chemically non-resistive glues. It leads to rapid glue destruction and appearance of leakages

what can not be accepted due to safety reasons. The unique feature of developed by us

microsensor was application of thin silicon wall separating fluidic microchannel from

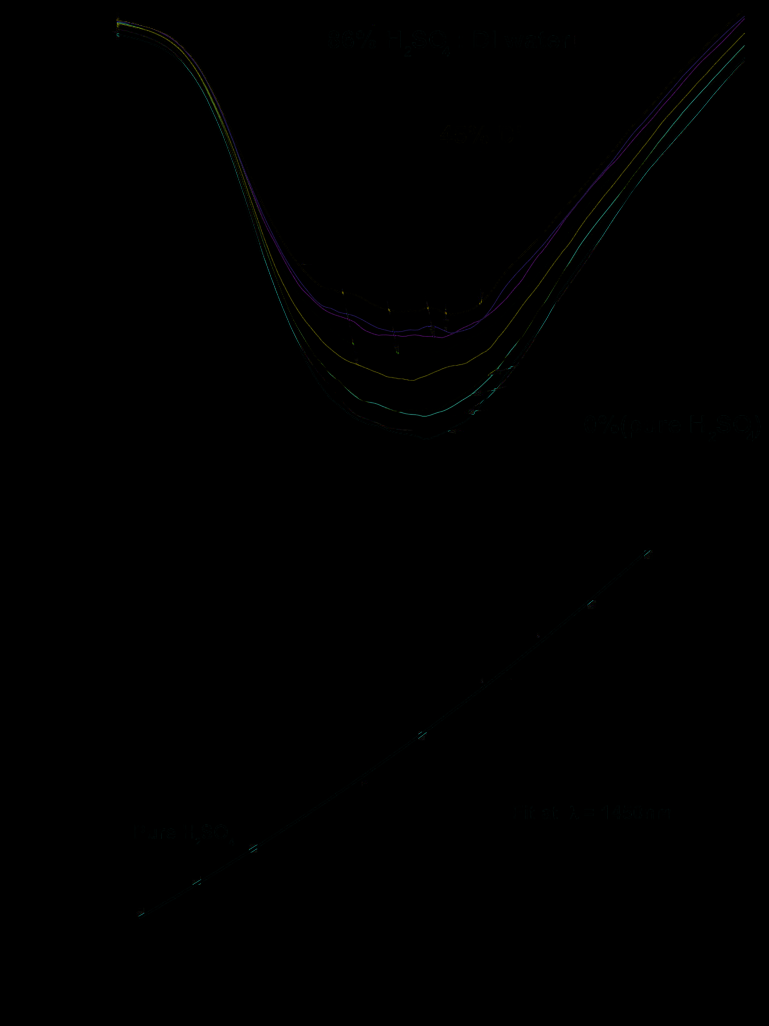

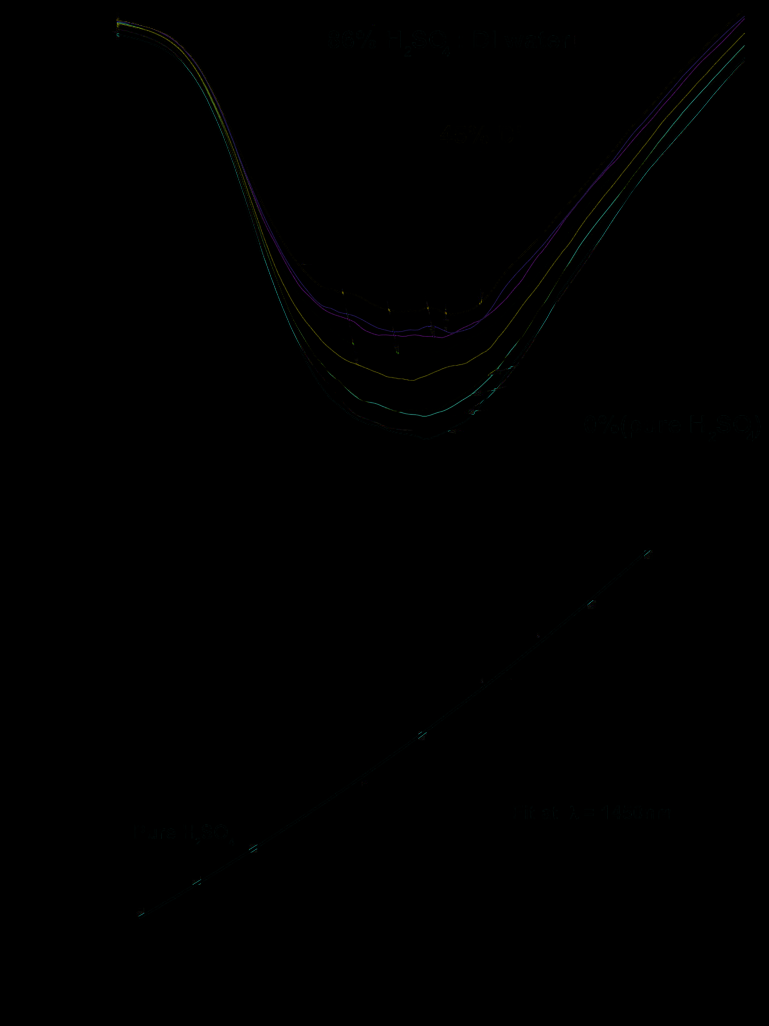

microchannel with optical fibers. It is well known that thin (below 20 m) silicon layer is

transparent for near-infrared light (Fig. 27). Thus, physical separation with simultaneous

NIR transmittance was obtained.

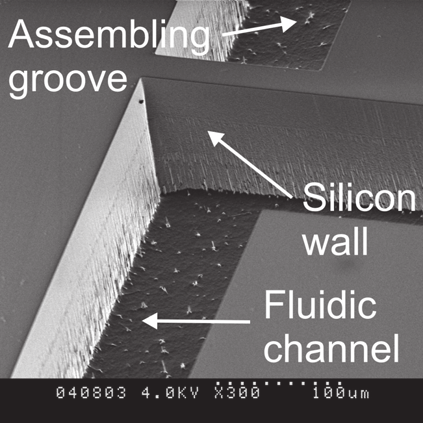

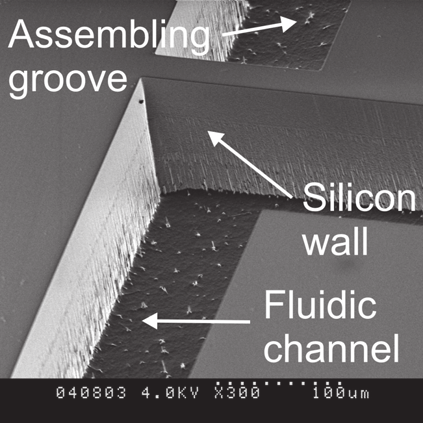

The technology of novel optical microsensor utilized standard microengineering techniques.

The fluidic channel and alignment grooves were etched by deep reaction ion etching (DRIE)

in 380 m thick, double-side polished, (100)-oriented silicon substrate. DRIE process has

been optimized to obtain the vertical side-walls of the channel. Two type of microchannels

were formed. The first type was microfluidical channels, the second one – microchannels for

positioning of optical fibers. After DRE etching these two types of channels were separated

by 20 m thick silicon wall with perpendicular walls. Photolithographically patterned 100

nm Al mask layer was used to form fluidic inlet/outlet holes form back side of the wafer.

The silicon substrate was thermally wet oxidized again to obtain 0.3 m SiO2 isolation layer

serving as chemically resistive layer. Next, the silicon substrate was anodically bonded

(450oC, 1.5 kV) to a Borofloat® 33 glass (Schott, Germany).

High quality bonding process was required to ensure the leakproofness of the channel.

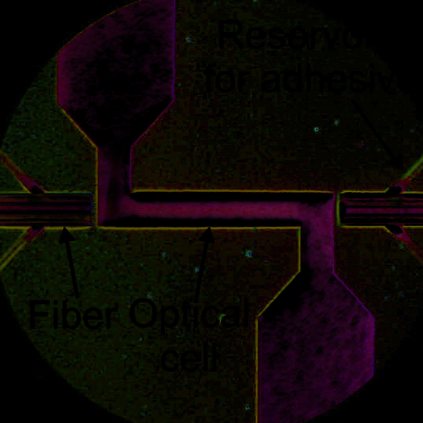

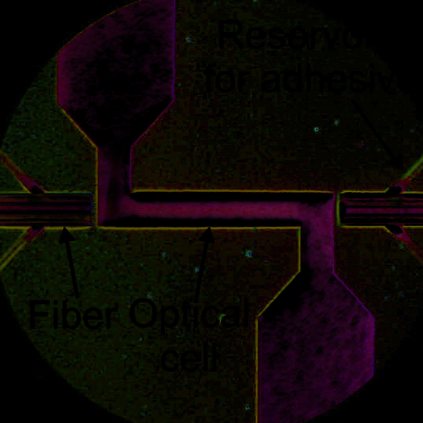

Finally, the optical fibers equipped with SMA connections were positioned in the alignment

Microsensors for Microreaction and Lab-on-a-chip Applications

131

grooves and immobilized by a droplet of UV-curable optical glue UVO-114 (Epo-Tec,

Germany) (Fig. 28).

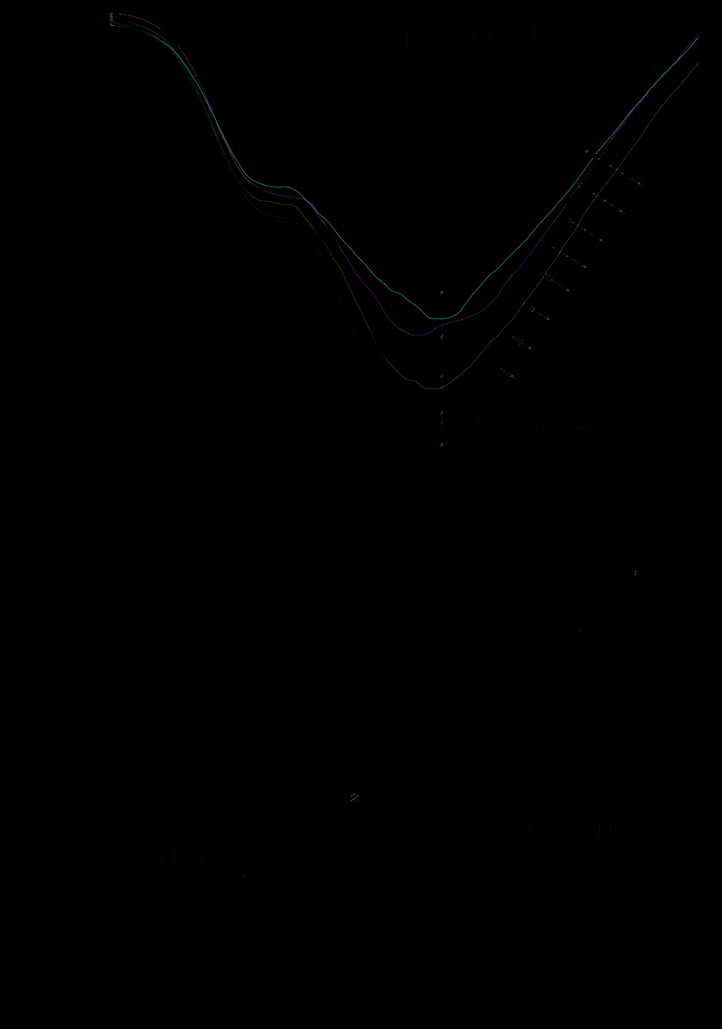

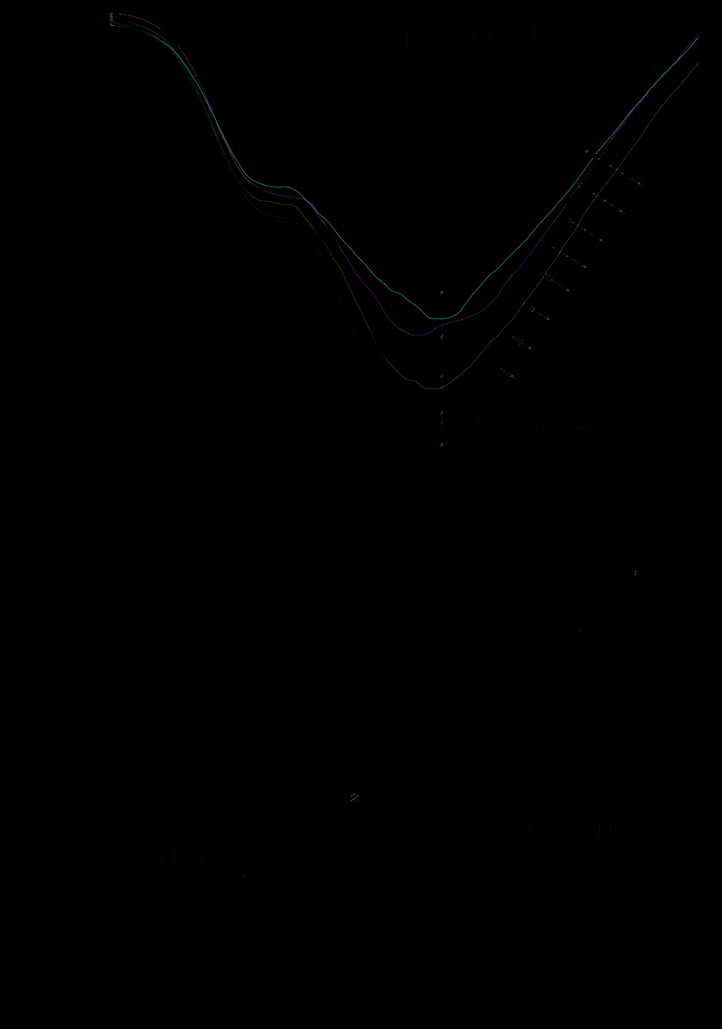

12000

11000

13 um

21 um

10000

25 um

9000

]

32 um

8000

37 um

ce [au

7000

49 um

6000

ittan

5000

smn 4000

raT 3000

2000

1000

0

550

600

650

700

750

800

850

900

950

Wavelength [nm]

Fig. 27. Transmittance of thin silicon membrane (thickness from 13 m to 49 m)

a) b)

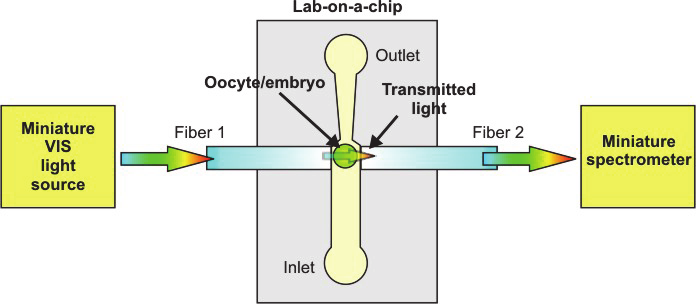

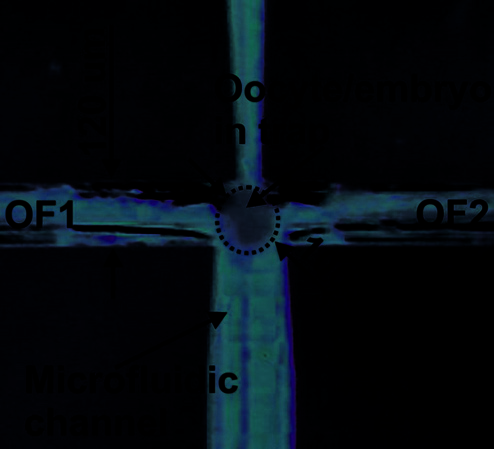

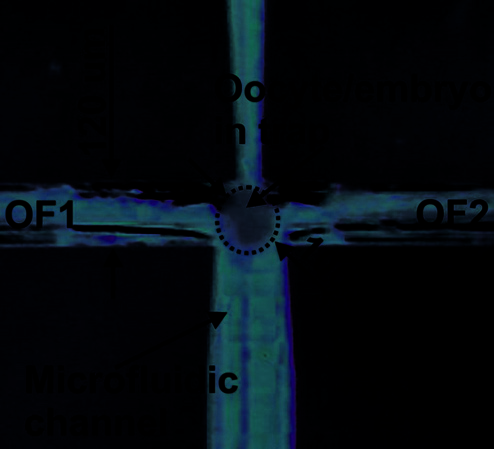

Fig. 28. NIR spectrophotometric microfluidical sensor: a) schematic top view and cross-

section of the microsensor, b) SEM picture of the thin silicon wall separating microfludical

channels for liquids and optical fiber positioning after DRIE etching (upper picture) and

optical microscope picture of the measurement cell with assembled optical fibers (lower

picture).

132

Microsensors

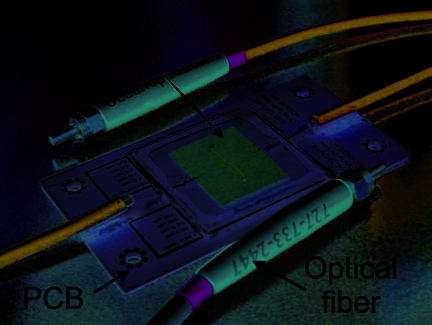

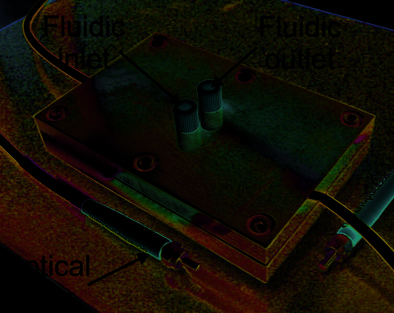

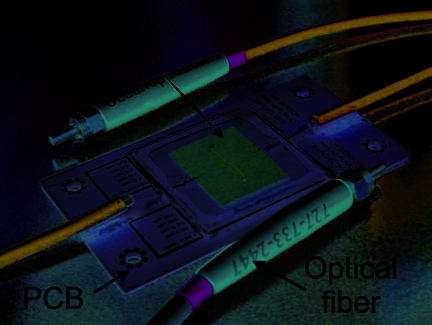

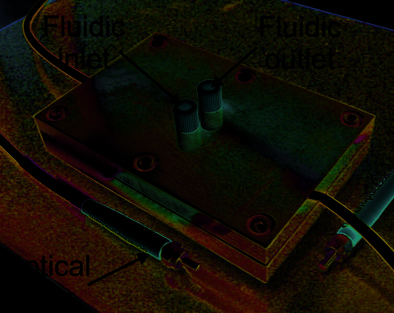

Assembled microfluidical sensor was placed on a PCB carrier and mounted in a metal

package with tight and chemically resistive standardized fluidic connections (UpChurch,

USA) (Fig. 29a, b).

a)

b)

c)

Fig. 29. NIR spectrophotometric microfluidical sensor: a) the chip mounted on a PCB ensuring

proper mechanical stiffness and robustness, b) the chip mounted in a metal package ready

with fluidic connections, c) scheme of the measurement set-up for NIR spectrophotometric

characterization of aggressive liquids by microfluidical silicon-glass sensor

The NIR system was composed of a halogen light source, a silicon-glass corrosion resistant

optical cell, and a NIR mini-spectrometer C9406 (Hamamatsu, Japan) (Fig. 29c). The cell

with optical path length of 5 mm had detection volume of only 90 nL. The system was

controlled by a notebook with suitable software.

The miniature spectrometric system has been tested experimentally by the measuring of

NIR spectra of several samples including highly corrosive reactants of nitration reaction.

The detection unit worked correctly at wide range of flow rates (0-300 ml/h) what

confirmed its mechanical robustness. The 24 h-long test with the measurement cell filled

with pure nitric acid followed by sulphuric acid showed corrosion resistance of the

detection chip. The spectra of pure nitric and sulphuric acids as well as theirs mixtures with

deionized water were successfully obtained (Fig. 30).

In further tests it has been clearly shown that the microsensor recognizes properly different

diesel oils and furnace oil as well as gasoline. Concentration of ETOH in Porto red wine has

been very well examined. Experimental results confirm the full applicability of the

miniature corrosion resistant NIR spectrometric system for use in wide range of

applications, e.g. mTAS, microreaction technology, biomedical/medical measurements. The

Microsensors for Microreaction and Lab-on-a-chip Applications

133

maximal wavelength is limited by the properties of array detector applied in miniature

Hamamatsu spectrometer. The use of longer NIR wavelengths (up to 2500 nm) is not limited

by the micromachined detection cell.

a)

b)

Fig. 30. The spectra of concentrated pure sulphuric (a) and nitric (b) acids as well as theirs

mixtures with deionized water, calibration curves describing absorbance versus DI water

content are shown below spectra

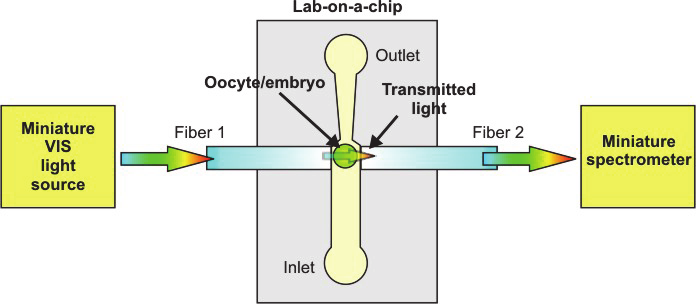

4.2 Absorbance VIS detector for optical characterization of living oocytes and

embryos

Optical characterization of living reproductive cells is an important issue in assisted

reproduction techniques. The major goal of these techniques is improvement of in vitro

fertilization process towards more successful breeding of farm animals. It is well known that

only 5-10% of in vitro fertilized oocytes are viable enough to reach full development

competence embryo stage. Assessment of development competence of oocytes and embryos

based on lab-on-a-chip system with analyze of the spectral characteristic of the cells, is an

important element in research on assisted reproductive technologies. Typical diameter of

porcine or bovine oocytes is in 100 m - 150 m range, similar dimensions are characteristic

for embryos. Due to size and volume incompatibility, spectrophotometric characterization

of these cells is impossible in typical measurement cuvette with 10 mm-long optical path

and at least a few hundreds microlitres volume. On the other hand, miniaturized

spectrometers and light sources co-working with optical fibers as light guiders to and from

characterized object are available now. What more, lab-on-a-chip techniques enables

134

Microsensors

fabrication of microchannels with diameter similar to the size of oocytes/embryos and

optical fibres (Szczepanska at al., 2009) (Fig. 31a).

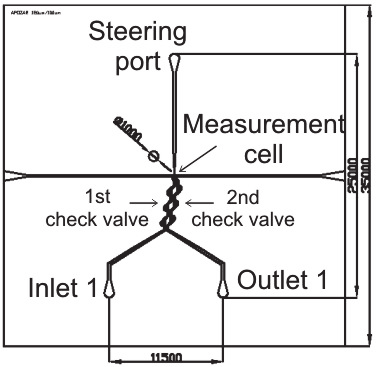

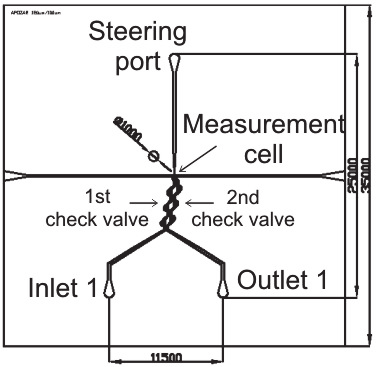

a) b)

Fig. 31. Scheme of an idea of the spectrophotometric characterization of single oocyte or

embryo in a lab-on-a-chip (a) and layout of the real lab-on-a-chip, the dimensions are in m

Lab-on-a-chip contains measurement cell, net of microchannels and passive valves for steering

of fluid and oocyte/embryo flow, and inlet/outlet holes for biological material

loading/unloading as well as a steering port for fluid flow management (Fig. 31b). The

biological material is introduced into the measurement cell by inlet 1, than passes through set

of passive Tesla’s valves (1st check valve). Next, characterized cell flows into the measurement

cell by sucking of the fluid by a pipette connected to the steering port of the chip. Topology of

the measurement cell ensures mechanical immobilization of the cell between two optical

fibers. After characterization, the cell is flushed back to the outlet 1 by passing through the

second set of Tesla’s valves (2nd check valve). Developed configuration enables steering of the

fluid flow with examined biological material transport with separation of the inlet and outlet.

The fluidic microchannels and microchannels for optical fibers (all 140 m deep) were

etched simultaneously in DRIE process in the 380 m - thick monocrystalline silicon wafer

(Fig. 32a). After etching, 0,3 m - thick thermal silicon oxide is was formed to passivate

chemically surface of the chip. Next, the wafer was anodically bonded (4500C, 1,5 kV) to a

borosilicate glass (Borofloat Schott, Germany) with previously mechanically drilled inlet

and outlet via - holes. Following, optical fibers with outer diameter of 120 m and 100 m

core (Ocean Optics, USA) were mounted. Fronts of the fibers were perfectly aligned each to

other thanks to high precision of DRIE etching. Fibers were aligned to the edge of

microfluidical channel, ensuring immobilization of the oocyte without its mechanical

destruction (Fig. 32c). Fibers were fixed by the use of UV NOA 61 epoxy hard glue

(Thorlabs, Sweden). Off-chip ends of both fibers were finished with standard SMA 905

connectors compatible with optical connections of the lamp and the spectrometer. Finally,

the chip was positioned in a metal package ensuring stable operation during

oocyte/embryo management within the chip (Fig. 32b).

The single oocyte/embryo was introduced into lab-on-a-chip by manual pipeting followed

by transport of the cell into the measurement cell thanks to capillary forces. After short

measurement (circa 5 seconds) of the optical spectra, the biological material was carefully

flushed-back to the outlet by applying pressure into the steering port. Then the cell was

captured to a sterile transporting container for further treatment.

Microsensors for Microreaction and Lab-on-a-chip Applications

135

The measurement set-up consisted of VIS/NIR light source (a halogen lamp by

OceanOptics, USA), developed by us lab-on-a-chip, miniature spectrometer (Ocean Optics,

USA) and a personal computer with specialized software (this set-up was similar to

presented on figure 31).

a) b) c)

Fig. 32. Lab-on-a-chip for VIS spectrophotometric characterization of oocytes/embryos: a)

enlarged view of the silicon chip after DRIE etching - microchannels for optical fibers,

measurement cell in the center and Tesla’s valves set are visible, b) packaged lab-on-a-chip

ready to work in comparison to Polish 2 zloty coin, c) view of the measurement cell with

trapped cell (OF1 and OF2 are optical fibers no 1 and 2)

Totally, over five hundreds of porcine and bovine oocytes, as well as almost one hundred of

bovine embryos were optically characterized by novel methodology and lab-on-a-chip.

Differentiation of collected spectral characteristics of the cells coming from different

classification groups (for example ovarian follicle size or morphological properties) has been

observed (Fig. 33). On the base of collected data, set of numerical values, describing

subjectively optical properties of examined cell, has been proposed: absorbance level for

specific wavelength, absorbance ratio for two wavelengths and wavelength position of the

absorbance maxima in VIS region.

a) b)

Fig. 33. Example of absorbance spectra obtained for: a) porcine oocytes coming from

different sizes of ovarian follicles, b) bovine oocytes for different morphological classes

136

Microsensors

Further experiments confirmed non-destructive nature of spectrophotometric oocyte

characterization. Successful in vitro bovine oocyte fertilization after lab-on-a-chip

examination has been achieved. This result opens a way towards oocytes selection for

artificial fertilization of farm animals oocytes as well as quality assessment of embryos prior

to the implantation.

4.3 Fluorometric detector

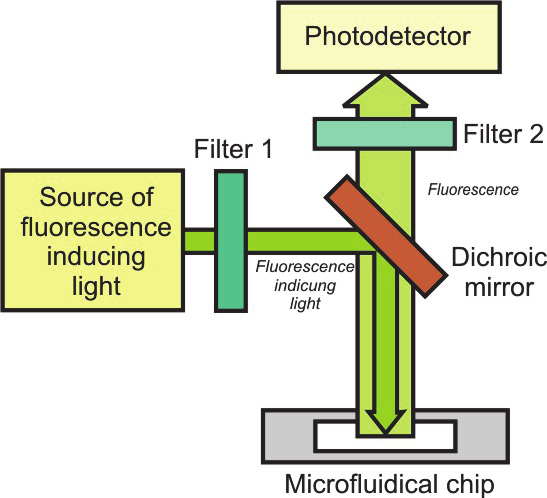

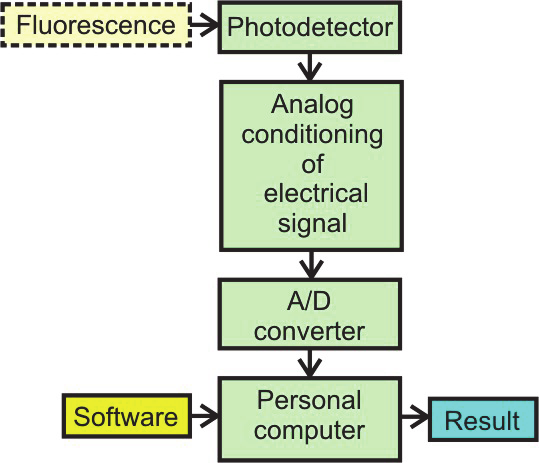

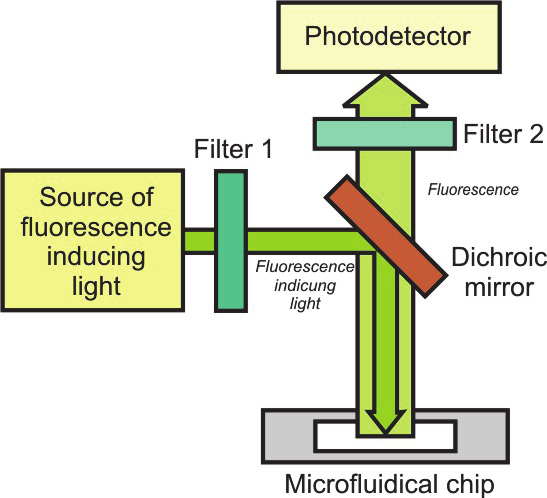

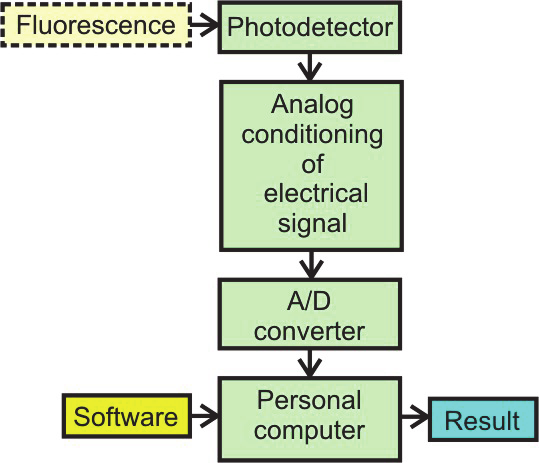

Labs-on-a-chip dedicated for fluorescence detection of analyte must enable introduction of

the fluorescence inducing light and collection of the fluorescence light from an area of

interest within the chip. Usually, the chips are whole made of visible light-transparent

materials – like glass, PDMS, SU-8, COC or other polymers – or only a top cover of the chip

is made of glass, PDMS or other light-transparent materials. Most of the chips are design to

co-work with typical apparatus applied for fluorescence induction and readout –

epifluorescence microscope (Fig. 34). In this devices, light, usually from arc lamp, light

emitting diode (LED) or laser, is restricted to a narrow range of wavelengths that can

effectively excitate a fluorochrome and be strongly filtered by the detection channel. The

narrow wavelength range is ensured by one or more interference filters and a dichroic

mirror. Fluorescence light emitted by the fluorochrome is collected by the microscope

objective and guided to a photodetector, passing through filters and dichroic mirror to

exclude the excitation light. Common detectors include photomultipliers tube (PMT),

semiconductor photodiodes and cooled charge coupled devices (CCD) as sensing matrix in

video cameras or lines in spectrometers. Light sources and photodetectors co-work with

analog conditioning electronics. The electronic circuits amplify electrical signal with

simultaneous reduction of noises. Most of the conditioning electronics is realized by the use

of analog circuits. These circuits must ensure high signal to noise ratio (SNR) before the

analog signal is digitalized. Therefore, configuration of these analog circuits is sophisticated

and only the highest quality elements can be used.

a) b)

Fig. 34. Fluorescence detection by epifluorescence microscope: a ) scheme of the methods, b)

path of fluorescence signal conditioning

Although, fluorescence detection is widely used for many years, the configuration of

detection apparatus co-working with labs-on-a-chip is based on solutions developed over 20

Microsensors for Microreaction and Lab-on-a-chip Applications

137

years ago. Therefore, rapid development of the LOCs must be followed by development of

novel methodologies and technical solutions surrounding the chips and leading towards

successful application of the microfludical chips in the point-of-care devices.

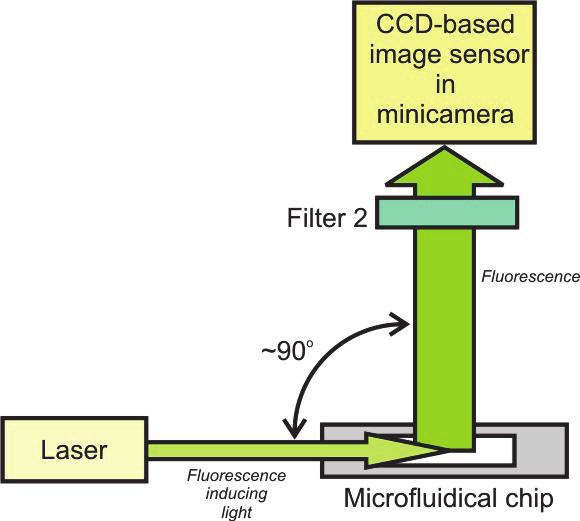

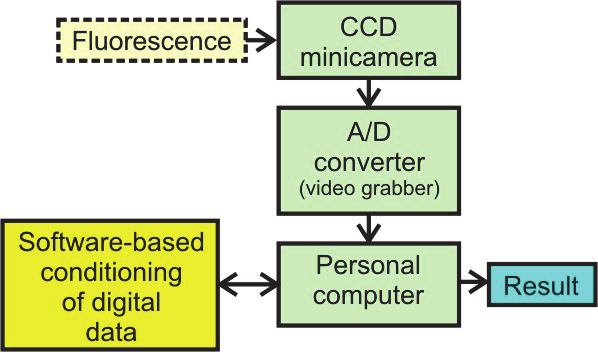

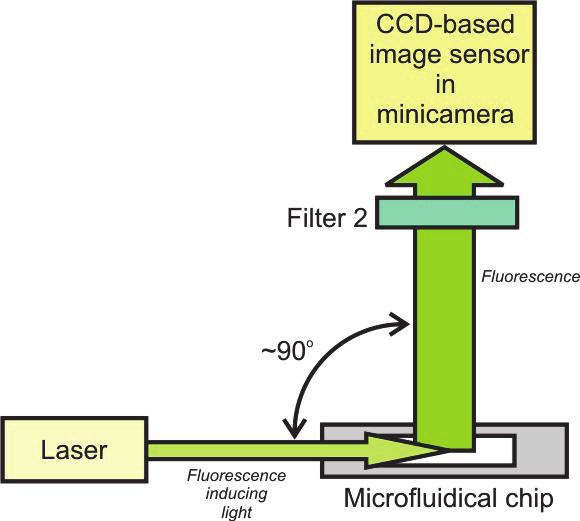

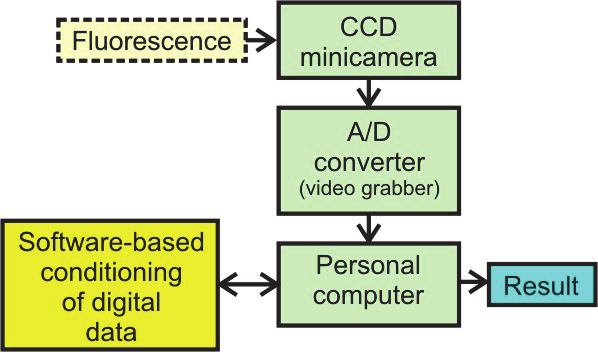

In the novel concept of the optical instrumentation for fluorescence induction and readout,

application of recent developments in optoelectronics and informatics is involved (Fig. 35).

a) b)

Fig. 35. Fluorescence detection by image sensor and orthogonal configuration of

induction/detection channels microscope: a ) scheme of the methods, b) path of fluorescence

signal conditioning

The fluorescence light is induced by a miniature semiconductor laser. Narrow- spectrum of

the laser light eliminates application of emission filter. Collimated laser light is introduced -

by edge coupling to a light guiding side wall of the chip - directly into detection area of the

chip. The view of the detection area containing fluorescence signal is collected by a CCD

image sensor being a part of low-cost minicamera module. The detection unit is positioned

perpendicularly in relation to the surface of the chip and laser beam. It enables geometrical

separation of the laser excitation light and fluorescence signal without application of

dichroic mirror, what significantly simplifies the optical part of the detection unit.

Therefore, detection unit consist of only one optical filter passing through the fluorescence

light and a miniature black/white CCD camera with the objective. The non-conditioned

analog output signal from the minicamera is digitalized by one-channel low-cost frame

grabber connected to a personal computer (PC). PC stores images in a memory and

specialized software carries out analyze of the captured images to give information on

fluorescence intensity. Thus, digital conditioning of the fluorescence signal by the software-

base image analyze in spite of analog conditioning is applied in the novel concept. Unique

feature of the novel methodology is possible re-analyze of the images which are stored in

the computer memory. It is not available in typical instrumentation with “non-imagining”

photodetectors (PMT or photodiode) when an operator has no chance for the second analye

of carried out experiment.

Novel fluorescence detection methodology and instrumentation co-working with various

labs-ona-chip have been successfully applied in many life-science applications –a portable

real-time PCR DNA analyzer, a novel portable cocaine detector, a miniature microcytometer

for optical characterization of biosamples or on-chip DNA gel electrophoresis.

138

Microsensors

One of the most interesting and promising applications of LOCs and presented here

fluorescence methodology is portable device for detection of food borne pathogens –

Campyloabcer j. and Salmonella spp. by specific amplification of bacteria’s extracted DNA with real-time detection of fluorescence – real-time polymerase chain reaction (PCR). This

instrumentation has been developed under European project OPTOLABCARD (Ruano-

Lopez at al., 2009). The device consists of a disposable real-time PCR chip, a docking station

with a specialized chip holder (Fig. 36) and electronics circuits and specialized software for

fluorescence signal detection and PCR process temperature profile management.

a)

b)

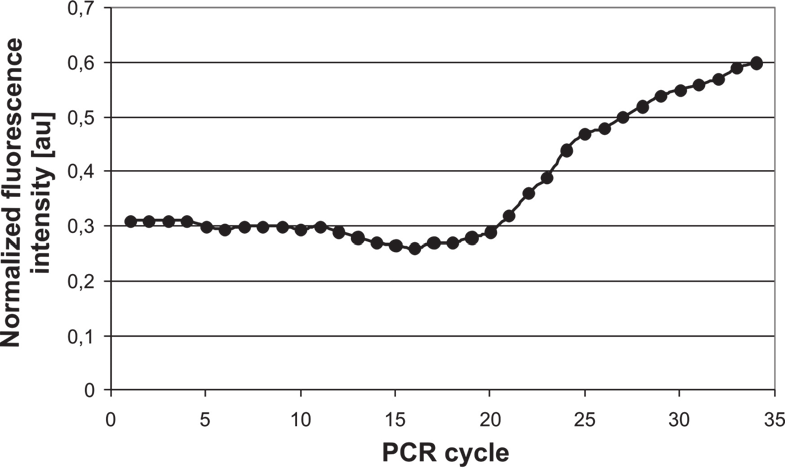

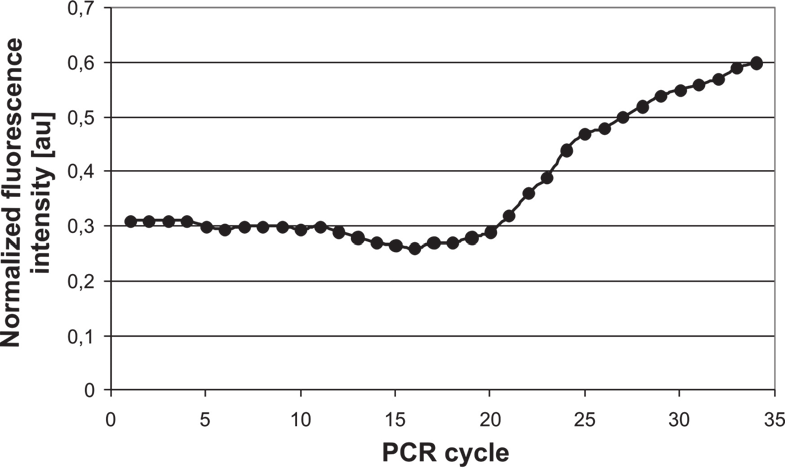

Fig. 36. Portable real-time PCR DNA analyzer utilizing disposable chips: a) view of the

docking station with mounted chip holder, b) typical real-time PCR S-curve of Campylobacter

j. DNA amplification and detection

The disposable glass/SU-8 chip (1 x 1 cm2) with integrated heater and temperature sensor is

placed in a plastic chip holder (2.8 x 2.8 . 0.5 cm3) with integrated electrical contacts to the

chip and some electronics for temperature management. The chip holder has miniature

electrical connection to a specialized PCR temperature controller connected to PC. The

holder with ready to use chip is positioned in the docking station (15 x 5 x 7 cm3) in the way

ensuring laser light introduction into PCR microchamber and fluorescence light collection.

The pre-validation tests of LOC-based system for detection of Campylobacter j. were carried

out with 48 chicken fecal samples. All the steps - from sample preparation to final result -

Microsensors for Microreaction and Lab-on-a-chip Applications

139

were performed in the single chip with 2.5 μl volume of reagents. Red-line fluorochrome

(TO-PRO 3) induced by red laser (635 nm, 1 mW) has been applied. The detection unit

utilized a long-pass 650 nm interference filter. Typical for real-time PCR fluorescence signal

increase during PCR of positive sample has been observed. The ratio of PCR efficiencies

between on-chip and on-tube was up to 300%. The sensitivity of on-chip PCR was

determined as 0.7-7 ng/ml of template DNA. The real-time PCR process took 30 min – at

least 4 times shorter than PCR on-tube.

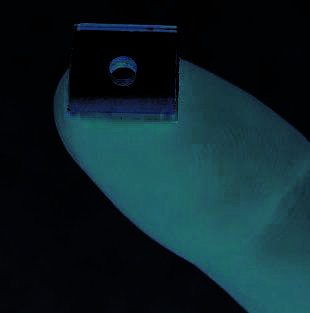

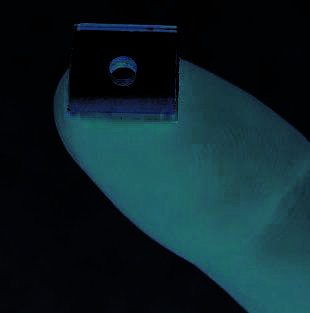

Similar device but utilizing reusable chip has been developed under Polish national project

(Fig. 37). The device was dedicated for rapid detection E. coli in water sample. The chip was

made of silicon and glass (Fig. 37b). It was passive chip without integrated heater and

temperature sensor. PCR temperature profiling was realized by external in relation to the

chip Peltier module–based thermocycler. Due to high chemical resistivity of applied chip

materials and assembling technique (anodic bonding) it was possible to clean the chip after

PCR by the use of standard sterilization processes (chemical or thermal). Thus, the chip was

reusable in contrast to the disposable polymer chips.

a) b)

Fig. 37. Desktop real-time PCR device co-working with silicon-glass reusable chips: a) view

of the instrument, b) 1 cm x 1 cm chip on author’s finer

The second interesting application of the miniature semiconductor laser and CCD-based

detection unit is a portable cocaine detector developed under European project

LABONFOIL (Walczak at al. 2009). The cocaine test is forecasted to be used as prevention

test for professional drivers of heavy trucks or buses. The device consist of a disposable

wearable cartridge with implemented biological part for cocaine/metabolite detection in a

human sweat sample and a hand-held optical reader connected to a computer. The

disposable cartridge contains lab-on-a-paper for sweat sample collection and

immunochromatography-based cocaine or its metabolite separation and detection. The

hand-held reader utilizes semiconductor red laser diode in the excitation channel and 670

nm interference filter co-working with the minicamera in the fluorescence readout channel.

The reader is supplied by USB port of a portable computer (Fig. 38). Preliminary tests of the

instrumentation confirmed high sensitivity of the optical reader. Lowest detection limit of

t