without shaft binding, the packing should be re-

enough to close the float switch.

placed. Provide proper drains from pump bases.

(9) Be sure all guards are in place before start-

(2) Packing replacement. Occasionally packing

ing the unit.

will require replacement because of normal wear or

b. After starting.

improper gland adjustment which causes drying or

(1) On low pressure units, adjust the vent pet-

burning. Use only soft, square, packing of proper

cock so that it is open just sufficiently to allow

size. Cut packing into rings which will fit snugly

escape of steam and air as rapidly as condensate

around shaft with ends just meeting. Be sure the

flows into the receiver.

ends are square. Remove gland nuts, take out gland

(2) See that motor rotates in proper direction.

halves and pick out old rings of packing. Clean the

(3) See that all pipe connections are tight.

shaft and packing box of dirt or sediment and insert

(4) See that the float switch starts and stops the

packing rings, pushing each succeeding ring back

pump at desired levels of water in the receiver.

into place. Stagger packing ring joint ends to

(5) See that the motor picks up speed quickly

ensure a good seal. Reinstall gland halves, bolts,

and maintains a constant rotation rate. If motor is

and nuts, and be sure that gland followers enter the

brush type, see that it does not spark profusely.

packing box to a depth of at least ‘/8 inch. Adjust

(6) Check the packing-gland adjustment.

the glands.

(7) Observe operation of the unit closely for 3

c. Shutting down. When shutting the pump unit

hours after starting and at regular intervals there-

down for any considerable period, open the motor

after. A new, properly operating pumping unit

disconnect switch. Drain the unit by removing drain

should be carefully watched to note its initial per-

plugs at the bottom of the receiver tank and pump

formance, for later comparison checks. Consult

casing until all water drains out. Never expose the

manufacturer*s instructions.

pump unit to freezing temperatures when filled with

water. Cover the motor and switches to protect

4-22.

Maintenance.

them against dust and moisture.

a. General.

d. Pump lubrication. Keep a regular lubrication

(1) At regular intervals lubricate the pump and

schedule and avoid both over and under lubrication.

motor as specified in lubrication instructions.

When oil lubrication is used, a good grade neutral,

(2) Maintain proper adjustment of the packing

medium viscosity, mineral oil is satisfactory. Grease

glands and change packing when deteriorated.

lubrication requires more careful lubricant selection,

(3) Keep the inside and outside of the motor

because there are a great many products from

and controls free of moisture, oil and dirt. If neces-

which to choose. The important factors in choice of

sary blow out their interiors with a bellows. If

grease for a pump are: its resistance to water,

switch contacts become corroded or pitted they

determined by the soap-base used in its

should be smooth and treated with a contact pre-

manufacture; and its consistency as related to

server or replaced. If the motor is of the brush type,

operating temperature and method of application.

replace the brushes when necessary.

Lime-soap-base greases are relatively insoluble and

(4) Wearing parts on centrifugal pumps, such as

non-emulsifying and should be used where water

bearings and wearing rings, are readily accessible.

may come in contact with the bearing. The higher

To get peak performance, check these parts at

the operating temperature, the heavier the grease

intervals depending upon severity of service, and

should be. Use only ball bearing lubricants for

replace worn parts if necessary.

grease lubricated ball bearings; never use graphite.

(5) To ensure the best operation of the unit

Lubricate the motor according to directions on the

make a systematic inspection periodically.

motor instruction sheet.

b. Packing boxes.

(1) Gland adjustment. Adjust packing glands so

4-23.

Typical operating difficulties.

there is a weep or slight leakage of water around

a. Pump fails to operate.

the shaft when the pump is operating. This is

(1) Fuse blown or thermal unit is tripped or

necessary for cooling and lubrication, and keeps

loose.

the packing in good condition. To adjust glands,

4-20

TM 5-642

(2) Shaft binding, or impeller blocked.

4-24.

Steam pressure pumping systems.

(3) Switch contacts corroded or shorted, or ter-

a. General. This type of condensate handling

minal connections broken somewhere in circuit.

system is an energy saving, highly efficient way to

(4) Float control mechanism not functioning or

pump or lift liquids in many types of operations. It

float waterlogged.

is particularly suited for effectively handling con-

(5) Wiring hookup or electrical service provid-

densate from all types of heating and processing

ed is incorrect, or switches are not set for oper-

equipment. Instead of using motor driven pumps,

ation.

this system uses steam or other gases under pres-

(6) Motor is grounded or burnt, or brushes,

sure as the motive force. Unlike conventional con-

when present, are stuck or worn.

densate pumps, a steam powered pump can handle

(7) Electrical service or phase failure.

temperatures over 185 EF without the need for

(8) Receiver vent is not open.

venting or cooling. It requires no high maintenace

b. Fuses blown or thermal units trip.

stuffing boxes, motors or starters. It contains no

(1) Fuse rating used is incorrect.

revolving shafts and utilizes a minimum of moving

(2) Shaft is stuck or not rotating freely.

parts.

(3) Loose connection somewhere in circuit.

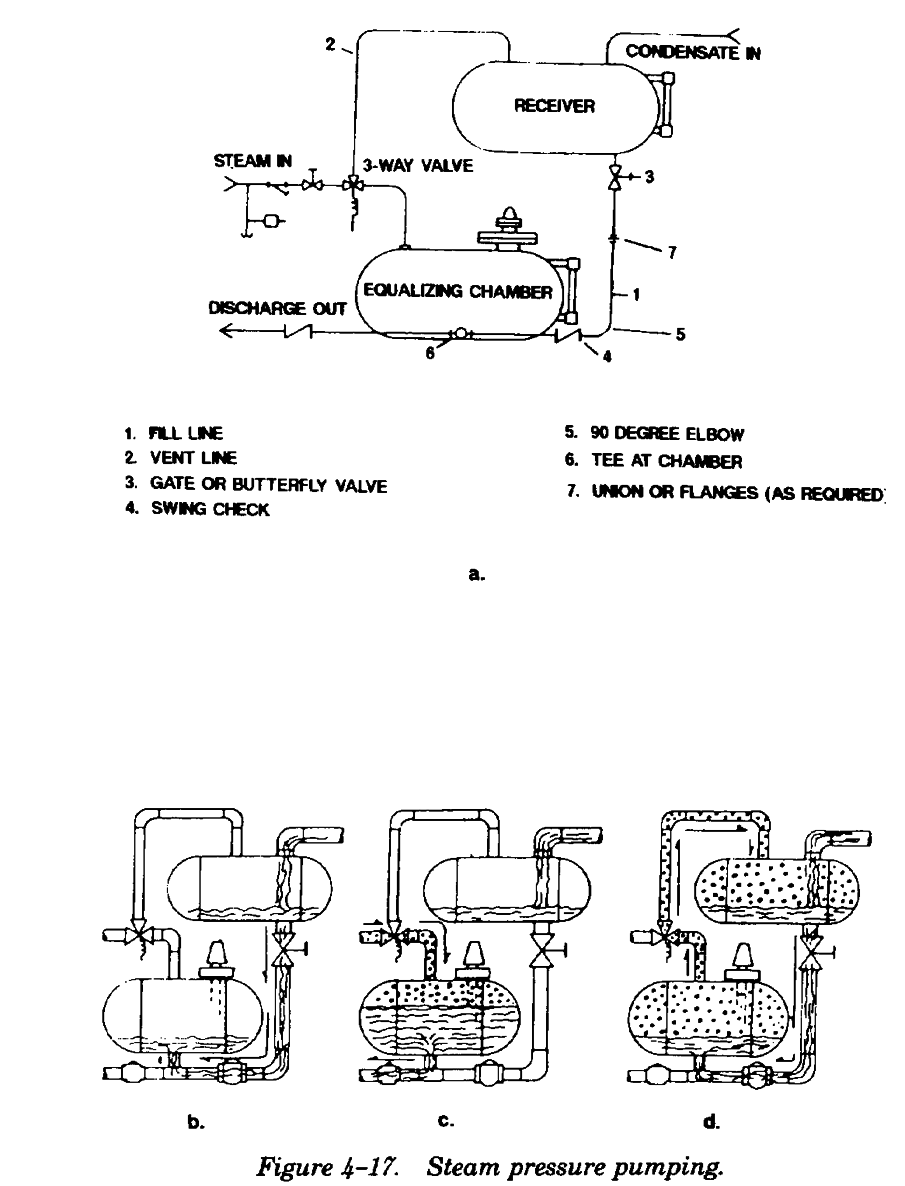

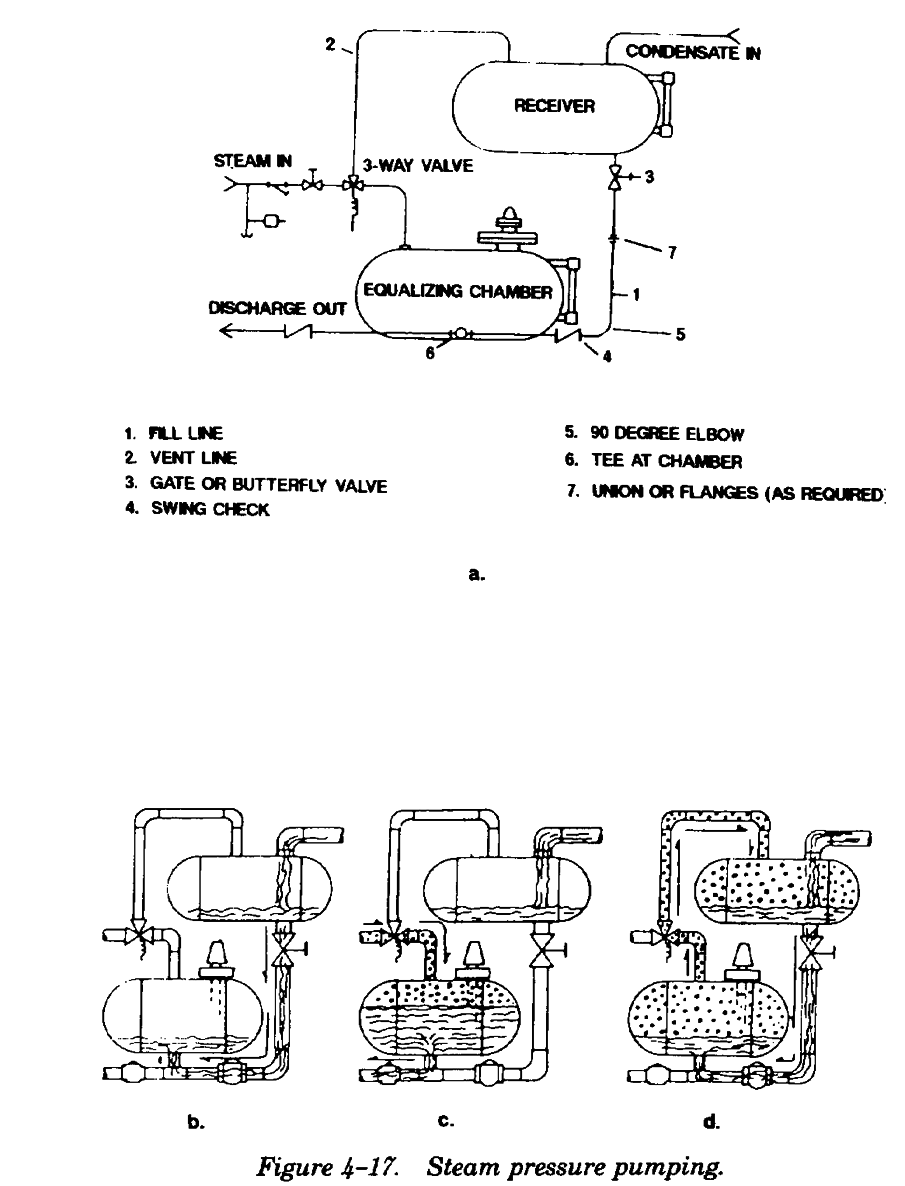

b. Operation. Figure 4-17 shows the operating

(4) Controls are worn or arcing.

cycle for one type of steam powered pumping

(5) Motor is grounded or partially burnt out.

system. Condensate from the equipment being

(6) Brushes, when present, are sparking pro-

drained enters the receiver tank and flows down the

fusely or sticking. Commutator is scored or brushes

fill line into the equalizing chamber (figure 4-

worn.

17(1)). When a predetermined high level is reached

(7) Motor is overloading.

in the equalization chamber, the level control

(8) Fuse or thermal unit location is too hot if

system sends out a signal which causes the 3-way

placed near boiler or flue.

valve to cycle. When this valve cycles, the vent line

(9) Short circuit in wiring.

is closed off and high pressure steam is admitted to

c. Pump runs continuously.

the equalization chamber. This steam pressure is

(1) Float is stuck in raised position.

confined above the condensate in the chamber and

(2) Float switch adjustment is improper.

its effect is to move the condensate out of the

(3) Switch contacts are burnt closed.

chamber and into the discharge line. When the

(4) Pump is “steam bound” due to very high

condensate reaches a predetermined low level, the

water temperature.

level control system sends another signal causing

(5) Discharge head is higher than anticipated.

the 3-way valve to revert to its original position.

(6) Motor speed is too slow or voltage low.

Residual steam remaining in the equalizing chamber

(7) Pump is defective or capacity too small.

will flow through the vent line into the receiver

(8) Receiver is dirty. Pump suction clogged.

enabling the pressures in the two tanks to equalize

(9) Vacuum in receiver is reducing discharge

with each other. When this is completed, flow of

head on pump. See that vent is open.

condensate from the receiver tank to the equalizing

d. Pump operates at slow or variable speed.

chamber will start again. The cycle then repeats

(1) Switch contacts are arcing.

itself.

(2) Loose connection in electric circuit.

(3) Low voltage, or phase failure in polyphase

electrical service.

(4) Motor is partially burnt or grounded.

(5) Motor brushes, when present, are worn,

stuck, or spring tension is weak. Commutator may

be corroded.

(6) Clutch is defective in single phase repulsion

induction motor.

(7) If shaft is binding, check for improper gland

adjustment, impeller rubbing, impeller clogged, or

a bent shaft.

4-21

TM 5-642

once the condensate reaches the predetermined

high level of the equalizing chamber. At this

moment the level control device sends a signal

causing the 3-way valve to actuate. This signal can

be electrical or pneumatic. When the 3-way valve

actuates, it closes its normally open port in the vent

line and opens its normally closed port in the steam

line.

(2) Equalization and discharge cycle. The

steam flow through the 3-way valve enters the

equalizing chamber at a point above the condensate

(figure 4-17(3)). The initial pressure in the tank

immediately begins to increase. Until tank pressure

exceeds discharge line pressure no condensate will

be discharged. This period is called the equalization

cycle and represents a small fraction of the

discharge cycle. As the tank pressure increases

above discharge line pressure, condensate flow

starts and will continue until the predetermined low

level is reached. At this time the level control

device sends a signal which allows the 3-way valve

to revert to its original position.

(3) Vent cycle. Several events take place during

the vent cycle (figure 4-17(4)). In its closed

position, the 3-way valve prevents high pressure

steam from entering the equalizing chamber, but its

normally open port will allow the steam used for

discharge to flow into the receiver through the vent

line. Until this steam pressure is equalized with the

receiver, no condensate flow will occur between the

two tanks because the residual pressure keeps the

fill line swing check closed. Condensate entering

(1) Fill cycle. When condensate from equip-

the receiver during discharge and vent cycles

ment being drained enters the receiver, it will also

remains in the receiver until the next fill cycle

enter the fill line connecting the two tanks (figure

begins.

4-17(2)). Since the 3-way valve is not energized, its

c. Troubleshooting. As with any troubleshooting

normally open port will allow both tanks to be

procedure, care should be exercised when disas-

pressure equalized through the vent connection.

sembling a pipe line, valve or other pressure fit-

Therefore, the flow of condensate is by gravity

tings. Steam and condensate lines should be valved

head only. Typically, gravity head is 1 to 3 psi.

off and initial inspection should be made to ensure

Therefore, it is important that friction losses be

that no residual pressure remains in the valved off

minimized. While filling is taking place there is no

section(s). This same care should be followed when

steam flow through the 3-way valve and no con-

working with the electrical components. A trouble-

densate flow into the discharge line. The check

shooting guide for steam pressure powered pump-

valve in the discharge line prevents back flow into

ing systems is in appendix C.

the equalizing chamber. The fill cycle is complete

Section VI. VACUUM PUMPS

4-25.

General.

complete with a receiver, separating tank, and

a. The usual vacuum pump unit consists of a

automatic controls mounted as an integrated unit

vacuum section which withdraws the air-vapor

on one base. There are also special steam turbine

mixture and discharges air to the atmosphere, and

driven units which are operated from the heating

a water removal unit which discharges condensate

system steam supply. Under special conditions such

to the boiler. The vacuum pump unit is furnished

as an installation where it is necessary to return

condensate to a high pressure boiler, auxiliary

4-22

TM 5-642

water pumps are supplied. In some instances

should drain to a receiver or flash tank through a

separate air and water pumps are used.

high pressure trap. The receiver should have an

b. For rating purposes, vacuum pumps are clas-

equalizing connection to a low pressure steam main

sified as low and high vacuum. Low vacuum pumps

and drain through a low pressure trap to the

are those rated for maintaining less than 5½ inches

vacuum return main.

of mercury vacuum in the system and high vacuum

pumps are those rated to maintain vacuum at or

4-26.

Installation.

above 5½ inches.

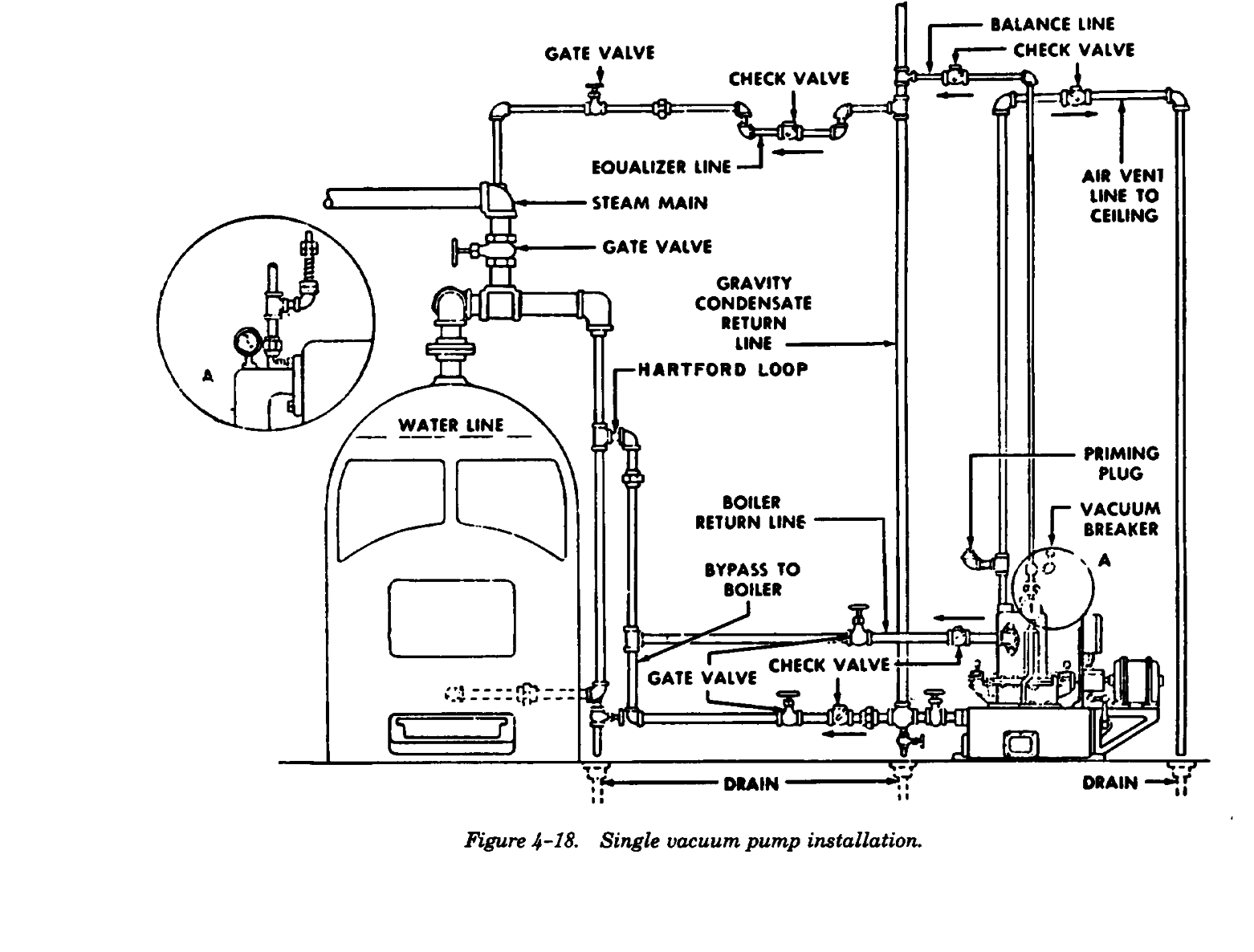

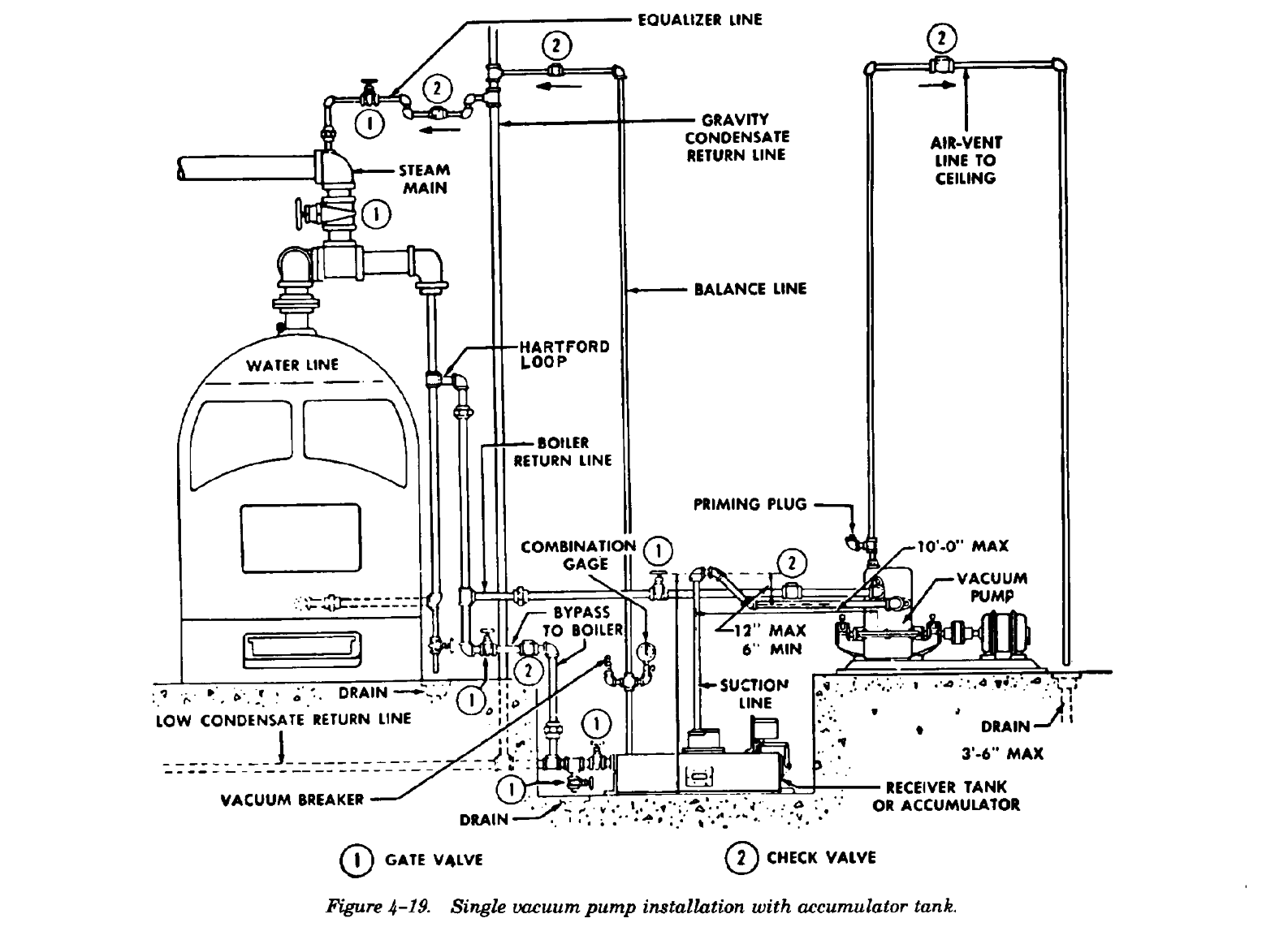

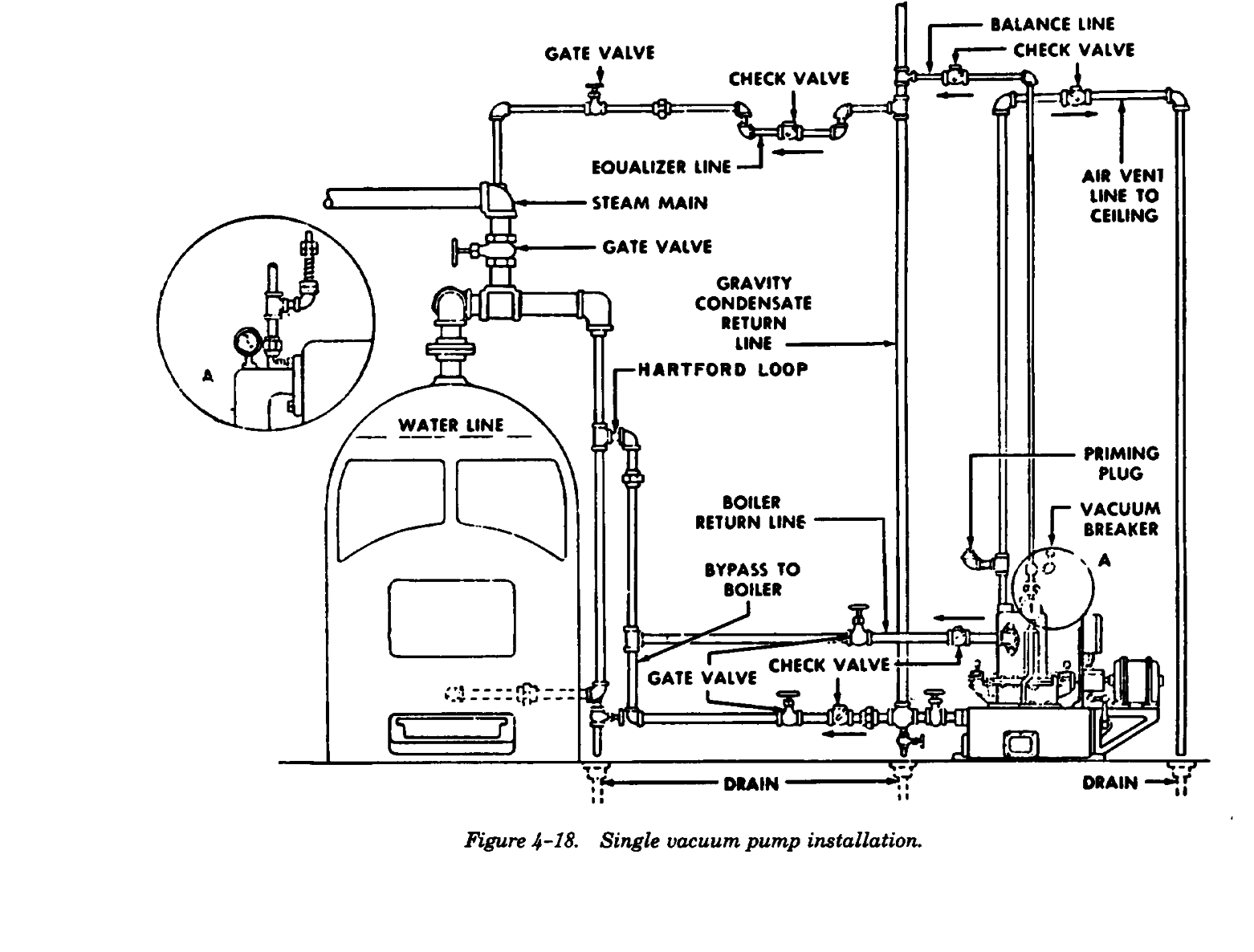

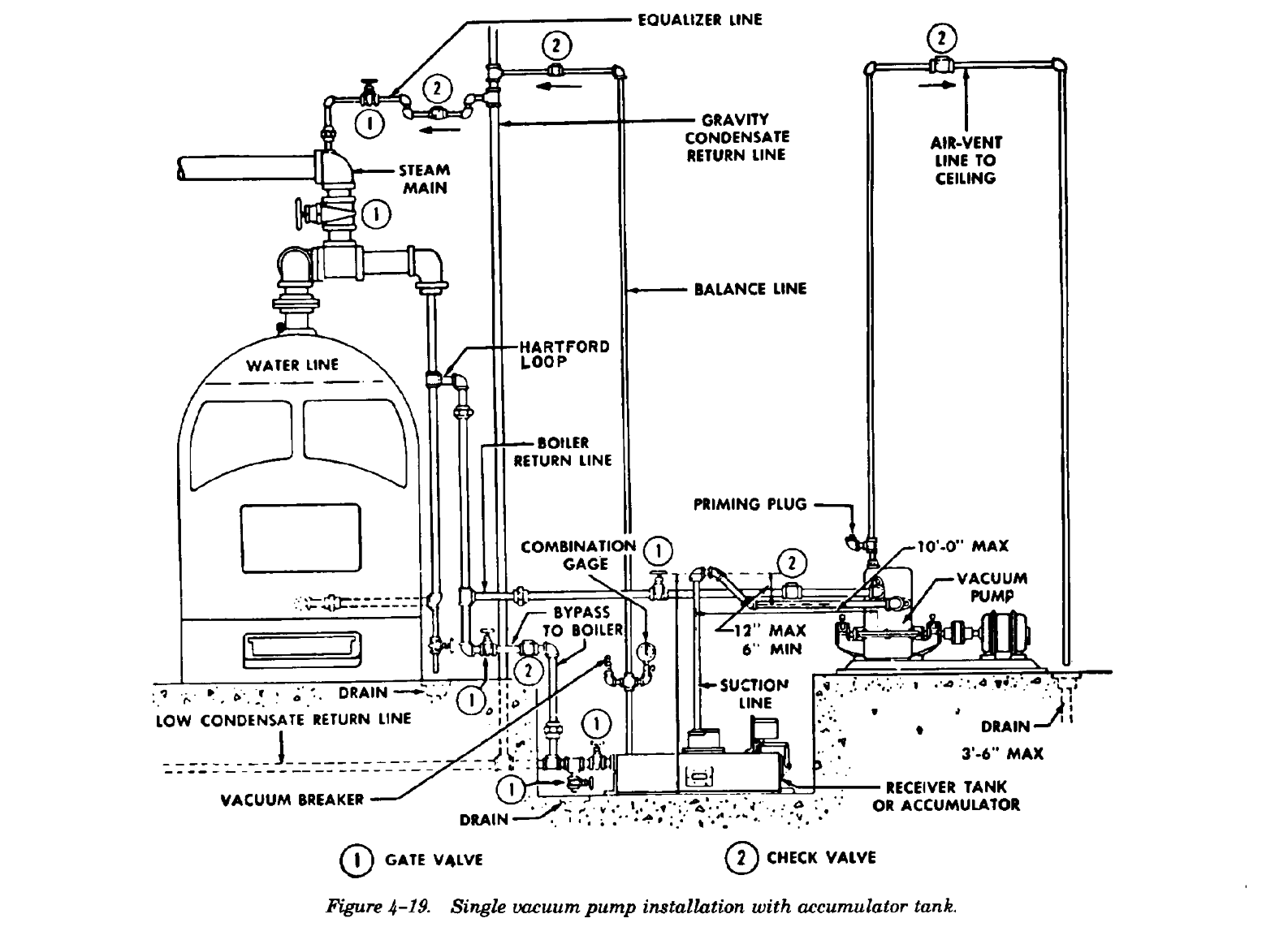

a. General. Figures 4-18 and 4-19 illustrate cor-

c. It is essential in vacuum installations that the

rect methods for installing vacuum pump units. In

entire system is tight in order to reduce the amount

connecting pipes to the pump or receiver, a union

of inward air leakage. Furthermore, it is essential

is included in each line as close as possible to the

that very high temperature steam is prevented from

unit for convenience in installation or repair. Pipe

entering vacuum return lines through leaky traps

stress upon the unit should be prevented. Pipes

and high pressure drips. The condensate from

used should not be smaller in size than their con-

equipment using steam at high pressure should not

nections on the unit and should be at least one or

be connected directly to a vacuum return line, but

two sizes larger if runs are long.

4-23

TM 5-642

b. Pipe connections.

(7) Pipes must be airtight and all steam traps

(1) A valved connection to a drain in the con-

must be of a suitable type, properly located, and in

densate return line is installed to permit draining or

good operating condition.

flushing of the system.

(2) A valved bypass from the condensate

4-27.

Controls.

return to the boiler return line is installed to

The vacuum pump is controlled by a vacuum regu-

permit operation by gravity in case of a power fail-

lator which cuts in when the vacuum drops to the

ure.

lowest point desired and cuts out when the vacuum

(3) The boiler return line is connected by

has been increased to the highest point. These

Hartford Loop.

points are varied to suit particular system or

(4) A receiver vent or equalizer line to a dry

operating conditions. In addition to this vacuum

vertical return riser is used to permit a continuous

control, a float control is included which automati-

flow of condensate into the receiver.

cally starts the pump whenever sufficient conden-

(5) An air-discharge vent line with a horizontal

sate accumulates in the receiver, independent of the

switch check valve is run up to a point as close to

amount of vacuum in the system. A selector switch

the ceiling as possible and back down to a drain.

is usually provided to allow the vacuum pump to

(6) A dry equalizer line between the condensate

operate as a condensate pump. This operation takes

return line and steam header, including a gate valve

place on float control and when vacuum control is

and tight seating check valve, is used to equalize

in the off position. The selector switch also

boiler vacuum when steam is shut off and to permit

provides manual or continuous operation when

normal return of condensate to pump receiver.

desired. A fused motor-disconnect switch is always

4-24

TM 5-642

provided in each motor circuit. Exclusive of

return line and running pump on float and vacuum

continuous duty models, all standard vacuum

control. Observe the operating time necessary to

pump units are furnished with automatic controls

create the vacuum for which the pump is set.

necessary for requirements of the motor furnished.

(4) Open the gate valve on the condensate

A float switch governed by the water level in the

return and check the time required for the pump to

receiver and a vacuum regulator controlled by the

create a vacuum in return system, keeping in mind

vacuum in the system are provided. In addition, all

that in large systems a reasonable period may

vacuum pump units have a three-way selector

normally be necessary.

switch for choice of continuous operation,

(5) Check the packing boxes for proper leak-

operation with float and vacuum control, or

age.

operation with float control only. This permits,

(6) After the pump is in operation, clean the

among other things, cutting out the vacuum regu-

inlet strainer as required by the manufacturer*s

lator when vacuum is not required.

instructions.

4-28.

Initial operation and cleaning.

e. Vacuum regulation. Regulate the pump to

create the vacuum desired by adjusting a spring

Piping systems may contain considerable quantities

tension nut in the vacuum control switch according

of scale, grease, dirt, or metal shavings. To protect

against damage from foreign material, the heating

to directions given in the switch instructions. The

system should be operated for 2 weeks with the

normal range is from 2 to 6 inches of mercury

condensate return line open to a waste drain before

vacuum.

the pump is first put into operation.

f.

Vacuum breaker valve. The vacuum breaker

a. Before starting Check the following items

or relief valve is usually set to open at 10 inches of

before starting the unit.

mercury and is adjusted by regulating the tension of

(1) Be sure the pump and motor have been lu-

the valve spring. The relief valve ordinarily requires

bricated as indicated by the manufacturer*s lubri-

no special care. It is used to relieve excessive

cation instructions.

vacuums that might result when float control is still

(2) Turn the shaft by hand to see that it rotates

activated after the desired vacuum has been

freely.

created.

(3) See that the characteristics of voltage and

g. Selector switch. Selector switches provided

frequency on the motor nameplate coincide with the

on vacuum pump units with automatic control have

electrical service provided. Check to see that all

three positions for pump operation marked Contin-

thermal units are “set” for operation.

uous, Float and Vacuum, and Float Only. Properly

(4) See that the drain valve is closed and all

necessary line valves open.

handled, this feature permits a flexibility of oper-

b. Priming the pump. Most vacuum pumps must

ation yielding both economy and effective pump

be primed before the pump is put into operation. To

performance. A few recommendations for operation

do this, remove the priming plug which is on the air

of the selector switch are given below:

vent line just above the pump and pour clean water

(1) “Continuous”. The pump will run continu-

through the elbow fitting into the pump casing.

ously independent of float or vacuum switches.

Replace the plug.

This mode of operation is used:

c. Starting the pump. Set the selector switch for

(a) To run the pump continuously for trial

float and vacuum control, or continuous operation,

test, or under unusual service conditions.

and close the motor disconnect switch.

(b) To ensure rapid heat-up in the morning.

d. After starting pump. After the pump has been

started check the following items.

(2) Float and vacuum. Pump operation is gov-

(1) See that the shaft rotates in the direction

erned by either vacuum regulator or float switch.

indicated by the rotation arrow on pump. Vertical

The pump operates when water is accumulated

units rotate clockwise looking down the motor.

beyond a set level in the receiver tank or when

Horizontal units rotate clockwise looking at the

vacuum in the return system falls below the mini-

pump from the motor end.

mum setting. The pump should be operated at this

(2) On larger units, check the flexible coupling

position for normal and heavy duty.

connection of the pump and motor shafts, and note

(3) “Float only.” The pump is governed by the

if the pump is noisy. If so recheck for improper

float switch only and the pump operates when

alignment or clearance.

return condensate in the receiver rises above high

(3) Check pump operation and control adjust-

water level. Operation is independent of the

ment by closing the gate valve on the condensate

4-25

TM 5-642

vacuum control switch. Do not operate the pump at

(4) Check stuffing boxes for proper packing

this position unless conde