CHAPTER 6

WARM AIR SYSTEMS

Section I. DESCRIPTION OF SYSTEMS

6-1. Warm air furnaces.

connection is made below all parts of the furnace

The primary function of a warm air furnace is to

which radiate enough heat to cause a countercur-

burn fuel efficiently and to transfer the heat gen-

rent of warm air, because such a current opposes

erated to the circulating air of a warm air heating

the flow of cooled air into the furnace.

system. Most furnaces consist of a combustion

(2) The most common source of trouble in

chamber (primary heating surface). The furnace

gravity systems is insufficient duct area, usually in

may be cast iron, steel, or a combination of the two.

the cold air (return) duct. The total cross-sectional

The heat transfer per unit area of heating surface is

area of the cold air duct(s) must be at least equal to

essentially the same for cast iron and steel where

the total cross-sectional area of all warm air

both are operated at the same temperature

(supply) ducts. If it is necessary to supply additional

difference. With either cast iron or steel, thicker

heat to a space at the end of a long duct run, this

material yields longer life without materially

can be accomplished by throttling the balancing

affecting heat transfer. The furnace may be fired

dampers in other supply ducts to favor the deficient

with any of the common fuels and may be of the

area or installing a booster fan in the deficient duct

gravity or forced air type. Gravity warm air

to force the air stream.

furnaces depend upon convection currents to obtain

the head required to produce the airflow; forced air

furnaces produce the necessary airflow with fans or

blowers and are usually equipped with air filters.

6-2. Gravity warm air heating systems.

Operation of gravity warm air heating systems is

dependent upon the difference in density (weight)

of warm and cold air. Warm air is less dense

(lighter) than cooler air and will rise if cooler air is

available to displace it. Satisfactory operation of a

gravity warm air heating system depends upon

three interrelated factors: size and “pull” of the air

ducts; building heat loss and; the heat available

from the furnace.

a. Ducted gravity systems.

(1) In a ducted gravity system (figure 6-1),

warm air is conveyed from the furnace bonnet (top

section of the furnace casing), through metal ducts,

to the spaces to be heated. Vertical ducts (stacks)

connect with registers usually installed in room

baseboards, floors, or sidewalls just above the

baseboards. Stacks are generally located within

inside partitions to prevent chilling of the supply air

b. Ductless gravity systems. Ductless gravity

and consequent reduction in head; cooled air return

furnaces are often installed on floor level; they are

registers may be located in either cold or warm

simply oversized jacketed space heaters. The most

walls, but cold walls are preferred (unless a long,

common difficulty experienced with this type of

high-friction-loss duct is required). Gravity warm

furnace is a return air opening (at the floor) of in-

air systems often have only one or two centrally

sufficient area. The return air opening should be

located return registers, all on the first floor.

made on two or three sides wherever possible. In-

Upstream of the furnace casing, return ducts

sulation should be provided above the furnace to

usually join a single large duct which enters the

avoid possible fire hazards.

casing near the floor or furnace foundation. This

6-1

TM 5-642

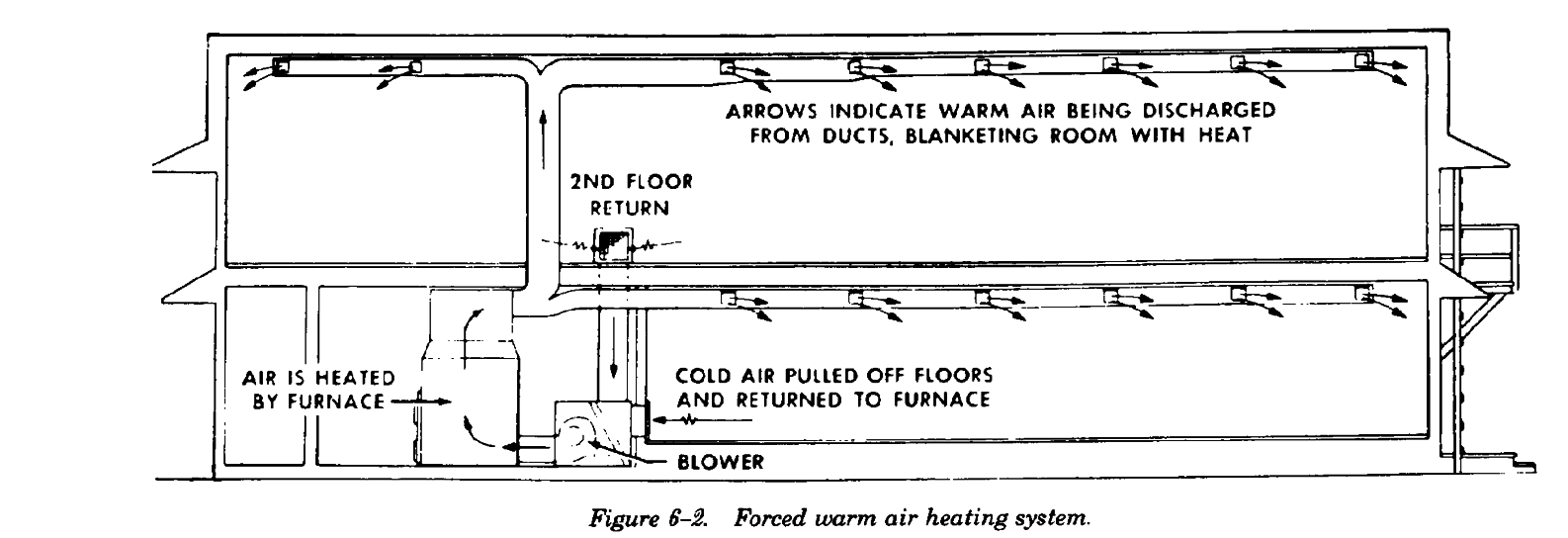

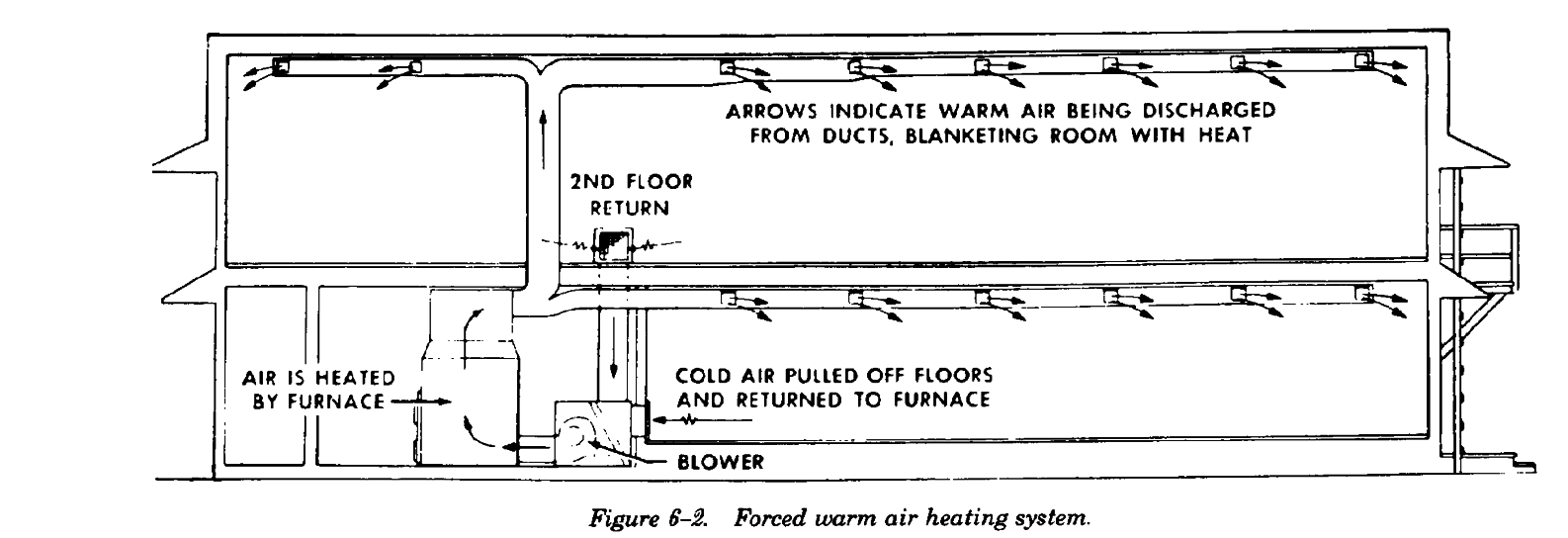

6-3. Forced warm air heating systems.

allowing the most convenient duct runs to be

The principal of operation of forced air heating

installed. Figure 6-2 shows a typical forced air

systems differs from that of gravity heating systems

heating system. In addition to the prime movers

in that a fan or blower is included in the former to

(fans), the components of a forced air heating

insure and regulate air movement. Due to the

distribution system include supply and return ducts,

assistance of the fan, duct pitch can be disregarded

registers, dampers, and insulation.

a. Outside wall delivery system. In this system,

the heated area. The damper may be modulated or

supply grilles are located along the outside (perim-

fixed in position.

eter) walls, near the sources of greatest heat loss.

(2) Air filter. An air filter is located in the inlet

These supply grilles (or registers) are designed to

air duct, just upstream of the air heater.

blanket the perimeter areas and mix with the cold

(3) Return air damper. A return air damper,

air from infiltration points thereby reducing or

installed upstream of the air filter, permits a regu-

eliminating discomfort due to drafts.

lated recirculation of heated air into the outside air

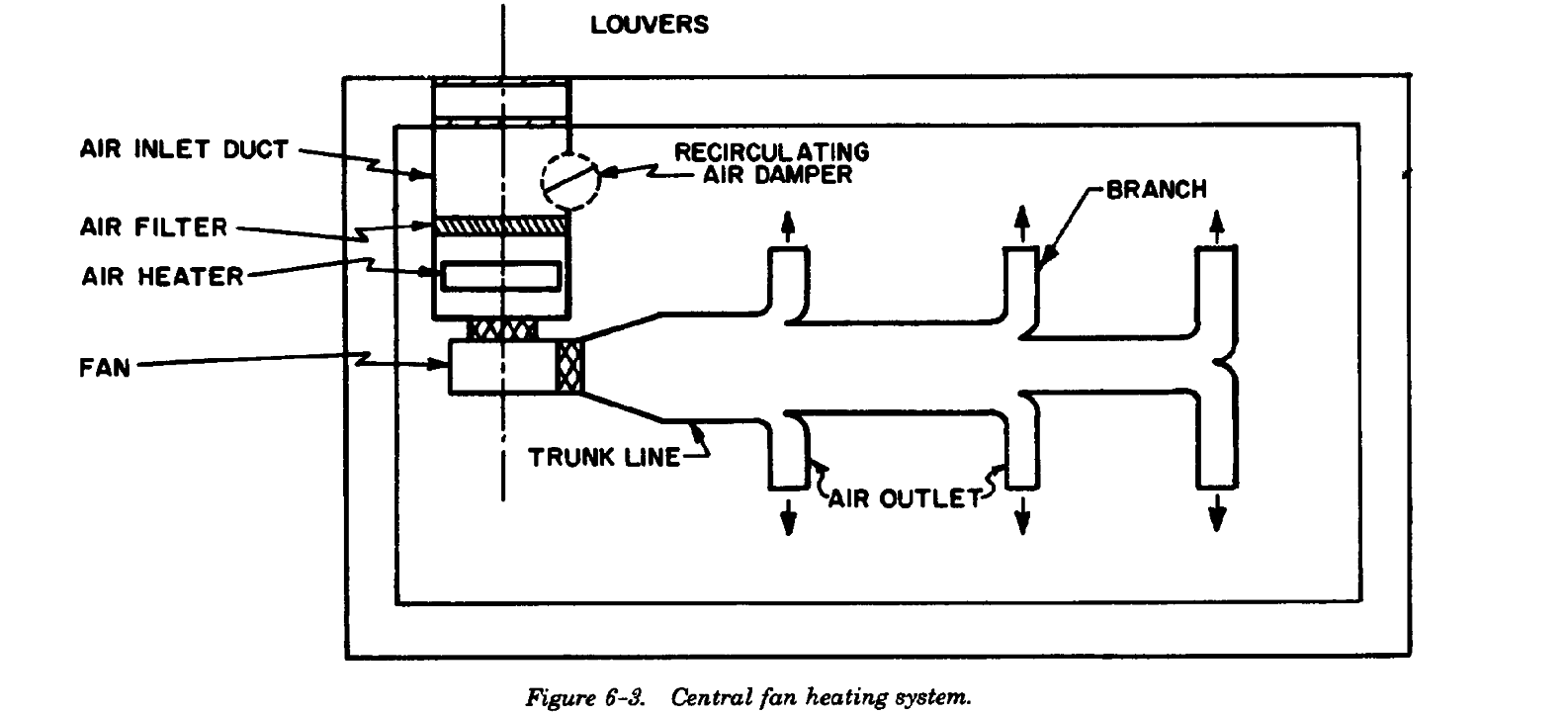

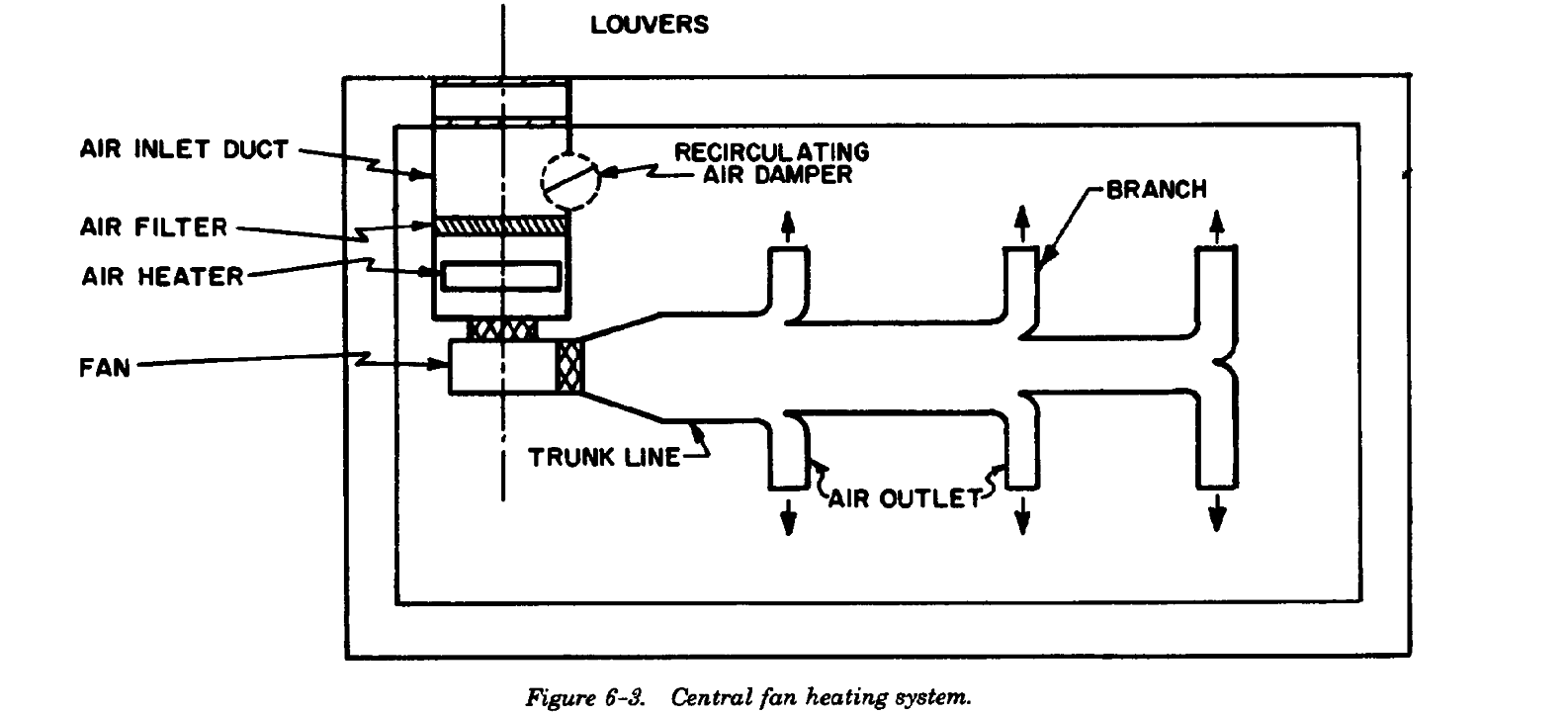

b. Central fan delivery system. This system

inlet duct. The combined operation of this damper

(figure 6-3) sometimes performs both heating and

and the outside air damper (which controls the

ventilation functions in large buildings. The air

influx of cold air) provides for tempering the

heaters in this system are heat exchangers consist-

outside air introduced into the system.

ing of pipe coils, finned tubes, or cast iron sections

(4) Air heater. The air heater (a heat exchanger

connected into stacks or units by nipples. The in-

heated by steam or hot water) is located in the

termediate heat carrier is either hot water or steam

mixed air duct, downstream of the air filter.

(from boilers, convertors, etc.) circuited through

(5) Fan. A motor operated fan, located after

the heating elements of the heat exchanger. A fan

the air heater, draws the tempered air through the

blows (or draws) air through the air heater and

heat and discharges it to a trunk line. “Blow-

supplies it to the spaces to be heated through the

through” arrangements locate the fan upstream of

distribution ductwork. Because the amount of air

the air heater.

required for heating purposes usually exceeds that

(6) Trunk line. This is a main duct with indi-

required for ventilation, economy of operation is

vidual branches taken off at intervals to carry the

improved by recirculating a portion of the heated

tempered air to the required spaces. Dampers at

air. A common central fan delivery system includes

either the branch take-off points or the branch

the following:

outlets provide balanced air distribution. The duct

(1) Outside air inlet duct. This duct is fitted

may be made from galvanized steel sheets; both

with a damper to control the influx of outside air to

aluminum and non-metallic ducts also are used extensively.

6-2

TM 5-642

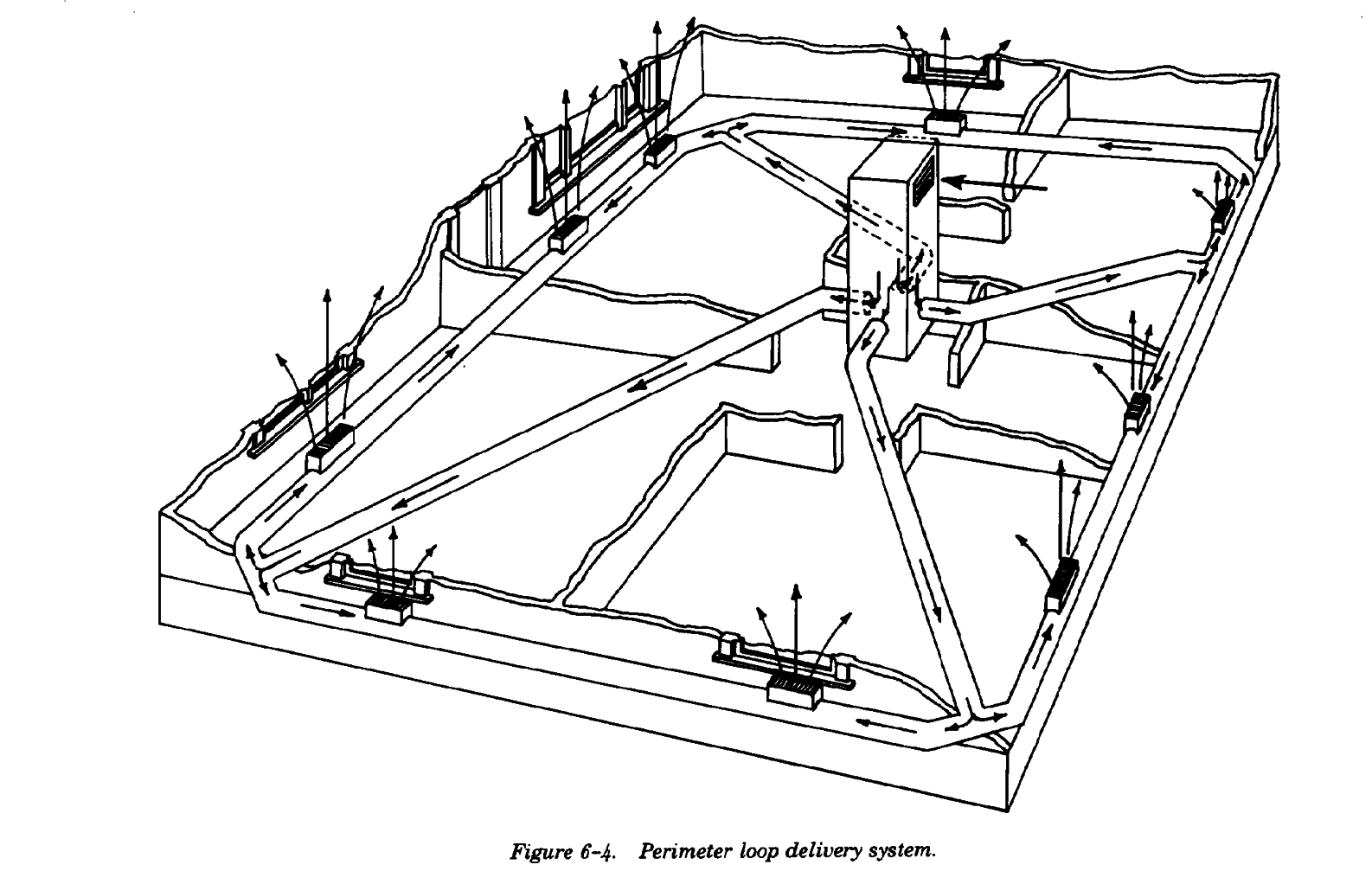

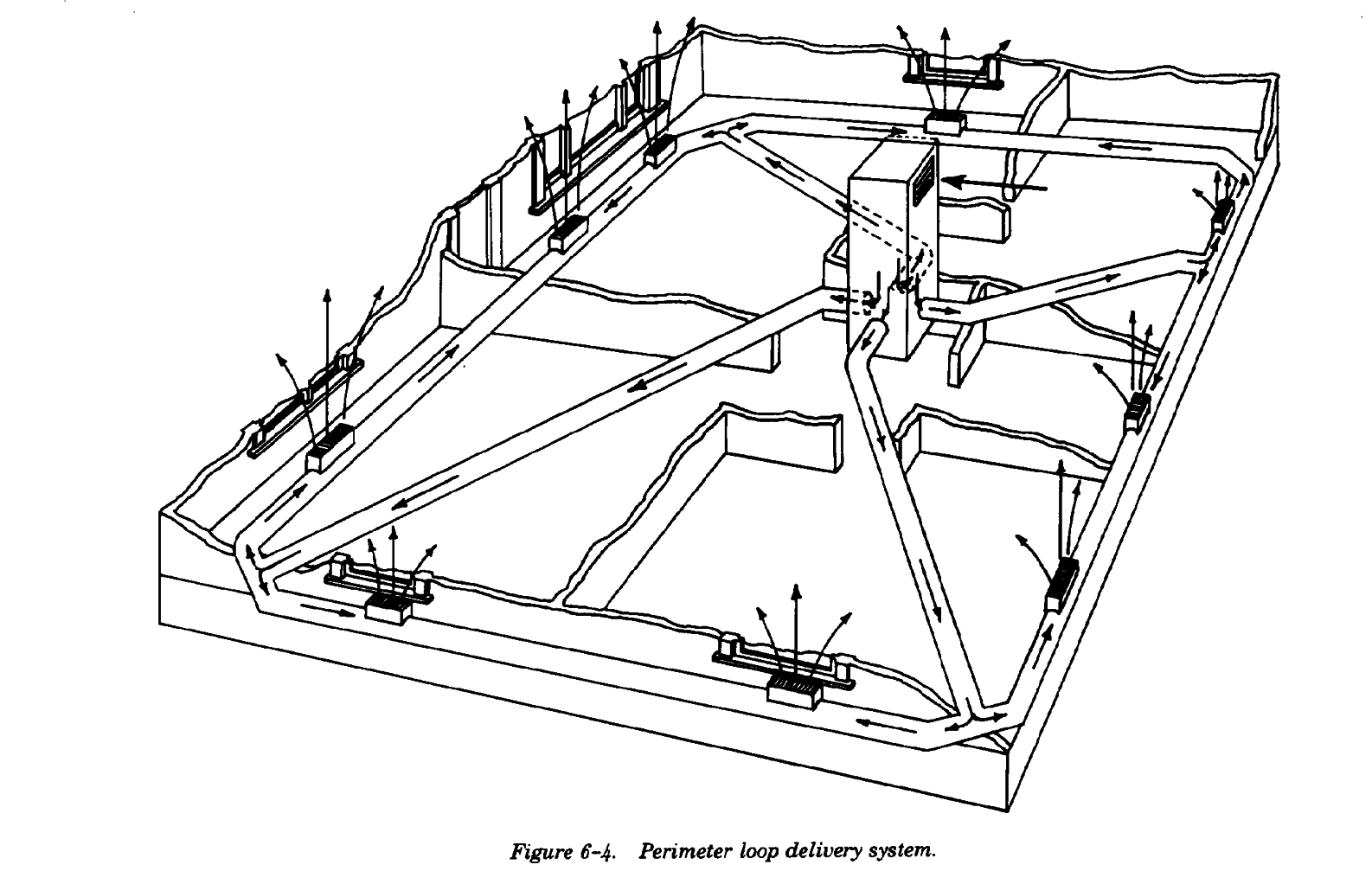

c. Perimeter delivery systems. Perimeter systems

furnace is located. In perimeter systems, a

usually employ the outside wall delivery system. Air

downflow furnace is normally used. In this type

returns to the furnace through centrally located,

furnace, cold air enters the unit from above and is

high sidewall or ceiling grilles. Return ducts may be

discharged as warm air from the bottom or lower

located in attics or other unheated spaces. Return

part of the furnace casing. Figure 6-4 illustrates one

air may be taken from crawl spaces and basements,

type of perimeter system called a loop system.

but never from a confined space in which the

6-3

TM 5-642

d. Inside wall delivery system. Supply grilles are

sired spaces. With annular ceiling diffusers, the

located on an inside (warm) wall, either high or

airstream is spread a full 360 degrees and the rate

near the floor. Return registers are located near the

of diffusion is high; however, the throw is rather

greatest exterior exposure. High wall registers

short, requiring (or in some cases allowing) high air

deliver the air either horizontally or slightly down-

discharge velocities.

ward, so that it does not strike the ceiling or wall.

For best results, multi-directional grilles are used,

6-4. Ratings of warm air furnaces.

distributing the airflow uniformly. To reduce the

Furnace rating is usually determined by BTU de-

discharge velocity, grilles are used with an area

livery per hour at the bonnet. Standard ratings for

larger than that of the connecting duct. Location of

different manufacturer*s furnaces can be obtained

the warm air return grille depends on the location

from the various trade associations, depending

of the supply grilles.

upon the type of fuel fired by the furnace.

e. Ceiling delivery system. This system employs

ceiling diffusers to deliver the warm air to the de-

Section II. COAL FIRED WARM AIR FURNACES

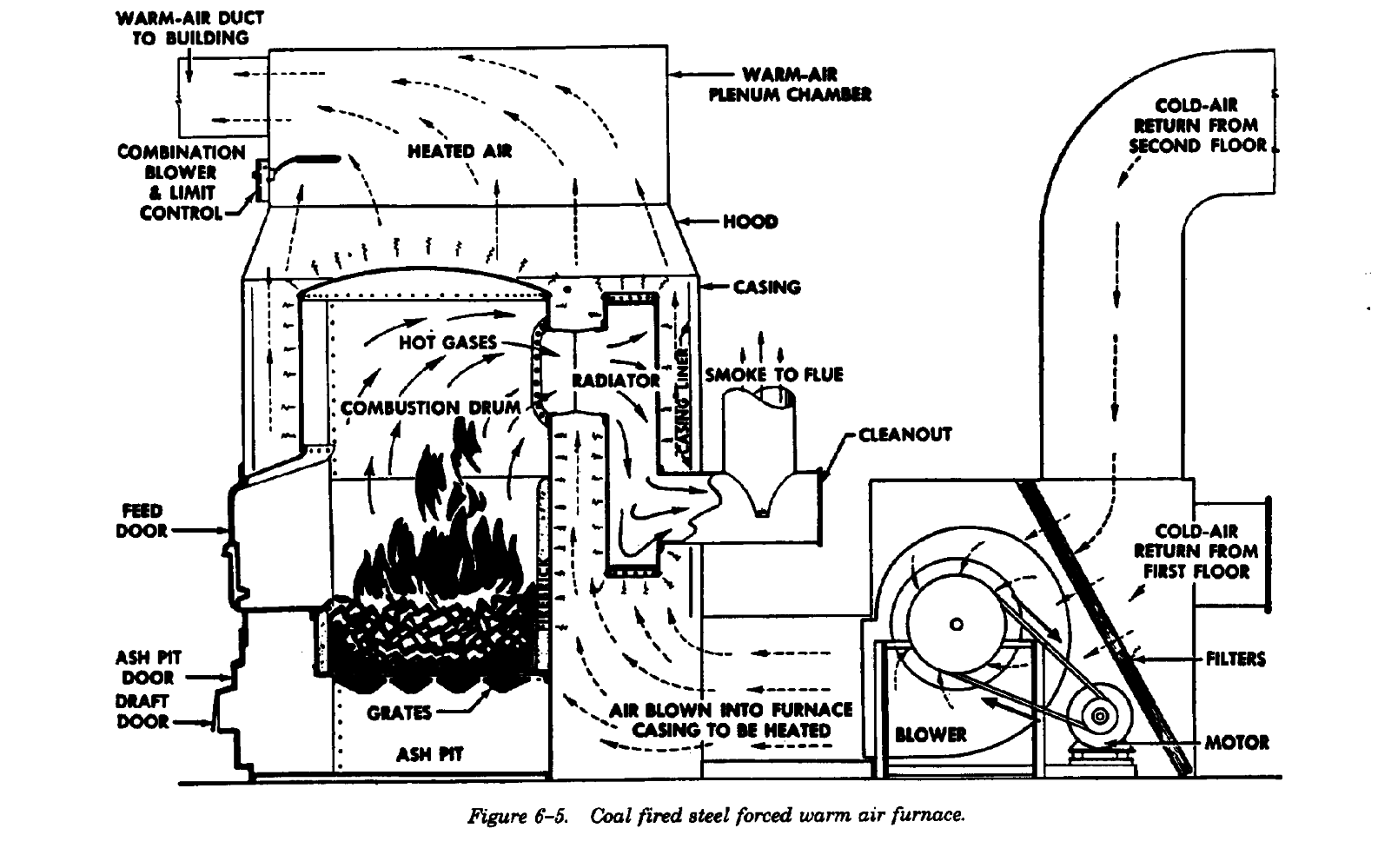

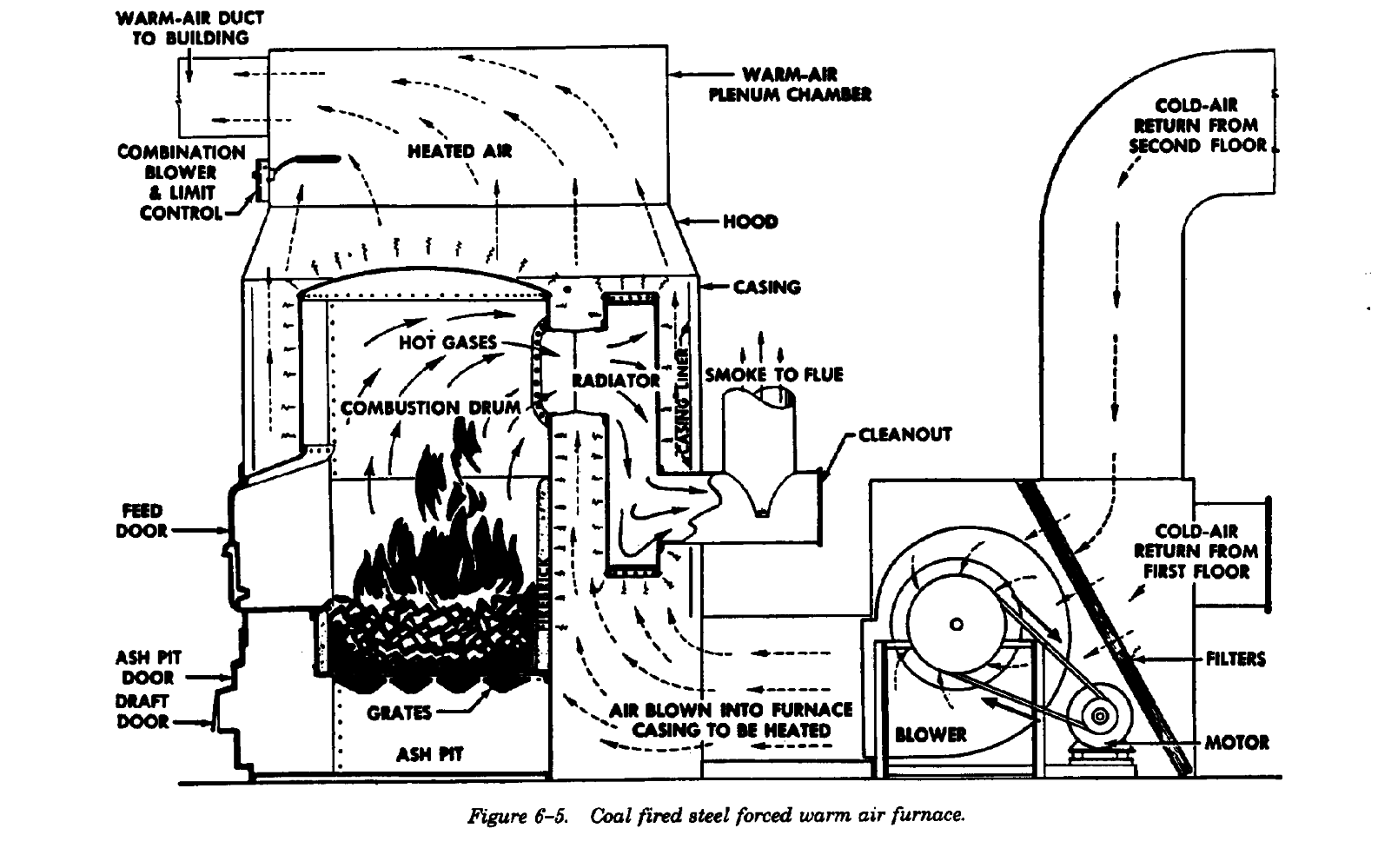

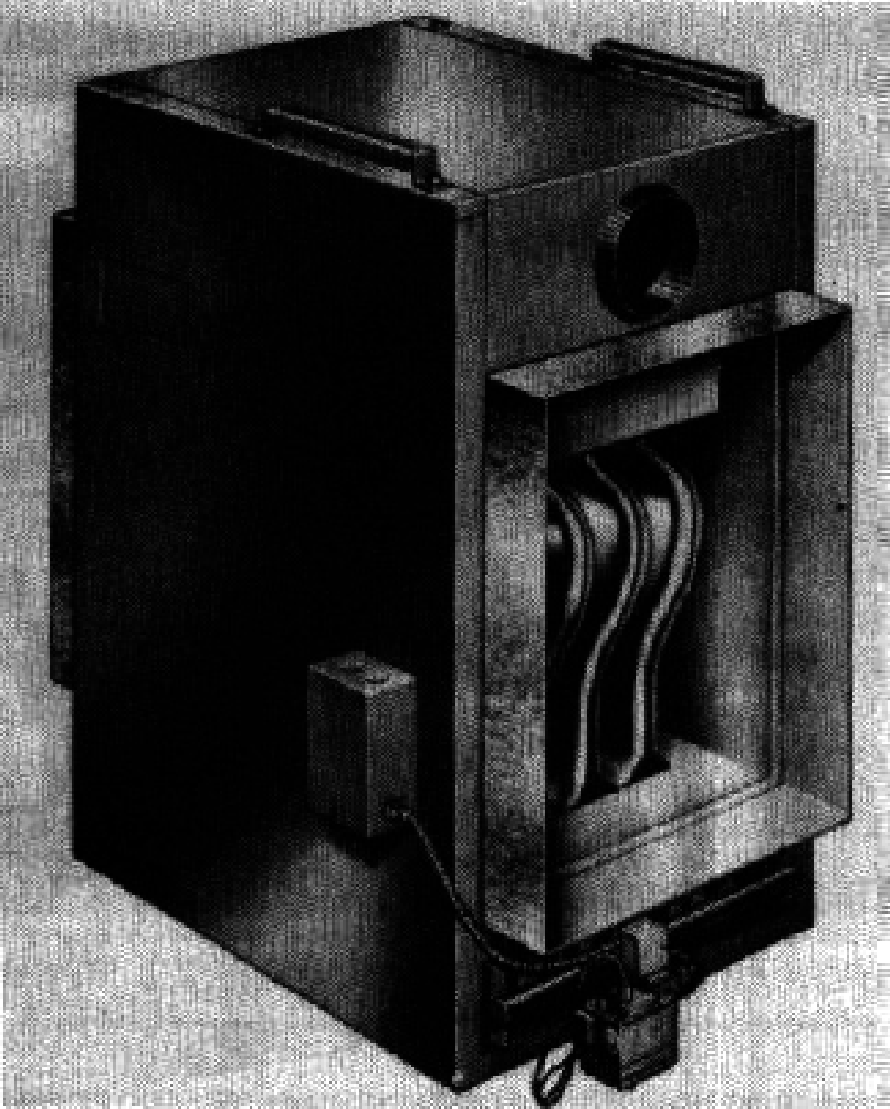

6-5. Steel furnaces.

(secondary heating surface) attached to the rear of

Steel furnaces (figure 6-5) are constructed of heavy

the combustion chamber. In large sizes, two addi-

gauge steel, riveted and caulked or welded at the

tional radiators may be installed on the sides of the

joints to make them air-tight. The fire-feed, ashpit,

furnace. All radiators must have a cleanout

and draft doors, usually made of cast iron, are

opening. Steel furnaces are, in general, more

located at the front of the furnace. In smaller sizes,

common than cast iron furnaces on Army installations.

steel furnaces usually have a single radiator

6-4

TM 5-642

6-6. Cast iron furnaces.

x [BTU content per pound of coal] x [0.65

Cast iron furnaces are constructed in sections which

(efficiency)]

are made airtight by the use of liberal amounts of

b. Furnaces with more than 294,000 BTUH

furnace cement. Use cement supplied by the furnace

output.

manufacturer in a fashion consistent with the

BTUH output at the furnace bonnet = [area

manufacturer*s recommendations. The radiator

of grate in square feet] x [10.0 pounds of

(secondary heating surface) is usually located on

coal] x [BTU content per pound of coal] x

top of the combustion chamber dome. Both steel

[0.70 (efficiency)]

and cast iron coal fired furnaces must be installed

on a solid masonry base. Do not install on a base

6-8. Smokepipe.

made with wood or other combustible material.

The smokestack from furnace to chimney must be

18 gauge or heavier steel, and at least as large (in

6-7. Ratings and sizes.

cross-sectional area) as the furnace collar. Avoid

Ratings are determined by BTU per hour (BTUH)

the use of elbows wherever possible. Install the

delivery at the bonnet. Standard code ratings are

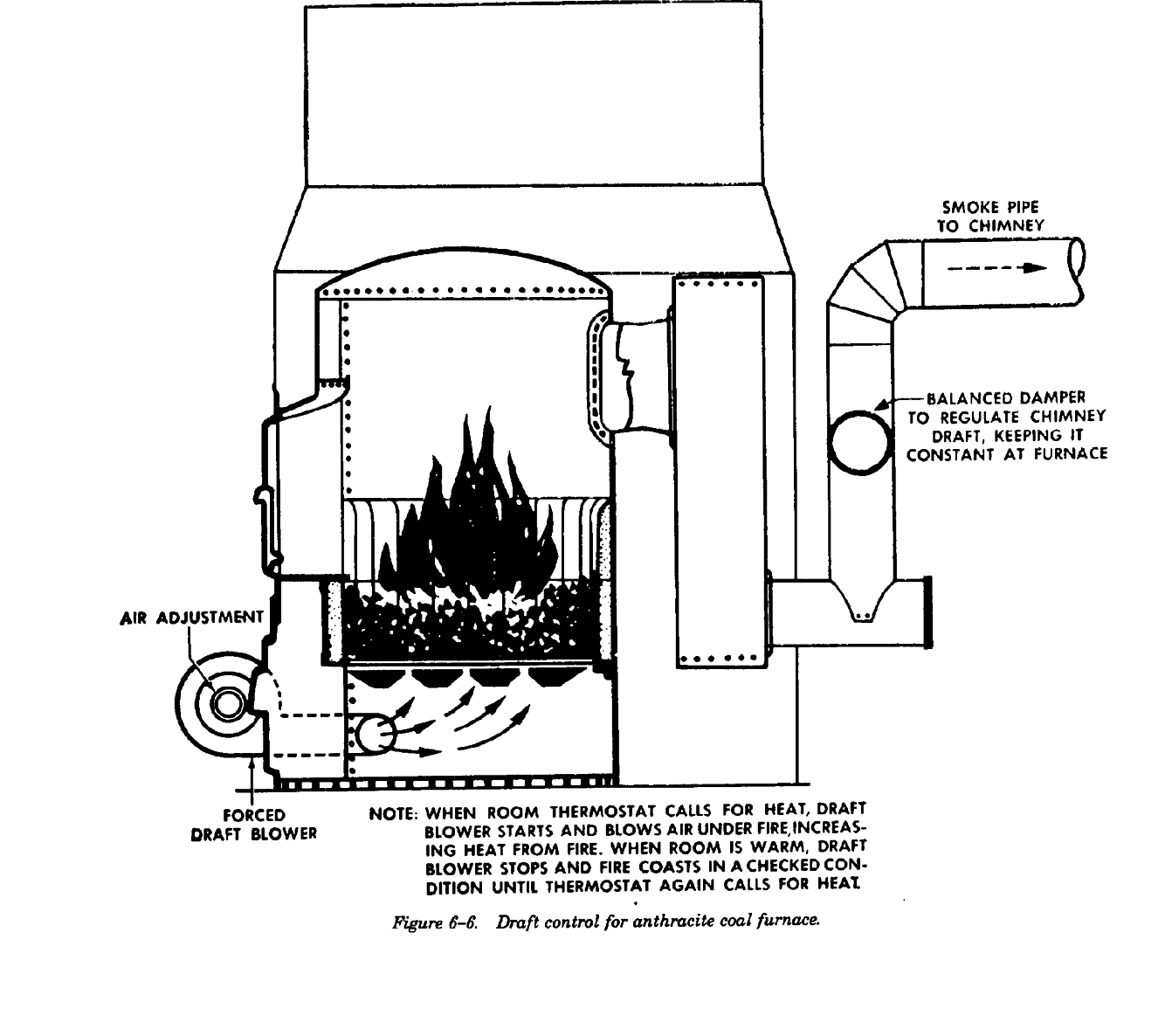

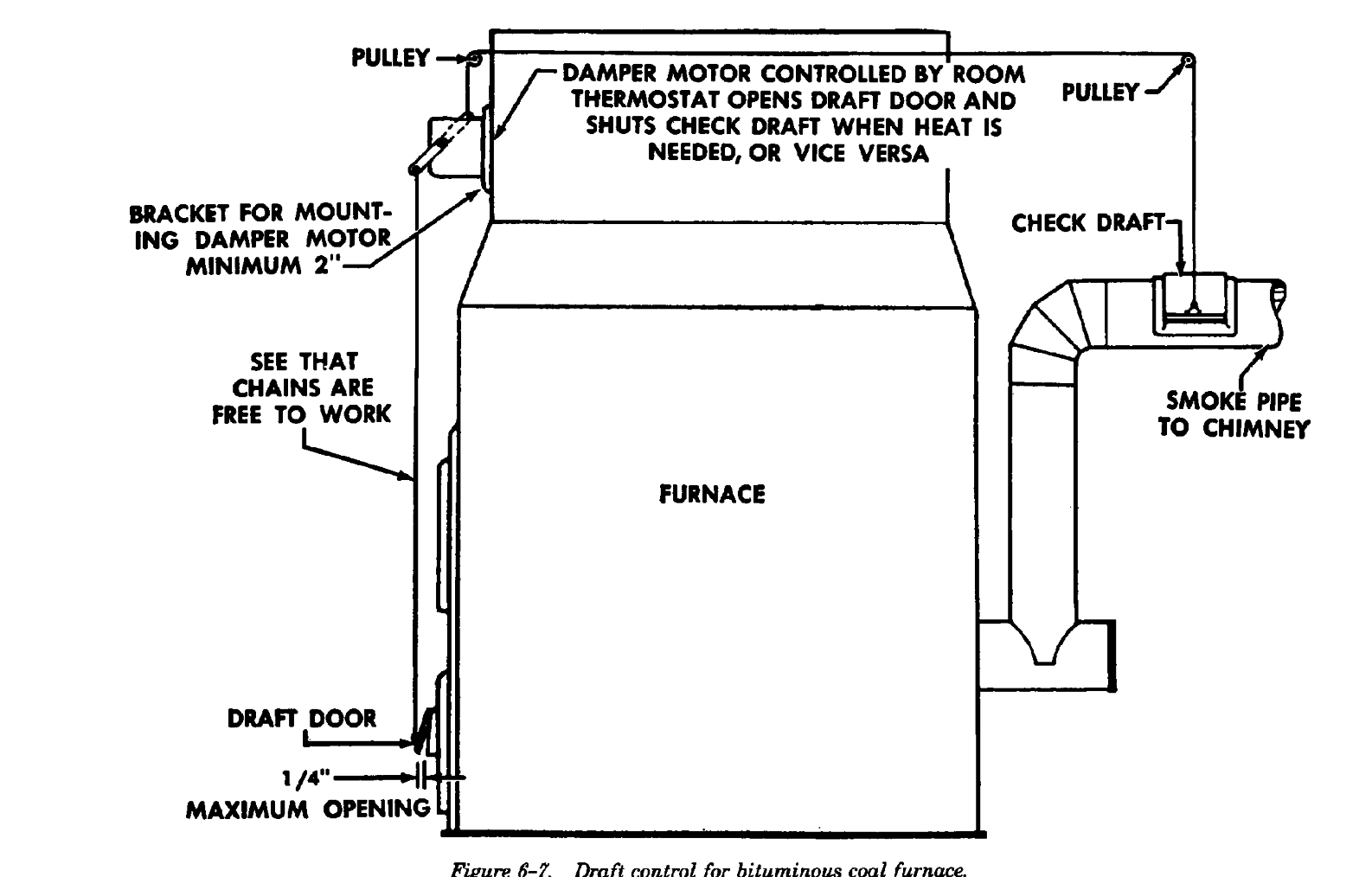

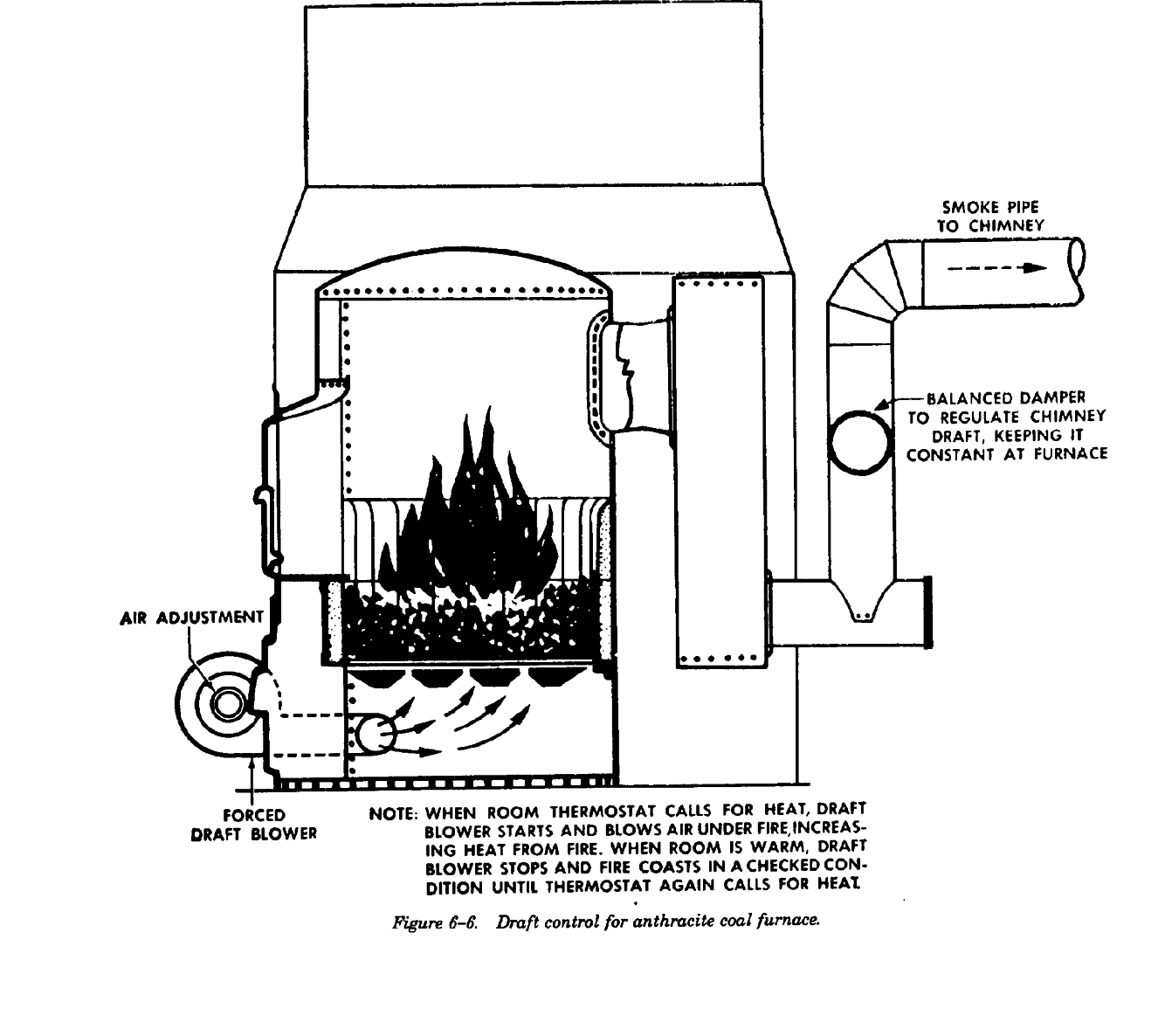

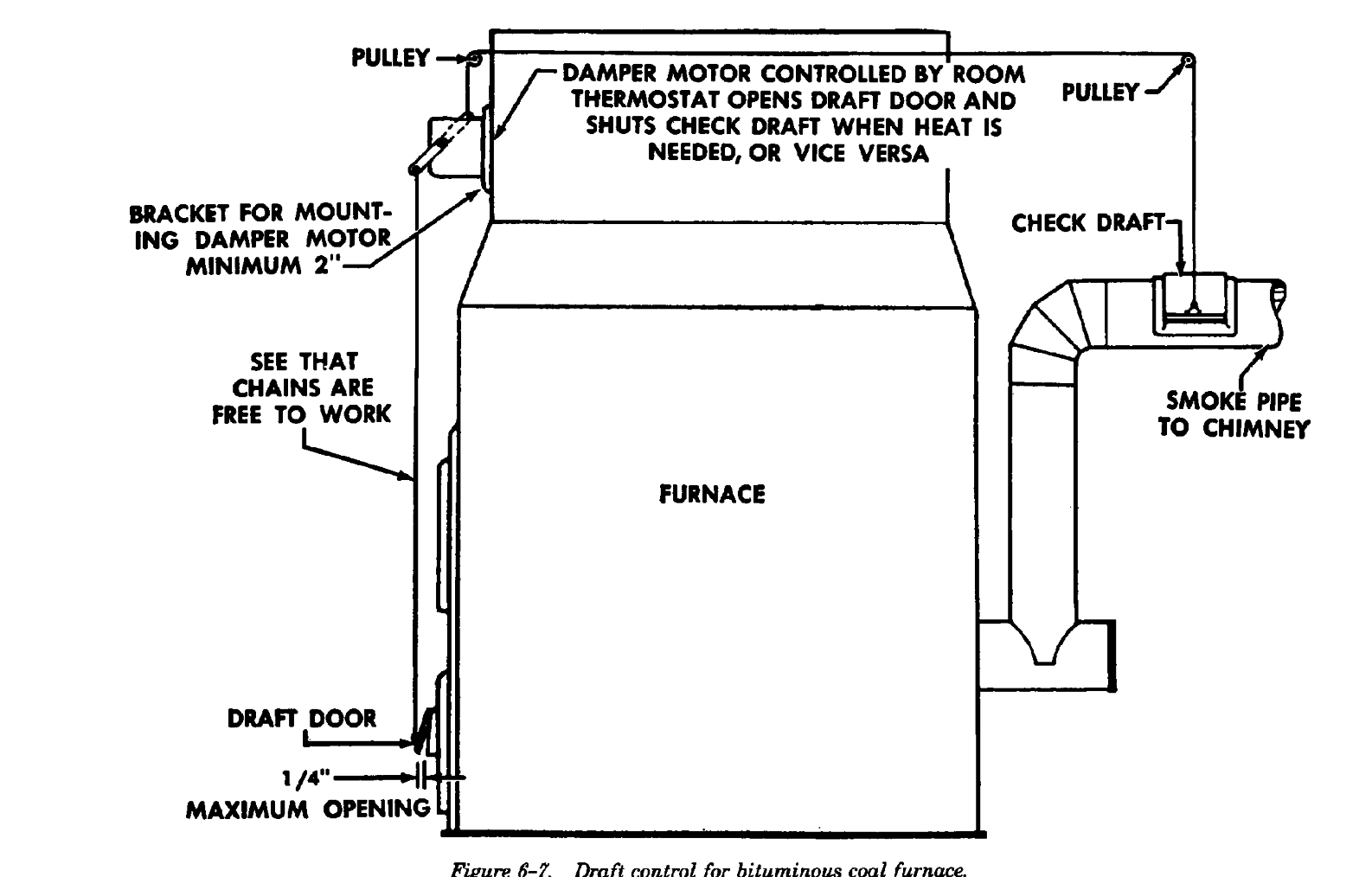

check draft used with bituminous or anthracite coal

used in sizing coal fired furnaces, in accordance

with hinges on the top sides of the smokepipe for

with the following formulas:

easy (chain) operation by the damper motor. For

a. Furnaces with 294,000 BTUH or less output.

buckwheat coal, a checkdraft is generally omitted,

BTUH output at the furnace bonnet = [area

but a balanced atmospheric type damper should be

of grate in square feet] x [7.5 pounds of coal]

installed to regulate chimney draft. (See figures 6-6

and 6-7.)

6-5

TM 5-642

6-6

TM 5-642

6-9. Motor damper.

used, particular attention must be given to them.

Install the motor damper such that it has no direct

Rectangular chimneys must be carefully checked,

contact with the furnace or bonnet. Motors

from the standpoint of both area and dimensions.

installed on the bonnet or furnace are should be

a. Area. A chimney must have a cross-sectional

mounted on a bracket which extends out to allow

area greater than or equal to that of the smoke-pipe

for air passage, or are mounted on insulators to

outlet from the furnace. The smaller dimension of

prevent excessive heating.

of a rectangular flue must be at least two-thirds of

the smokepipe diameter. Chimney cross-sectional

6-10.

Chimney.

area must be increased 4 percent for each 1,000

feet of elevation above sea level.

The importance of the chimney in the proper com-

b. Height. Follow manufacturer*s recommenda-

bustion of coal cannot be overemphasized. Every

tions on chimney height at all times. Height of the

pound of coal requires from 150 to 250 cubic feet

chimney may be 85 percent of the recommended

of air for proper combustion; sufficient draft must

height without requiring compensation; however,

be maintained through the fuel bed to supply this

for each 10-percent decrease below recommended

amount of air. A blocked chimney or chimney

height, add 6 percent to the grate area to get the

downdraft can cause inadequate draft and there-

same furnace heat output (BTUH). All chimneys

fore, incomplete combustion and create carbon

must extend at least 2 feet above the peak of the

monoxide. A chimney must have sufficient area and

roof and in no cases should chimney height be less

height, and must be tight from bottom to top. The

than 15 feet, even for small furnaces.

most efficient chimney shape is round; however,

because rectangular chimneys are commonly

6-7

TM 5-642

Section III. OIL FIRED WARM AIR FURNACES

6-11.

General description.

6-13 Oil conversion furnace.

Oil fired furnaces may be designed and built exclu-

Coal furnaces may be modified for oil firing capa-

sively for use with fuel oil, or oil conversion burn-

bilities by installing oil conversion burners in ex-

ers may be installed in furnaces originally burning

isting coal furnaces.

coal. Standard design and installation practices for

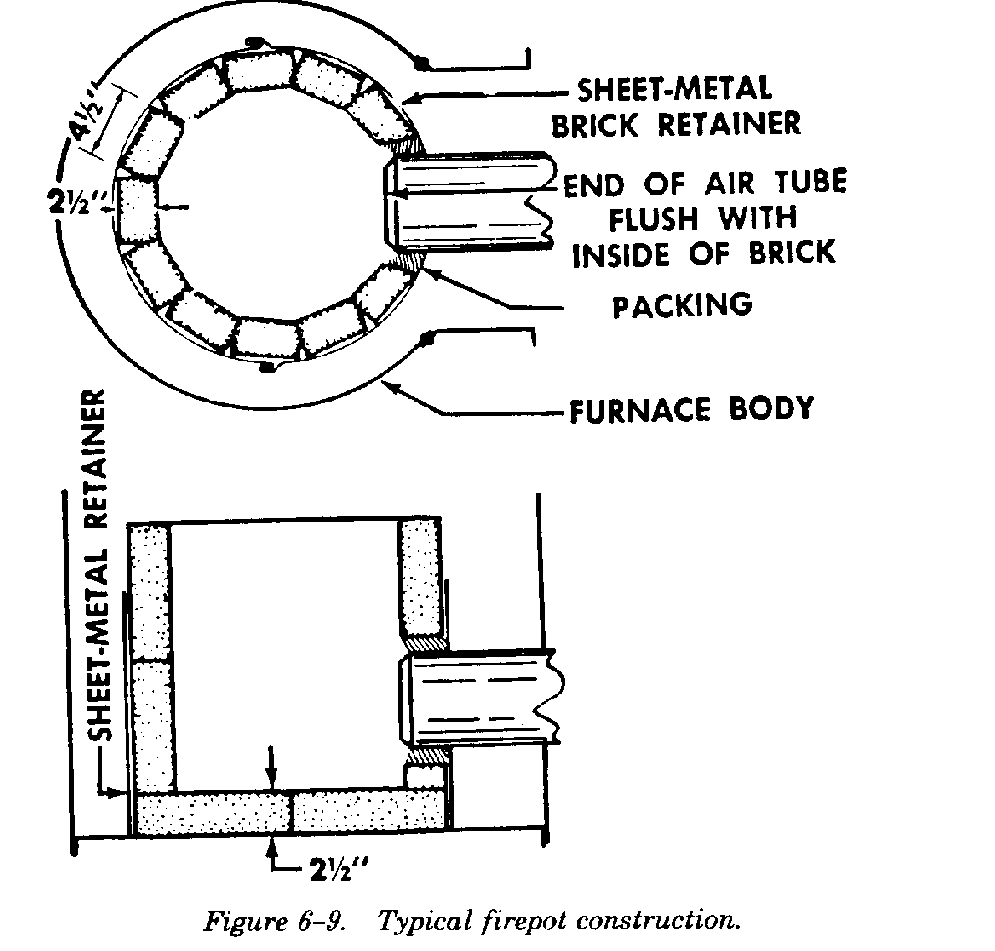

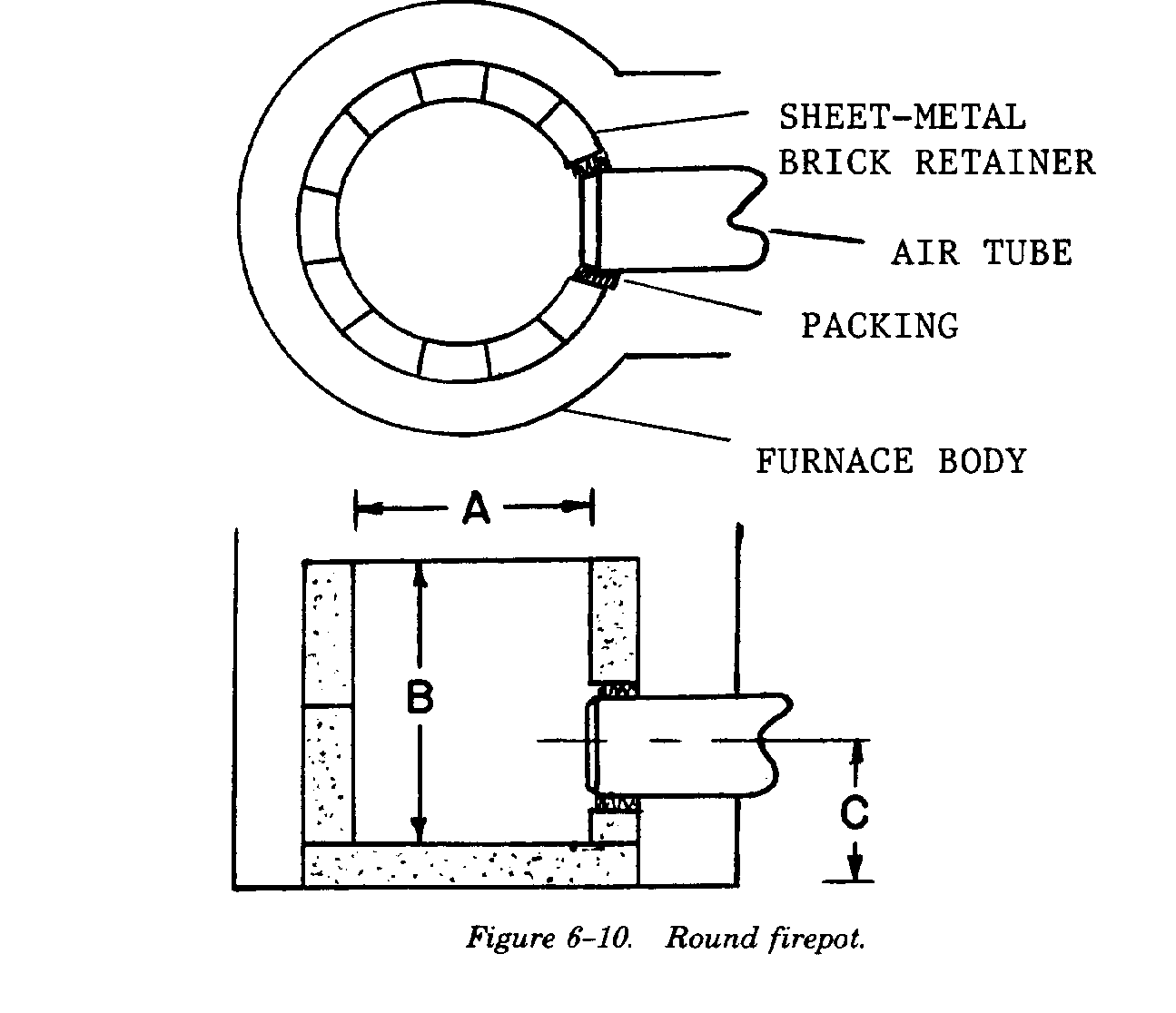

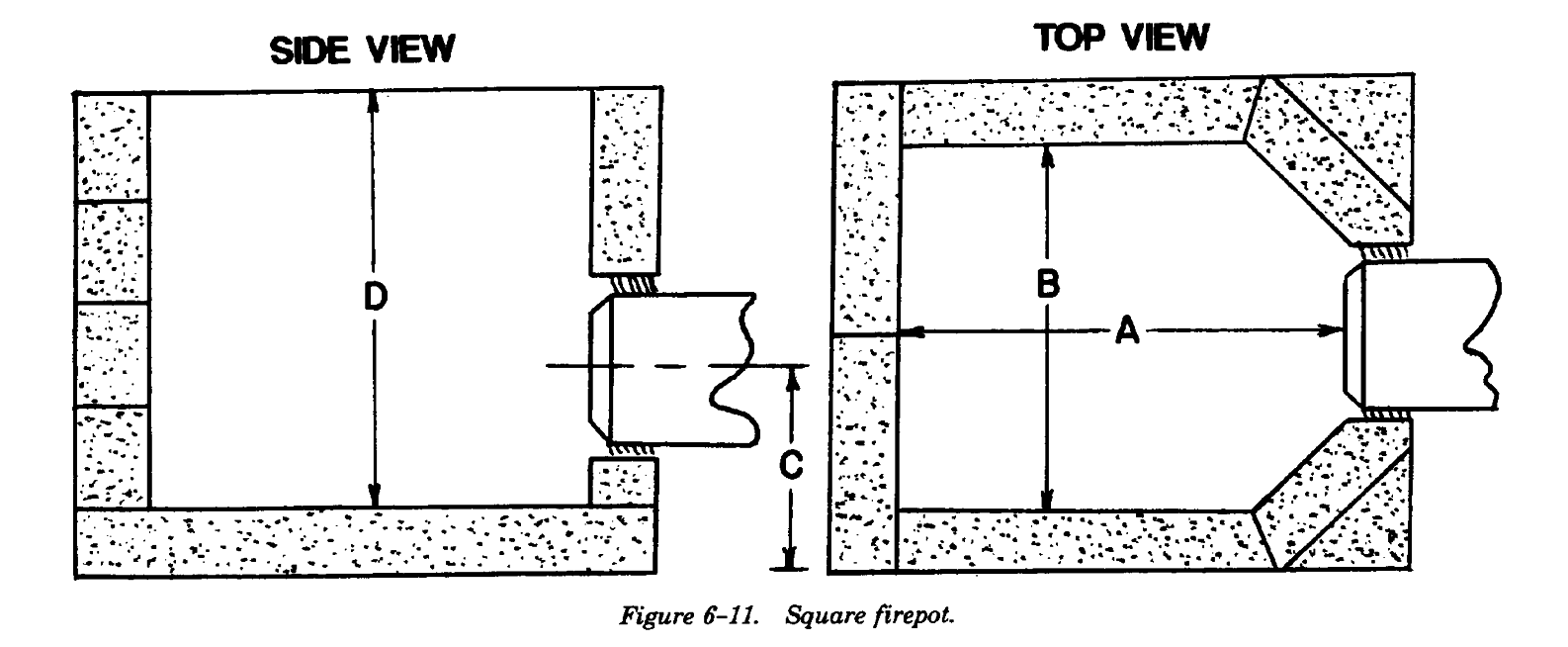

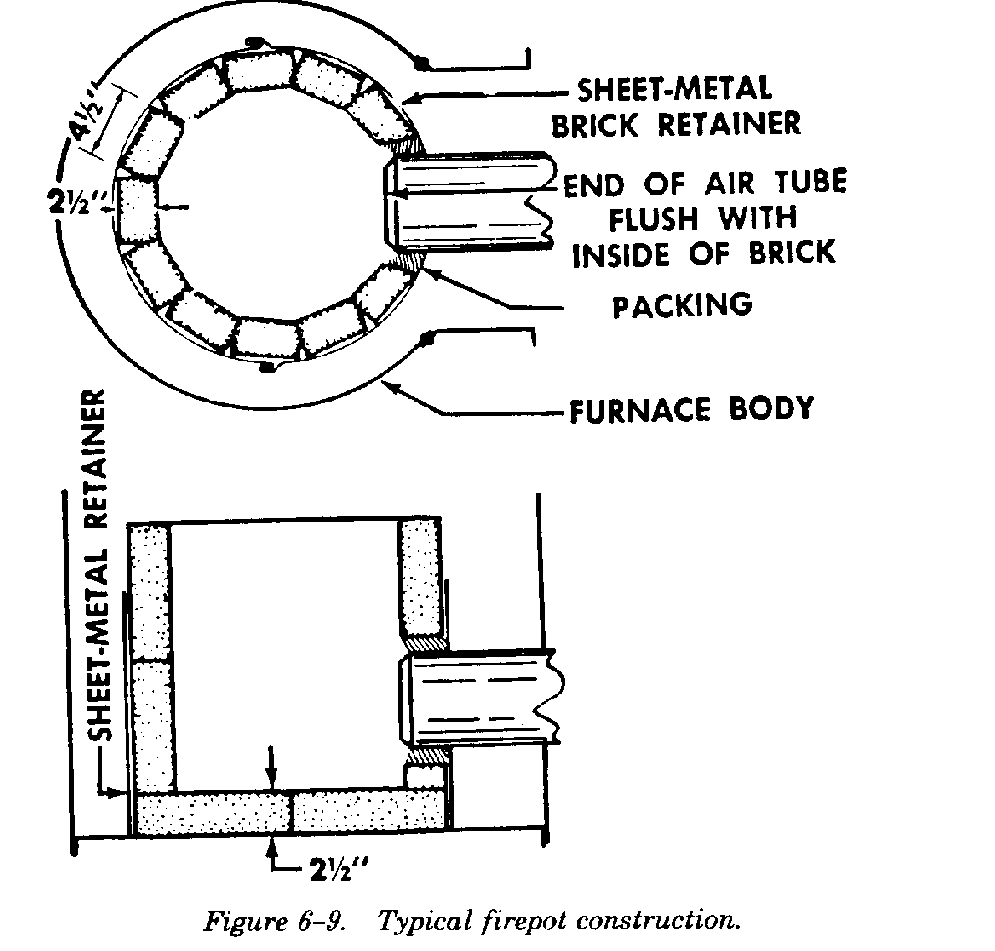

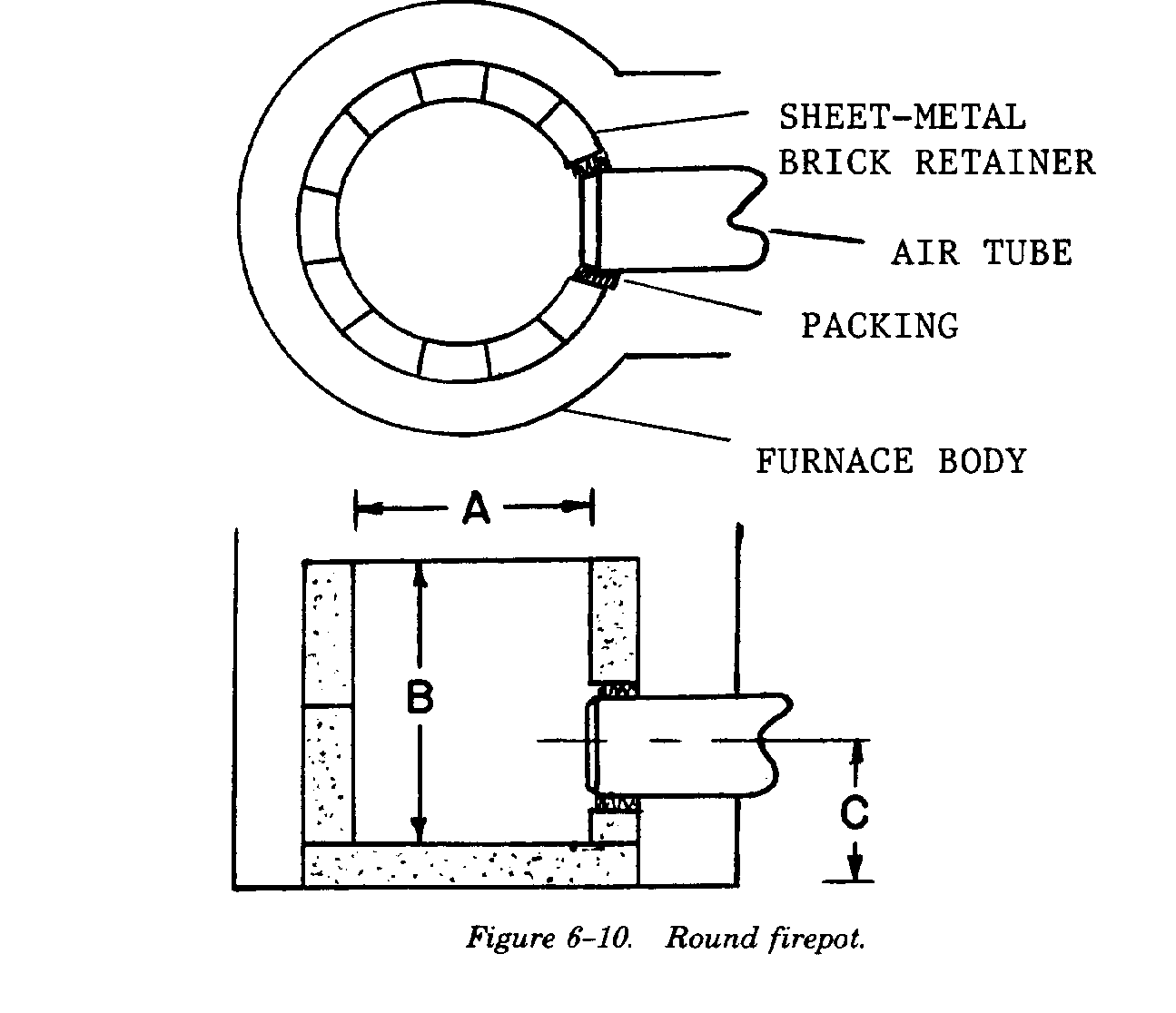

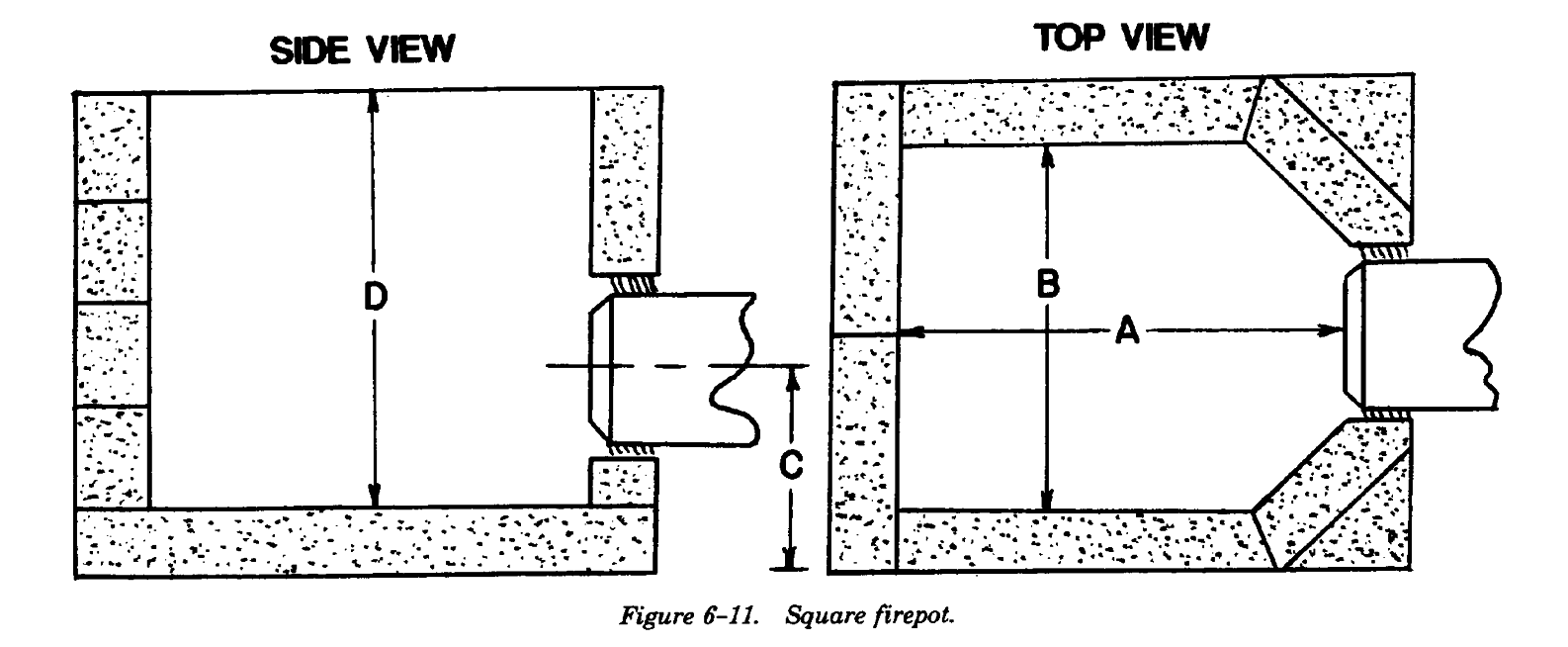

a. Firepot. The firepot may be either round or

fire prevention are detailed in the applicable codes,

square. Normally, a 24-gauge sheet metal drum is

technical manuals, and manufacturer*s literature.

set on a brick floor inside the furnace. The sheet

metal acts as a retainer for the firepot wall. Bricks

6-12.

Oil furnaces.

are cemented with special mortar, made for the

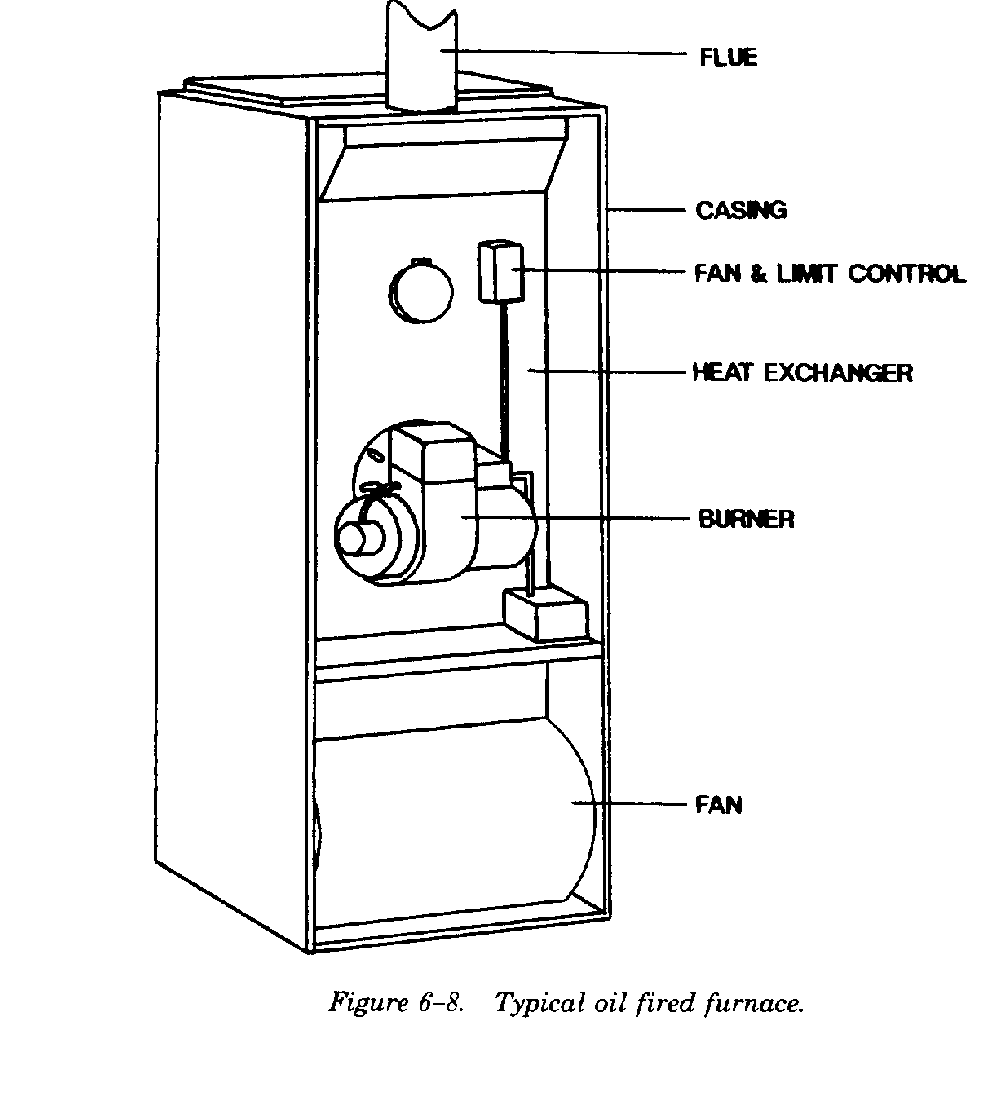

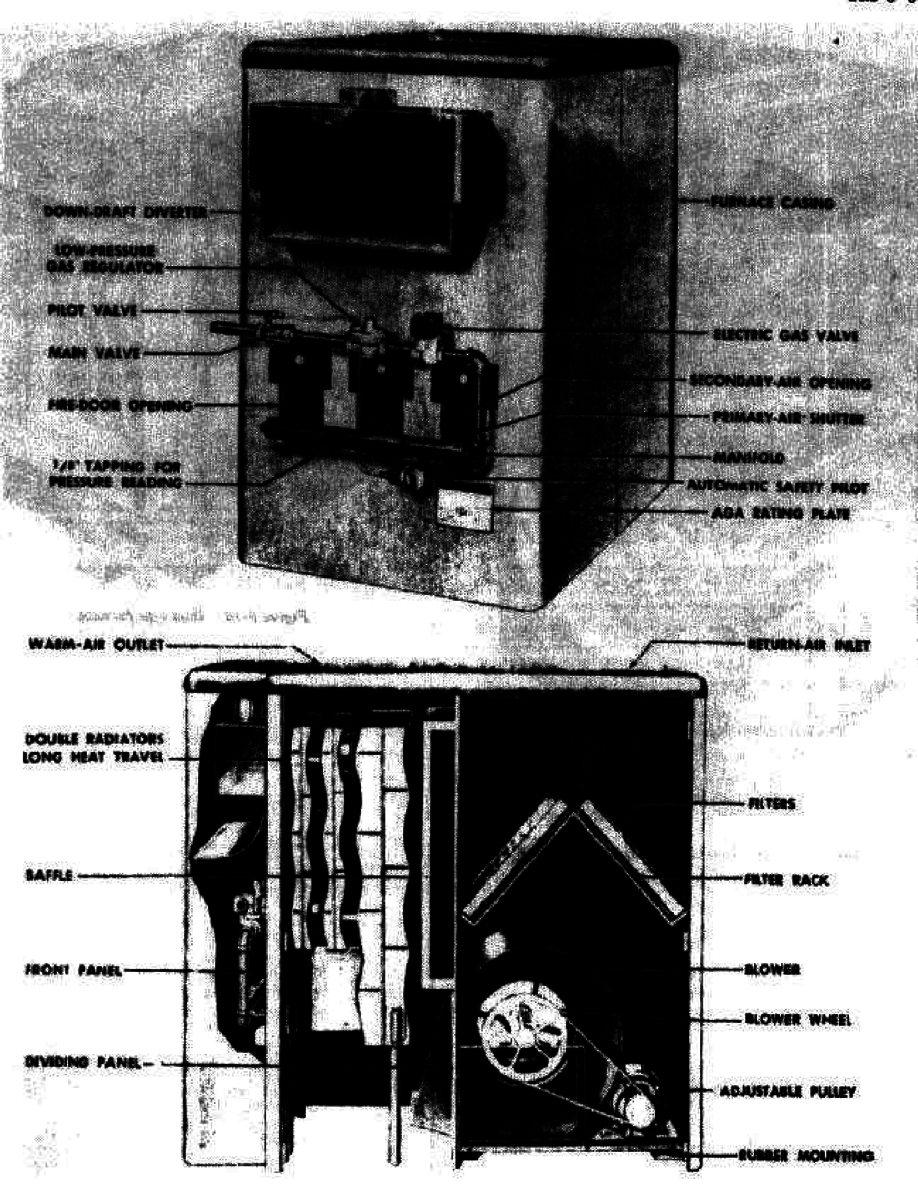

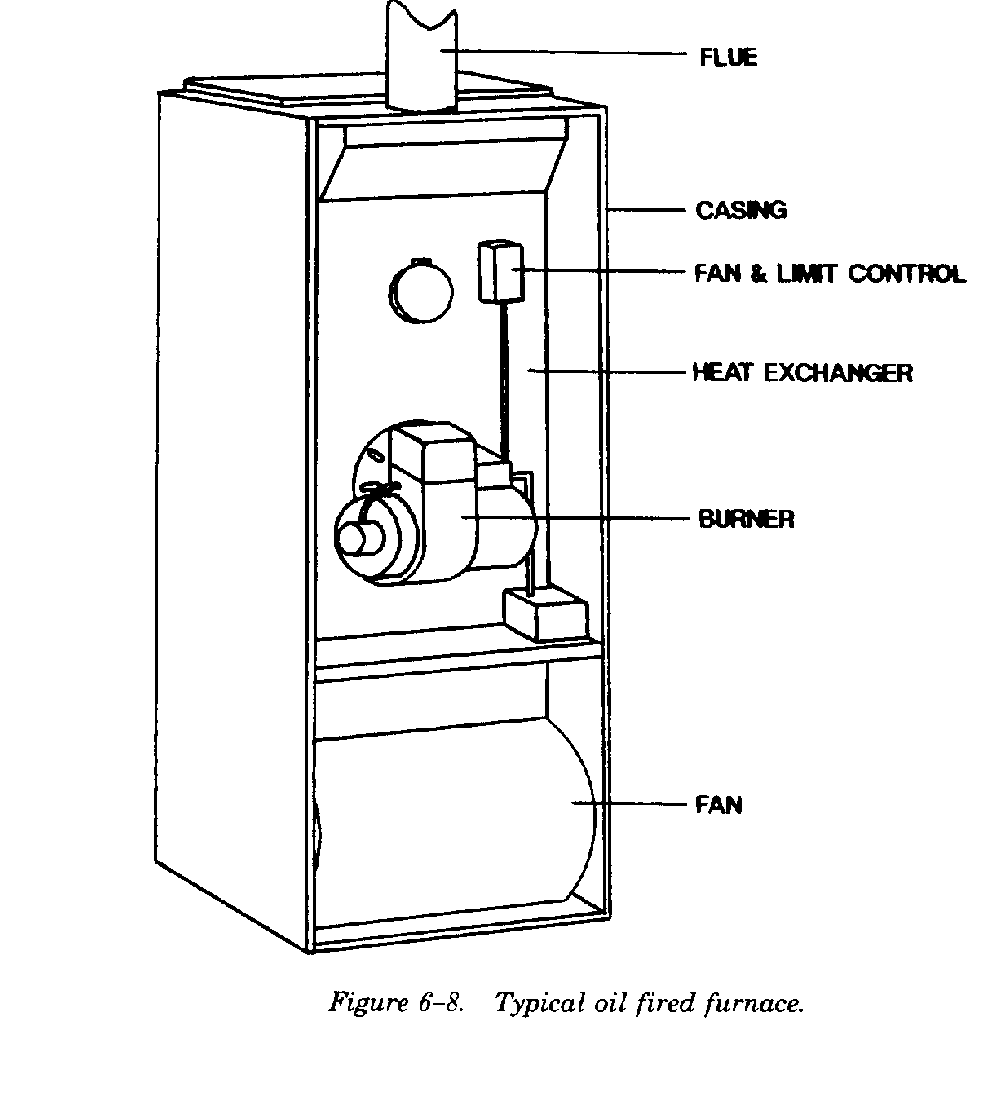

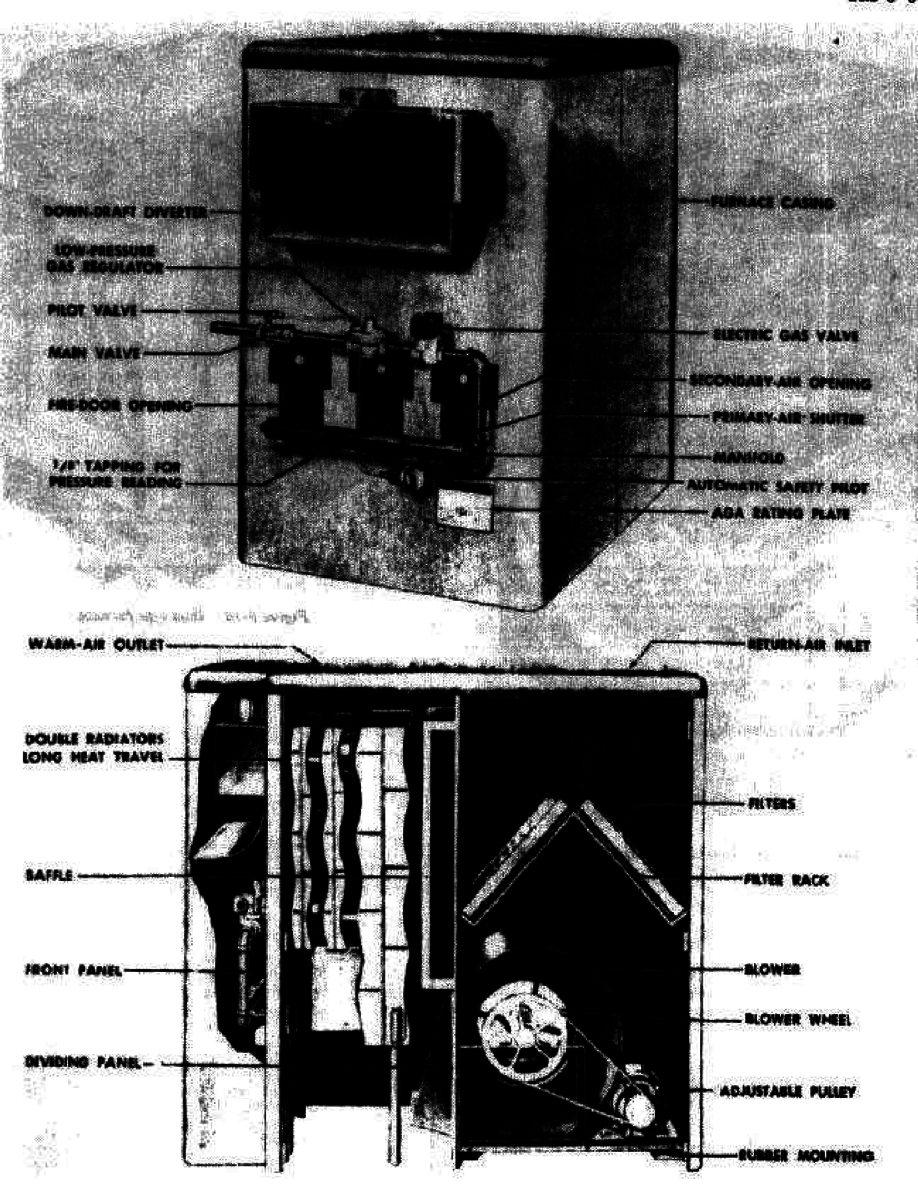

With oil furnaces, maximum efficiency (beyond that

particular brick used. The space between the fire-

possible with oil conversion burners) is the result of

pot wall and the furnace body is not filled. Heat is

proper sizing of the combustion chamber and the

allowed to flow behind the refractory pot. In gravi-

firepot volumes, longer heat travel, and very large

ty warm air installations, a radiation shield is in-

heating surfaces. Oil furnaces are usually of the

stalled between furnace body and casing to prevent

blowthru type, with an air space pressure greater

radiant heat from retarding cold air circulation.

than the combustion chamber pressure. Compact

Refer to figure 6-9 for typical firepot construction.

fan-furnace-burner units may be installed in

basements, attics, or other locations with limited

space. Figure 6-8 illustrates a typical oil fired

furnace.

b. Oil conversion burner installation.

(1) Installing burner.

(a) Set burner with end of blast tube flush

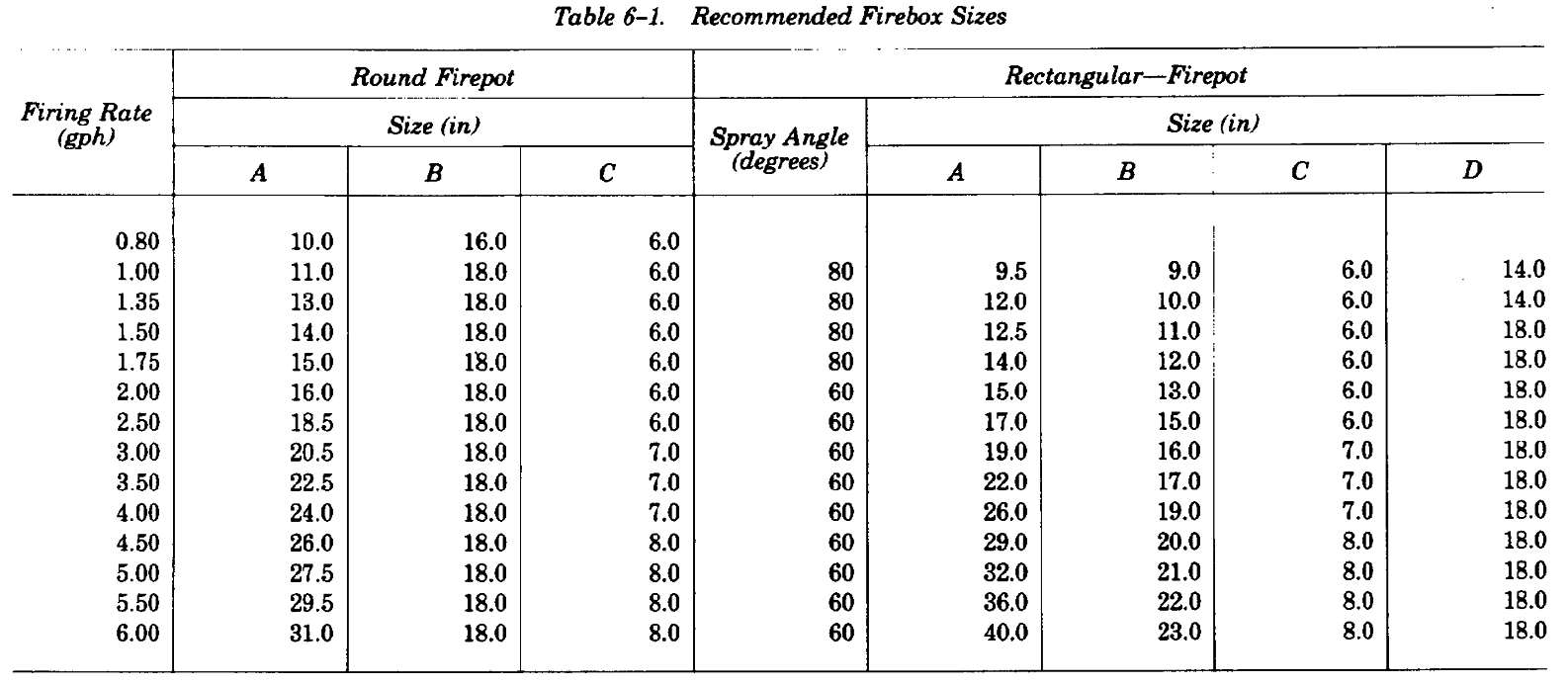

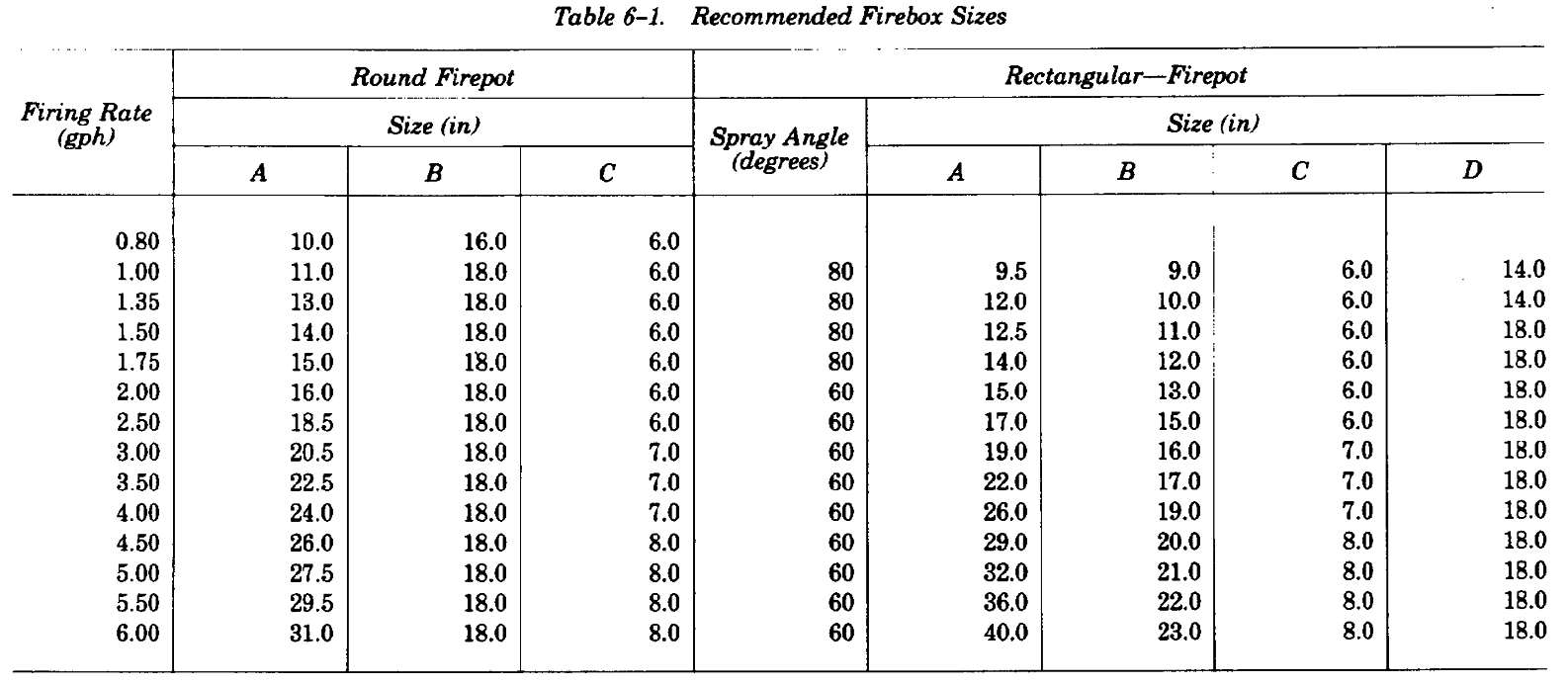

with the inside wall of the firepot. (See Table 6-1

and firepot diagrams, figures 6-10 and 6-11.)

6-8

TM 5-642

6-9

TM 5-642

(b) Pack around the blast tube to close the

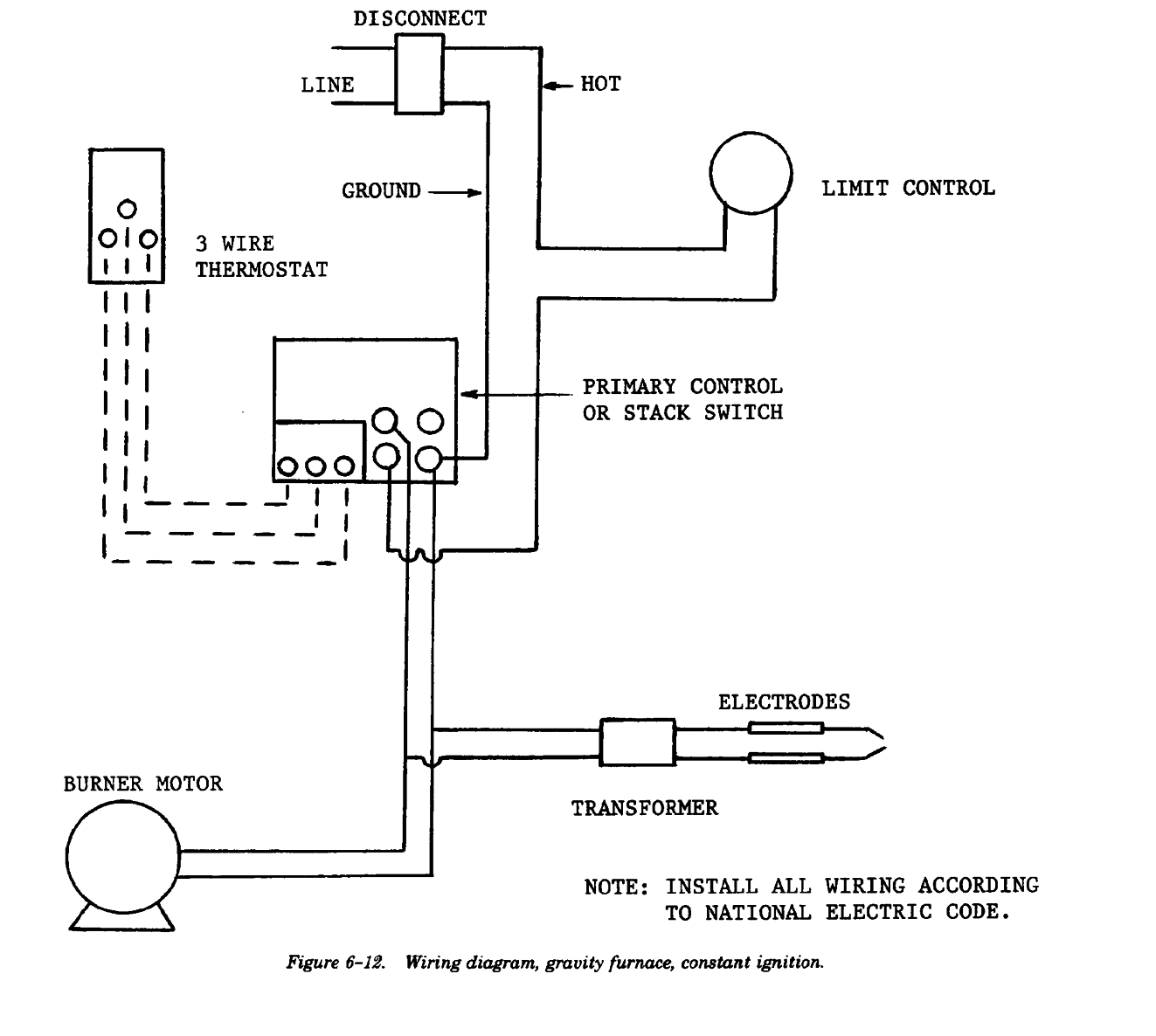

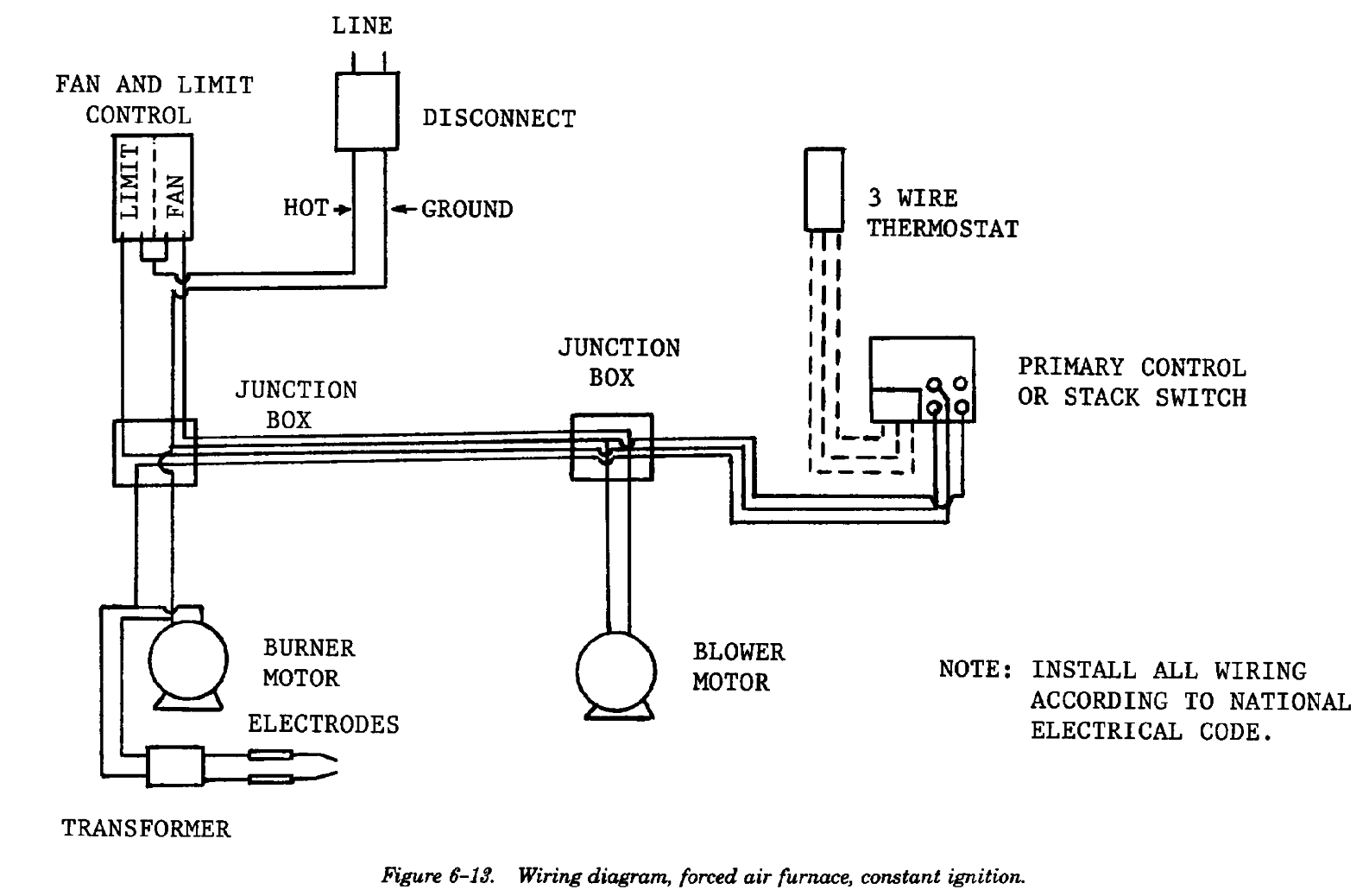

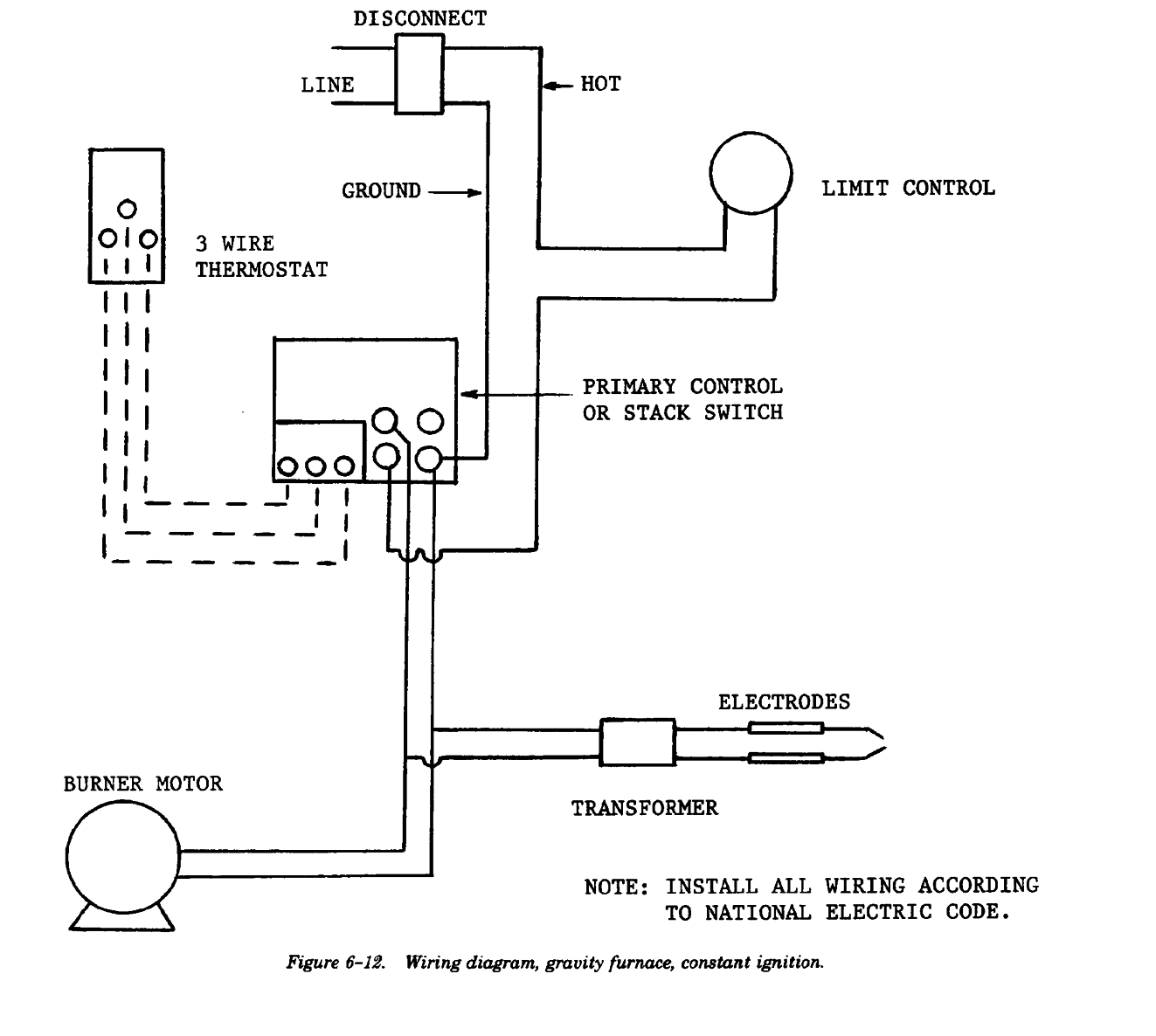

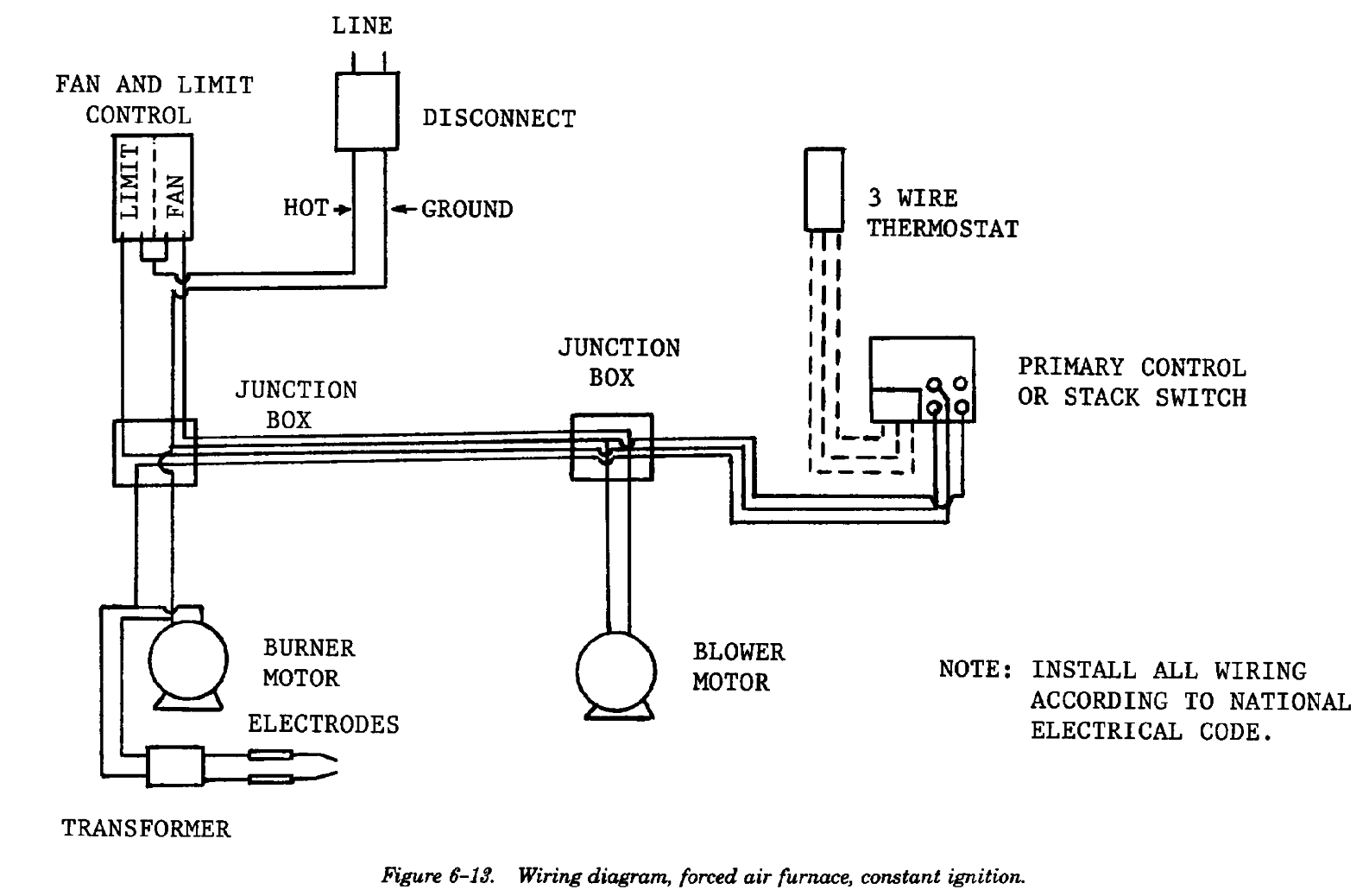

(2) Installing constant ignition controls.

gap between the refractory and the burner blast

(a) Select the appropriate wiring diagram

tube. This prevents the flame from licking back on

from figures 6-12 and 6-13, depending on the air

the blast tube and eventually burning it off. Leave

distribution system type (gravity or forced air).

a groove at the bottom of the packing so that oil

These diagrams are for constant ignition burners.

dripping from the blast tube can drain into the

firepot.

(c) Secure the burner to the floor with lag

screws unless some other provision has been made

in the furnace unit for locking the burner in place.

6-10

TM 5-642

6-11

TM 5-642

(b) Check the polarity of the wiring circuit

quent burner cycling and temperature fluctuations

carefully to ensure that “hot” and ground connec-

within the building. In no case should the nozzle

tions are as shown in the appropriate wiring dia-

ever be sized larger than the input rating of the

gram.

furnace. Assuming a furnace efficiency of 70 per-

(c) Note that the burner motor and ignition

cent, the nozzle can be sized as follows:

transformer are wired in parallel; that is, one wire

Nozzle Rate, GPH=(BTUH Heat Loss)/(138,200

from each is connected to the “hot” line and the

x .70)

remaining wire from each is connected to the

(4) Nozzle selection. Choose nozzles used in

ground wire. If RF suppression (radio filter) is re-

small units carefully. If a new unit using a new

quired, it should be wired in parallel with both the

nozzle does not produce a perfect fire, try several

burner motor and ignition transformer.

other nozzles with the same markings. Trouble can

(3) Nozzle sizing. Size the nozzle so that the

occur even with new nozzles despite care used in

furnace will provide enough heat to match the cal-

its selection. For this reason, keep several spare

culated heat loss of the building at design condi-

nozzles in stock.

tions. Oversizing results in lowered efficiency, fre-

Section IV. GAS FIRED WARM AIR FURNACES

6-14.

General.

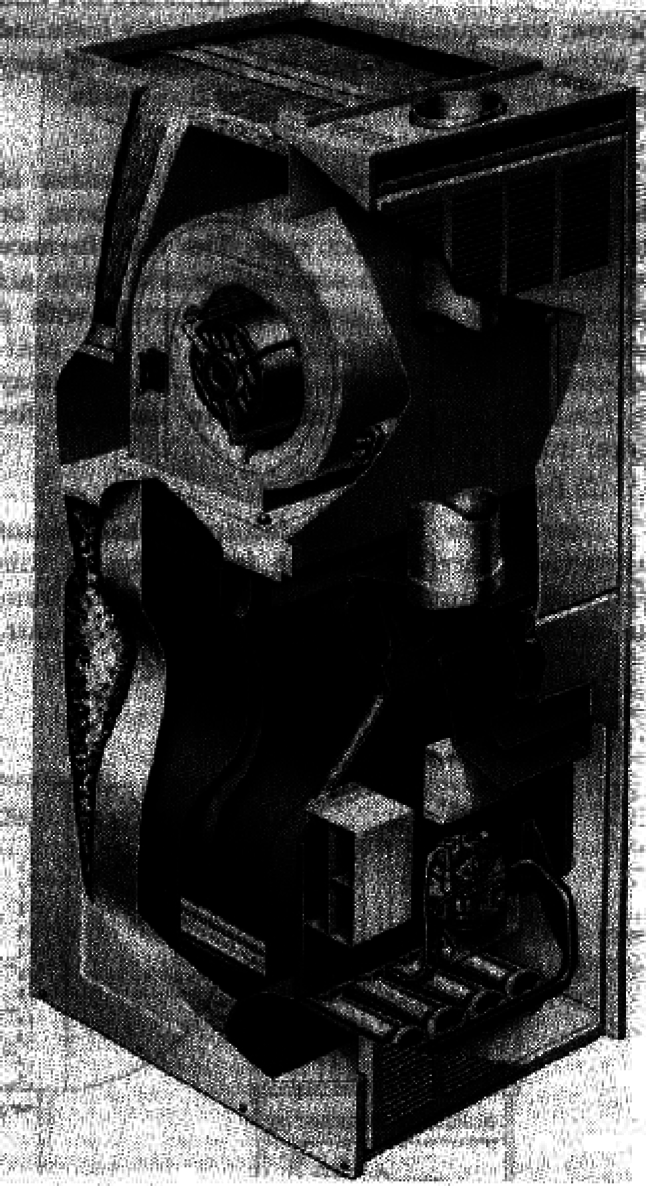

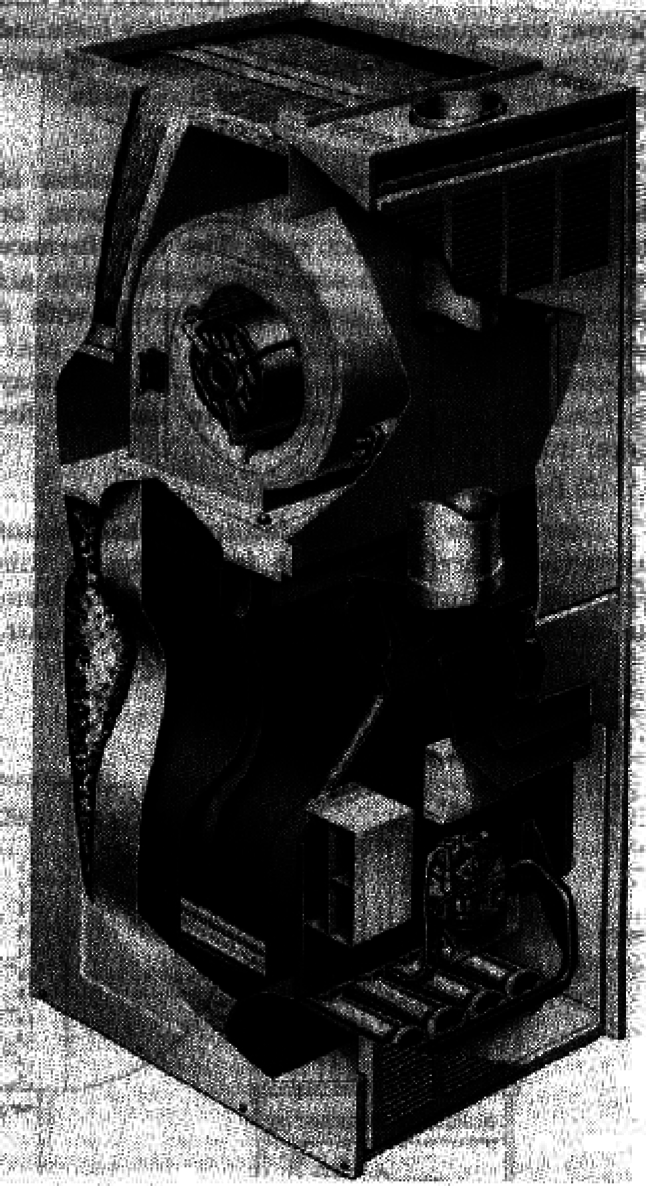

or “Hi-Boy” type with the combustion chamber

Gas fired warm air furnaces may be of the central

above the blower (figure 6-15), or they may be of

type with the blower mounted on the same level as

the duct or horizontal radiator type (figure 6-16).

the combustion chamber (figure 6-14), the elevated

6-12

TM 5-642

Figure 6-14. Gas fired central furnace.

6-13

TM 5-642

Figure 6-16. Duct type furnace.

Figure 6-15. Gas fired elevated upflow furnace.

6-14

TM 5-642

6-15.

Construction.

Air is directed through the blower and heat ex-

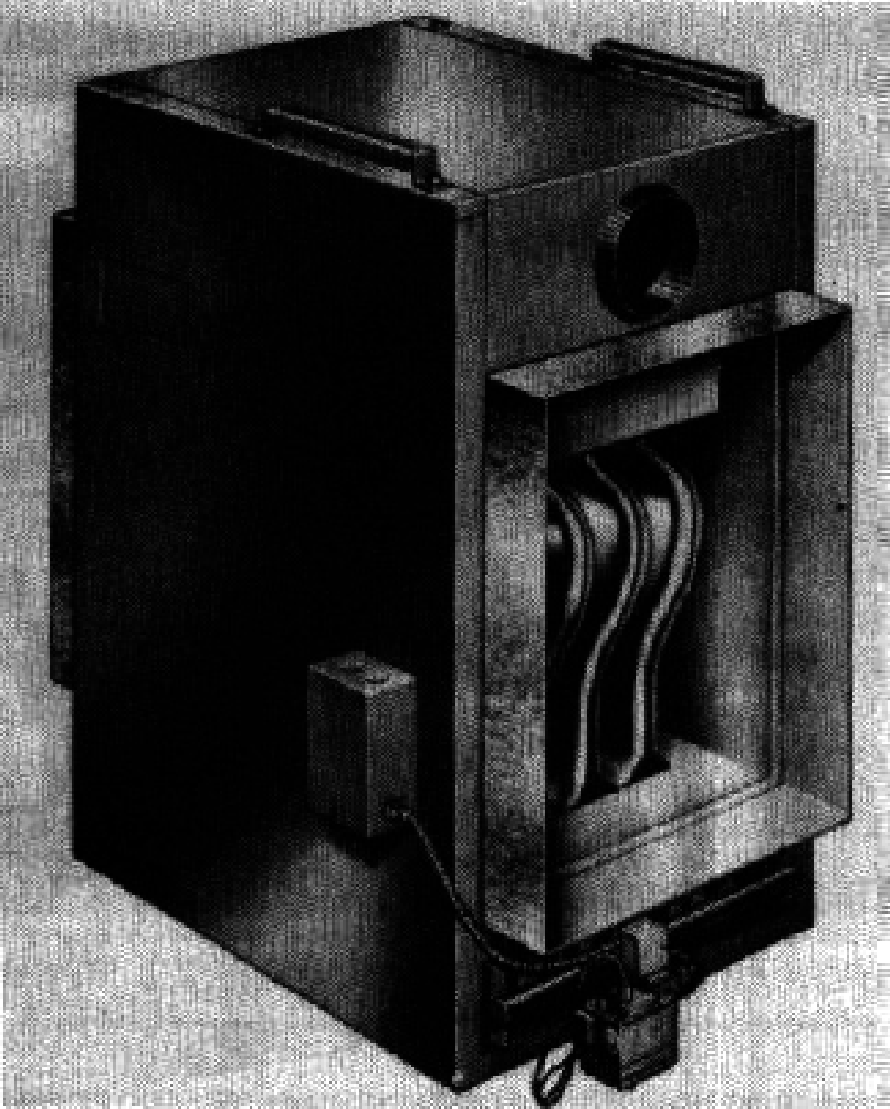

Gas fired warm air furnaces are made of cast iron

changer and is discharged at the bottom of the unit.

or steel. They are usually constructed with one or

These type units are typically used in underfloor air

more radiators or special radiating surfaces to

distribution systems. Figure 6-17 shows a typical

obtain maximum efficiency. They may be used in

downflow furnace.

either gravity or forced air installations.

6-16.

Furnace rating.

Always set the gas input rate consistent with the

manufacturer*s input rating; never exceed this

rating. Heat delivery at the bonnet drops approxi-

mately 5 percent for each 1000 feet of elevation

above sea level. Thus, if a furnace has a rating of

100,000 BTUH output at sea level, it will deliver

only 75,000 BTUH at an elevation of 5000 feet

above sea level. Furnaces must be sized consistent

with this rule when they are intended for use at

higher elevations.

6-17.

Central furnaces.

Central furnaces may be supplied with the controls

and downdraft diverter exposed, or one or both of

these may be enclosed in a single cabinet if