployment. Wastewater treatment plants (WWTPs) may also require gray water to dilute concentrated black water.

b. Make use of existing facilities that are available. If deployed near a municipal WWTP or sewage line, coordinate with local contracting and environmental offices to determine if connection to a municipal WWTP via collection lines is economically feasible and environmentally sound.

c. Gray water from showers and laundry will be discharged to the best facility available be it municipal or camp WWTP, leach field, or facultative lagoon in accordance with camp standards.

7–3. Reverse osmosis water purification unit (ROWPU) wastewater

Brine and wastewater produced from filter maintenance should be discharged to a WWTP. If a WWTP is not available, the ROWPU wastes may be discharged to a soakage pit or trench.

During training, the brine can be blended with the excess product water before disposal. In the United States, National Pollutant Discharge Elimination System permits must be obtained prior to any ROWPU discharge to natural waters. Otherwise, wastewater must be collected and backhauled to garrison.

7–4. Vehicle washing

Vehicle washing should only occur at designated washracks. Within the United States, wastewater from these washracks must pass through a functioning oil-water separator prior to discharge to a sanitary sewer or permitted discharge point. No soap or emulsifiers should be used with oil-water separators unless specifically approved. During deployments, wastewater from vehicle washracks may discharge to a lagoon for treatment or storage.

7–5. Handwash devices

Handwash devices must drain into a soakage pit or soakage trench according to FM 4-25.12 or be connected to the camp wastewater system.

7–6. Wastewater from decontamination

Wastewater from decontamination stations will be discharged into soakage pits or sumps away from natural water sources according to TB MED 577. When the unit vacates the area, any such soakage pits or sumps will be closed and marked properly. Wastewater collected from decontamination activities will be assessed for classification as HW according to chapter 4 of this TB MED.

7–7. Nonpotable water reuse

Gray and black water may be treated and disinfected according to TB MED 577 prior to reuse for dust control and other nonpotable uses. The treated effluent shall not have a biochemical oxygen demand (BOD5) greater than 30 parts per million (ppm) or total suspended solids greater than 30 ppm. Sufficient disinfection shall be demonstrated by measurement of a detectable total chlorine residual 30 minutes after addition of chlorine. Additional treatment may be required in certain host nations and within the United States for protection of public health. Because of the stringent treatment requirements, it is usually not feasible to reuse black water in field environments.

7–8. Field wastewater disposal devices

Until WWTPs are made available, gray water should be disposed of in soakage pits or evaporation beds.

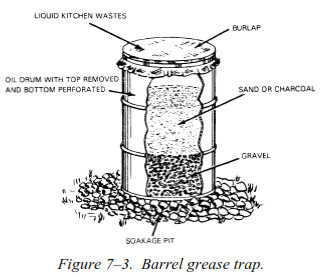

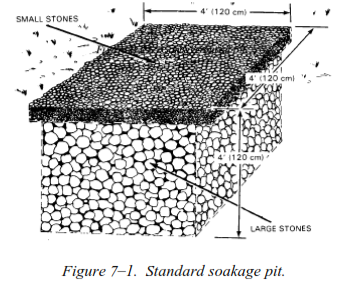

a. Soakage pits. In areas where the soil can be excavated to a depth of 4 feet without encountering ground water, soakage pits measuring 4 feet square by 4 feet deep should be constructed and filled with coarse well-draining material (see figure 7–1).

b. Soakage trenches. In areas where ground-water level or a rock formation precludes digging a full soakage pit, a pit measuring 2 feet square by 1 foot deep should be constructed and filled with coarse well-draining material. One-foot wide trenches should then be dug radiating outward from the pit in each direction. These trenches should vary in depth from 1 foot at the pit to 1.5 feet at the outer edges. Fill the trenches with the same well-draining material as the center pit.

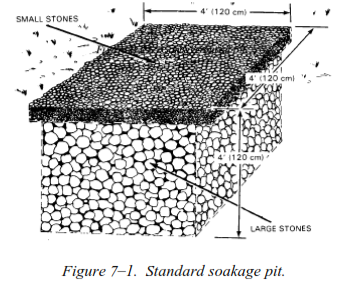

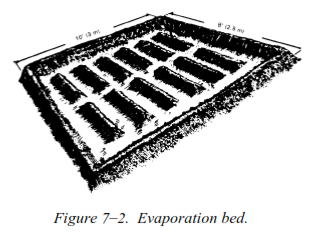

c. Evaporation beds. Evaporation beds may be used in hot, dry climates. They may also be used where clay soil prevents the use of standard soakage pits. The beds measuring 8 feet by 10 feet are constructed by scraping off the topsoil and creating dikes around the beds tall enough to contain 3 inches of liquid (see figure 7–2).

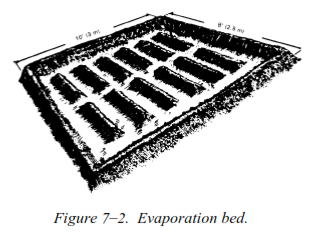

d. Grease traps. Wastewater from food service operations should be passed through a grease trap prior to disposal in soakage pits/trenches and evaporation beds to prevent clogging, vector hazards, and odors. See figure 7–3 for an example of a field expedient grease trap.