CHAPTER 8

SPILL PLANNING AND RESPONSE

8–1. Spill prevention and response plan

A Spill Prevention and Response Plan should be developed for each field or contingency operation. The major operations that need to have a copy of this plan are tactical refueling, maintenance, and POL/HM/HW storage and transportation. The plan should be kept in a location easily accessible to the Facility Incident Commander and the Facility Response Team.

The plan should address, at a minimum, site-specific prevention measures, response procedures, and spill response equipment requirements for each major operation. For a more complete description of Spill Prevention and Response Plans, see FM 3-100.4 and 40 CFR 112.

8–2. Spill prevention measures

The spill prevention portion of plans should include—

a. Name and contact information of the Facility Incident Commander.

b. Facilities information.

c. Inventory of POL/HM/HW at each storage, handling, and transfer site.

d. Map with distance to nearby water bodies and predicted direction of flow.

e. Description of the prevention, controls, and countermeasures for each site such as secondary containment and periodic inspections.

f. Readily available emergency equipment.

g. Evacuation plan.

h. Description of deficiencies.

8–3. Spill response procedures

In the event of a POL/HM/HW spill, the procedures listed below must be implemented immediately by trained personnel within the unit. Personal safety must never be compromised during the response. Should the situation exceed unit capabilities, evacuate the area, inform the chain of command, and contact the local Hazardous Material Spill Response Team or Range Control. Emergency telephone numbers or radio frequencies should be obtained and distributed throughout the brigade before the field or contingency operation begins.

a. Protect yourself. Use the required PPE specified in the MSDS for the spilled material (or field expedient PPE such as impermeable gloves and goggles) and evacuate all nonessential personnel from the immediate area.

b. Stop the flow. The flow of POL/HM/HW must be stopped at the source in order to control the spill. This may be as simple as placing the container upright or closing a valve. In the event of a flammable material spill, use only nonsparking tools and ensure metal-to-metal contact is avoided since a spark could ignite the material.

c. Contain the spill. Proper containment includes placing drip pans where the material contacts the soil, placing soil berms or sand bags around the contaminated area, and placing absorbent material in the area of the spill. The purpose of this step is to prevent the spread of contamination.

d. Report the spill. Notify the chain of command and unit HW manager immediately. The local Hazardous Material Spill Response Team or Range Control should be notified if additional assistance is needed.

e. Clean the spill. Equipment used to clean a spill must be chosen carefully. Use only nonsparking tools if the material is flammable or explosive. For corrosive materials, use equipment that will not corrode or deteriorate (for example, nonmetallic equipment). Collect used absorbent and contaminated soil in plastic bags, and transfer the plastic bags into a labeled sturdy container to be disposed of as HW. Cleanup standards for petroleum-contaminated water call for removal of the POL sheen, and reduction of total petroleum hydrocarbons to 2000 ppm and gasoline to 10 ppm. During the initial period of camp development (0 to 6 months), petroleum-contaminated water will be treated with absorbent material. Engineers or contractors will move it offsite. During the temporary period (6 to 24 months) oil-water separators can be employed. Petroleum-contaminated soil may be transported offsite during the initial phase. During the temporary phase, petroleum-contaminated soil will be transported offsite or, preferably, bioremediated onsite by land farming.

f. Replace spill response equipment. Obtain replacement spill response equipment through the unit supply channels to ensure personnel can properly respond in the event of another spill.

8–4. Spill response equipment

Spill response equipment is essential in protecting the environment in the event of a POL/HM/HW spill. The type and amount of spill response equipment needed is dependent upon the operation. Units may also need to acquire hydrophobic absorbent materials for operations conducted in areas susceptible to large amounts of precipitation. Spill response equipment required for specific operations is discussed below.

a. Tactical refueling operations. Tactical refueling operations are limited to the handling of fuel products such as diesel and motor gasoline. The extent of the operations and load-carrying capabilities of fuel tankers and heavy expanded mobility tactical trucks restrict the amount and type of spill response equipment needed. In the event of a major spill during refueling operations, personnel primarily need two nonsparking picks and two nonsparking shovels to excavate contaminated soil and several large plastic bags to contain the excavated soil for disposal as HW. Approximately 10 pounds of absorbent and several small plastic bags are sufficient to respond to small volume spills on a hardstand. Nonsparking tools should also be readily available. Additional resources can be obtained through the supply channels as required.

b. Field maintenance operations. Field maintenance operations deal with all Class III items. Repeated small volume spills are typical during field maintenance operations. Approximately 25 pounds of absorbent, two nonsparking shovels, two brooms, and several small plastic bags for contaminated absorbent are sufficient to maintain field maintenance operations during field and contingency operations. Additional resources can be obtained through the supply channels as required.

c. HM/HW storage. Hazardous material and hazardous waste storage operations deal with all Class III items. Leaking containers and small volume spills are common during field HM/HW storage operations. Approximately 15 pounds of absorbent, two nonsparking shovels, two brooms, and several small plastic bags for contaminated absorbent are needed at each storage area. Additional resources can be obtained through the supply channels as required.

d. HM/HW transportation. Hazardous material and hazardous waste transportation operations deal with all Class III items. Leaking containers and small volume spills are common during HW transportation operations; however, the potential exists for large volume spills in the event of an accident. Each approved vehicle for HM/HW transportation should have approximately 25 pounds of absorbent, two picks, two shovels, one broom, and several small and large plastic bags for contaminated soil. Additional resources can be obtained through the supply channels if deemed necessary.

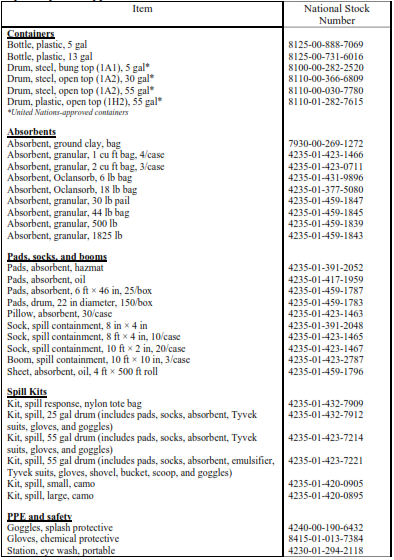

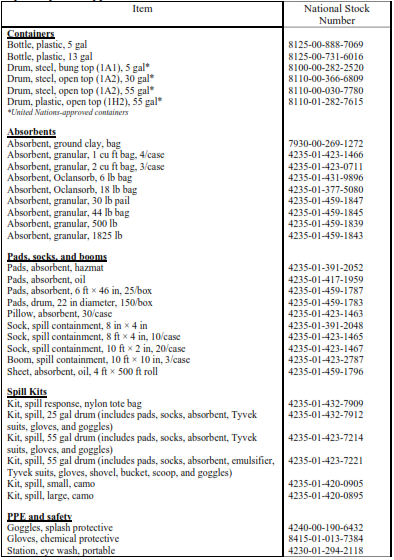

Table 8–1

Spill response supplies