CHAPTER 4

STEAM HEATING SYSTEMS

4-1. General.

requires the generation of steam at maximum

A steam heating system consists of the following

efficiency and in sufficient quantity to equalize

elements: a steam source; supply piping to carry the

building heat losses, proper delivery of the steam to

steam from the source to the heating equipment;

the heating terminal, expelling entrapped air, and

heating equipment, such as radiators located in

returning all condensate, to the boiler rapidly.

areas to be heated; and return piping to carry the

Steam cannot enter a space filled with air or water

condensate from the heating equipment back to the

at a pressure equal to the steam pressure.

steam source. Steam heating systems are classified

Therefore, it is important to eliminate air and to

according to piping arrangement and method of

remove water from the distribution system. All hot

returning the condensate to the boiler. The

pipe lines exposed to contact by personnel must be

successful operation of a steam heating system

properly insulated or guarded.

Section I. DESCRIPTION OF SYSTEMS

4-2. General.

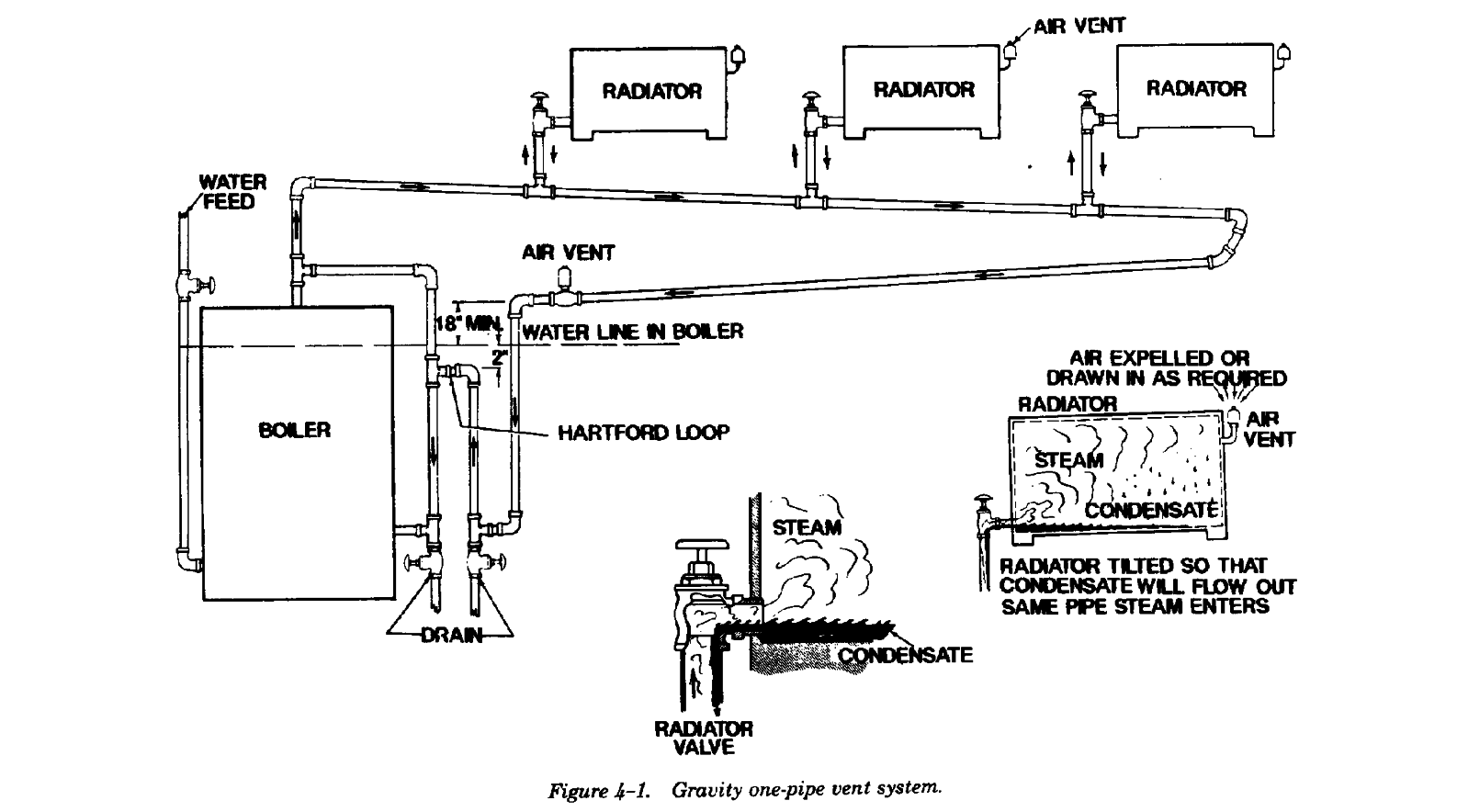

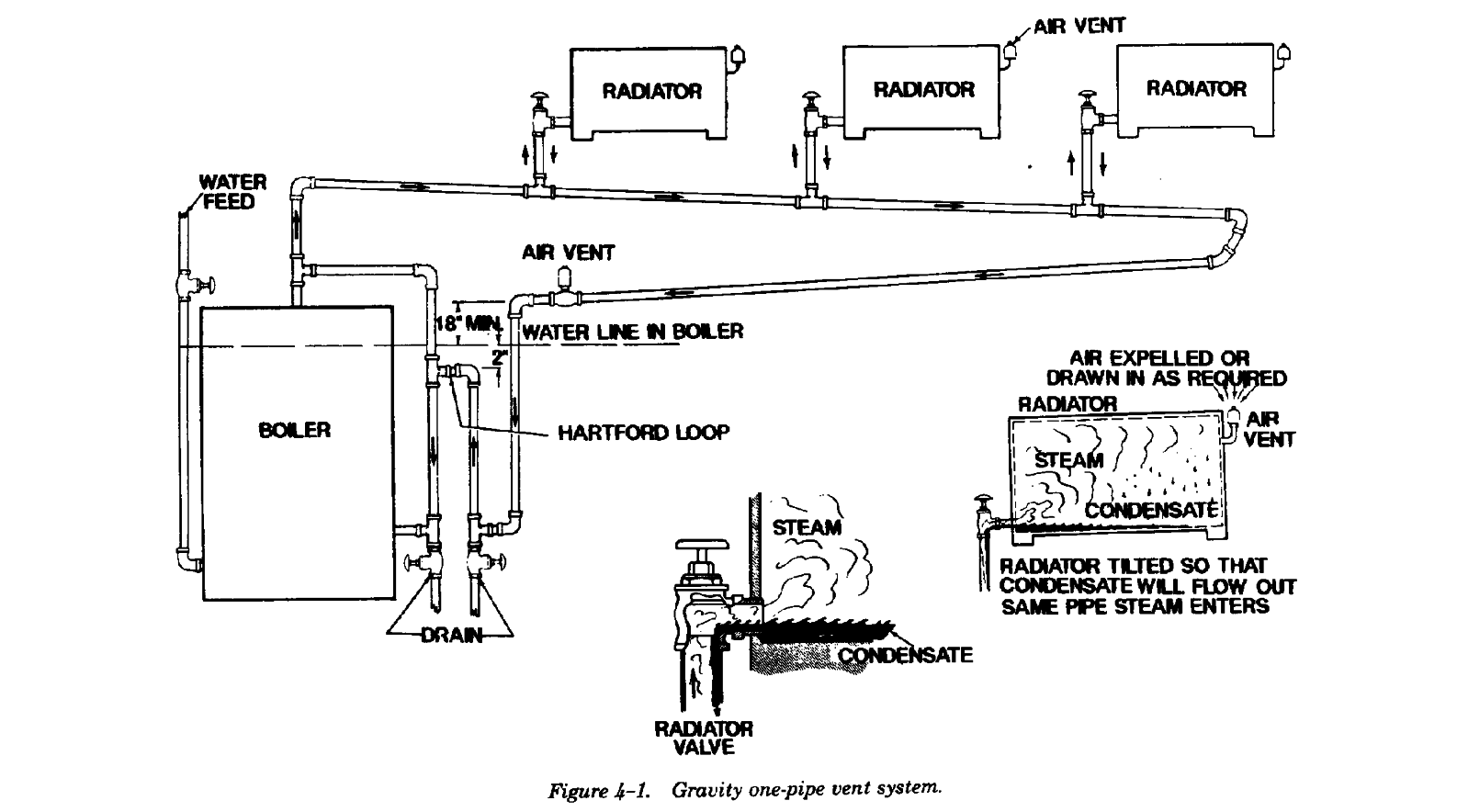

4-3. Gravity one-pipe air vent system.

Steam heating systems are classified according to

The gravity one-pipe air vent system was one of the

the method of returning the condensate to the

earliest types in use. Because the condensate is

boiler, whether by gravity or by mechanical means.

returned to the boiler by gravity, this system is

In the gravity system, the condensate is returned

usually confined to a single building. Steam is sup-

because of a static head of water in the return

plied by the boiler and is distributed through a

pipes. In this type of system all radiation must be

single piping system to radiators as shown in figure

above the boiler water line. In the mechanical

4-1. Return of the condensate is dependent on the

system, the condensate flows by gravity to a

hydrostatic head. Radiators are equipped with an

receiver and is then forced into the boiler under

inlet valve and an air valve. The air valve permits

pressure. The main difference between the

venting of air from the radiators and displacement

mechanical and the gravity systems is that radiation

by steam. Condensate is drained from the radiators

in the mechanical system can be located below the

through the same pipe which supplies steam.

boiler water line as long as there is a low spot to

which the condensate can be drained and from

which it can be pumped to the boiler, feed water

heater, or surge tank.

4-1

TM 5-642

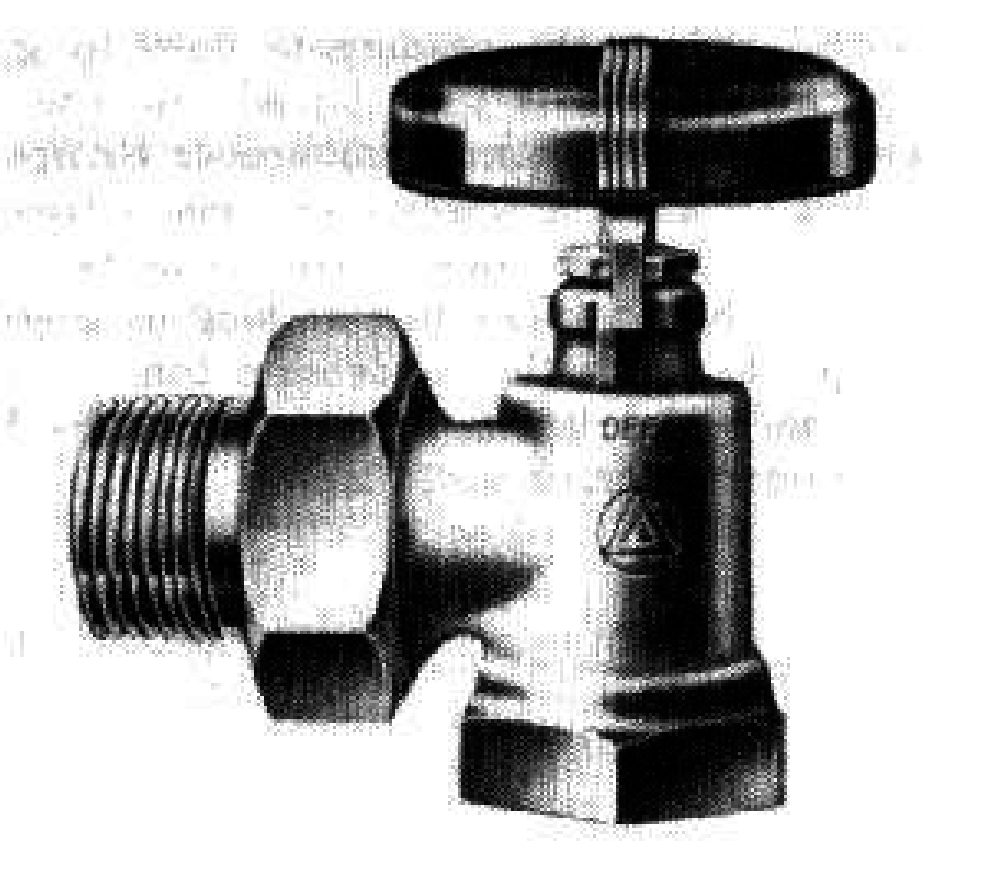

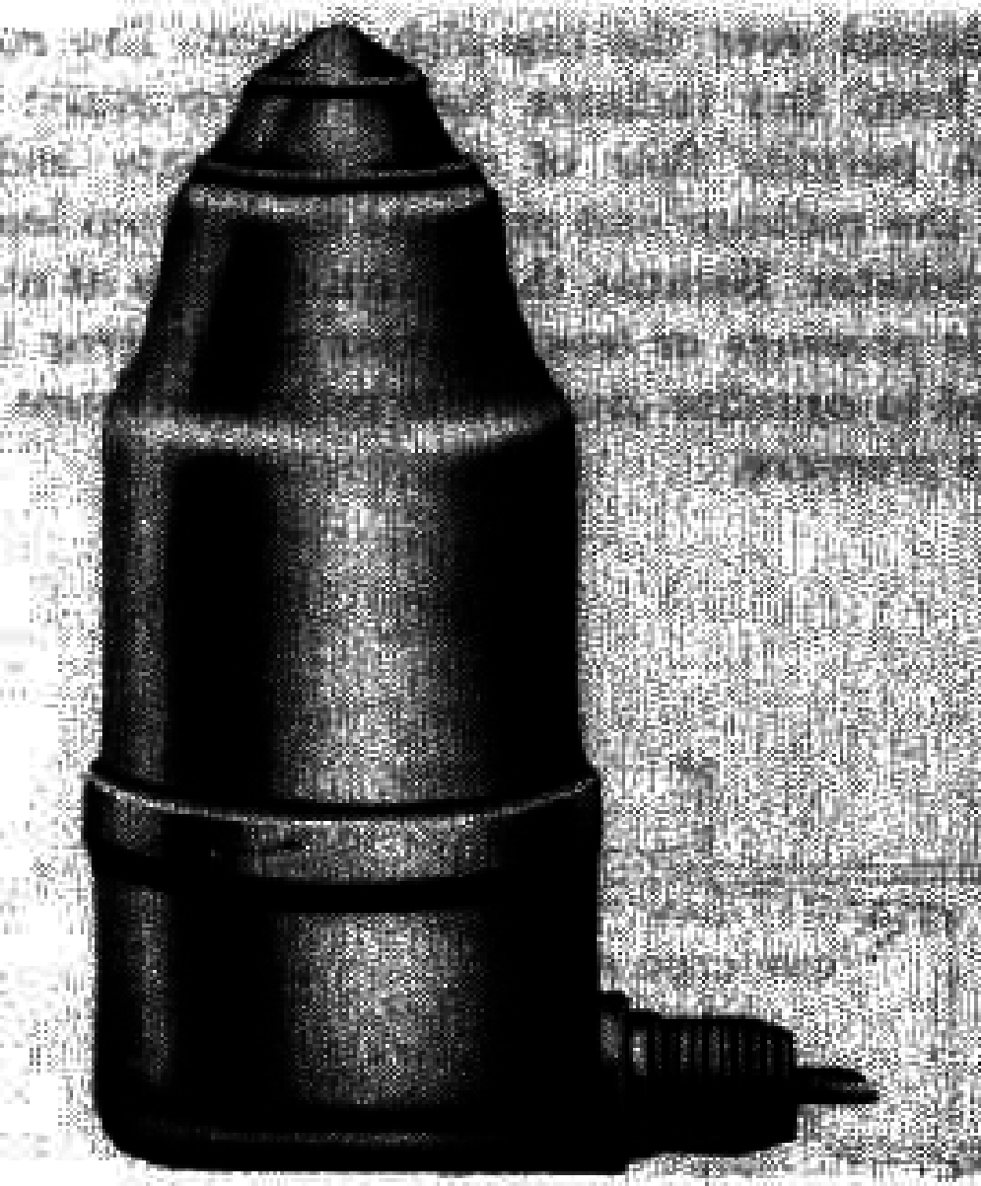

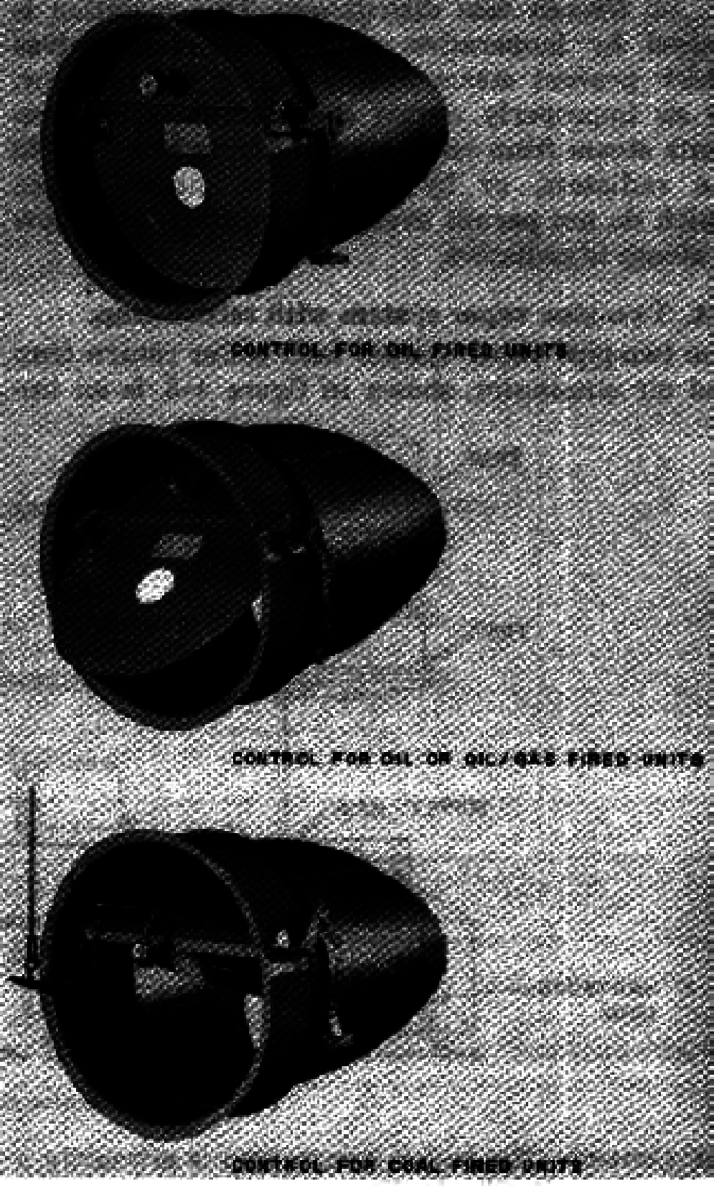

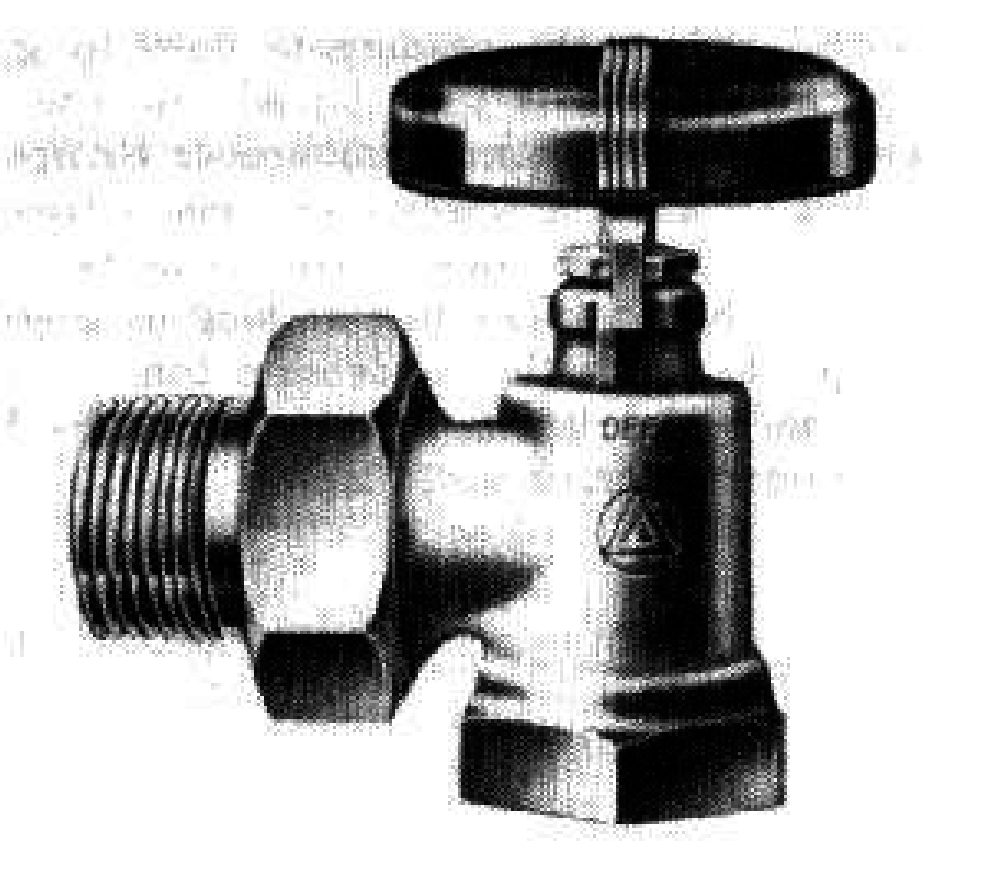

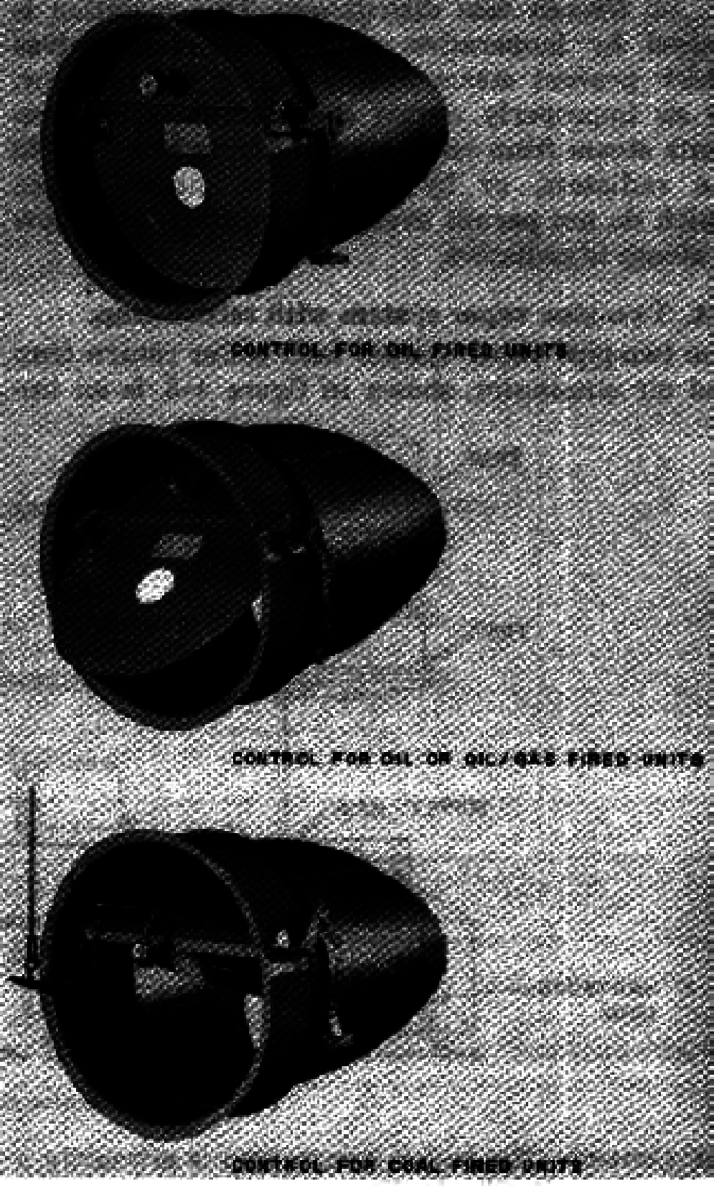

a. Controls. Appropriate controls for this system

include a barometric draft control for boiler pres-

sure control, or a pressure stat which controls a

motor which operates the damper. Direct control of

steam flow by use of mechanically operated steam

valves is generally avoided due to difficulties in

removing condensate after shut-off, and also due to

the usual fluctuating steam pressure and flow

characteristics of the gravity system. The gravity

distribution system includes the boiler, radiators,

piping, angle radiator valves of the on-off type as

shown in figure 4-2, automatic air vent as shown in

figure 4-3, and a barometric draft control as shown

in figure 4-4.

Figure 4-2. Angle radiator valve.

4-2

TM 5-642

Figure 4-3. Automatic air vent.

Figure 4-4. Barometric draft control.

b. Typical operating problems.

(1) Radiator heat failure. This is caused by air

binding as a result of plugged or defective air vents,

or by water logging due to insufficient radiator

pitch (toward valve) or to partially closed radiator

valves which permit trapping of condensate by the

partial vacuum created.

(2) Excessive noise. This is caused by air vent

failure and air binding of mains, insufficient radiator

pitch resulting in entrapment of water, plugged or

partially plugged wet return mains causing

condensate to back up into steam mains, or

improper pitch of mains and radiator branches.

(3) Fluctuating water line. This is caused by

excessive pressure drop in long mains and insuffi-

cient head between the end of the main and the

boiler water line to overcome the pressure drop.

Grease or oil in the boiler water will also cause a

fluctuating water line.

4-3

TM 5-642

(4) Uneven heat distribution. This condition is

provement over the one-pipe system. The return

caused by inoperative radiator air vent valves which

line from the radiator has a thermostatic trap which

prevent steam from entering the radiator, by an

permits flow of only condensate and air from the

improperly vented steam main which prevents

radiator and prevents steam from leaving the

steam from reaching the piping branches to the

radiator. Because the return main is at atmospheric

radiators, or by improperly pitched pipes which do

pressure or less, a boiler return trap is installed to

not permit even and uninterrupted flow of steam to

equalize condensate return pressure with boiler

radiators.

pressure.

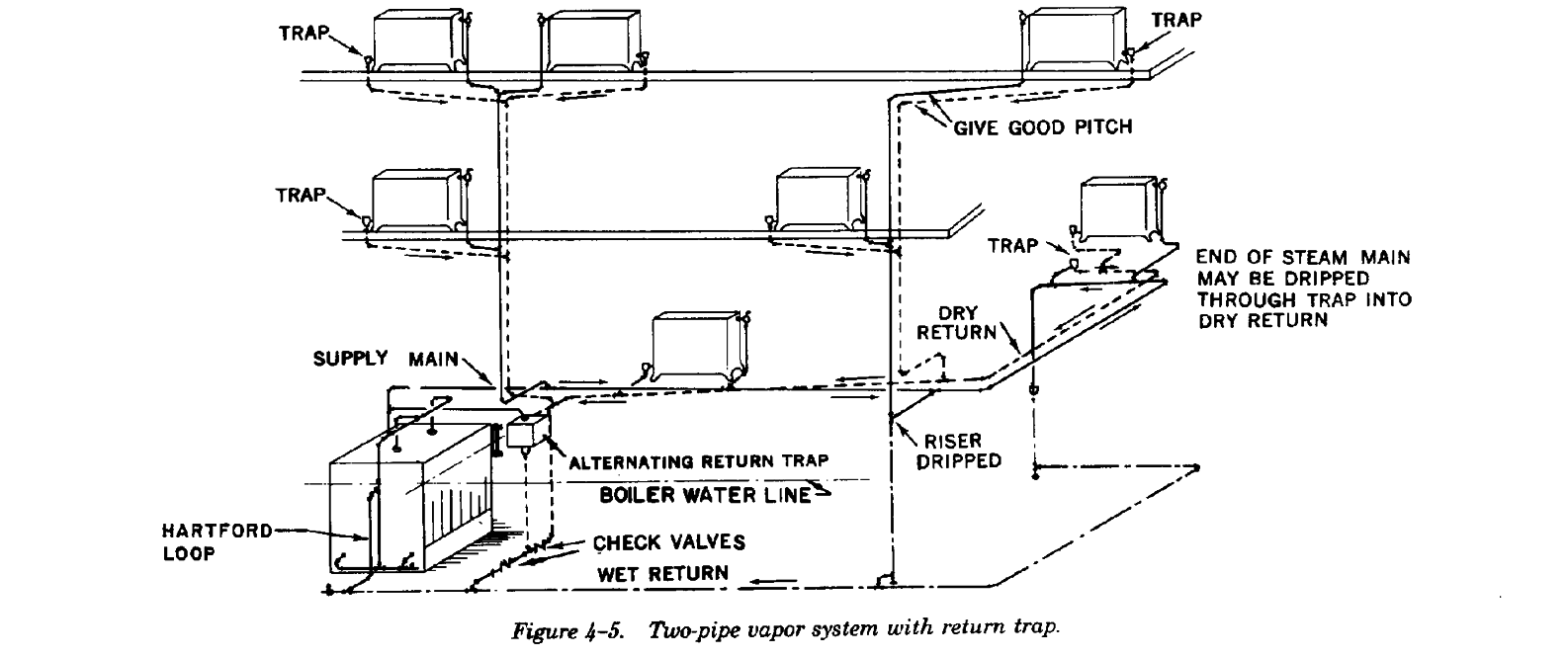

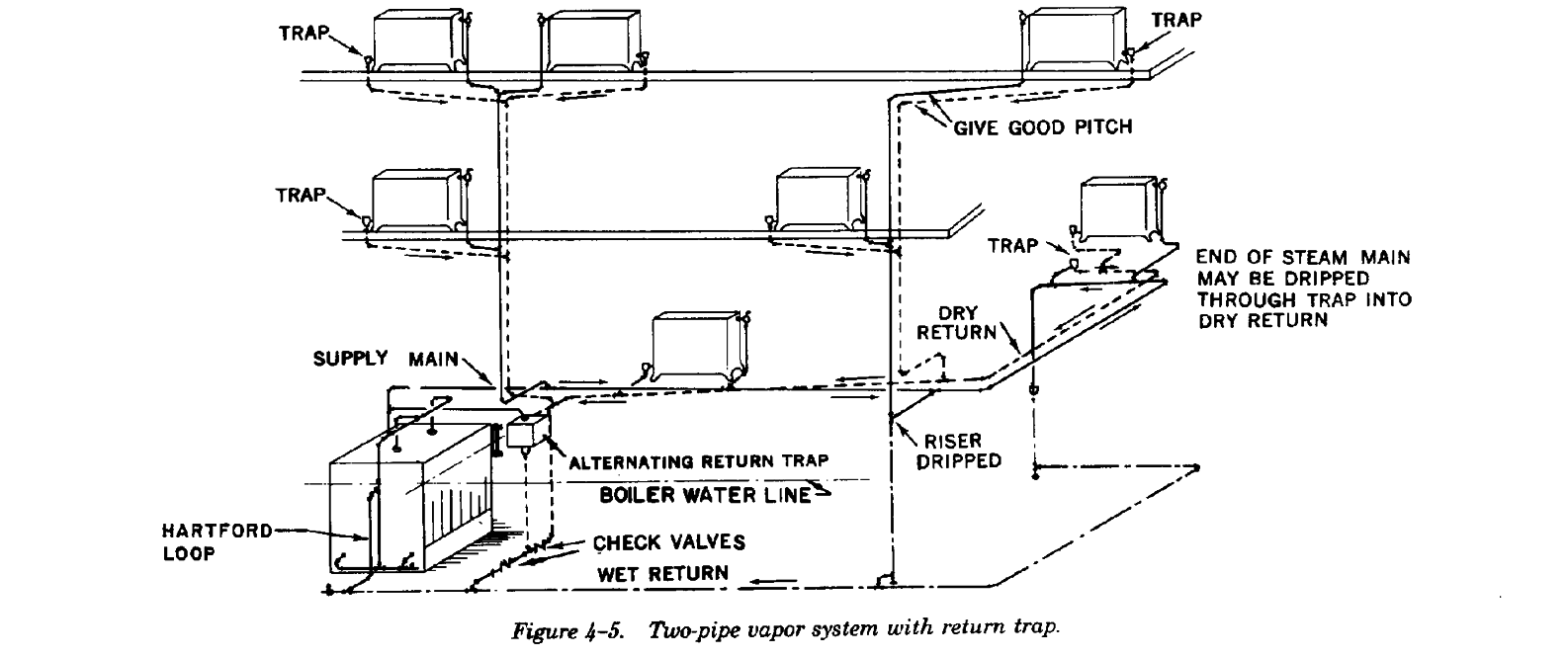

4-4. Two-pipe vapor system with return trap.

The two-pipe vapor system with boiler return trap

and air eliminator, shown in figure 4-5, is an im-

a. Controls. The boiler return trap is primarily a

usually air tight and can be operated at

double valved float mechanism which permits

subatmospheric pressures as low as 15 inches to 20

equalization of boiler pressure and pressure within

inches of water vacuum. This system is not used

the return trap. The boiler return trap is installed on

with unit heaters or blast coils which cause the

a vertical pipe in the return system adjacent to the

condensate to be returned in slugs and the rate to

boiler. The return trap has a valved steam

be variable. Appropriate controls for this type of

connection to the boiler header and a vent connec-

system are similar to those for gravity systems.

tion to an air eliminator. Condensate rises into the

b. Typical operating problems.

return trap when the boiler is under pressure; the

(1) Radiator heat failure. This is caused by

float-actuated vent valve is open during this part of

plugged or defective main air vents and by radiators

the cycle. When condensate reaches the trip level of

waterlogged due to insufficient radiator pitch

the trap, which is always below the bottom of the

toward return connection. Radiator heat failure is

dry return, the float actuated valves reverse. The

also caused by clogged radiator traps and center air

vent closes and the steam valve opens. This

binding due to steam entry from both the return and

equalizes pressure above the condensate in the float

supply ends if the trap is leaking because of failure

trap with that of the boiler and causes the

of the thermal element.

condensate in the trap to flow into the boiler. When

(2) System heat failure. This is caused by

low level is reached, the float actuated steam and

clogged or defective air eliminators or improper

vent valves again reverse. The steam valve closes

operation of return traps. Return traps must be set

and vent valve opens, relieves the pressure in the

level and have leveling tabs for proper installation.

trap, and again permits the condensate from the

Return trap floats usually actuate the valves

system to rise into the return trap. This system is

through a system of balanced weight arms which

4-4

TM 5-642

may develop incorrect adjustment. The two check

steam and the return flow of condensate equals the

valves at the base of the return trap must be in good

rate of steam generation. It is therefore necessary to

condition and the flow must be directed toward the

start a cold system with a slightly higher waterline

boiler. The air eliminator and vent valve mechanism

to provide for flow of condensate in the return

must be cleaned periodically to assure free action.

system and storage of condensate in the receiver.

The system may bind if excessive trap leakage

The high and low levels of the pump float valve

occurs.

setting should be set with adequate difference to

(3) Air eliminator failure. Water spurt from the

eliminate frequent pump cycling. The settings

air eliminator is caused by defective return trap

should, however, be close enough so that the

operation or by a clogged connection to boiler.

condensate discharge will not be large enough to

(4) Water line failure or fluctuation. This is

cause excessive changes in normal boiler water

caused by boiler pressure beyond the limit of the

level. Make-up water to this installation is supplied

trap, improper adjustment of the return trap, or

by manual feed or through automatic water feeders.

boiler water contaminated with oil or grease.

Automatic water feeders should be set at the

minimum safe boiler water level to eliminate

4-5. Two-pipe vapor system with condensate

unnecessary feed at low periods of the pump oper-

pump.

ating cycle. This pump control cycle is considered

The two-pipe vapor system with condensate pump

most satisfactory and results in little difficulty of

is similar to the two-pipe vapor system with air

operation.

eliminator return trap, except that the condensate is

(2) Waterline mounted float switch. With this

returned to the boiler by a power driven centrifugal

control method the float switch is mounted in a

pump instead of a return trap. The system includes

separate chamber with pipe connections above and

a separate main, radiators fed at the top, and a

below the boiler water line. Since the pump may

return system with thermostatically trapped outlets

start at periods when the pump receiver is not filled,

at the bottom of the radiators opposite the feed

a float controlled make-up water valve is connected

end. The return main terminates at the receiver of

to the pump receiver to maintain a minimum water

the condensate pump and all air in the system is

level in the receiver. This arrangement maintains a

vented through a vent on the receiver. With use of

water level which does not vary too much and

a condensate pump, all returns to the pump are dry

eliminates the lag of condensate feed described

and radiators may be located below the boiler water

above. Operating difficulties encountered with this

line; this is not possible in the systems previously

type of control usually more than offset the

described. Ends of steam mains are dripped and

advantages. The float switch located on the boiler

vented into the dry return main through

water line is a source of mechanical difficulty

combination float and thermostat (F&T) traps. The

because of its small operating level range. If the

two-pipe vapor system with condensate pump is

water line control is out of cycle with the

frequently adapted to relatively large installations,

condensate return from the system, considerable

particularly when unit heaters or blast coils are used

make-up is used and condensate is wasted through

and is probably the most practical and trouble free

the pump vent or overflow, unless there is surplus

system. In addition to the boiler pressure controls,

storage space in the receiver. The float operated

thermostatically controlled radiator valves or zone

receiver make-up valve is a source of unnecessary

control valves may be used, since the return system

make-up of raw water to the receiver. This pump

is considered to be at atmospheric or lower

control system is suited only for systems which do

pressure. This permits gravity flow of condensate

not return all of the condensate to the boiler. This

to the pump receiver.

would include isolated buildings for which return is

a. Controls. The condensate pump is normally

not practical or economical or installations where

controlled by a float activated switch located either

open steam jets are used, such as for dishwashers

in the condensate receiver or in a pipe located at

and steam tables.

the boiler waterline.

b. Typical operating problems.

(1) Receiver mounted float switch. When the

(1) Radiator heat failure. This is caused by in-

condensate from the system fills the receiver to a

operative traps or improper radiator pitch.

predetermined high level, the pump starts and, in

(2) System failure. This is caused by clogged or

turn, stops when a predetermined low level in the

closed air vents at the pump receiver, by flooding of

receiver is reached. Water between the two levels

the return due to improper cut-in of the pump or by

is discharged to the boiler. In this system, there is

lack of pump capacity. Steam or air binding of the

an initial lag in return of condensate. The boiler

system caused by leaking traps may also occur.

waterline lowers until the system has filled with

4-5

TM 5-642

(3) Overflow from receiver vent. This is caused

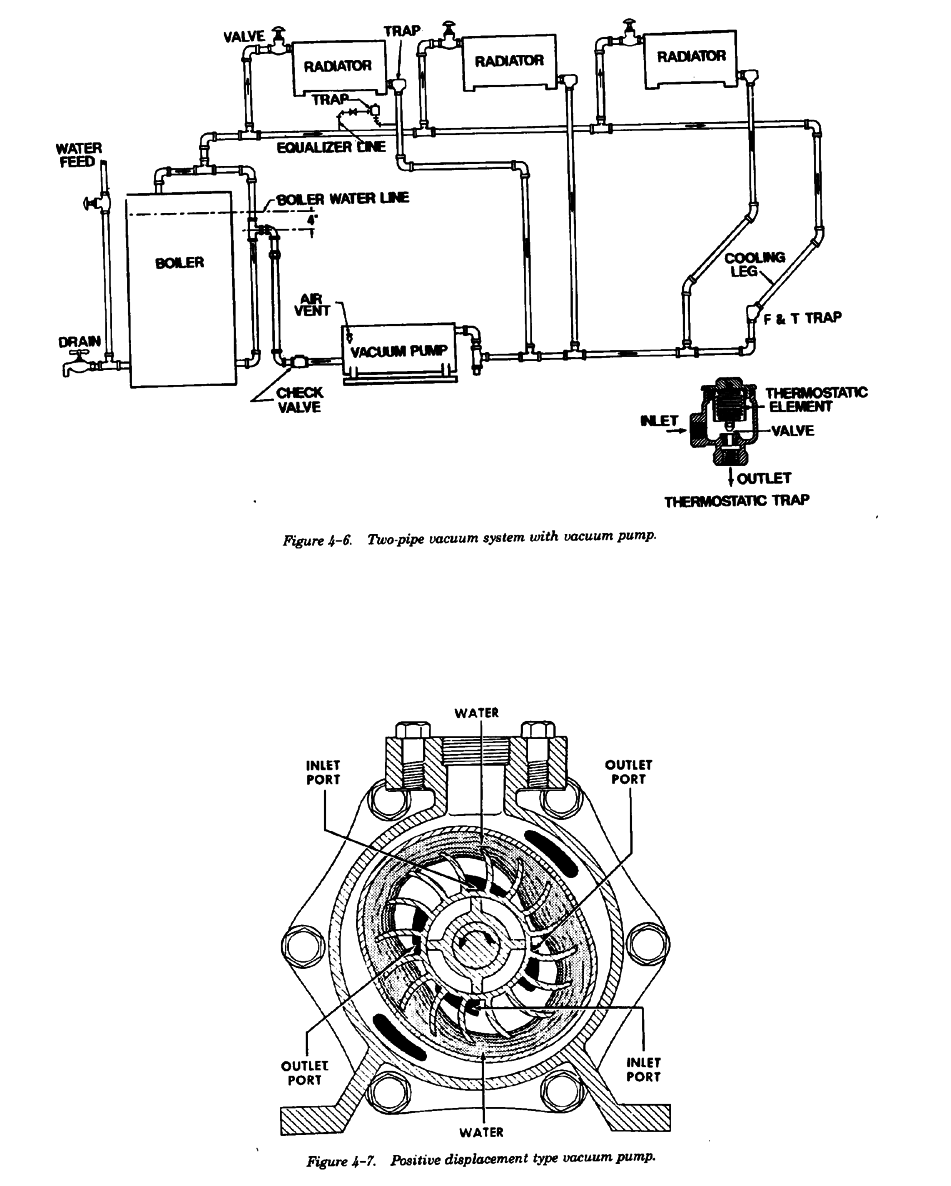

and air is discharged at the bottom of the opposite

by improper pump cut-in, inadequate pump capac-

end of the radiator through a thermostatic trap. All

ity, clogged discharge piping or failure of the check

returns are dry and terminate at the vacuum pump.

valve on the pump discharge pipe. Failure of the

The vacuum pump is usually motor driven,

check valve on the discharge side of the boiler feed

although low pressure steam turbines are

pump permits flow of the boiler water through the

sometimes used. The vacuum pump returns

pump and then to the receiver. The pump must then

condensate to the boiler and maintains a vacuum or

return the leakage to the boiler and this might be

sub-atmospheric pressure in the return system. The

beyond the capacity of the pump. Hot condensate

maintenance of a vacuum in the return system (3 to

or hot boiler water back-up may cause vapor lock

10 inches water gauge) enables almost

of centrifugal pumps and the pump will fail to

instantaneous filling of heating units at low steam

discharge to the boiler. Overflow will occur in

pressure (0 to 2 psig) since air removal is not

pumps in which float controlled make-up valves

dependent on steam pressure. This system is used

feeding the receiver are defective. This will cause

in all types of buildings and offers a definite

excessive make-up water feed and flooding of the

advantage for operation of indirect radiation units,

system.

heating coils and ventilating units, and for other

(4) Air returning to receiver tank and heating

units for which close automatic control is required.

system. It is advisable to provide a ball check or a

Quick filling of steam elements for this system is

vacuum vent for the air vent from the receiving

obtained since steam spaces are under vacuum

tank. This type of vent permits discharge of air

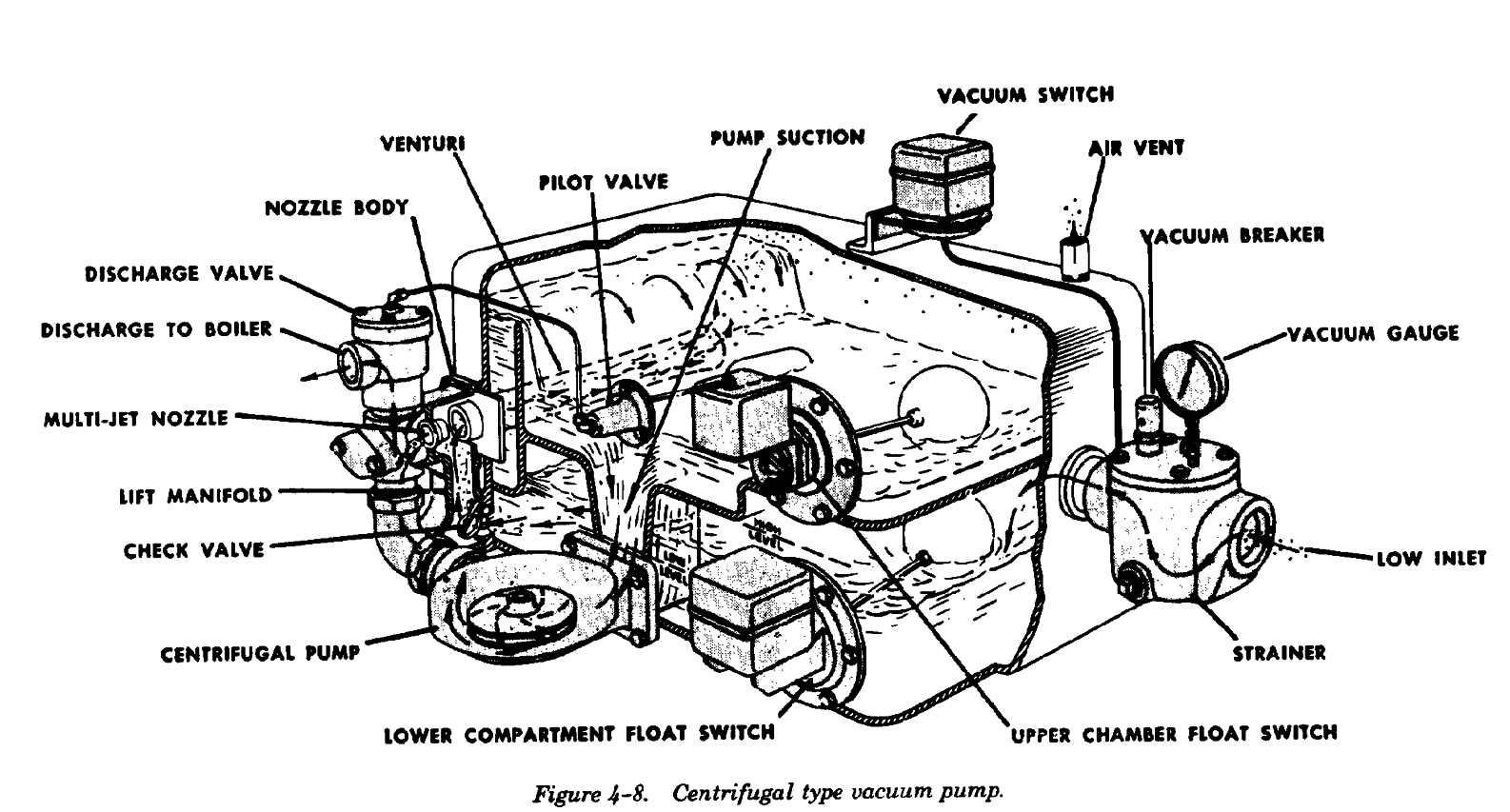

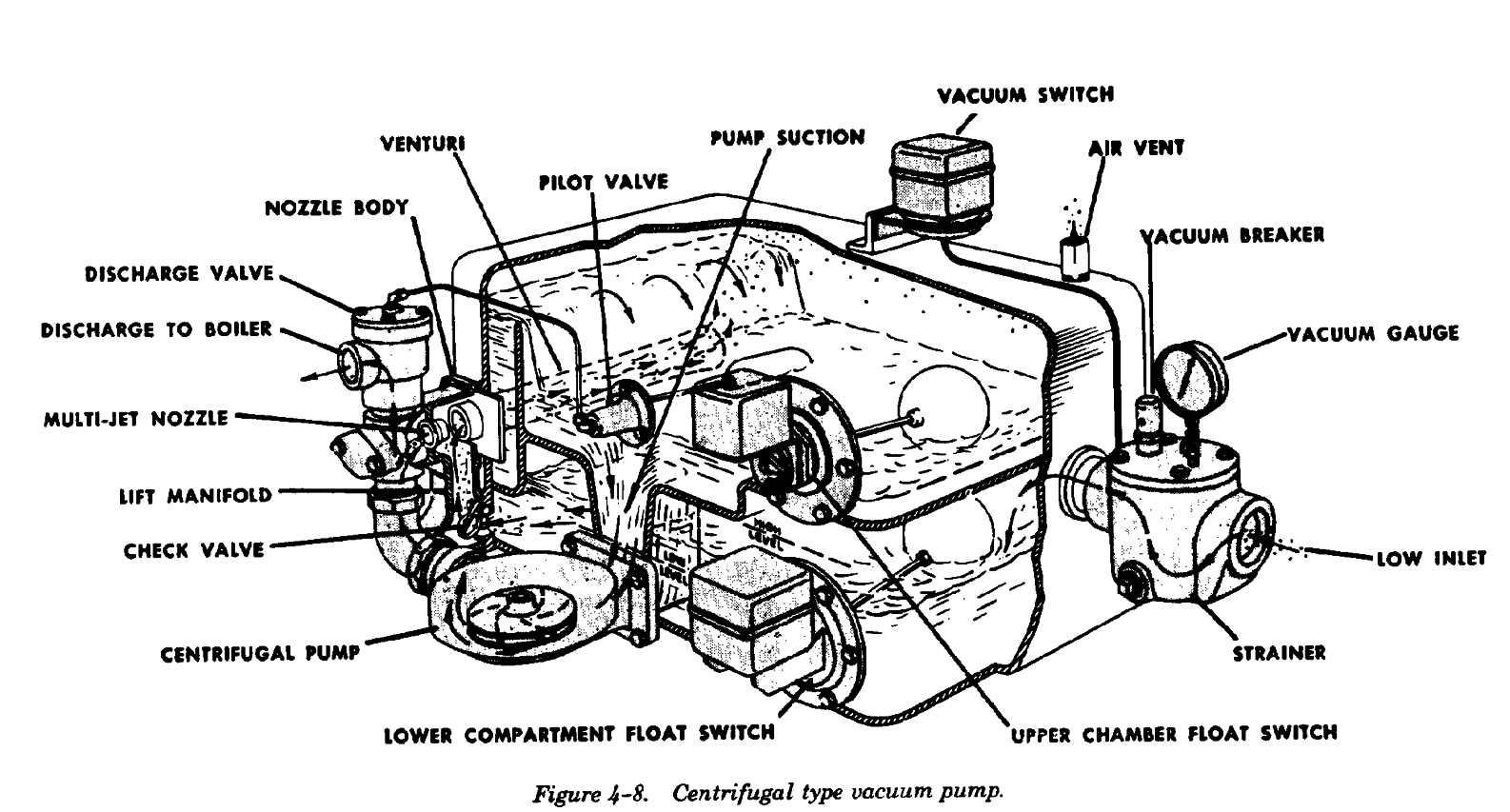

during periods of shut-off. Vacuum pumps are two

from the system and prevents return of air to the

general designs, positive displacement and centrif-

receiving tank and heating system. A vacuum of

ugal type. These are shown in figures 4-7 and 4-8.

from 1 to 5 inches water gauge can be created if the

Both types have a centifugal pump to return water

system is tight.

to the boiler. The vacuum pump withdraws air and

water from the system, separates air from water,

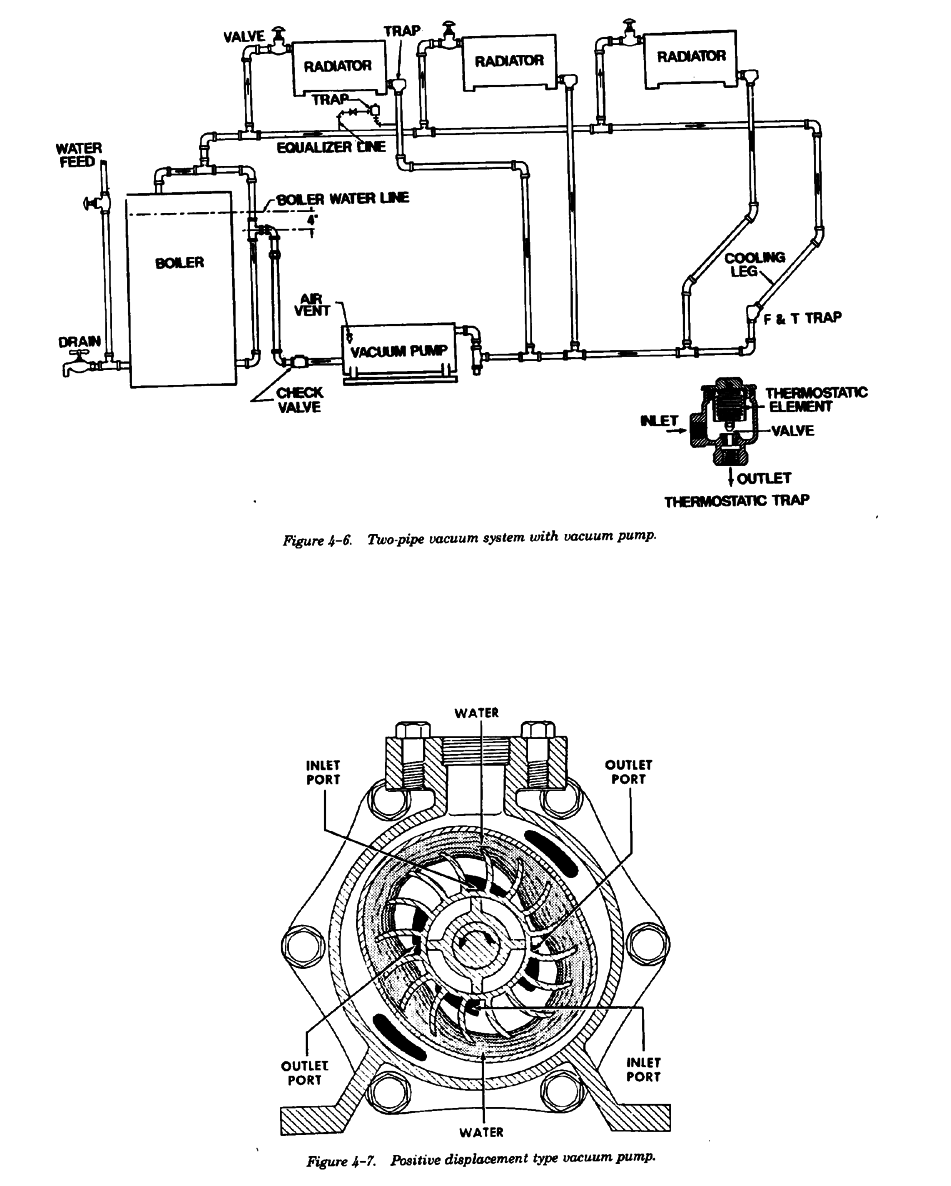

4-6. Two-pipe vacuum system with vacuum

expels air to the atmosphere and pumps water back

pump.

to the boiler. Usually the vacuum pump is equipped

The two-pipe vacuum system with vacuum pump

with a float switch as well as a vacuum switch and

shown in figure 4-6 is similar to the two-pipe vapor

can be operated as a condensate pump unit. The

system with condensate pump. The piping system

float switch should be used only when the vacuum

includes separate steam and return mains. Steam is

system is defective and then only until defects can

supplied at the top of the radiators and condensate

be repaired or corrected.

4-6

TM 5-642

4-7

TM 5-642

a. Controls. Controls for vacuum type heating

(2) System failure. This occurs when the

systems include boiler pressure control, vacuum

vacuum pump fails to clear the system of air. The

and float control for the pump, and may include

system may also fail because mains are improperly

appropriate types of thermostatic or pressure con-

pitched or trap failures allow excessive steam leak-

trolled shut-off or modulating valves for control of

age or water logging of steam mains.

heating elements.

(3) Overflow from pump vent. This occurs be

b. Typical operating problems.

cause of inadequate pump capacity; defective

(1) Radiator heat failure. This is due to defec-

valves, jets, or pump clearances; or stoppage in the

tive or clogged thermostatic traps or improper ra-

pump discharge connection to the boiler.

diator pitch.

Section II. BOILER TYPES

4-7. Cast iron boilers.

supply steam header is at the top center of the

In general, cast iron boilers are shipped in sections

boiler; the return headers are located laterally near

and assembled at the installation site. Small boilers,

the foundation. Heated water rises through the

however, are factory assembled and shipped as a

vertical sections from the return water headers, and

unit. Cast iron boilers are usually referred to as

steam is taken from the supply steam header at the

sectional boilers. Figure 4-9 shows a sectional cast

top of the unit. Cast iron boilers usually range in

iron steam boiler commonly used in steam heating

capacity from two boiler horsepower (1 boiler

systems. The unit shown is an independent header

horsepower equals 33,500 BTU/hr) up to 100

type, in which each section is actually an individual

boiler horsepower.

boiler connected to supply and return headers. The

4-8

TM 5-642

Figure 4-9. Sectional cast iron steam boiler.

a. Initial operation and cleaning

(d) Check for air leaks, particularly at the

(1) Checking. Prior to start up after a pro-

joint between sections and the base and between

longed shutdown, the complete installation should

the base and foundation.

be carefully checked. Follow the steps described

(e) Be sure that the make-up water and

below:

supply water piping is in good operating condition,

(a) Examine the combustion chamber and gas

condensate return equipment is properly connected,

passes; determine that all debris has been removed,

and that electrical connections are complete and

and check burners or grates, if applicable, for

properly fused.

proper operation.

(f) Determine the correct normal and low

(b) Check steam and return header-valves,

water levels. If the levels are not marked, place

gauge glass valves, and stop cocks for proper

permanent markings at suitable locations on the

action.

front of the boiler adjacent to the gauge glass or on

(c) Check the damper regulator and connec-

the frame work of the gauge glass. Manufacturer*s

tions (coal fired systems) and check draft dampers

literature should be used to determine the proper

for proper action.

water level.

4-9

TM 5-642

(2) Initial filling. Remove the pop-safety valve

radiators is accomplished in steps as suggested, the

and make a valved overflow pipe connection be-

boiler load will be relatively low and manual

tween the safety valve opening and a floor drain or

maintenance of the water line simplified. Open the

ground outside boiler room. Open the overflow

drain caps in the mains during this clean-out

valve and petcocks at the water line, then fill the

process, if convenient.

boiler until water overflows through the temporary

(g) A steam heating boiler and piping system

overflow. Close the water connections valve and

will not operate satisfactorily if oil or other

impurities are present in the system. Proper internal

open the drain allowing all water to run out of the

clean-out of the boiler and piping eliminates

boiler. Refill the boiler to the correct water level

unnecessary operating difficulties later. Do not

plus approximately two inches, then close the

connect the return system to the boiler until the

petcocks and remove the t