nent washable type filters, follow carefully cleaning

accordance with applicable technical manuals and

directions supplied by filter manufacturer or consult

manufacturer*s instructions.

applicable technical manuals. Washable filters

b. Direct drive blower. Figure 6-29 shows a

should be renewed with adhesive spray following

typical arrangement of a blower with direct drive.

cleaning to enable them to pick up dust effectively.

(1) Blower speed adjustment. In alternating

c. Electronic air cleaners. This type unit

current applications, the blower speed is limited to

employs the principle of electrostatic precipitation.

the available motor speed. For example, a two

Particles in the air entering the unit become

speed motor will provide two blower speeds. In

positively charged and are attracted by the

direct current applications, motor controllers are

negatively charged collector plates and held there.

installed to provide a wide range of blower speed

Periodic washing of collector plates is required.

variation.

Application of adhesive coating on a prefilter may

(2) Other maintenance. Procedures for motor

be required. Follow carefully manufacturers*

and blower alignment and lubrication, and adjust-

instructions for proper maintenance of these units.

ment of blower bearings and thrust collars are the

d. Activated charcoal filters. These filters are in-

same as previously described for belt driven blow-

stalled in the return air plenum of warm air furnaces

ers.

or in self-contained purifying units consisting of one

or more activated charcoal filters, blower, and

housing. Disposable filters should be replaced

periodically per manufacturers* recommendations.

Manufacturer*s instructions should be followed for

the maintenance of permanent filters.

6-38.

Humidifiers.

a. Pan type humidifiers. Most humidifiers used

in Army warm air systems are the pan type with a

float to regulate the water level (figure 6-30). Be-

cause of the high temperature to which the float

valve is subjected, it frequently sticks in an open or

closed position. To release the valve, move the

float ball up and down to allow water pressure to

clean the dirt or other accumulation from the seat.

Frequent jiggling of this float control will prevent

sticking. If water is comparatively free of solids, the

humidifier float seldom requires service. If the

water condition is bad however, considerable diffi-

culty may arise. It is of prime importance to check

the installation of the pan to see that it does not

overflow on the combustion chamber or radiator of

the furnace. Pan type humidifiers must be regularly

cleaned to prevent accumulation of minerals

precipitating from the water. Chemicals specifically

made for use in humidifiers can be added to the pan

Figure 6-29. Direct drive blower.

to keep minerals in suspension until they can be

c. Heat exchangers and burners. Clean with a

flushed out. Biocides are also available which can

vacuum and/or brush.

be added to the pan to prevent algae and bac-

teriological growth. At the end of each heating

6-37.

Air filter maintenance.

season, turn off the water supply, clean the hu-

a. Replaceable type filters. Dirty filters impede

midifier and leave it empty until the next heating

air circulation, regardless of blower speed. If little

season.

or no air passes over the furnace, the building will

be insufficiently heated and the furnace will over-

6-29

TM 5-642

Figure 6-30. Pan type humidifier.

b. Other humidifiers. Other types of

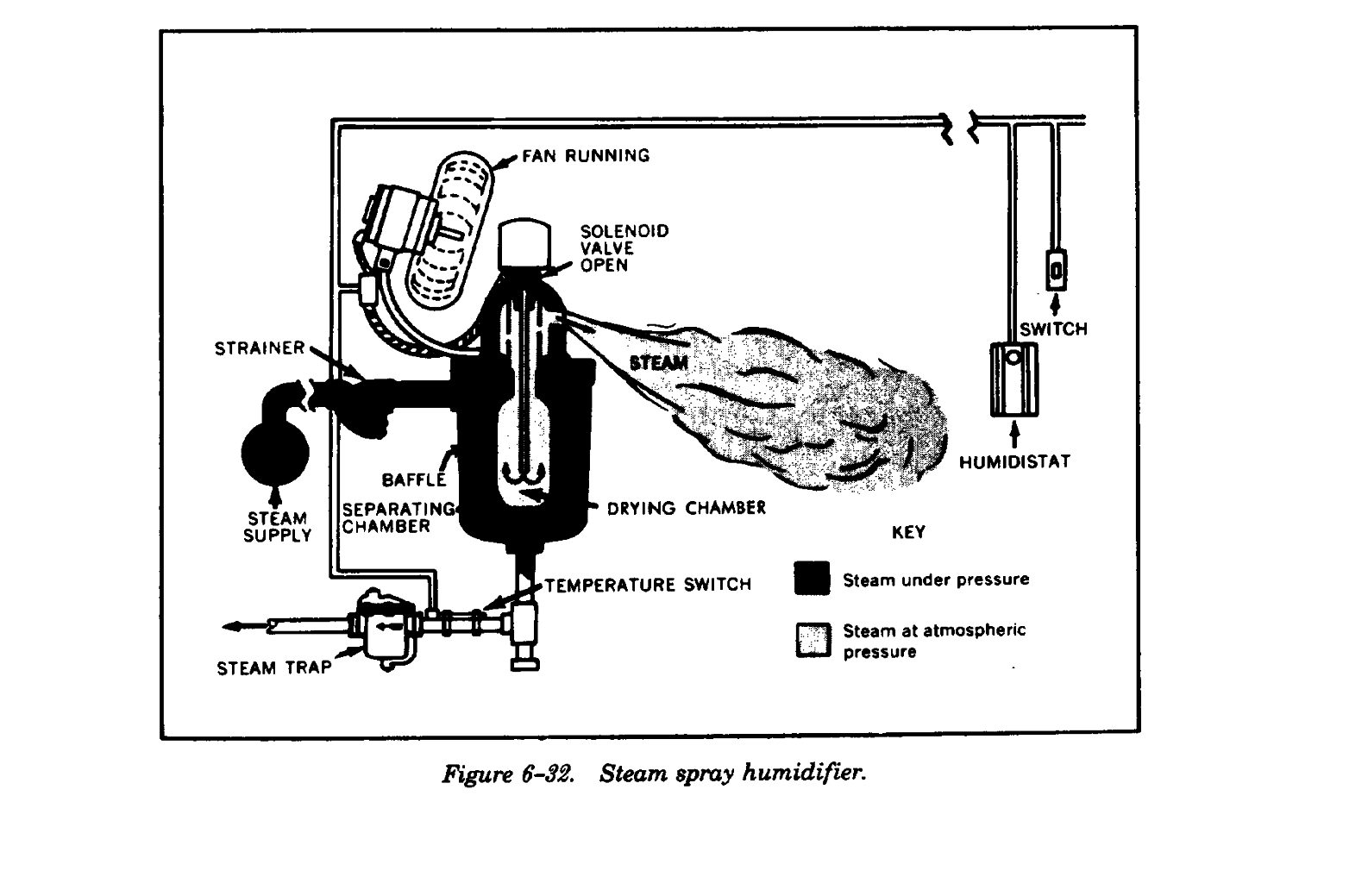

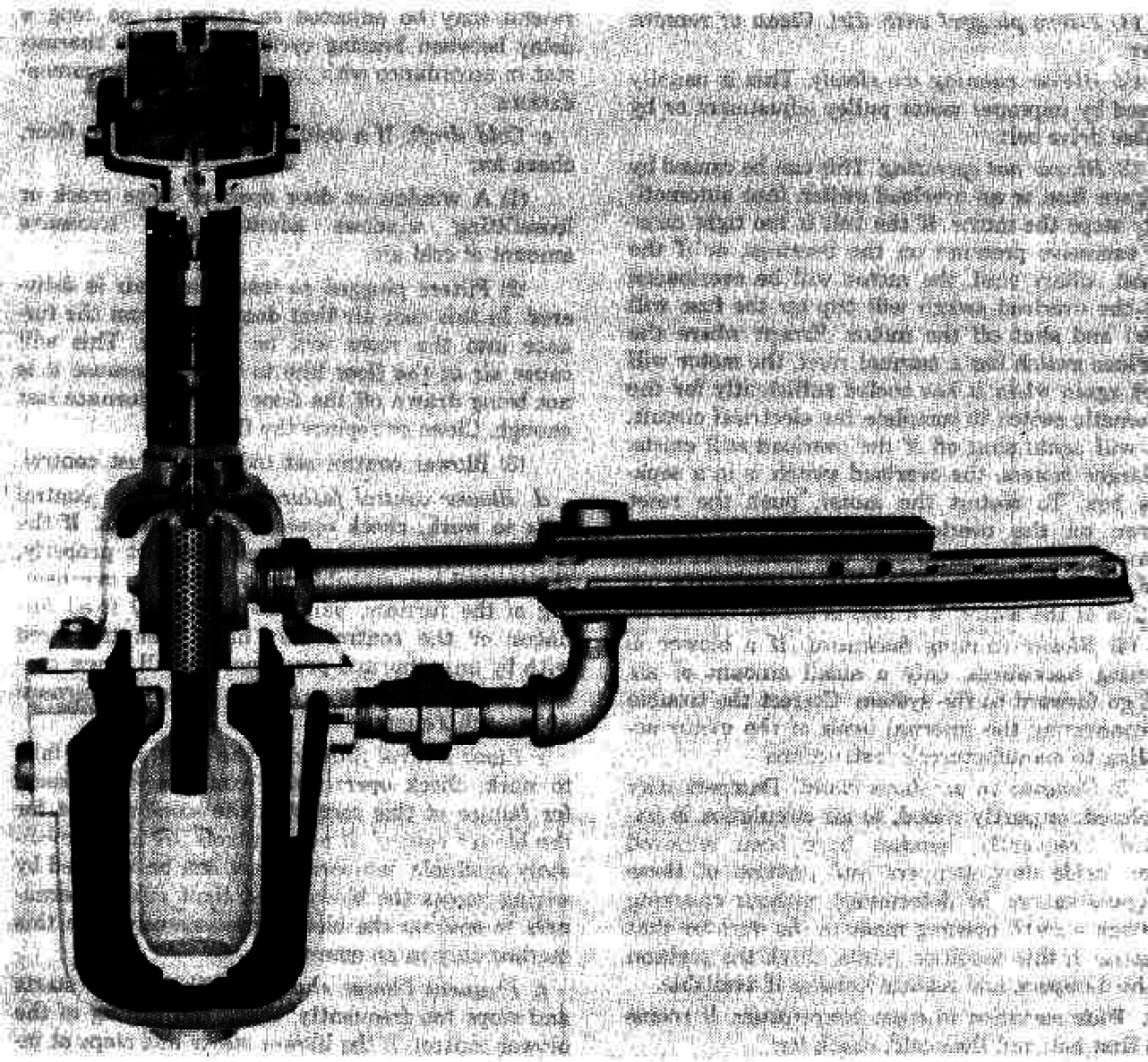

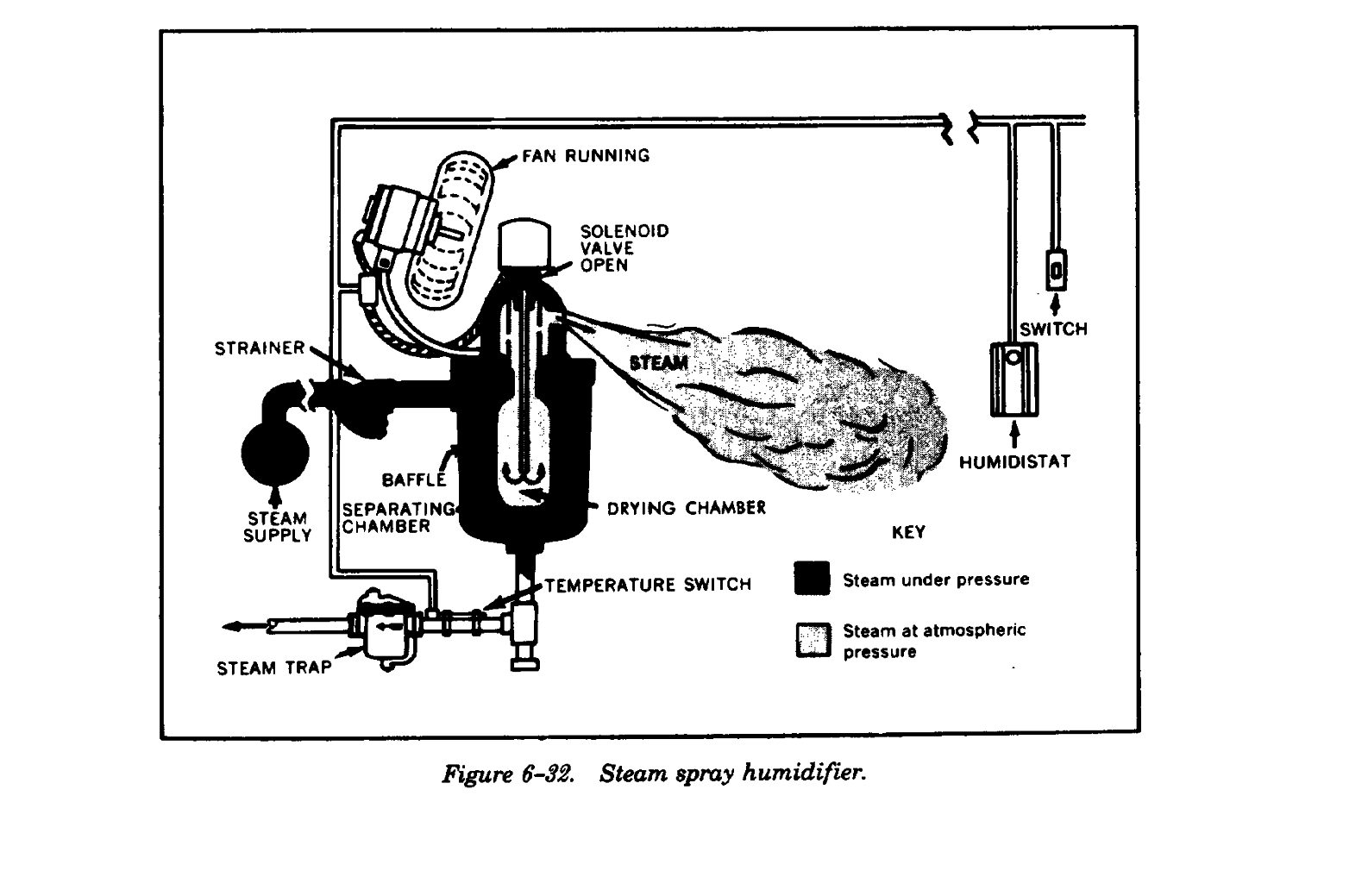

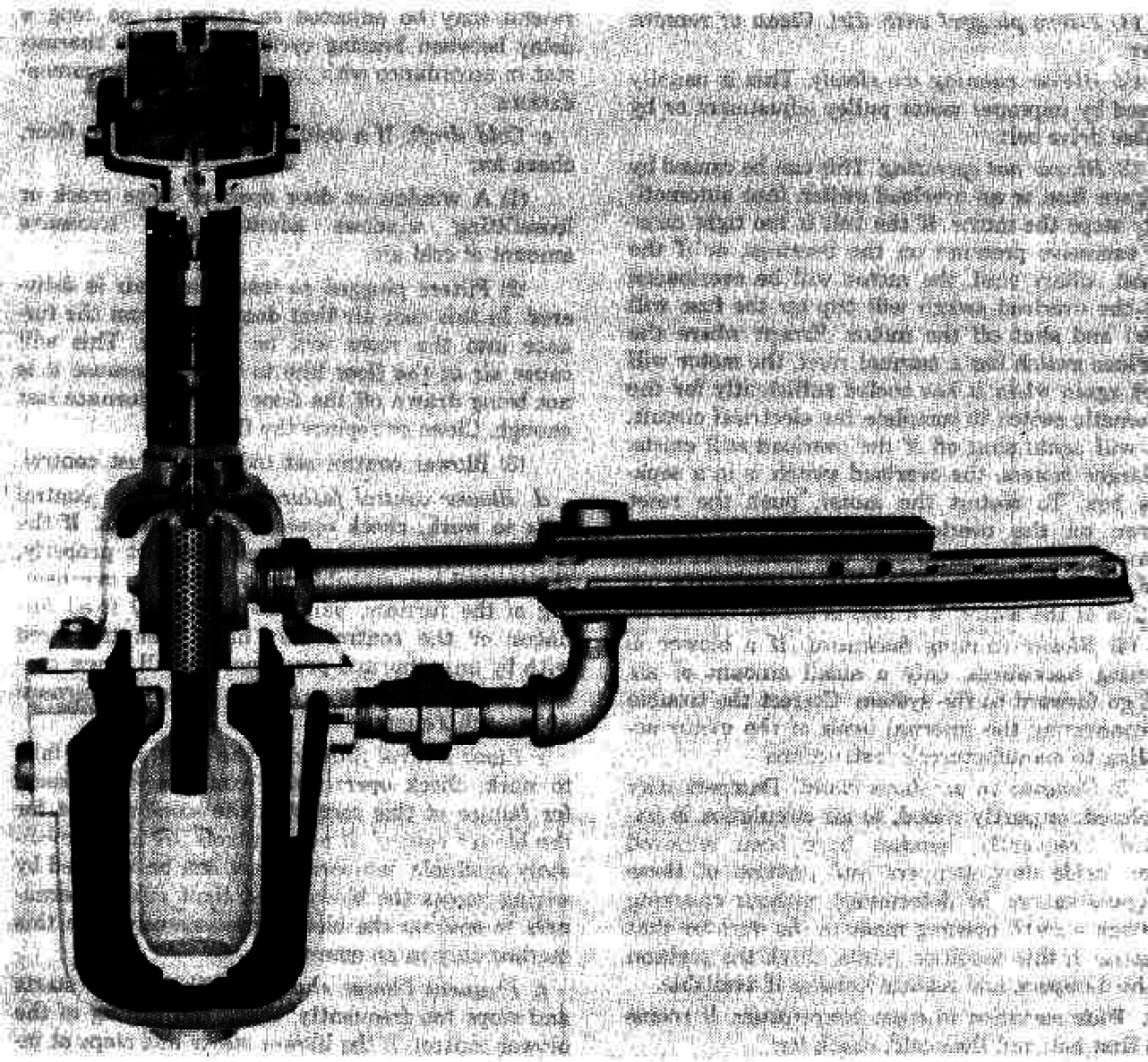

a separator, superheating it, and then distributing it

humidifiers used on Army installations are the

through a steam jacket manifold. Steam that has

centrifugal atomizer, steam spray, and steam

been treated with amine type chemicals should not

jacketed manifold types. With the centrifugal

be used for direct humidification. These chemicals

atomizer type (figure 6-31) a high speed rotating

are toxic and are carried over with steam. Steam is

disc imparts motion to a fine stream of water

normally free from minerals and thus mineral

directed against its center. Stationary blades further

accumulation on steam humidifiers is not a

atomize the water and direct it away from the disc

problem. It is good practice however, to clean this

and housing. With the steam spray humidifier

type of humidifier each year to prevent nozzles

(figure 6-32) dry mineral free steam is produced

from clogging. Centrifugal humidifiers and

and discharged directly into the atmosphere. With

surrounding ductwork should also be cleaned

the steam jacketed manifold humidifier (figure 6-

annually.

33) steam is dried and purifled by passing it through

6-30

TM 5-642

Figure 6-31. Centrifugal atomizer humidifier.

6-31

TM 5-642

6-32

TM 5-642

Figure 6-33. Steam jacketed manifold humidifier.

6-39.

Blower and limit controls.

may be used in cold climates, or where a long duct

A combination blower and limit control is generally

is installed, or to meet some other local condition.

installed in the top of the furnace casing in an

b. Limit control adjustment. Set the limit control

opening provided by the manufacturer. It is in-

to turn off the fire at 175F in milder climates and

stalled 10 to 18 inches above the top of the com-

200F in colder climates, and to turn it back on at

bustion chamber and in a location that is easily

155F in milder climates and 170F in colder cli-

accessible for inspection and adjustment.

mates. Never set the limit control any higher than

a. Blower control adjustment. Set blower

necessary to keep the building at the proper tem-

control, or furnacestat, to stop blower between 90F

perature.

and 100F in the plenum chamber. Adjust the

control to start blower at 115F for gas or oil, and

6-40.

Troubleshooting.

125F for coal. The blower should run almost

Common operating difficulties and methods of cor-

continuously when the outside temperature is 40F

recting them are outlined below.

or below. The more continuously the blower runs,

a. Insufficient heat. If not enough heat is sup-

the better the building will be heated, particularly in

plied, check for:

cold weather. A slightly higher temperature setting

6-33

TM 5-642

(1) Filters plugged with dirt. Clean or remove

(2) Room thermostat out of adjustment. The

filter.

throttling range or anticipator setting on the ther-

(2) Blower running too slowly. This is usually

mostat may be adjusted so there is too long a delay

caused by improper motor pulley adjustment or by

between heating cycles. Adjust the thermostat in

a loose drive belt.

accordance with manufacturer*s recommendations.

(3) Blower not operating. This can be caused

c. Cold draft. If a cold draft is noticed on floor,

by a blown fuse or an overload switch that

check for:

automatically stops the motor. If the belt is too

(1) A window or door open or large crack or

tight causing excessive pressure on the bearings, or

loosefitting windows admitting an excessive

if the thrust collars bind, the motor will be

amount of cold air.

overloaded and the overload switch will trip (or the

(2) Filters plugged so insufficient air is deliv-

fuse will blow) and shut off the motor. Except

ered. In this case air that does come from the fur-

where the overload switch has a manual reset, the

nace into the room will be very hot. This will cause

motor will start again when it has cooled

air at the floor line to be cold because it is not being

sufficiently for the automatic switch to complete

drawn off the floor into the furnace fast enough.

the electrical circuit, but will again shut off if the

Clean or replace the filters.

overload still exists. In larger motors, the overload

(3) Blower control set too low; adjust control.

switch is in a separate box. To restart the motor,

d. Blower control failure. If the blower control

push the reset button on the overload switch.

fails to work, check operation of contacts. If the

Whenever the motor is found to be cutting out

control fails to make or break contact properly, the

because of overload, eliminate the overload before

control has probably been ruined by overheating of

continuing operation of the motor. If a fuse is

the furnace, particularly in coal fired furnaces; or

blown, replace it.

the control may have been tampered with by

(4) Blower running backward. If a blower is

unauthorized personnel. Install a new control. Do

running backwards, only a small amount of air will

not operate a forced warm air furnace without this

go forward to the system. Correct the trouble by

control.

connecting the internal leads of the motor ac-

e. Limit control failure. If the limit control fails

cording to manufacturer*s instructions.

to work, check operation of contacts. The reason

(5) Dampers in air ducts closed. Dampers may

for failure of this control is the same as that for the

be closed, or partly closed, so air circulation is im-

blower control. If new controls are not immediately

peded. Frequently, handles have been removed

available, temporary heat can be obtained by wiring

from inside duct dampers and position of these

across the blower and limit control terminals to

dampers cannot be determined without checking

operate the blower continuously. Use this method

through a small opening made in the duct for that

only in an emergency.

purpose. If this condition exists, check the position

f.

Frequent blower shutoff If the blower starts

of the dampers, and replace handles if available.

and stops too frequently, check the setting of the

b. Wide variation in room temperature. If rooms

blower control. If the blower starts and stops at in-

are first hot, and then cold, check for:

tervals of 2 or 3 minutes, motor life will be short-

(1) Blower control set too high. If the blower

ened. This also overheats the overload switch in the

control setting is too high, the blower will not start

blower control. Increase the differential between

until the furnace is very hot and a surplus of heat is

starting and stopping temperatures on blower

then blown into the building. Set blower control

control by 10F. This will usually overcome the

down in accordance with recommendations for

difficulty.

blower control settings. To test for this condition,

g. High outlet temperature. Outlet temperature

turn on the manual switch controlling the blower

should not exceed 160F for an extended period of

and permit it to operate continuously. If this

time. The most frequent cause of high outlet tem-

relieves the condition, the blower control is set too

perature is insufficient airflow. This can be caused

high.

by blocked filters, too low a fan speed, or restricted

ductwork.

6-34

TM 5-642

Section VIII. ENERGY CONSERVATION

6-41.

Space temperature setback.

6-42.

Maintenance of duct insulation.

Energy expended to heat buildings to comfort con-

a. Warm air ducts are commonly installed with-

ditions when they are unoccupied is wasted. Save

out insulation and are typically routed from the

energy by setting back the temperature level at

equipment room through unoccupied spaces, shafts,

these times. The savings which can result vary with

and ceiling voids where their heat loss is

the length of time and the number of degrees that

unproductive in meeting the occupied space heating

temperatures are set back. The percentage savings

load. Although the temperature difference between

will be greater in warmer climates, but the gross

duct and ambient temperature is relatively small,

energy saved will be greater in cold climates. In

heat loss in long duct runs can be significant.

areas where it is not necessary to maintain high

b. Of equal importance is the temperature drop

temperatures during occupied periods, i.e. corridors

of supply air that accompanies heat loss. In long

and lobbies, maintain even lower temperatures than

duct runs serving many rooms on one zone, this

for the other spaces. Implement setback by

will result in the last room having a lower supply air

resetting thermostats manually (if automatic

temperature than the first. The tendency in this case

setback control has not been installed), or adjusting

is to heat the last room to comfort conditions

controls to suggested temperatures (if clock, day-

resulting in overheating in each preceding room.

nite, or other automatic reset controls are

c. Warm air ducts may be insulated with rigid

available). Climate, type of system, and building

fibrous material stuck on or fixed with special clips

construction will determine the length of the startup

or bands. They may also be insulated with flexible

period required to attain daytime temperature

mats clipped or wired on (this is particularly

levels. Experiment to decide upon the optimal

applicable for round or oval ducts). Ducts may also

setback temperature and startup time for any

be insulated with spray-on foam or fibrous material

particular building. If, in extremely cold weather,

as used for insulating undersides of roofs. It is

experience indicates that the heating system does

worth considering insulating roofs and ducts as one

not raise the temperature sufficiently by the time the

contract.

building opens for the day, set temperatures back to

d. Insulation applied to ducts supplying only

a level higher than those recommended here for

warm air need not be vapor sealed. Insulation ap-

those periods of time only. So called “smart

plied to ducts supplying warm air in winter and cold

thermostats” and computerized Energy Monitoring

air in summer must be vapor sealed to prevent

and Control Systems (EMCS) automatically

condensation forming within the insulation.

calculate the most effective time to end setback.

6-35

TM 5-642

APPENDIX A

RELATED PUBLICATIONS

Government Publications.

Department of the Army.

TM 5-650

Central Boiler Plants

TM 5-745

Heating, Ventilating, Air Conditioning and Sheet Metal Works

TM 5-785

Engineering Weather Data

TM 5-810-1

Mechanical Design-Heating, Ventilating and Air Conditioning

TM 5-843-3

Ground Storage of Coal

Non-Government Publications.

Air Conditioning and Refrigeration Institute (ARI), 1501 Wilson Blvd., 6th Floor., Arlington, VA

22209

Guideline F-88

Selection, Installation and Servicing of Residential Humidifiers

Standards:

610-82

Central System Humidifiers

670-85

Fans and Blowers

680-86

Residential Air Filter Equipment

American Boiler Manufacturers Association (ABMA), Suite 160, 950 N. Glebe Rd., Arlington, VA

22203

Boiler Water Limits and Steam Purity Recommendations for Watertube Boilers (3rd Edition, 1982)

Boiler Water Requirements and Associated Steam Purity for Commercial Boilers (1st Edition, 1984)

Guidelines for Burner Adjustments of Commercial Oil-Fired Boilers

A Guide to Clean and Efficient Operation of Coal Stoker Fired Boilers

Lexicon — Boiler and Auxiliary Equipment (5th Edition, 1987) Operation and Maintenance Safety

Manual

Thermal Shock Damage to Hot Water Boilers as a Result of Energy Conservation Measures

American Gas Association (A GA), 1515 Wilson Blvd., Arlington, VA 22209

Directory of Certified Appliances and Accessories

Standards:

Z21.8-84

Installation of Domestic Gas Conversion Burners

Z21.13-87

Gas-Fired Low Pressure Steam and Hot Water Boilers

Z21.47-87

Gas-Fired Central Furnaces

Z21.66

Automatic Vent Damper Devices for Use with Gas-Fired Appliances

Z83.6-87

Gas-Fired Infrared Heaters

Z83.8-85

Gas Unit Heaters

American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE), 1791

Tullie Circle, NE., Atlanta, GA 30229

Handbooks:

HVAC Systems and Applications, 1987

Equipment, 1988

Fundamentals, 1989

A-1

TM 5-642

American Society of Mechanical Engineers (ASME), 45 East 47th Street, New York, NY 10017

Boiler and Pressure Vessel Code, and Interpretations:

Section IV

Construction of Heating Boilers

Section VI

Recommended Rules for Care and Operation of Heating Boilers

Section VIII

Pressure Vessels, Division 1

National Fire Protection Association (NFPA), Batterymarch Park, Quincy, MA 02269 National Fire

Codes:

31

Standard for Installation of Oil Burning Equipment

54

National Fuel Gas Code

85A

Standard for Prevention of Furnace Explosions in Fuel-Oil and Natural

Gas-Fired Single Burner Boiler Furnaces

851

Recommended Practices for Stoker Operation

Sheet Metal and Air Conditioning Contractors* National Association (SMACNA), 8224 Old

Courthouse Rd., Vienna, VA 22180

HVAC Duct Construction Standards, Metal and Flexible

HVAC Systems — Testing, Adjusting and Balancing

Installation Standards for Heating, Air Conditioning and Solar Systems

A-2

TM 5-642

APPENDIX B

TROUBLESHOOTING UNDERFEED STOKERS

Symptom

Probable cause

Remedy

Using too much fuel.

Thin fuel bed due to excess air Decrease air supply or increase coal

from fan.

feed.

Thin fuel bed due to too much Adjust overfire draft by resetting

draft.

dampers, or installing automatic

dampers.

Dirty heating surface.

Keep heating surfaces clean of soot

and fly ash.

Insufficient heat.

Not enough coal feed (thin fuel Increase rate of feed and adjust air

bed).

from fan.

Fuel bed too deep.

Increase air supply, decrease fuel

feed.

Improper furnace draft.

See that overfire draft is sufficient to

carry away products of com-

bustion. Check design and con-

dition of chimney.

Limit control set too low.

Adjust limit control to weather

conditions. Increase settings

during cold weather, decrease

during warm weather.

Excessive heat.

Fuel bed too heavy.

Decrease coal feed, adjust air

supply.

Limit control set too high.

Lower setting.

Hold-fire or out-fire control set Hold-fire controls are made to keep

improperly,

fire from going out.

Set to hold fire only; set 2 minutes

for each ½ hour.

Excess furnace draft. (Fire goes Adjust draft controls to lower draft.

out during off period)

Insufficient draft.

Chimney may be blocked or too

small. Reset draft controls to in

crease draft.

Insufficient air in furnace room.

Increase combustion air openings in

furnace room.

Dirty fuel bed.

Remove excess fly ash and clinkers

from fire.

Coke trees.

Adjust air supply to fuel feed,

check furnace draft.

Overload or pin sheared.

Clinker in retort.

Maintain clean fires and proper

adjustment of stoker.

B-1

TM 5-642

Symptom

Probable cause

Remedy

Obstruction in feed tube.

Shut off stoker and remove ob-

struction.

Feed screw worn or broken.

Replace feed screw.

Coke ball in retort.

Remove coke ball, adjust feed and air

supply.

Smoke from chimney.

Insufficient combustion air.

Increase air. Check tuyere openings,

windbox, fan blade and heating

surfaces; clean if necessary.

Insufficient combustion space.

Consult stoker manufacturer.

Smoke from fire door.

Insufficient furnace draft or too Increase draf