The gravity sand system is an early swimming pool

processing of public drinking water supplies, so the

design that has been largely outdated by the pressure

technology of sand filtration was quite naturally

system which can be installed and operated in a much

developed by public health agencies and the water works

smaller area. Although the sand bed functions as a filter

industry. During the development stage water was

medium in the same manner in both systems, the gravity

traditionally filtered at a rate of 3 gallons per minute per

plant requires a much larger ground space than its

square foot (galimin/ft2) of sand bed surface area.

equivalent pressure plant. Also, the backwashing

Thus, if a given system requires a total flow of 600

procedure requires increases in both manual labor and

gal/min, a filter system has to contain 200 square feet of

water waste.

sand surface area. Today it is still common practice to

use 3 galimin/ft2 as a standard of design and operation

12-11. BACKWASH THEORY.

of swimming pool sand filters.

Backwashing cleans the filter by reversing the flow and

causing the water to course upward through the bed.

12-8. HIGH RATE SAND FILTER CONSTRUCTION.

The backwash water action tends to slightly expand the

The typical high rate sand filter is a round pressure

bed, causing the sand particles to tremble and scrub

vessel with a special influent baffle in the top of the tank,

against each other allowing the collected soil to break

a bed of filter sand, and a mechanical underdrain system

free and wash out of the filter vessel to a point of

to collect the filtered water for recirculation. The

disposal. In rapid sand filter systems the backwash

underdrain is often designed to serve as a barrier to the

cycle is normally continued until the backwash effluent is

migration of the sand bed and as a backwash water

observed to be free of soil, a period of about 8 to 10

distributor without the requirement of the stratified gravel

minutes per cell. In high rate filters, backwash is

bed which was traditionally used in the rapid sand

accomplished in about 2 minutes because of the greater

systems.

velocity of the backwash water.

12-9. HIGH RATE SAND FILTER OPERATION.

12-12. BACKWASH OPERATION.

a. The total plant size and hydraulic characteristics

a. Backwashing the high rate filter is simple

of the high rate system differs substantially from the

because there is generally only one tank in the system.

rapid sand filter. Instead of operating at the traditional

However, the operator should understand the backwash

flow rate of 3 gal/min/ft2, it operates at flow rates of 15 to

function in the older rapid sand systems, based on

25 gal/min/ft2 of filter surface area. Because the total

several important observations.

flow requirements of a given pool can be satisfied

b. The accumulation of foreign material in a

through a sand bed of considerably smaller surface area

swimming pool filter causes the soil to clump to some

than in the case of rapid sand systems, the physical plant

extent. Hair or lint often serves as a structure, and balls

of the high rate filter is much smaller as well. It is

of organic material (mud balls) form and become

therefore possible, for example, to adequately filter a 90,

imbedded in the top layer of sand. If backwash velocities

000-gallon pool through a single high rate filter tank

are insufficient to wash the clumps to waste, they will

48inches in diameter, whereas a rapid sand system for

work their way deeper into the filter bed creating

the same pool would require the use of a battery of three

channels which ultimately permit unfiltered water to take

filter tanks, each 72 inches in diameter. Appendices F,

a path of least resistance through the medium.

Sizing a Rapid Sand Filter and G, Sizing a Diatomite

c. Another undesirable result of insufficient

Filter show the steps and assumptions for these

backwash velocities is termed calcification. If the bed is

calculations.

not disturbed enough to expand slightly, it may eventually

b. The high rate system provides an effluent of ex

become encrusted with a cement like mass and become

12-3

TM 5-662

impervious to the flow of water. This phenomenon is

ing of the rapid sand filter system involves much more

particularly likely-to occur if pH and total alkalinity of the

than a mere reversal of flow. The operator must

pool water are permitted to become unreasonably high.

establish the backwash flow rate with care to avoid the

d. Both an inadequate backwash velocity and a

problems which result from either inadequate or

backwash rate which substantially exceed 15 gal/min/ft2

excessive flow rates. In addition, the operator must

(25 gallminlft2 for high rate sand filters) are undesirable.

comply with any discharge flow restrictions in the facility

In some circumstances the full capacity of the

National Pollutant Discharge Elimination System

recirculation pump will cause the sand and gravel bed to

(NPDES) permit. State and/or local authorities should be

tumble and partially invert the sand layer and the layer of

consulted for compliance advice.

small gravel immediately beneath it. If this condition

occurs, channeling can take place similar to that caused

12-13. EQUIPMENT INSPECTION.

by the mud-balling described above. The condition can

Regardless of the protection methods used, the bed or

be corrected only by removing and reloading the first two

the rapid sand filter should be periodically inspected. If

strata of media.

signs of mud-balling or calcification are observed, the

e. As indicated in the above discussions, backwash

bed should be soaked with corrective chemicals such as

acids and detergents.

12-4

TM 5-662

CHAPTER 13

DIATOMACEOUS EARTH FILTRATION

13-1. GENERAL.

tubes, disks or wafers assembled to a pipe or pipe

a. Diatomaceous earth filtration is commonly used

manifold which receives the filtered water and directs it

for swimming pool water and makes use of a dirt-

through the recirculation system piping to the pool.

collecting medium which is discarded along with the dirt

itself when the filter cycle is completed. Although three

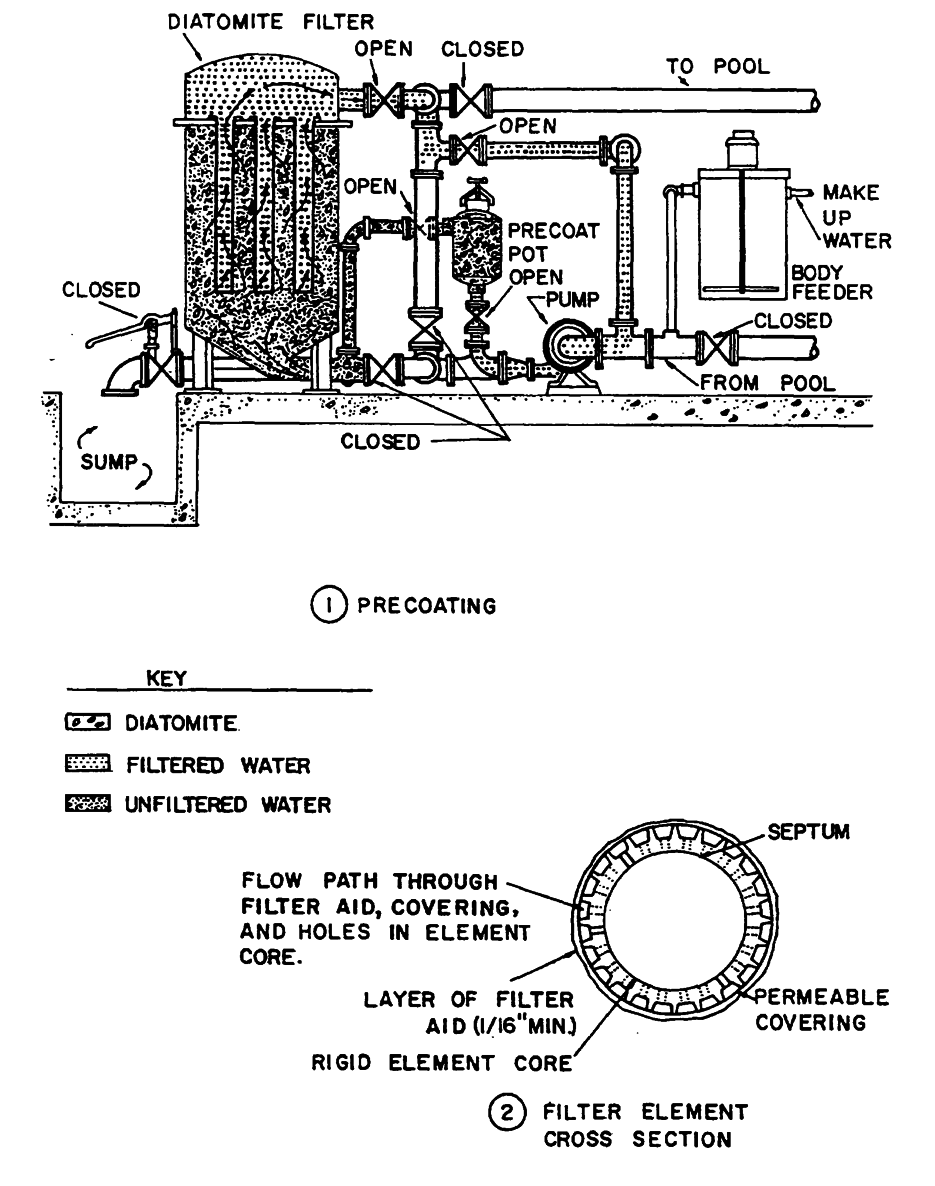

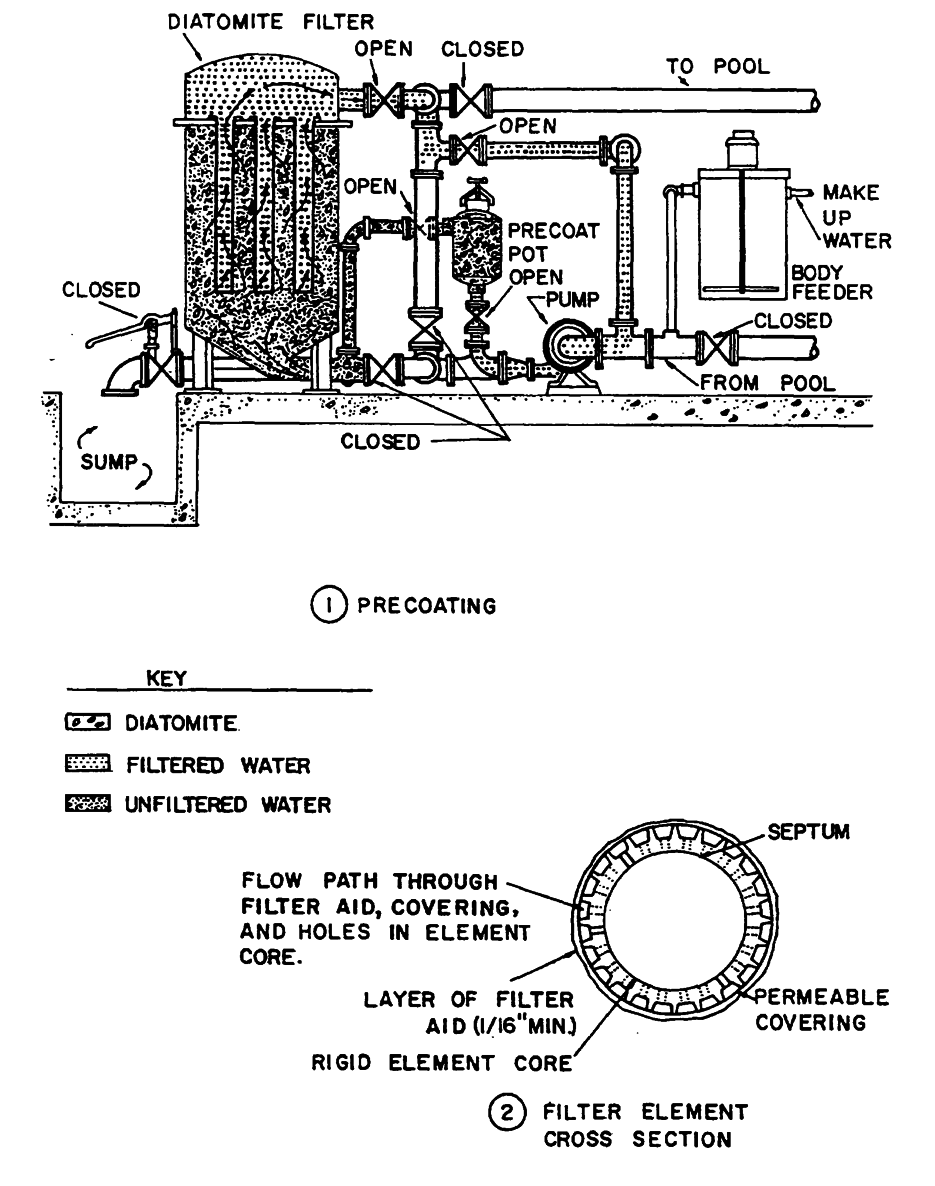

13-4. PRECOATING THE FILTER SEPTUM.

or four disposable media can be used in such systems,

a. The act of depositing the filter cake upon the

the one most commonly used is diatomaceous earth. It

septum is called "precoating." It involves mixing a slurry

is therefore adopted as a term of reference to describe

of diatomaceous earth and water, and then introducing

such filters throughout this chapter.

the mixture at a point in the recirculation system which

b. A cost comparison of different types of filters

will result in the slurry eventually being deposited upon

should be conducted before installing diatomaceous

the septum.

earth filters. These filters have a history of high

b. The precoat slurry formula provides for a precoat

maintenance and repair cost.

cake thickness of 1/16 of an inch minimum. This is

accomplished by preparing a slurry which contains 1/10

13-2. THE FILTER MEDIA.

pound of diatomite powder for each square foot of

a. To the naked eye, diatomaceous earth is a fine

septum surface area to be coated. It is good practice to

white powder, but under the microscope it is seen to

mix a slurry containing 1-1/2 pounds of diatomaceous

possess certain unique properties which make it highly

earth powder for each 10 square feet of septum surface

desirable as a filter medium. As an individual particle, it

area because some of the slurry will pass through the

exists in many shapes, all of which resemble a petrified

septum and be deposited in the pool or delivered to

tumbleweed of near microscopic size. It resembles the

waste during the initial precoating of the septum. A

tumbleweed because it is a lacy, weblike particle which is

precoat thicker than 1116 inch is not objectionable, but a

approximately 90 percent void and 10 percent solid fiber.

precoat of inadequate thickness can be a serious

It is petrified in a literal sense because it is the rigid,

operational error. An inadequate thickness will not only

skeleton like fossil of a very small form of plant life from

reduce filtration efficiency, but will also leave the septum

prehistoric times.

fabric unprotected and exposed to direct soil

b. The characteristics which make diatomite a filter

accumulation. Septum fabric that becomes soiled with

medium can thus be seen when one imagines a cake or

sticky organic material will not properly release its soiled

crust of small, rigid, porous particles piled one upon the

filter cake during the cleaning (backwashing) cycle. As a

other to form a fine screen, being placed in the path of a

result, the septum itself will become clogged with

flowing stream of water (see figure 13.1). The openings

unreleased filter cake, reducing the available filter

in the screen are large enough to permit the flow of

surface area and causing the filter to become short-

water, but small enough to obstruct the passage of

cycled and inefficient.

virtually the smallest particle of foreign material. Even

droplets of viscous oil like liquids will be caught in the

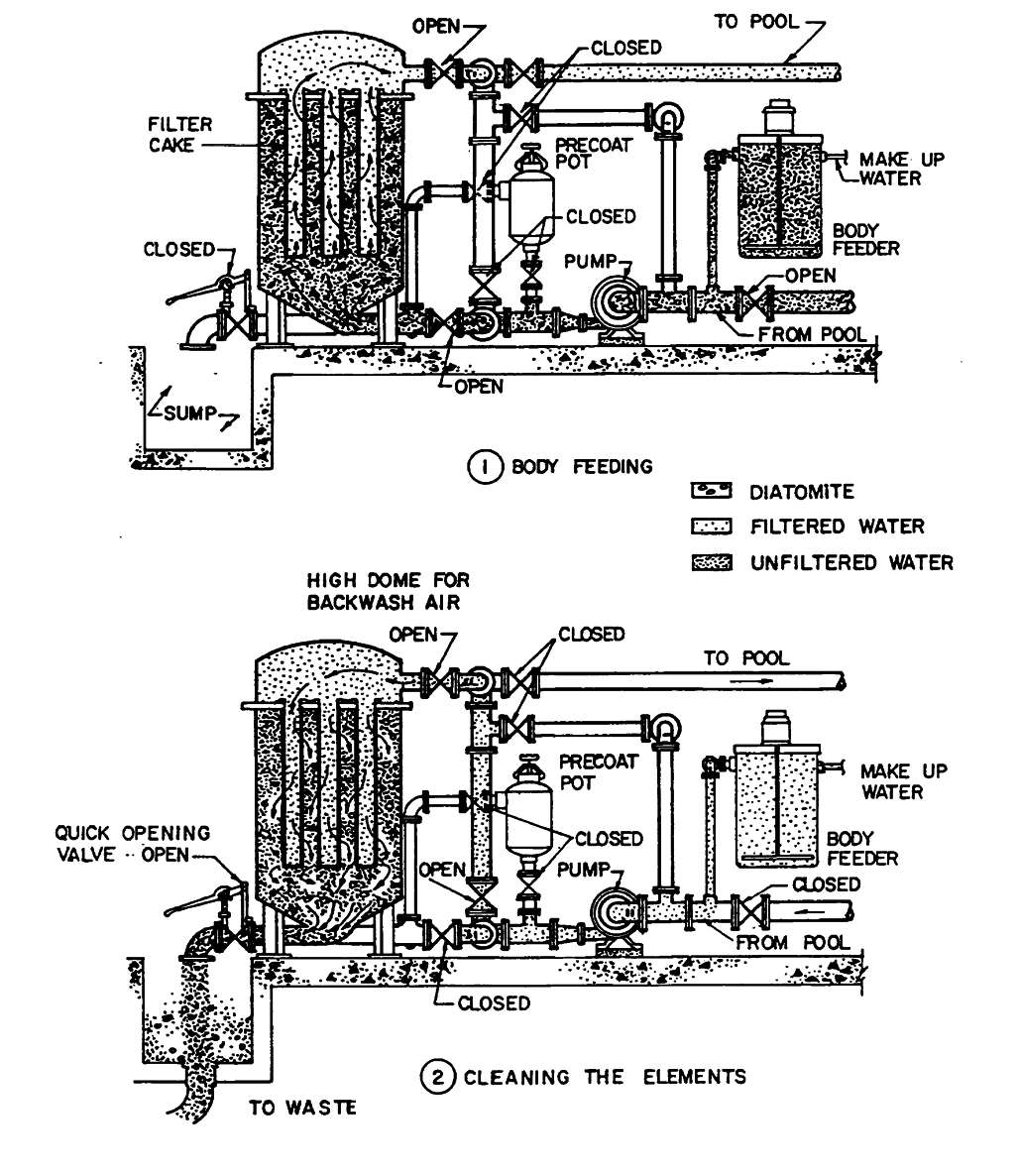

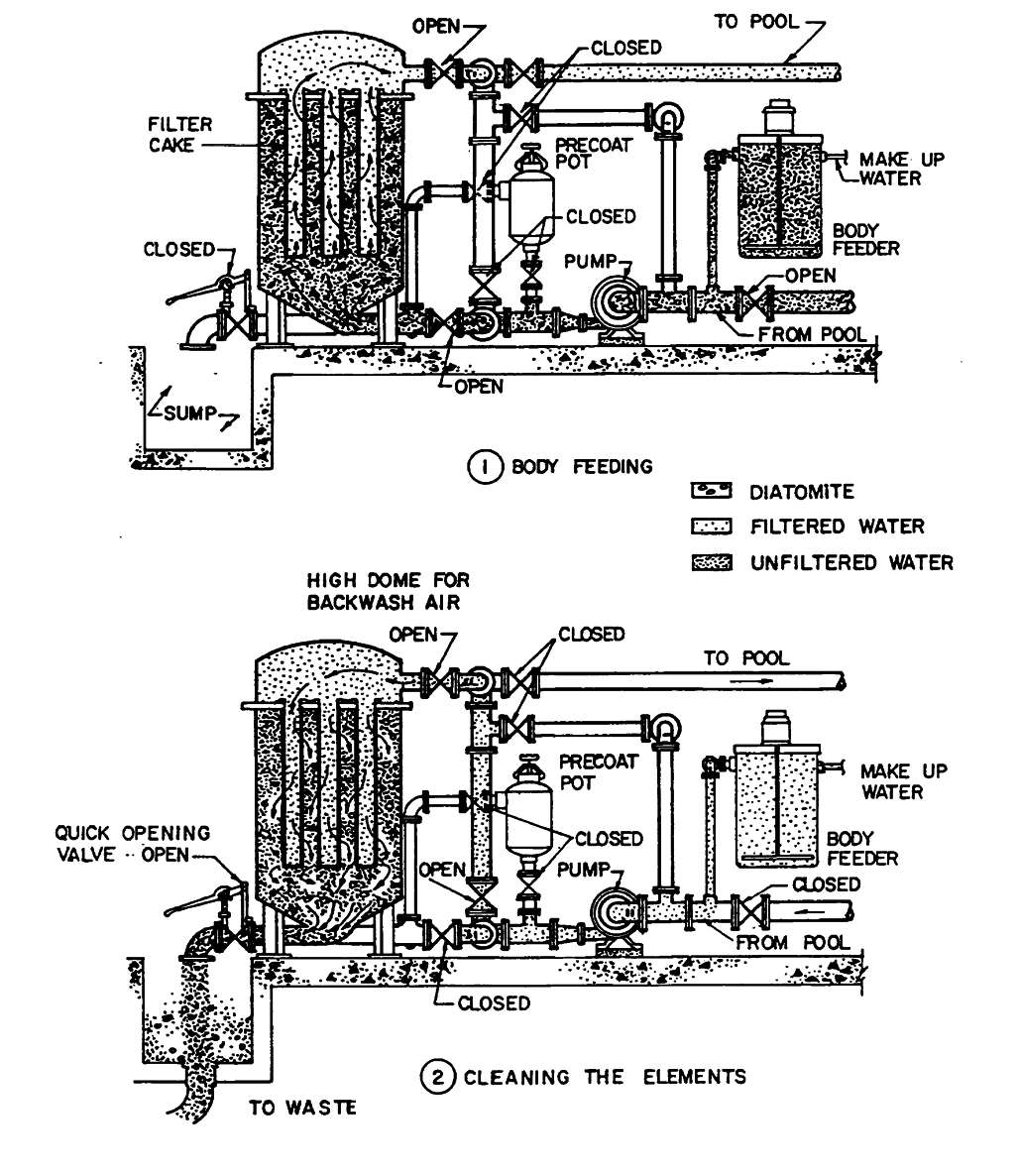

13-5. CONTINUOUS BODY FEEDING THE FILTER.

screen. The diatomaceous earth filter cake is therefore

a. An operator must understand the function of

a highly efficient filter medium, so efficient in fact, that it

diatomaceous earth as a filter medium in order to

requires special care to keep it porous and functioning

understand why a single precoat of a filter septum will

for extended periods of time.

not keep a filter functioning for long. Because the soil is

filtered out at the surface of the filter cake, the cake is

13-3. THE FILTER SEPTUM.

soon slimed over and clogged with solids which inhibit

All diatomaceous earth filters are equipped with septums

flow. Such a condition produces very short filter cycles,

(often referred to as the filter elements) or devices upon

making the diatomaceous earth system objectionable for

which the diatomaceous earth powder is collected in its

this reason alone. It is possible to keep the filter cake

cake form. The septum may be a cylindrical tube or a

porous and to increase its dirt-holding capacity by

wafer like structure covered with a plastic or metal fabric

continuing to feed filter aid (diatomaceous earth) into the

of sufficiently fine weave to collect the filter cake. The

system through the process known as

septum is often a bundle of

13-1

TM 5-662

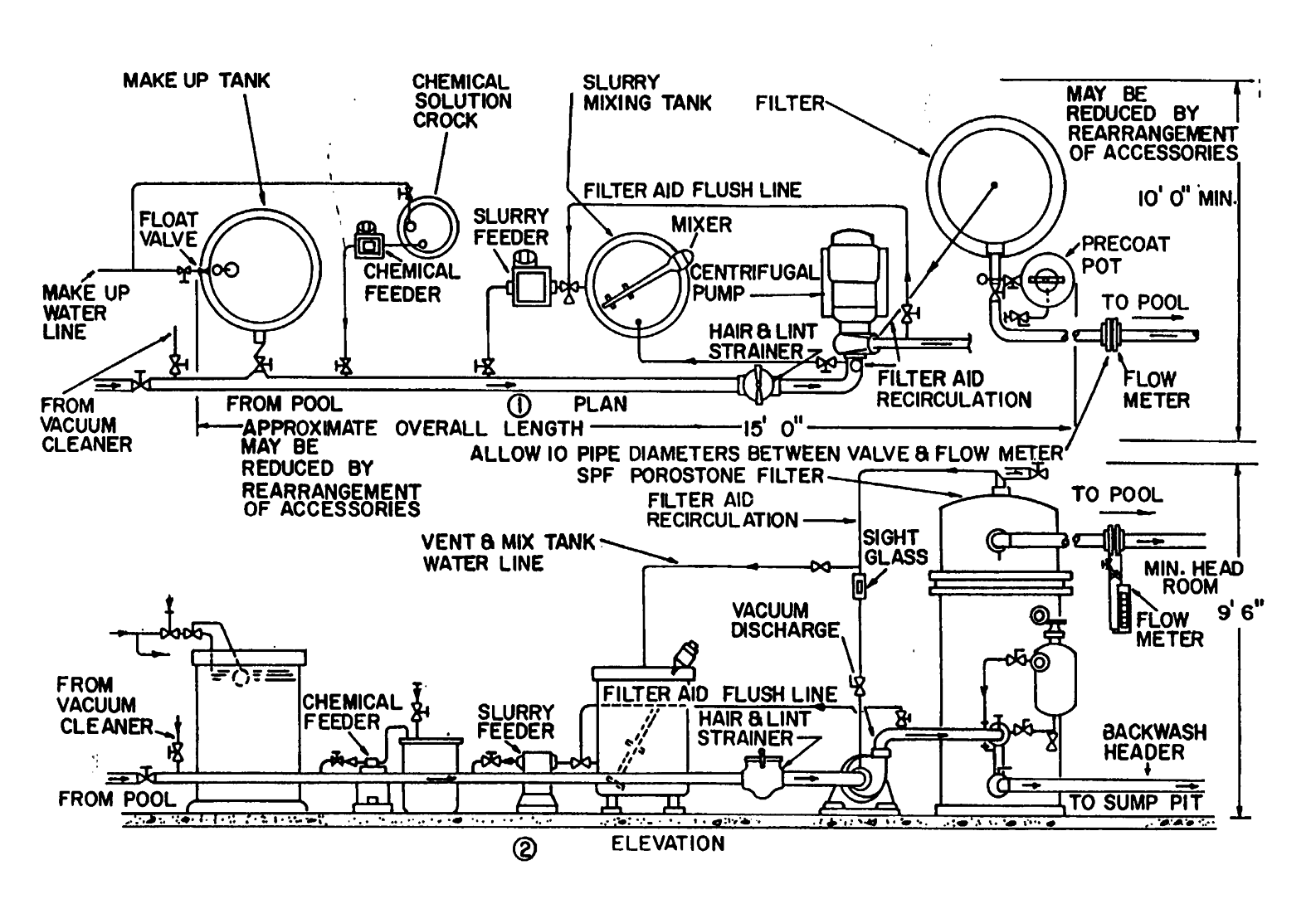

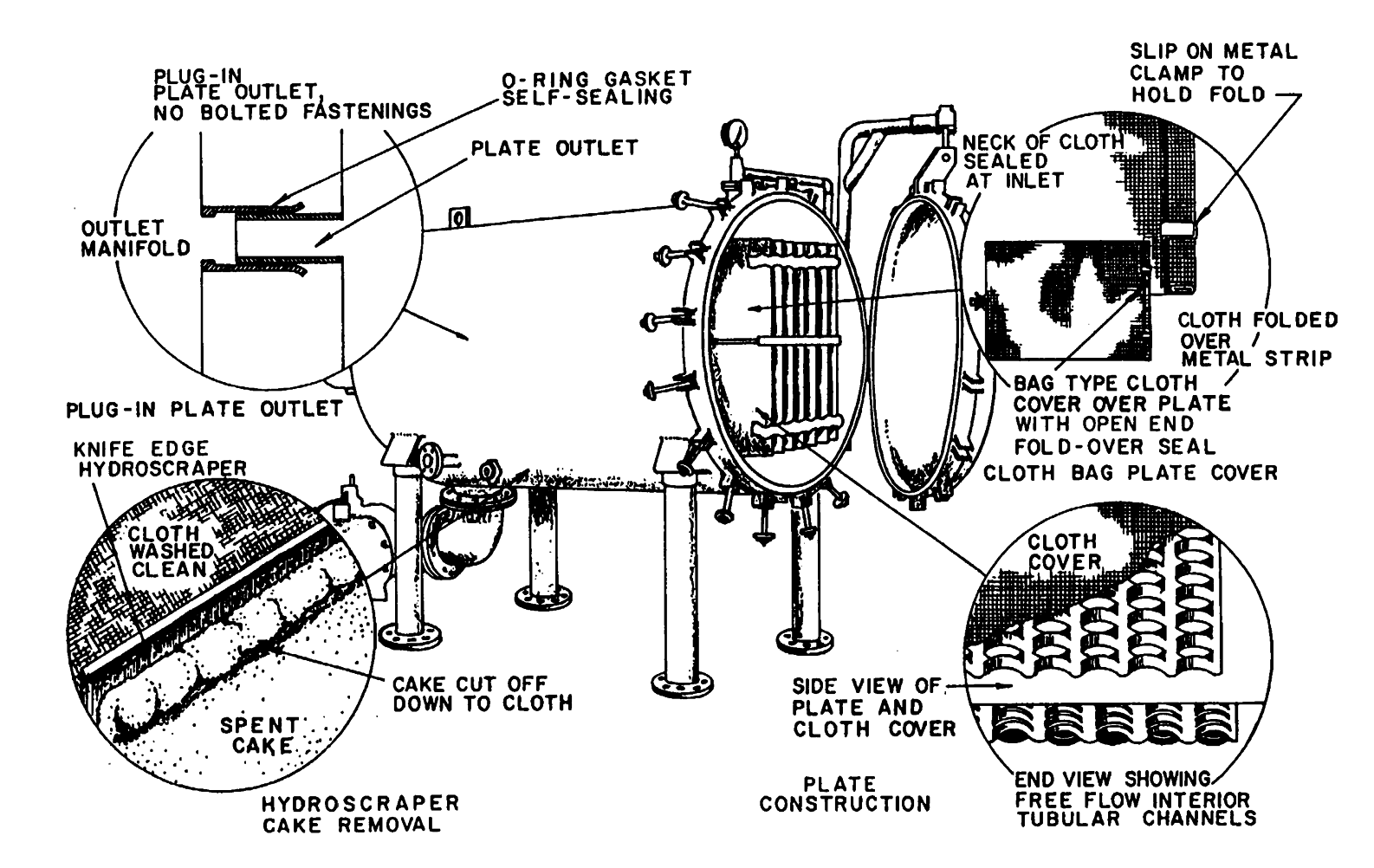

Figure 13-1. Typical diatomite filter

13-2

TM 5-662

body feeding or slurry feeding.

This

involves

a mixture of diatomite and water, a motor driven agitator

introducing a continuous feed of diatomaceous earth

or propeller to keep the diatomite in suspension, and a

filter powder into the unfiltered pool water as it

metering pump which draws the slurry from the tank and

approaches the filter system. By mixing the porous filter

pumps it to the unfiltered water stream. A relatively

aid particles into the soiled water, the filter cake receives

dilute slurry is desirable because the diatomaceous earth

a mixture of particles, some of which are dirt solids, and

particles tend to settle and pack or clog at points of low

some of which are porous diatomaceous earth particles

velocity in the pump, fittings, and solution tubing. A ratio

which actually increases the dirt-collecting and

of 1/2 pound of diatomite per gallon of water is probably

dirtholding capacity. Although body feeding causes the

ideal, but the ratio is not critical; much heavier slurries

filter cake to swell and thicken, it increases its capacity to

can be handled if the operator keeps the equipment

collect and store soil in the process, so the filter cycle is

functioning properly. Regardless of the ratio of diatomite

extended far beyond what would be provided if body

to water, the slurry feed should be prepared daily, if

feeding were not practiced. (See figures 13.2 and 13-3).

possible, or at least every other day. The diatomaceous

b. The slurry feeding technique is variable and

earth particle is very brittle and prolonged agitation in the

controlled in a highly discretionary manner by the

slurry tank will tend to fracture the particles and greatly

operator. If bathing loads are heavy, with resultant heavy

reduce their efficiency as a filter medium. (See figure

dirt accumulation, the operator increases the rate of body

13.5).

feed. As bathing loads subside the experienced operator

continues the heavy feed until the heavy soil

13-9. FLOW RATES AND FILTER SIZING.

accumulation has been largely picked up in the filter.

a. As in the case of the sand filter, the size of the

The operator then reduces the rate of feed until the need

diatomaceous earth filter is governed by the size of the

for heavy feeding is again presented. Body feeding, like

pool. However, because diatomaceous earth filtration is

chlorine feeding, is measured against demand and the

relatively new technology, an inherited flow rate is not

rates are adjusted accordingly.

available to serve as a guide in sizing the filter system.

Instead, the optimum flow rates have been determined

13-6. THE PHYSICAL PLANT.

from experience in the laboratory and in the field.

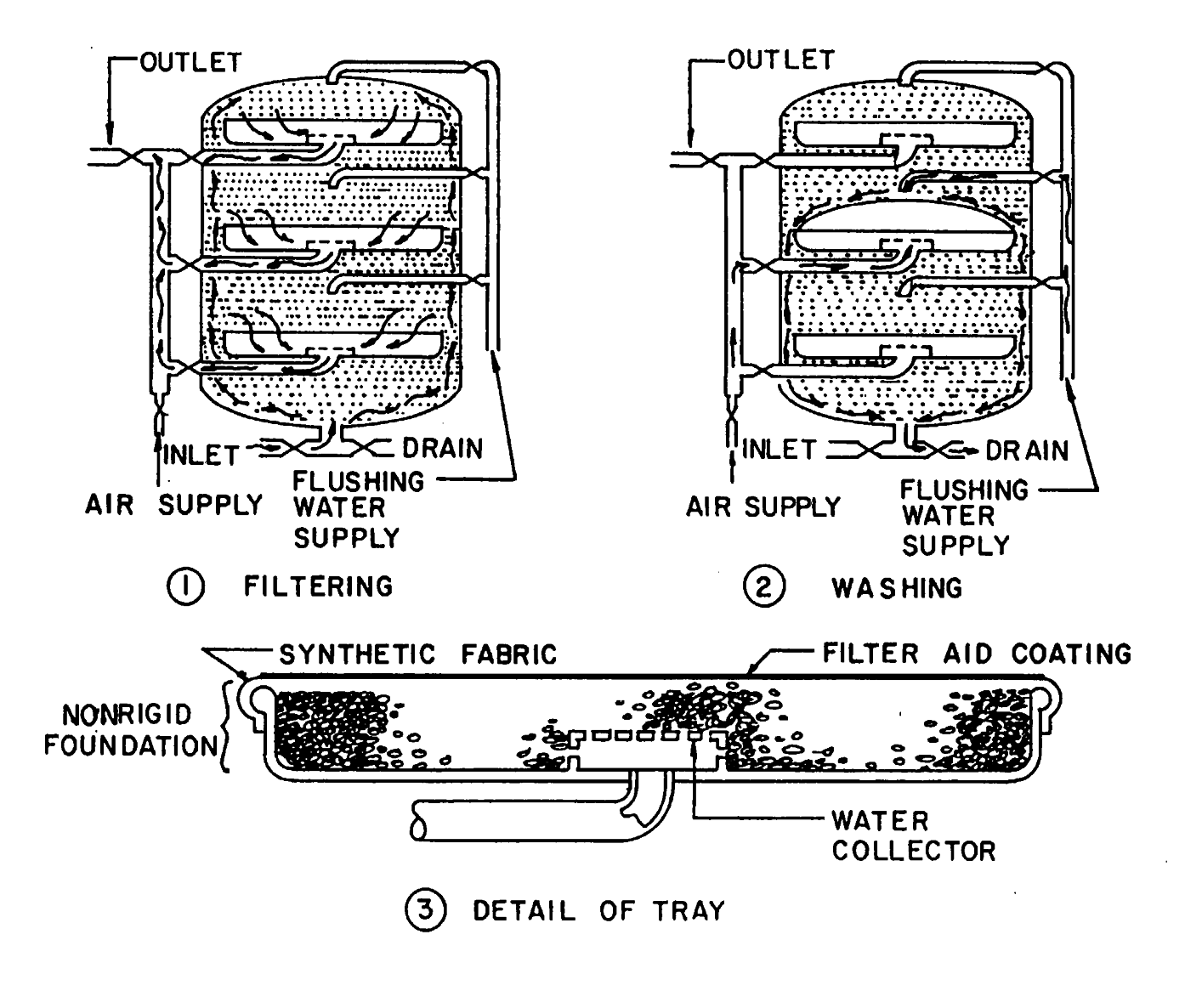

Understanding the functions of the filter medium and

b. Experience has shown that the filter flow rate is

septum makes the diatomaceous earth filter plant rather

far more critical in the operation of the diatomaceous

easy to visualize. It may be either a closed tank which

earth filter than in the operation of the sand system. It

operates under pressure, or an open tank from which the

was noted that flow rates can be substantially increased

water is drawn under vacuum to pump suction. In either

in sand filtration without materially affecting cycles. The

case the system is comprised of a tank to receive

diatomite filter, however, gives markedly reduced filter

unfiltered water, a septum to support the filter cake, and

runs as the flow rate is increased. Therefore, it has

a pipe or manifold to collect filtered water from the

become common practice to use diatomaceous earth

septum and deliver it to the distribution system piping. In

systems of sufficient size that they can be operated at

the case of the pressure type system, a crock or tank for

filter flow rates of 1 to 2 gal/min/square foot of filter

precoating the filter is attached either to the filter itself or

surface area.

to the adjacent piping. Many shapes, sizes, and design

configurations exist because there is a great deal of

13-10. GENERAL FILTER CLEANING.

latitude with respect to septum design and collector

The diatomaceous earth filter responds hydraulically to

piping arrangements. (See figure 13.4)

dirt loading in the same manner as the sand filter. As the

medium clogs with soil its resistance to the flow of water

13-7. DRY FEEDER.

increases, eventually requiring the medium to be cleaned

Two types of body feeding equipment are commonly

and recharged with filter powder. The manner in which

used. The vacuum diatomaceous earth filter may be

the filter is to be cleaned is largely predetermined by the

equipped with a "dry" feeder which consists of a hopper

manufacturer of the equipment, so there is little reason

containing the diatomite charge positioned over the filter

to discuss the various mechanical systems and

cell. A vibrator or other device may be used to deposit

procedures which are offered commercially. It is

measured amounts of diatomaceous earth directly into

worthwhile, however, to examine the basic differences

the filter.

between the vacuum and pressure type systems.

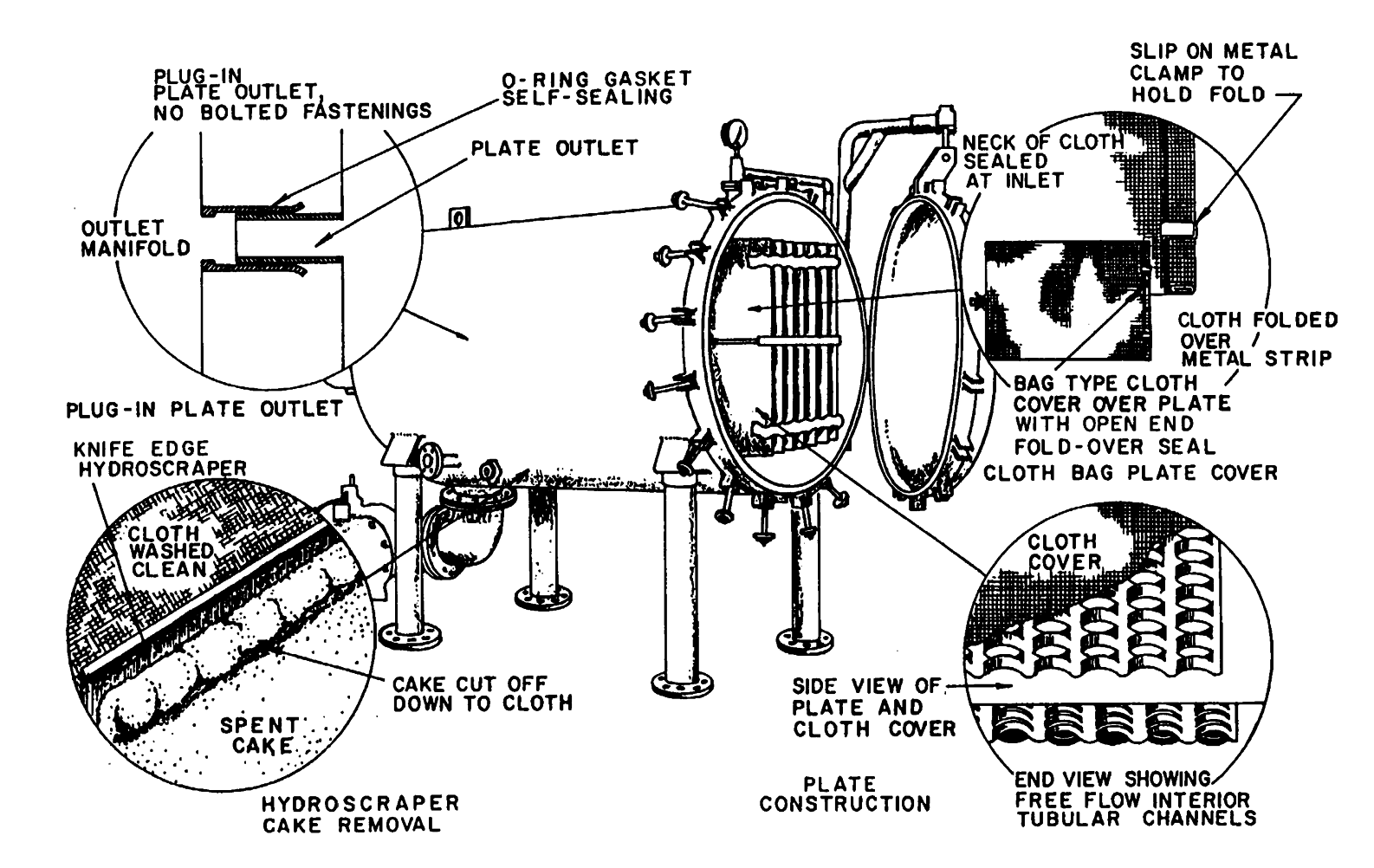

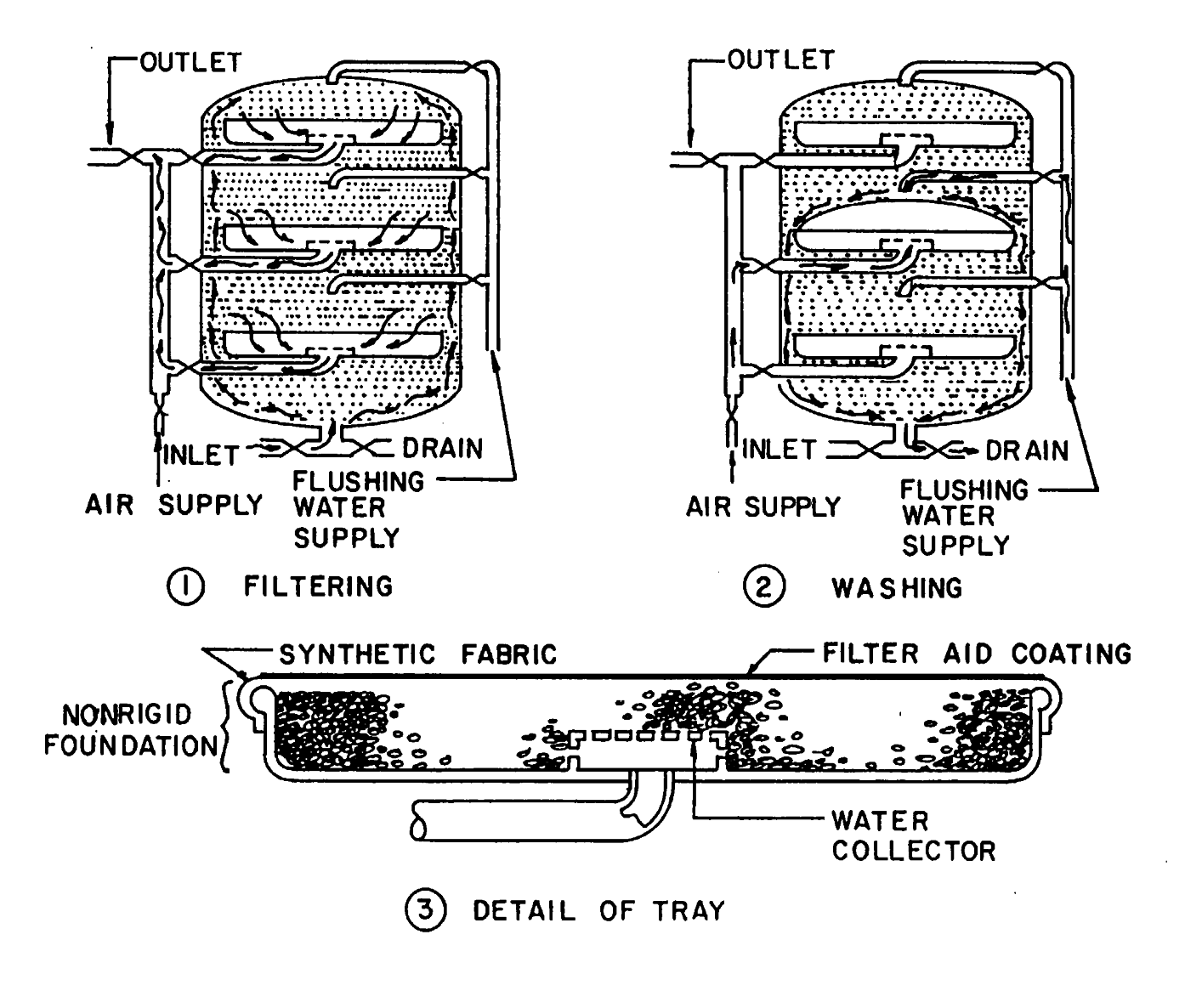

13-8. SLURRY FEEDER.

13-11. VACUUM SYSTEM FILTER CLEANING.

The more common system feeds the filter powder as a

The typical vacuum filter is an open tank. As the recir

slurry. The slurry feeder consists of a tank containing

13-3

TM 5-662

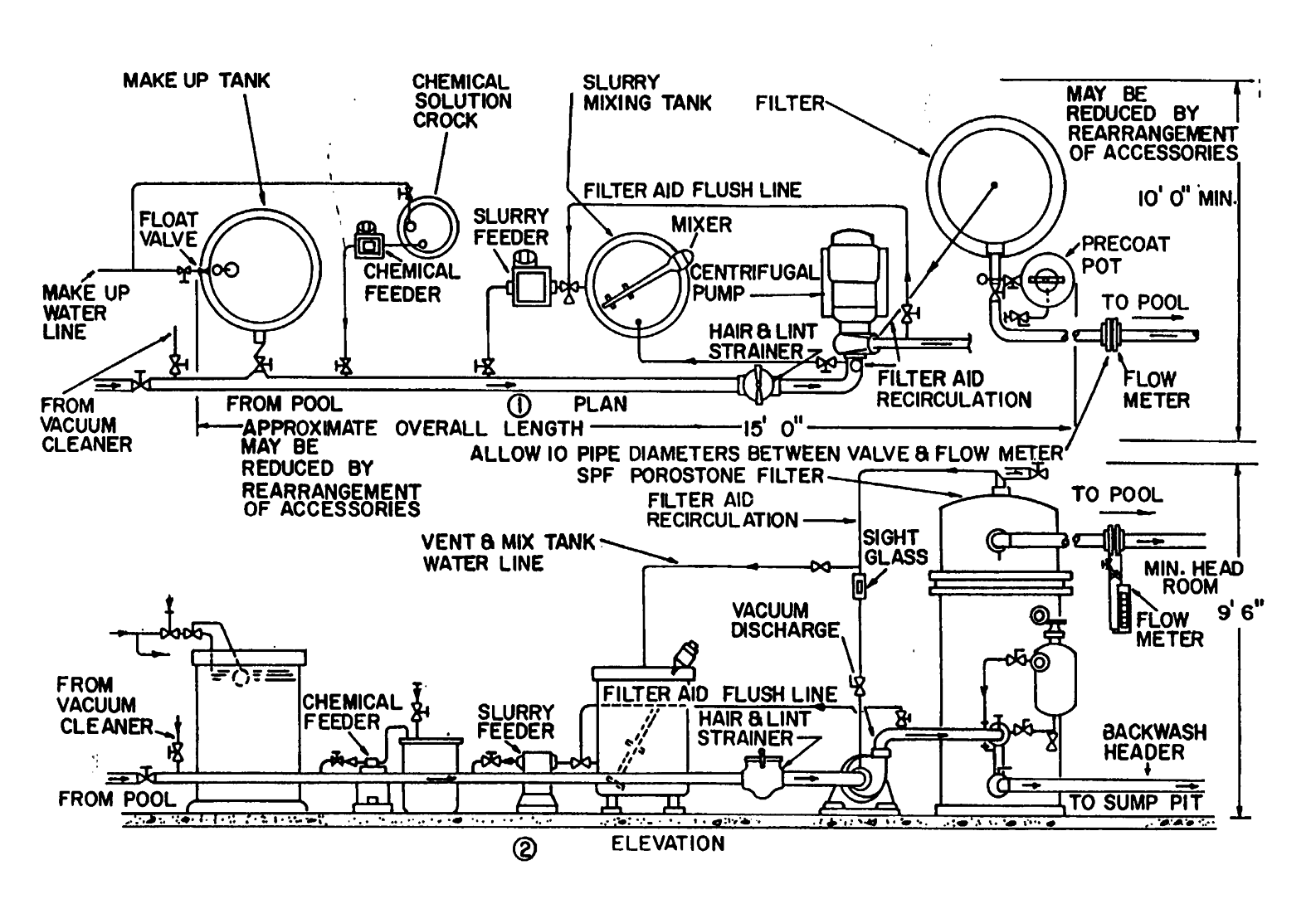

Figure 13-2. Body feeding and cleaning diatomite filters

13-4

TM 5-662

Figure 13-3. Tray type diatomaceous earth filters

13-5

TM 5-662

Figure 13-4. Typical heavy-duty diatomite swimming pool pressure filter with flat-type filter plates and cloth plate covers 13-6

TM 5-662

Figure 13-5. Typical filter room equipment

13-7

TM 5-662

culation pump draws the water through the septum the

through the septum, to jet spray the elements, or to flex

dirt loading and buildup of the filter cake can be visually

or move the elements within the vessel to assist in

observed by the pool operator. When the vacuum gage

releasing the soiled cake, etc. Also, the pressure filter is

and flow meter readings indicate that the filter should be

frequently equipped with visual inspection ports to assist

cleaned, the pump is stopped, the filter cell is drained,

the operator in appraising the efficiency of the cleaning

and the elements are manually washed down with the

operation.

high velocity stream from a garden hose. The operator

should make certain that all the soiled cake has been

13-13. INSPECTION SCHEDULE.

effectively removed from the filter elements before

The best cleaning systems and techniques, however,

returning the filter to service.

will not prevent the eventual accumulation of some soil in

the septum fabric and the loss of some filtration

13-12. PRESSURE SYSTEM FILTER CLEANING.

efficiency. For this reason it is good practice to

The pressure diatomite filter is normally a tightly sealed

periodically open the filter vessel and clean the septum

vessel which cannot be readily opened for manual

manually. The filter elements and socks should be

cleaning. Instead, the system has a combination of

inspected and cleaned at least every other week.

devices and procedures for reversing the flow of water

Diatomaceous earth filters should be rebuilt annually.

13-8

TM 5-662

CHAPTER 14

SWIMMING POOL HEATING

14-1. GENERAL.

14-7. SWIMMING POOL HEAT GAINS.

A swimming pool is a type of energy storage area with

a. Swimming pools are heated naturally through

heat gains and heat losses occurring continuously. The

sunlight that is absorbed directly into the water and by

amount of energy in the pool at any time is determined

the sides and bottom of the pool. Additional heat can be

by the temperature of the pool. Heat gains from sunlight

supplied by either solar, fossil fuel, or electric heaters.

absorbed directly by the pool and from heaters either

b. The amount of sunlight absorbed by a pool is

conventional, solar or both increase water temperature.

determined by the amount of sunlight reaching the pool

Heat losses to the sky, to the surrounding air, and to the

surface multiplied by the fraction of light the pool actually

ground decrease pool temperature.

absorbs. Such factors as location, time of year, and

amount of shading control the amount of sunlight

14-2. SOURCES OF HEAT GAIN AND LOSS.

available to a pool.

Pool water becomes colder when energy is withdrawn

c. The sunlight that is not absorbed by the water is

through heat losses. Heat losses occur primarily at the

reflected from the surface, sides, and bottom of the pool.

surface of the water through evaporation, conduction and

Typically, about 10 percent of the sunlight reaching the

convection, and thermal radiation. Relatively little heat is

pool is reflected rather than absorbed. Most of the

lost to the ground.

reflection, however, occurs at the surface of the water-

about 7 percent annually. The amount of sunlight

14-3. EVAPORATIVE LOSSES.

reflected from the sides and bottom of the pool is small,

These heat losses occur when the water at the surface

because much of the light has been absorbed by the

of the pool is changed into vapor and carried away in the

water.

air. Besides decreasing the pool temperature,

evaporation also results in significant loss of water and

14-8. POOL TEMPERATURE.

pool chemicals. Evaporation is increased by high wind

Medical authorities have determined that 780 F is the

speeds, high pool water temperature, high air

healthiest temperature for recreational swimming.

temperature, and low relative humidity.

Colder water results in a rapid loss of body heat,

especially if swimming is prolonged. Excessive pool

14-4. CONDUCTION AND CONVECTION LOSSES.

temperature, like excessive room temperature, is a

These losses are closely linked with evaporative losses

wasteful practice. Additionally, an overheated pool

and occur when heat from the pool surface is transferred

causes chemicals used to purify the water to evaporate

to the cooler surrounding air. Conduction and convection

more rapidly at higher temperatures, resulting in

losses increase with high wind speeds, low outside air

progressively larger heat losses.

temperatures, and high pool temperature.

14-9. SWIMMING SEASON.

14-5. THERMAL RADIATION.

The use of most heated pools is seasonal, varying i