MEMS Gyroscopes for Consumer and

Industrial Applications

MEMS Gyroscopes for Consumer and Industrial Applications

27

279

Segway (2011).

URL: http://www.segway.com

Seidel, H., Aikele, M., Rose, M. & Toelg, S. (2002). Safety relevant microsystems for automotive

applications, Microsystem Technologies 7(5): 244–248.

Senturia, S. D. (2001). Microsystem Design, Kluwer Academic Publishers.

Shakoor, R. I., Bazaz, S. A., Kraft, M., Lai, Y. & ul Hassan, M. M. (2009).

Thermal

Actuation Based 3-DoF Non-Resonant Microgyroscope Using MetalMUMPs, Sensors

9(4): 2389–2414.

Shearwood, C., Ho, K. Y., Williams, C. B. & Gong, H. (2000).

Development of a

levitated micromotor for application as a gyroscope, Sensors and Actuators A: Physical

83(1-3): 85 – 92.

Soderkvist, J. (1991). Piezoelectric beams and vibrating angular rate sensors, Ultrasonics,

Ferroelectrics and Frequency Control, IEEE Transactions on 38(3): 271–280.

Söderkvist, J. (1994). Micromachined gyroscopes, Sensors and Actuators A: Physical 43(1-3): 65

– 71.

Sparks, D., Zarabadi, S., Johnson, J., Jiang, Q., Chia, M., Larsen, O., Higdon, W. &

Castillo-Borelley, P. (1997). A CMOS integrated surface micromachined angular

rate sensor: it’s automotive applications, Solid State Sensors and Actuators, 1997.

TRANSDUCERS ’97 Chicago., 1997 International Conference on, Vol. 2, pp. 851–854

vol.2.

Stewart, R. E. (2009). Micro hemispheric resonator gyro, U.S. Patent 2009/0031831.

STMicroelectronics (2010).

URL: http://www.st.com/stonline/products/literature/ds/15812/lpr530al.pdf

Stringer, J. (2000).

The Air Force Institute of Technology (AFIT) Micro Electro-Mechanical

Systems (MEMS) Interferometric Gyroscope (MiG), Master’s thesis, Air Force Institute

of Technology (AFIT).

Tanaka, K., Mochida, Y., Sugimoto, M., Moriya, K., Hasegawa, T., Atsuchi, K. & Ohwada,

K. (1995). A micromachined vibrating gyroscope, Sensors and Actuators A: Physical

50(1-2): 111 – 115.

Tang, W., Nguyen, T.-C. & Howe, R. (1989).

Laterally driven polysilicon resonant

microstructures, Micro Electro Mechanical Systems, 1989, Proceedings, An Investigation

of Micro Structures, Sensors, Actuators, Machines and Robots. IEEE, pp. 53–59.

Tsai, N.-C., Huang, W.-M. & Chiang, C.-W. (2009). Magnetic actuator design for single-axis

micro-gyroscopes, Microsystem Technologies 15(4): 493–503.

Vellekoop, M. J. (1998). Acoustic wave sensors and their technology, Ultrasonics 36(1-5): 7 – 14.

Ultrasonics International 1997.

Voss, R., Bauer, K., Ficker, W., Gleissner, T., Kupke, W., Rose, M., Sassen, S., Schalk, J., Seidel,

H. & Stenzel, E. (1997). Silicon angular rate sensor for automotive applications with

piezoelectric drive and piezoresistive read-out, Solid State Sensors and Actuators, 1997.

TRANSDUCERS ’97 Chicago., 1997 International Conference on, Vol. 2, pp. 879–882

vol.2.

Weinberg, M. & Kourepenis, A. (2006). Error sources in in-plane silicon tuning-fork MEMS

gyroscopes, Microelectromechanical Systems, Journal of 15(3): 479–491.

Yazdi, N., Ayazi, F. & Najafi, K. (1998). Micromachined inertial sensors, Proceedings of the IEEE

86(8): 1640–1659.

28

280

Will-be-set-by-IN-TECH

Microsensors

Yokota, S., Imamura, T., Takemura, K., Edamura, K. & Kumagai, H. (2008).

A liquid

rate gyroscope using electro-conjugate fluid, Intelligent Sensors, Sensor Networks and

Information Processing, 2008. ISSNIP 2008. International Conference on, pp. 459–464.

Zhou, J., Yan, G., Zhu, Y., Xiao, Z. & Fan, J. (2005). Design and fabrication of a microfluid

angular rate sensor, Micro Electro Mechanical Systems, 2005. MEMS 2005. 18th IEEE

International Conference on, pp. 363–366.

Zhu, R., Ding, H., Su, Y. & Zhou, Z. (2006). Micromachined gas inertial sensor based on

convection heat transfer, Sensors and Actuators A: Physical 130-131: 68 – 74.

13

Planar Oxygen Sensors for Non Invasive

Imaging in Experimental Biology

Henning Tschiersch1, Gregor Liebsch2, Achim Stangelmayer2,

Ljudmilla Borisjuk1 and Hardy Rolletschek1

1Institut für Pflanzengenetik und

Kulturpflanzenforschung (IPK), Gatersleben,

2PreSens Precision Sensing GmbH, Regensburg,

Germany

1. Introduction

The presence of molecular oxygen is a sine qua non for aerobic metabolism. In both plant and

animal mitochondria, it acts as the terminal electron acceptor for oxidative phosphorylation

occurring during cellular respiration, and is necessary for the generation of ATP, the

common energy currency within the living cell (Atkinson, 1977; Cooper, 2000). It is the

major by-product of photosynthesis in which plant biomass is accumulated by the

conversion of carbon dioxide into polymeric compounds. Since respiration and

photosynthesis are so fundamental to life on earth, an understanding of the mechanisms

underlying oxygen consumption, production and homoeostasis has become a significant

field of both biological and biotechnological research (Volkmer et al., 2009).

Oxygen (micro-) sensors, which are widely used in the life sciences, are designed to provide

a precise measurement of the concentration of oxygen within a localized region of a tissue or

an organ (Borisjuk & Rolletschek, 2009). Most of these devices have been based on

miniaturized Clark-type electrodes (Revsbech & Jørgensen, 1986), in which oxygen diffuses

into the sensor via a permeable membrane, following which its reduction at the cathode

generates a measurable electrical current. This approach can deliver a spatial resolution at

the low µm scale. Increasingly this technology is being replaced by optical oxygen

microsensors (micro-optodes) based on fibre optic materials (Klimant et al., 1995;

Rolletschek et al., 2009), in which the concentration is assessed in tapered glass fibres of tip

size ~50µm via the dynamic quenching of a luminophore. This approach enjoys several

advantages over the electrochemical detection system, as detailed elsewhere (Kühl &

Polerecky, 2008; Rolletschek et al., 2009).

Importantly, microsensor-based approaches are invasive, which means that a given

biological sample cannot be readily studied over a prolonged time period. Furthermore, the

internal structure of most biological samples is far from homogeneous, with complex

compartmentation being the norm. As a result, whole tissue measurements can only reflect

the mean performance of a tissue, and cannot report variation between distinct

compartments. This loss of richness compromises the value of such data for elucidating the

biology of the tissue as a whole. At best, conventional sensor systems assess oxygen

282

Microsensors

concentrations across a transect, leaving its two dimensional distribution unknown. Lifting

this limitation requires the development of a planar sensor.

Here, we present a novel oxygen sensing approach, in which image processing has been

combined with optical sensor technology. The optical sensor foil (i.e. the planar optode)

attached to the surface of the sample translates the oxygen signal into a light signal, which is

then captured and interpreted pixel by pixel by a digital camera. Since a single image

captures an array of sensor points, the system permits an instantaneous two-dimensional

mapping of oxygen distribution. While some analagous approaches have already been

described in the literature (Liebsch et al., 2000; Glud et al., 2005; Kühl & Polerecky, 2008), the

system we describe here represents a significant improvement with respect to spatial

resolution, handling and image processing, and eventually ease of use. Two applications of

the system are described in some detail: the first involves a respiring (oxygen consuming)

root of oilseed rape ( Brassica napus), and the second a photosynthetically active (oxygen

generating) leaf of Cabomba caroliniana, an aquatic perennial herbaceous plant. In both,

marked oxygen gradients were detected across both time and space. In combination with

the use of specific inhibitors, the planar sensor system can be expected to permit a spatially

well resolved analysis of respiration or photosynthesis. We conclude that the new planar

sensor setup provides fascinating opportunities for research in all areas of life sciences.

2. Planar oxygen sensors – design, calibration and applications

The following chapters provide an overview on (i) the technical features of the novel planar

sensor setup, and (ii) the possibilities for its use in plant biology, in particular to study

respiration (oxygen consumption) and photosynthesis (oxygen production).

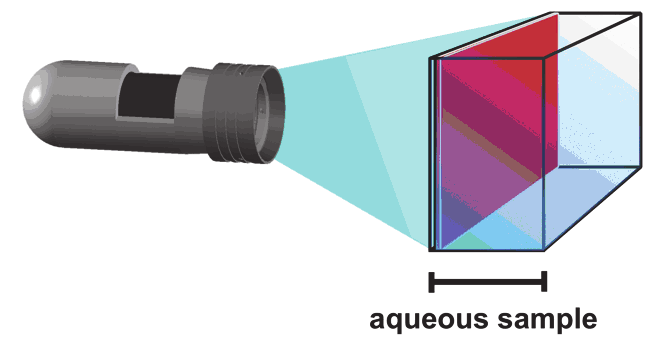

2.1 Experimental design for life time imaging of oxygen

Digital revolution in photography induced a giant trend towards capturing images and

creating movies of nearly everything one can think of. Beside scientific and industrial

cameras the market of consumer imaging devices is constantly growing and continually

new products are launched showing increased resolution while being miniaturized. The

enhancement of image quality and downsizing affects all market segments of consumer

cameras, high-quality SLR cameras as well as low-tech webcams and mobile phone cameras.

As a result, the use of such consumer devices is also of increasing interest in the field of

opto-chemical sensing where the response of a fluorescent sensor is recorded in order to

measure chemical analytes. Typically, for this application fairly bulky and sophisticated

camera systems (Holst et al., 1998; Schröder et al., 2007; Kühl & Polerecky, 2008) are used which support time resolved measurement. Measuring a lifetime dependent parameter is

generally preferred because of the favourable accuracy due to suppressing common

interferences including heterogeneous lightfield or sample coloration and auto-fluorescence

allowing even transparent sensor foils (Holst et al., 2001). This is not possible if using even

high-tech standard consumer cameras which allow ratiometric calibration schemes at best.

However, beside the restriction of transparent sensors ratiometric imaging has proved to be

also an excellent solution for measuring analyte contents of a sample quantitatively and two

dimensionally (Wang et al., 2008). Then, it depends on the sample target and analytical

problem if the possibility of miniaturisation and mobility overcompensates the restriction.

Especially in biological application fields of imaging with fluorescent optical sensors it is

desirable to use compact devices which are close to pocket size and can easily be taken to

Planar Oxygen Sensors for Non InvasiveImaging in Experimental Biology

283

the place of measurement. As a result, complex biological systems are not disturbed and can

be measured “as is” in their natural environment or green house. New reports address the

topic of applying portable consumer technology by using SLR cameras (Wang et al., 2010) or

even mobile phones (Filippini & Lundstrom, 2006) with the side-effect of substantially

reducing the costs for imaging devices at the same time. However, in these solutions the

question about suitable optical filters, macro lense and light source combinations is not

sufficiently solved. Especially a micrometer resolution is indispensable if investigating

biological processes of plant seeds, embryos, collenchyma or rhizospheres. Also in other

medical and biotechnical applications a high resolution is needed including monitoring

phase transitions in aquatic biology, mini bioreactors, tissue engineering and skin

microcirculation. Therefore, we developed the idea of using consumer camera technology

further and identified a type which fits perfectly to the demands of fluorescent optical

imaging: the USB microscope. The results presented here were measured with a prototype

of new imaging product series “VisiSens” (PreSens GmbH, Regensburg, Germany).

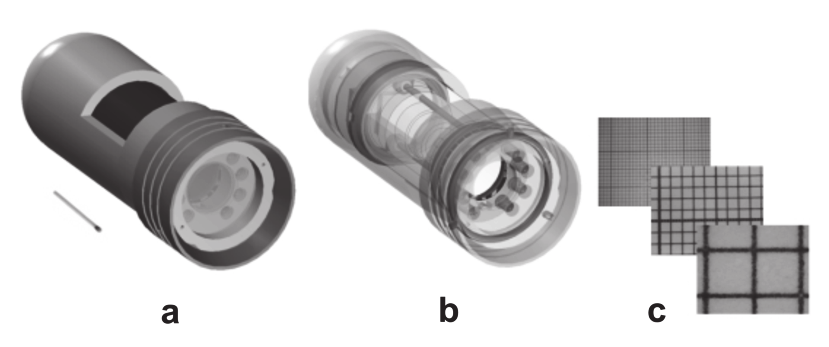

The market of USB microscopes is allocated to many types showing huge differences in

image quality. We based our development on a current high-end USB microscope with good

sensitivity and image quality and improved it for imaging fluorescence-optical sensors by

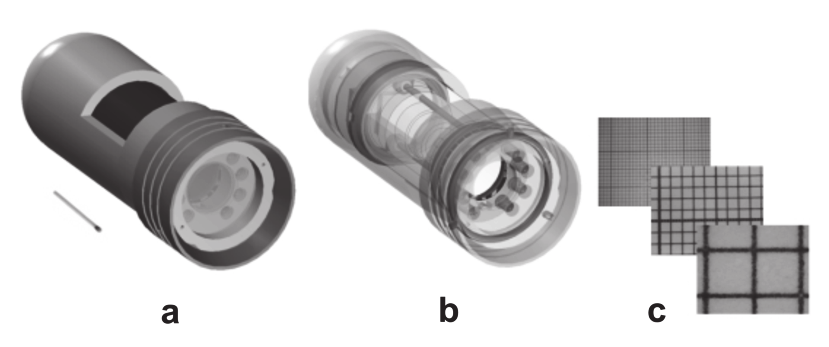

integrating an optic block with high quality LED PCB and optical filters. Figure 1 shows a

solid (left panel) and a transparent (middle panel) technical drawing of the measurement

head, showing its compactness and the arrangement of the respective components. The

three images beside show millimeter paper measured with different magnification settings.

Maximum magnification is approximately 200-fold where the field of view is ~ 2.5 x 2.0 mm.

Fig. 1. (a) Solid and (b) transparent technical drawing of the compact measurement head

incorporating a USB-microscope for imaging fluorescent sensor foils. Camera and light

source are powered via standard USB connector. (c) Images of millimeter paper

demonstrating the magnification up to 200-fold.

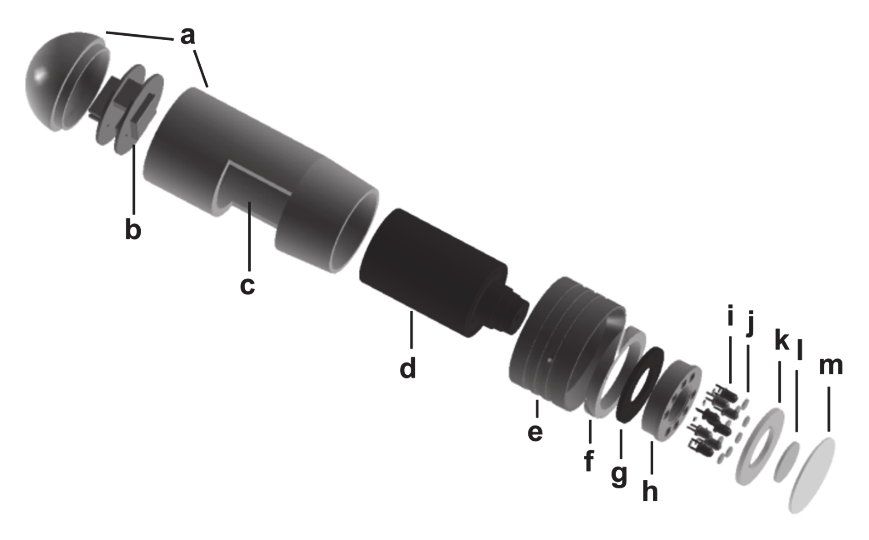

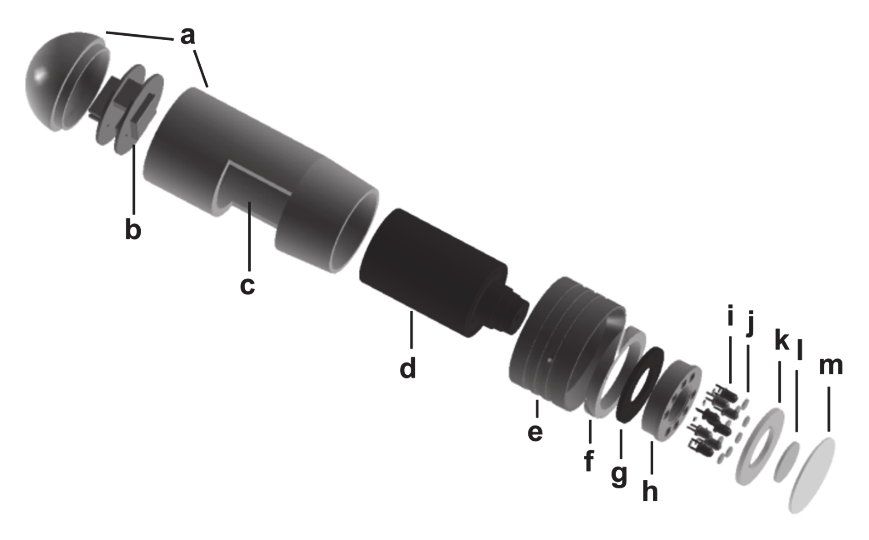

Figure 2 shows an explosion drawing of the USB microscope where the components are

addressed in detail. The all-aluminium detector head (a) integrates a color RGB CMOS chip

(b), a microscope lense (c) with manual focus, 8 blue emitting LEDs (i) which are driven by a

printed circuit board (PCB) (g) and aligned in an aluminium block (h) and optical filters for

light diffusion (j), excitation (k) and emission (l). The up to 200-fold magnified images are

recorded with a 1.3 megapixel (1280 x 1024) color chip which results in more than 300,000

independent sensing points (= pixel) for the respective sensor response (i.e. color channel of

the RGB chip). Maximum spatial image resolution is ~ 2.5 mm per 1280 pixel (~ 2 µm per

284

Microsensors

pixel). Maximum spatial sensor resolution depends on the sensor used and is typically ~ 25

to 100 µm. Power supply of the camera and the LED light source is provided via the

standard USB connector which makes the system laptop compatible and a portable device.

The dimensions of the detection head are 10 cm in length and 3.8 cm in diameter, the

working distance is typically from 1 to 5 cm. The camera can be used free hand or mounted

to a stand.

Fig. 2. Explosion drawing of the PreSens USB-microscope “VisiSens” optimized for imaging

of fluorescencent sensor foils: (a) aluminium housing, (b) RGB CMOS-chip, (c) opening for

manual focus, (d) microscope lense, (e) filter tube, (f) mounting and adjustment ring

(g) transmitter PCB, (h) LED reflector block, (i) LEDs, (j) diffusor, (k) short pass excitation

filter, (l) long pass emission filter and (m) sapphire glass.

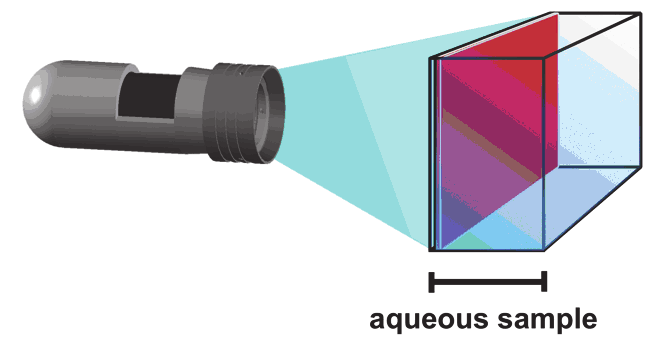

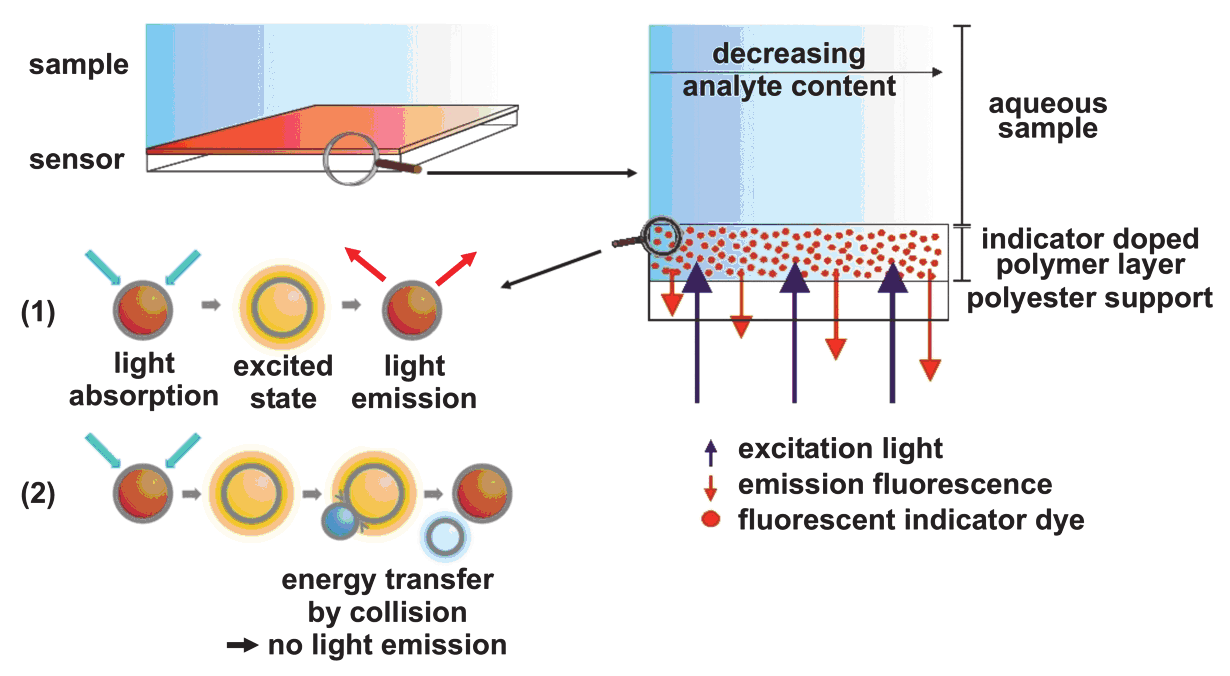

For the measurement the imaging system uses flexible sensor foils which allow two

dimensional recording of oxygen distributions in aqueous phase over an area typically

ranging from 5 x 5 mm2 up to 40 x 40 mm2. The planar sensors consist of an oxygen sensitive

dye and a reference dye which are immobilized in an oxygen permeable polymer matrix

and fixed on a transparent polyester support and overlaid with a white oxygen transparent

layer for optical isolation. We used a PreSens sensor foil which is not described here but

similar to that described in detail by Wang et al., (2010).

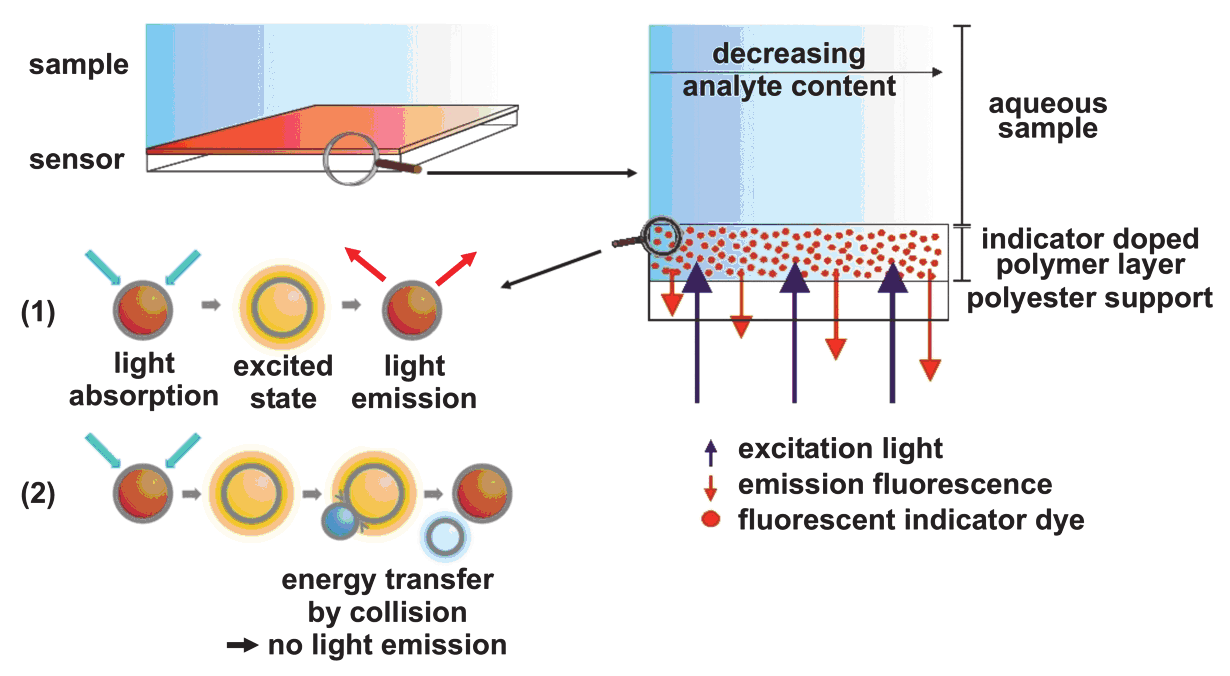

During the measurement the sensitive layer is in contact with the sample and the

fluorescence is measured from the backside. Every single indicator dye molecule is

interacting independently with oxygen in the form that the red fluorescence of the sensitive

dye is dynamically quenched. This means that the energy of the excited dye is transferred to

the oxygen molecule by collision (see Fig. 3) and consequently the intensity of the sensitive

dye is reduced with increasing oxygen content of the sample.

The reference dye, however, is not affected by oxygen and shows constantly a green light

signal. The working range of the oxygen sensor covers the typical biological range from 0 to

100% air saturation (corresponding to 6.04 mL of oxygen per liter freshwater at 25 °C and 101.3

kPa standard atmosphere). The sensors can be shaped to any desired geometry using a scissor.

Planar Oxygen Sensors for Non InvasiveImaging in Experimental Biology

285

A

B

Fig. 3. (A) Schematic of the sensor foil and principle of dynamic fluorescence quenching. The

sensor responds to oxygen by passing the energy of an excited state dye via collision to the

oxygen molecule. This results in fluorescence quenching with increasing oxygen content of

the sample. (B) Measurement set-up. The sensor consists of an indicator doped polymer

layer which is fixed on a transparent polyester support. During the measurement the sensor

has to be in direct contact with the sample. The sensor response is measured from outside

through a transparent window of the respective vessel.

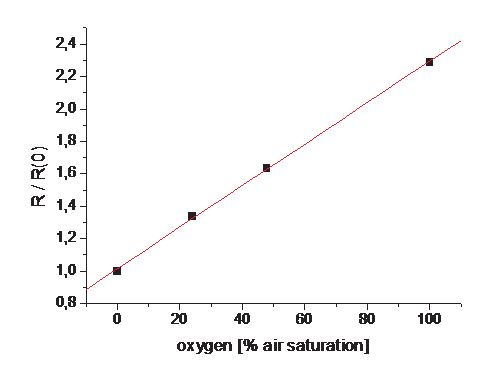

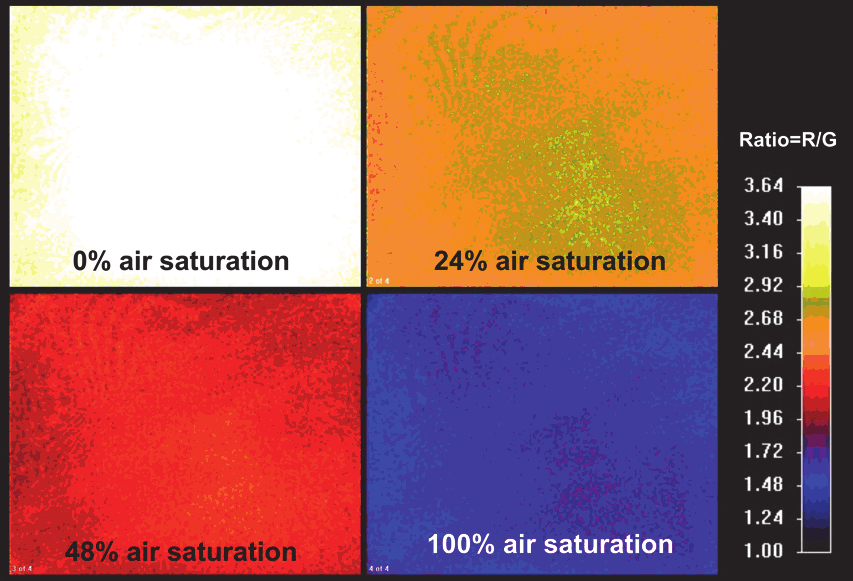

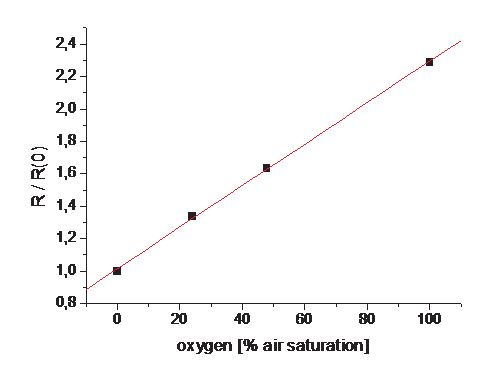

For quantitative evaluation of the sensor response we applied a ratiometric calibration

scheme. The sensitive dye and reference dye are excited with the identical light source at the

same time but emit at different bands of wavelength. In our case, both dyes are excited with

blue light and while the sensitive dye emits red light, the reference emits green light. We

selected dyes whose emission bands of wavelength meet exactly the red and green channel

sensitivity of our color RGB chip. This enables to obtain the green reference information

independently from the red sensor information within a single image at the same time. A

quantitative evaluation is done by rationing the red and green channel of the RGB image in

286

Microsensors

order to reference out the main interferences of intensity based measurements namely

inhomogeneous light field and dye concentration including varying sensor layer thickness.

The respective oxygen content is computed from the ratio applying a calibration function

which was derived from measuring the sensor response at known oxygen concentrations in

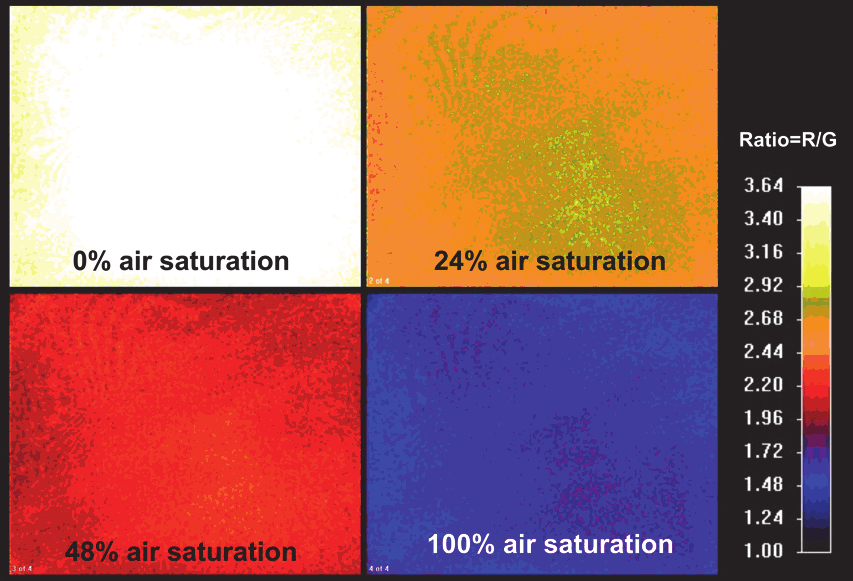

a chamber (Figure 4).

A

B

Fig. 4. (A) Calibration Images and data. The sensor was exposed to different oxygen gas

mixtures and the response was imaged. (B) The Stern-Vollmer plot leads to a linear relation

which was used for calculating the respective oxygen contents of the measurement images.

Planar Oxygen Sensors for Non InvasiveImaging in Experimental Biology

287

2.2 Application of planar optical sensors for oxygen measurements on plants

Unlike animals, plants are both producers and consumers of oxygen via photosynthesis and

cellular respiration, respectively. Plant leaves, stems and seed tissues generally possess

chloroplasts, producing oxygen under illumination ((Borisjuk and Rolletschek, 2009;

Tschiersch et al., 2011) whereas roots are a typical example of non-green tissues. Their oxygen

homoeostasis and exchange capabilities depend on the developmental state (age), several

tissue characteristics (e.g. cuticula) as well as environmental conditions (e.g. temperature)

(Armstrong et al., 1994, 2009). In particular, the complex anatomy of tissues often hampers

oxygen diffusion, thereby causing steep diffusion gradients and local oxygen deficiencies.

Planar oxygen sensors are an alternative to conventional microsensor-based techniques, and

allow to viualize the oxygen dynamics between tissues and surrounding media. Here, we

demonstrate the applicability of the planar sensor system to study oxygen dynamics in two

plant models: (i) the respirating (O2-consuming) root system of the crop plant oilseed rape

( Brassica napus), and (ii) the photosynthetically active (O2-producing) leaf of the water plant Cabomba caroliniana.

2.2.1 Imaging of oxygen consumption in living plant roots

Several contrasting plant species, that differ in their relative growth rates (herbs, grasses,

shrubs and trees), possess respiration rates in a relative narrow range between 20 and 52

nmol oxygen (g DW)-1 s-1 (Loveys et al., 2003). Similar values were reported for roots of crop

plant seedlings using clark-type electrodes (Tab. 1). For roots of oilseed rape seedlings we

measured mean respiration rates of ~ 79 nmol oxygen (g DW)-1 s-1 (own unpublished data).

Root respiration rate

Species

References

[nmol O2 (gDW)-1 s-1]

Oilseed rape ( Brassica napus)

79.3 this

study

Barley ( Hordeum vulgare)

16.2

Bloom et al., 1992

Wheat ( Triticum aestivum)

64.0

Kurimoto et al., 2004

Rice ( Oryza sativa)

39.1

Kurimoto et al., 2004

Corn ( Zea mays)

56.7

Hejl & Koster, 2004

Potato ( Solanum tuberosum)

14.8

Bouma et al., 1996

Tomato ( Solanum

15.8

Hadas & Okon, 1987

lycopersicum)

Pea ( Pisum sativum)

69.2

DeVisser et al., 1986

Soybean ( Glycine max. )

67.5

Millar et al., 1998

Table 1. Root respiration rates of various crop plants

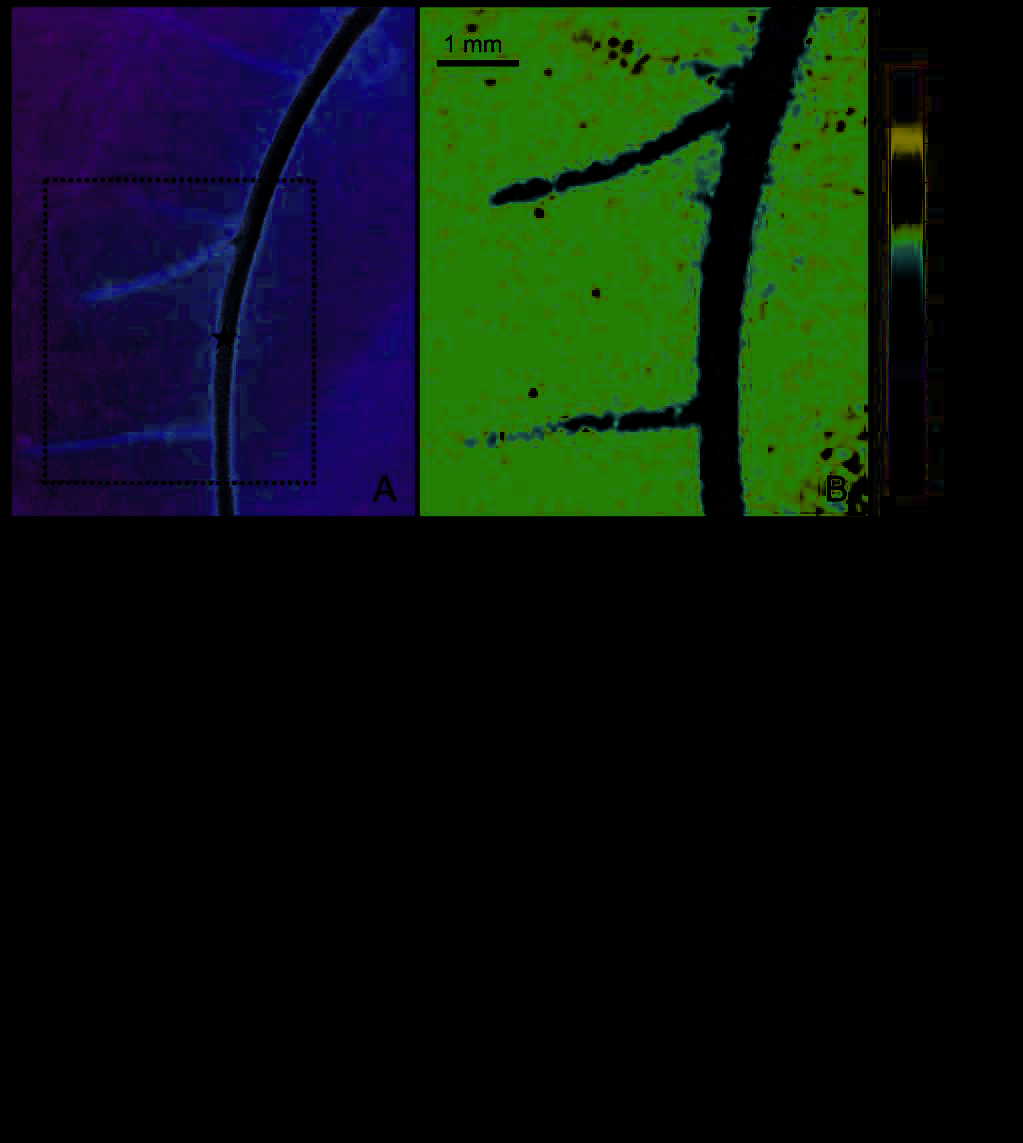

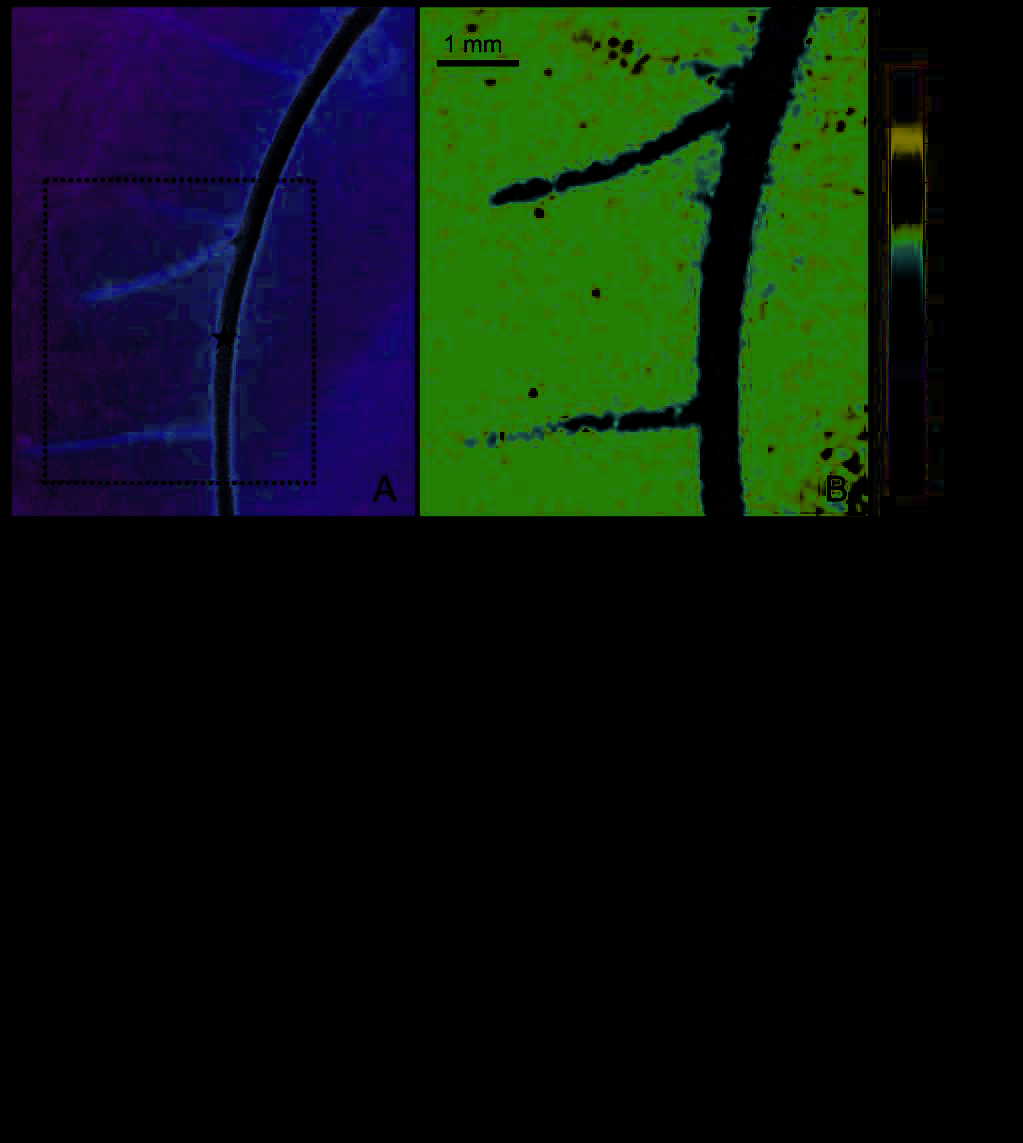

Using the planar oxygen sensor we here aimed to visualize quantitatively the oxygen

consumption of intact roots. For this purpose oilseed rape was grown on 0.9% Difco-agar for

14 days. For the measurement the root segments of seedlings were covered with the

transparent sensor foil. The use of transparent foils is of special importance because it allows the alignment between the sample structure and the measured oxygen distribution. The

sample was enclosed by an incubation chamber to limit oxygen diffusion from the outside.

This custom-made system allowed the combined imaging of the root (Fig. 5a) and the

oxygen concentration (Fig. 5b). In our experiment, the oxygen distribution in the sample

was followed over six hours with measuring points every 15 min. Based on the decline in

oxygen concentration over time, the respiration rate of the central root zone was calculated

288

Microsensors

as 0.015 % air saturation min-1, which corresponds to ~ 12.5 µmol oxygen h-1. The final

image of oxygen distribution in Fig. 5b demonstrates that oxygen consumption of the root

system can be mapped for distinct root regions with sub-millimetre resolution using the

planar sensor setup. It should be noted that the use of thin sensor foils and incubation

chambers is preferable, because this reduces diffusive smearing of the spatial oxygen

distribution, which otherwise can mask the true oxygen dynamics as well as its gradients.

Thus, it allows maximizing the spatial resolution in oxygen mapping.

Fig. 5.