Donner Quartz Rotation Sensor (QRS) (quartz cut axis orientation ≡ z-axis) (Gupta & Jenson, 1995; Knowles & Moore, 2004); (b) electrodes configuration for generating the drive tine

bending vibration; (b) electrodes configuration for sensing the pickup tine bending vibration.

16

268

Will-be-set-by-IN-TECH

Microsensors

Weinberg & Kourepenis, 2006)) or canceling the error from the measurement (using a

feed-forward cancellation scheme - (Antonello et al., 2009; Saukoski et al., 2007)).

• improving sensor linearity and bandwidth.

This is usually achieved by exploiting a

closed-loop sensing interface, in which the sense motion is nulled by employing a control

loop. The feedback signal used for nulling the sense motion contains the angular velocity

information, which can be extracted with a basic synchronous baseband demodulation

circuit. When a digital output must be provided, the feedback signal can be oversampled

and quantized with a coarse quantizer: in this case, the closed-loop sensing interface

behaves as a (electromechanical) ΣΔ modulator (Dong et al., 2008; Petkov & Boser, 2005).

• improving scale factor thermal stability. A temperature compensation loop can be sometimes

integrated on-board to reduce the sensitivity of the scale factor to temperature variations

(Jiancheng & Jianli, 2009).

Additional electronic functions may include self test and calibration, bias compensation, etc.

4. Industrial requirements

The specifications and test procedures for a single-axis CVG-based angular rate sensor have

been standardized in ( IEEE Standard Specification Format Guide and Test Procedure for Coriolis

Vibratory Gyros, 2004). The standard requirements for a CVG are specified in terms of its

performances, its mechanical and electrical interface characteristics, the environmental conditions, the sensor life time and reliability (usually measured as Mean Time Between Failure - MTBF).

The performance of a CVG is specified according to the following quantities, whose

definitions are taken from ( IEEE Standard for Inertial Sensor Terminology, 2001):

• Input range: the interval between the input limits within which a quantity is measured. The

input limits are defined as the extreme values of the input, generally plus or minus, within

which performance is of the specified accuracy. The full-scale (FS) input is the maximum

magnitude of the two input limits.

• Accuracy (or linearity error): the deviation of the output from a least-squares linear fit of the input-output data. It is generally expressed as a percentage of the input full-scale, or a

percent of output, or both.

The definition implicitly assumes that the ideal sensor exhibits a linear input-output

behavior (i.e. the static input-output sensor characteristic is a linear function).

• Scale factor 1 : the ratio of a change in output to a change in the input intended to be

measured, typically specified in [ V/ ◦/ s]. It is evaluated as the slope of the least squares straight line fit to input-output data.

In the ideal case, the scale-factor is constant over both the entire input range and the whole

sensor lifespan. In the real case, the following quantities are used to judge the scale factor

quality:

– asymmetry error: the difference between the scale factor measured with positive input

and that measured with negative input, specified as a fraction of the scale factor

measured over the input range.

1 Sometimes the term sensitivity is used as a synonym for scale factor. However, according to ( IEEE

Standard for Inertial Sensor Terminology, 2001), the term sensitivity is reserved for denoting the ratio of a change in output to a change in an undesirable or secondary input.

MEMS Gyroscopes for Consumer and

Industrial Applications

MEMS Gyroscopes for Consumer and Industrial Applications

17

269

– scale factor stability: the variation in scale factor over a specified time of continuous operation. Ambient temperature, power supply and additional factors pertinent to the

particular application should be specified.

– scale factor sensitivities: the ratio of change in scale factor to a change in an

undesirable input, such as the steady state operating temperature ( scale factor

temperature sensitivity) or the constant acceleration along any axis ( scale factor acceleration sensitivity). Additional sensitivities may be specified such as those due to variations in

supply voltage (including frequency, voltage, ripple, starting and operating current),

orientation, vibration, magnetic field, radiation, and other environments pertinent to

the particular application.

• Resolution: the smallest input change, for inputs greater than the noise level, that can be

reliably detected. It is usually evaluated as the minimum input change that produces a

change in output equal to some specified percentage (at least 50%) of the change in output

expected using the nominal scale factor.

• Drift rate: the portion of gyro output that is functionally independent of input rotation.

The systematic component of the drift rate ( systematic drift rate) includes:

1. Bias (or zero rate output - ZRO): the average over a specified time of gyro output

measured at specified operating conditions that has no correlation with input rotation.

Bias is typically expressed in [ ◦/ s] or [ ◦/ hr].

2. Environmentally sensitive drift rate: the components of systematic drift rate that are

sensitive to temperature (steady state, gradient, ramp), acceleration, vibration and

other quantities.

The random component of the drift rate ( random drift rate) includes:

1. Angle Random Walk (ARW): the angular error buildup with time that is due to white

√

√

noise in angular rate, typically expressed in [ ◦/ hr/ hr] or [ ◦/ s/ hr].

2. Rate Random Walk (RRW): the drift rate error buildup with time that is due to white

√

noise in angular acceleration, typically expressed in [ ◦/ hr/ hr].

3. Bias Instability: the random variation in bias as computed over specified finite sample

time and averaging time intervals, characterized by a 1/ f power spectral density,

typically expressed in [ ◦/ hr].

• Bandwidth: the range of frequency of the angular rate input that the gyroscope can detect.

Typically specified as the cutoff frequency coinciding to the − 3 dB point. Alternatively, the frequency response or transfer function could be specified.

• Activation time: it includes the turn-on time, i.e. the time from the initial application of power until a sensor produces a specified useful output, though not necessarily at

the accuracy of full specification performance, and the warm-up time, i.e. the time from

the initial application of power to reach specified performance under specified operating

conditions.

The mechanical and electrical requirements are usually specified in terms of:

• Outline, mounting dimensions, weight

• Gyro axes: the input axis (IA) is the axis about which a rotation of the case causes a maximum output; the input reference axis (IRA) is the direction of an axis (ideally parallel

to an input axis) as defined by the case mounting surfaces, or external case markings, or

both. In case of a multi-axis gyroscope, more than one IA (and, correspondingly, IRA) can

be defined.

18

270

Will-be-set-by-IN-TECH

Microsensors

• Seal: CVGs may be sealed using vacuum, gas or ambient environment.

• Acoustic noise emission

• Electrical impedances:

load impedances and impedances of excitation, monitoring,

temperature sensing and test circuits.

• Input power, grounding

• Output signals: the type and characteristics of output signals, such as analog voltage or

current, parallel or serial digital, or incremental angle pulses.

• Electromagnetic interference and electrostatic discharge (ESD) immunity.

The environmental requirements specify the environmental conditions (limits) and

perturbations during storage, transport and/or operation under which the sensor preserves

its functionality. Environmental characteristics account for:

• Linear and angular accelerations: both the acceleration (axis, direction, intensity) and exposure time should be defined.

• Linear and angular vibrations: both axes and direction of vibration should be defined. For a deterministic vibration, specifications include the type of vibration (e.g. sinusoidal) and

its characteristics (e.g. amplitude, frequency sweep range, exposure time). For a random

vibration, its spectral characteristic (e.g. power spectral density - PSD) is usually specified.

• Mechanical shock: it is specified in terms of axis, direction, wave shape, intensity (usually measured as a peak value in [ m/ s 2] or a multiple of the gravity acceleration g) and duration.

• Temperature range

• Others: may include ambient air pressure, humidity, electromagnetic fields, etc.

Conventionally, gyroscopes are classified into three different categories based on their

performance: inertial-grade, tactical-grade, and rate-grade devices (Yazdi et al., 1998). Table 1

summarizes the requirements for each of these categories.

RLGs, together with HLGs (R.R.Ragan (ed), 1984), are currently the angular rate sensors with

highest performance available in the market, and exhibit inertial grade performances. They

are used in the most demanding applications, especially those requiring extremely high scale

factor stability (typically, high precision space applications). FOGs normally achieves tactical

grade performances, while typical MEMS CVGs seldom exceed the rate grade performance

level, which is however satisfactory for most of the automotive and consumer electronics

applications.

Parameter

Rate grade Tactical grade Inertial grade

√

Angle Random Walk [ ◦/ hr]

> 0.5

0.5 ÷ 0.05

< 0.001

Bias drift [ ◦/ hr]

10 ÷ 1000

0.1 ÷ 10

< 0.01

Scale factor Accuracy [%]

0.1 ÷ 1

0.01 ÷ 0.1

< 0.001

Full Scale Range [ ◦/ s]

50 ÷ 1000

> 500

> 400

Max. Shock in 1 ms [ g s]

103

103 ÷ 104

103

Bandwidth, Hz

> 70

100

100

Table 1. Performance requirements for different classes of gyroscopes

MEMS Gyroscopes for Consumer and

Industrial Applications

MEMS Gyroscopes for Consumer and Industrial Applications

19

271

5. Benchmark tests for two commercial products

5.1 Invensense IDG-650 Dual-Axis Pitch & Roll MEMS Gyroscope

The Invensense IDG-650 (Invensense, 2010) is a dual-axis MEMS gyroscope consisting of two

independent out-of-plane resonating tuning fork CVGs (for pitch and roll axes) integrated

on the same silicon die.

The MEMS and CMOS integrated circuit (IC) are electrically

connected together through wafer level bonding, in such a way that the mechanical structure

is covered and hermetically sealed at the wafer level ( Nasiri-Fabrication - patent protected).

The hermetic sealing improves the sensor resistance to humidity, high temperature and

electromagnetic/radio frequency interferences (EMI/RFI). The sensor has selectable scale

factors and full scale ranges ( FS = ± 2000 ◦/ s for faster motions, or FS = ± 440 ◦/ s for slower motions). Both the output measurements are thermally compensated by an internal

compensation circuit, comprising an integrated onboard temperature

5.2 STMicroelectronics LPR530AL Dual-Axis Pitch & Roll MEMS Gyroscope

The STMicroelectronics LPR530AL (STMicroelectronics, 2010) is a dual-axis MEMS gyroscope

capable of measuring angular rates along pitch and roll axes. The mechanical sensing element

is a vibrating disk fabricated using STMicroelectronic’s proprietary surface micromachining

process called ThELMA ( Thick Epipoly Layer for Microactuators and Accelerometers).

The

mechanical element is obtained by etching a thicker polysilicon epitaxial layer ( ≈ 15 μm) grown on top of a sacrificial oxide layer ( ≈ 2 μm), which is removed at the end of the process (release step) by isotropic etching. A second wafer is bonded to the substrate with the purpose

of creating a protecting case for the micromechanical structure. The ThELMA micromachined

mechanical element and the CMOS controller are finally assembled together in the same

chip (hybrid solution: two chips in a single package) either in a side-by-side or a stacked

configuration.

STM LPR530AL IS IDG-500 IS IDG-650

• Scale factor

0.83

2

0.5

mV/ ◦/ s

• Scale factor ( × 4.5)

3.33

9.1

2.27

mV/ ◦/ s

• Scale factor calibration tolerance

5

6

6

%

• Scale factor calibration drift

0.034

0.067

0.067

%/ ◦C

over specified temperature (TA = 25 ◦)

• Full-scale

1200

500

2000

◦/ s

• Full-scale ( × 4.5)

300

110

440

◦/ s

• ZRO level

1.23

1.35

1.35

V

• ZRO tolerance

80

250

150

mV

• ZRO temperature sensitivity

0.083

0.417

0.667

◦/ s/ ◦C

over specified temperature (TA = 25 ◦ C)

• phase delay at 10 Hz

4.0

4.5

4.5

◦

• Turn-on time (typ)

200

50

50

ms

• Turn-on-time (max)

200

200

200

ms

• Total RMS noise

1.4

0.8

0.3

mV

• Nonlinearity

1

1

1

% of FS

• Cross-axis sensitivity

1

1

1

% of FS

• Supply voltage

2.7 ÷ 3.6

2.7 ÷ 3.3

2.7 ÷ 3.3

V

• Current absorption

6.8

7

7

mA

• Temperature range

− 40 ÷ 85

− 20 ÷ 85

− 20 ÷ 85

◦ C

• Package size

5 × 5 × 1.5

4 × 5 × 1.2 4 × 5 × 1.2

mm

Table 2. Specifications comparison for the gyroscopes under test

20

272

Will-be-set-by-IN-TECH

Microsensors

5.3 Comparative tests

The results of our comparative tests are briefly summarized in the following paragraphs.

Parts have been tested on a single-axis precision positioning and rate table (Aerosmith, 2005),

providing the desired angular rate profiles. An additional integral thermal chamber has been

installed on the table to allow thermal sensitivity/stress analyses.

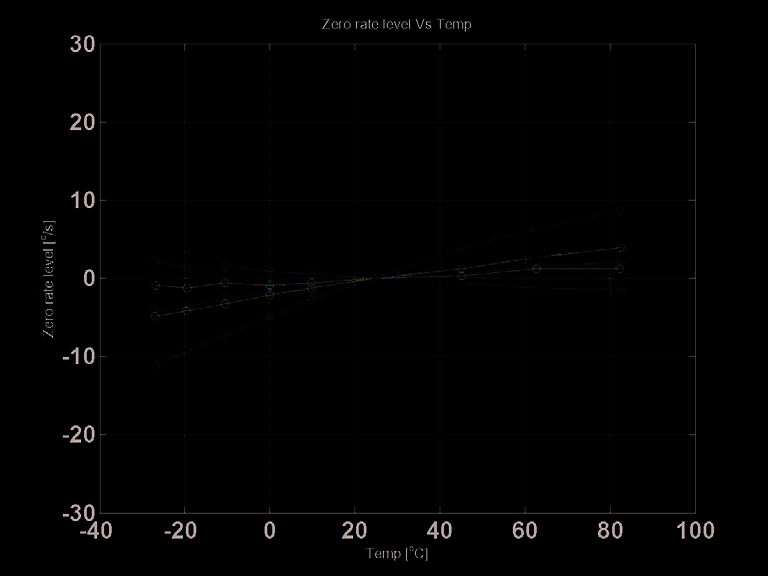

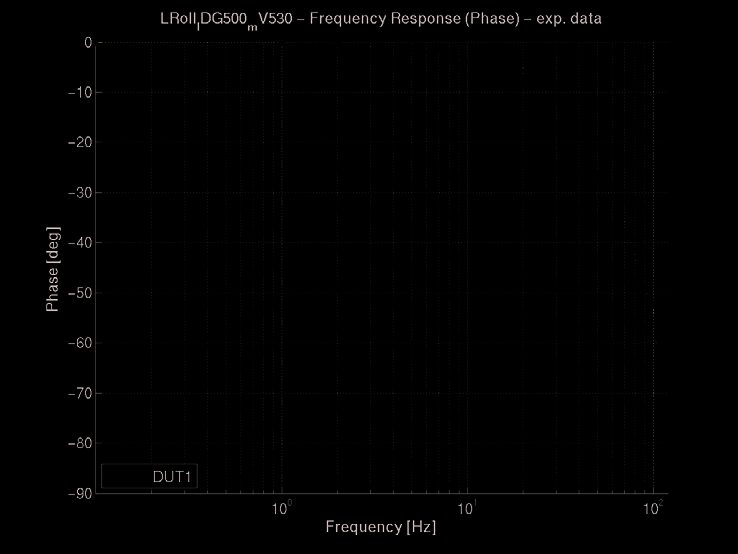

5.3.1 ZRO temperature sensitivity

The ZRO has been measured by setting the default FS (i.e. full-scale × 4.5 in Tab. 2) for both STM and IS sensors, and by varying the temperature over the range − 40 ◦ C ÷ 85 ◦ C in steps of 5 ◦ C. As shown in Fig. 11, the ZRO of the STM sensor appears to be slightly more insensitive

to temperature variations than the IS sensor; however, the temperature sensitivities of both

sensors are within specifications.

Fig. 11. ZRO temperature sensitivity test results: STM (left); IS (right).

5.3.2 ZRO mechanical stress sensitivity

The ZRO has been measured after applying different calibrated vertical loads on the sensor

package, by means of a load cell. It has been noted that only the STM sensor has a ZRO that is

immune to the applied mechanical stress; for what concerns the IS sensor, the ZRO variation

exceeds the value of 30 ◦/ s as the vertical load varies over the range 0 ÷ 4 kg (see Fig. 12).

Fig. 12. ZRO mechanical stress sensitivity test results: STM (left), IS (right).

MEMS Gyroscopes for Consumer and

Industrial Applications

MEMS Gyroscopes for Consumer and Industrial Applications

21

273

5.3.3 Scale factor temperature sensitivity

Scale factor measurements have been done at a constant angular rate of 150 ◦/ s, and by

varying the temperature over the range − 40 ◦ C ÷ 85 ◦ C in steps of 5 ◦ C. On average, both the STM and IS sensors exhibit a scale factor temperature sensitivity below 0.05 %/ ◦C and

thus within specifications (see Fig. 13) .

Fig. 13. Scale factor temperature sensitivity test results: STM (left); IS (right).

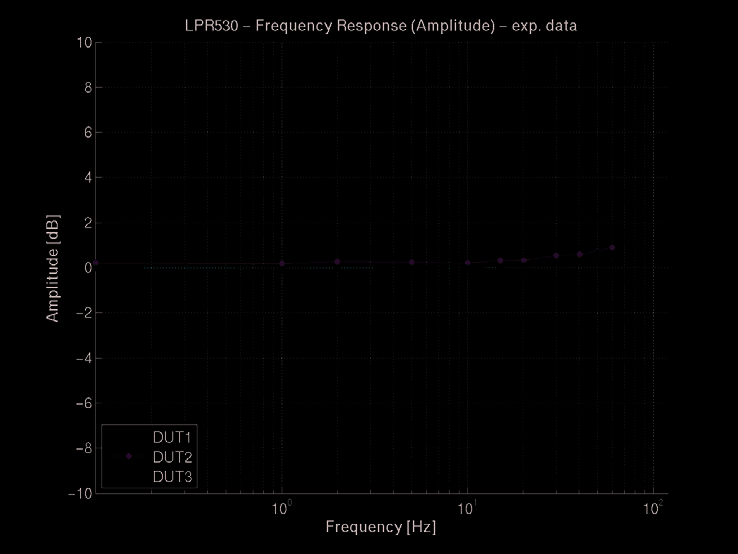

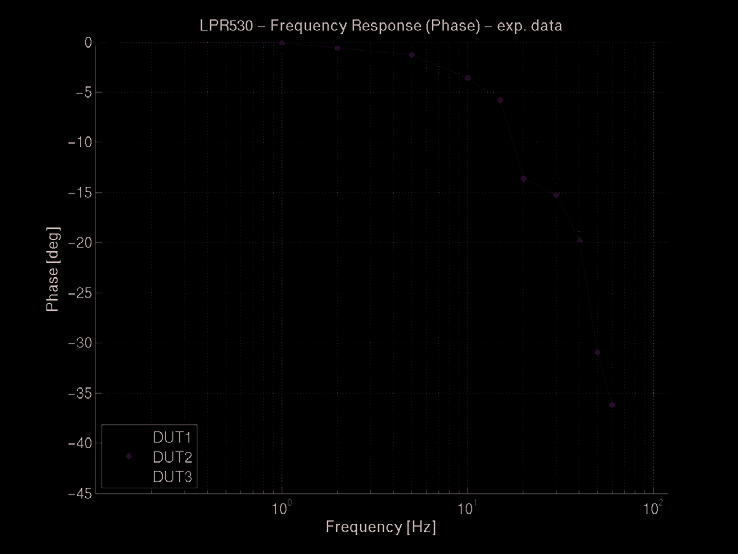

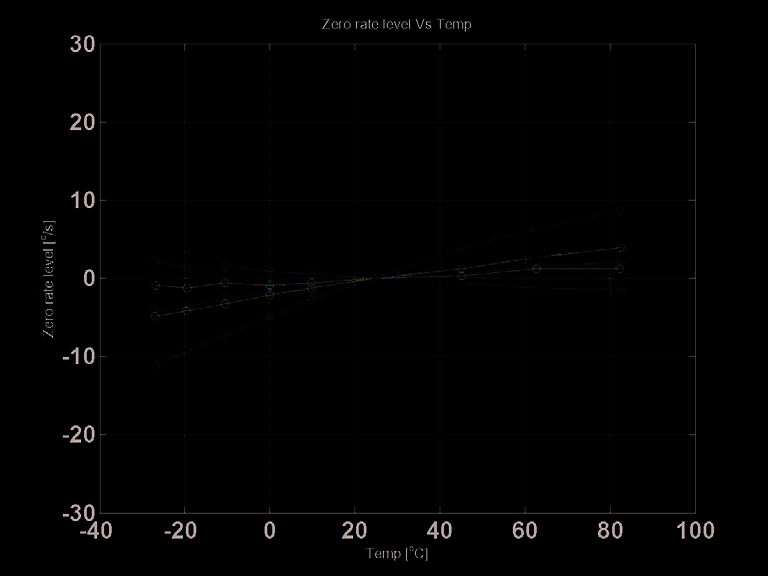

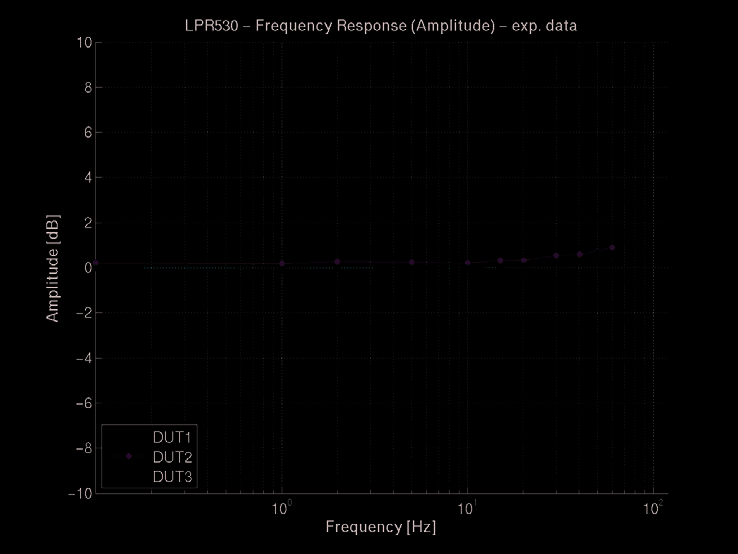

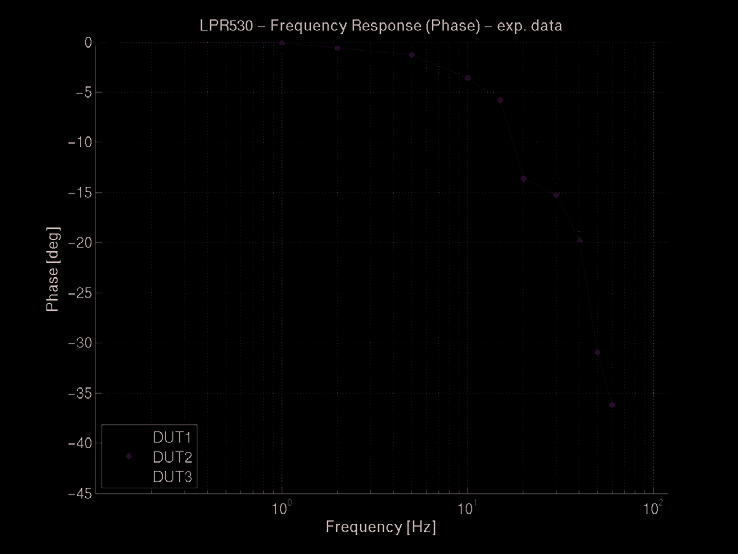

5.3.4 Frequency response

The sensor frequency response (from the angular rate input to sensor output measurement)

has been measured at 16 frequency points, almost regularly spaced in the frequency range

0.1 ÷ 100 Hz. Measurements have been carried out frequency-by-frequency, by evaluating the sensor magnitude and phase responses to an applied sinusoidal angular rate input. As it

can be observed in Figs. 14 and 15, the STM and IS sensors have almost identical frequency

responses, with a flat magnitude response up to 50 Hz and a phase lag of 45 ◦ at 80 Hz; the only noticeable difference consists of a flatter magnitude response of the STM sensor at higher

frequencies.

Fig. 14. STM LPR530AL measured frequency response: magnitude (left); phase (right).

22

274

Will-be-set-by-IN-TECH

Microsensors

Fig. 15. IS IDG-500/650 measured frequency response: magnitude (left); phase (right).

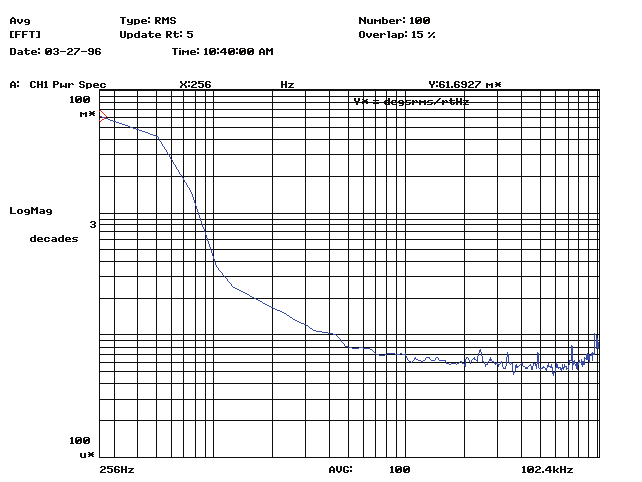

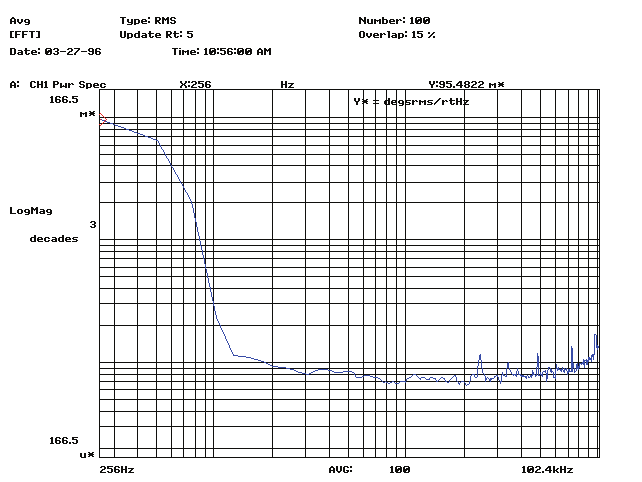

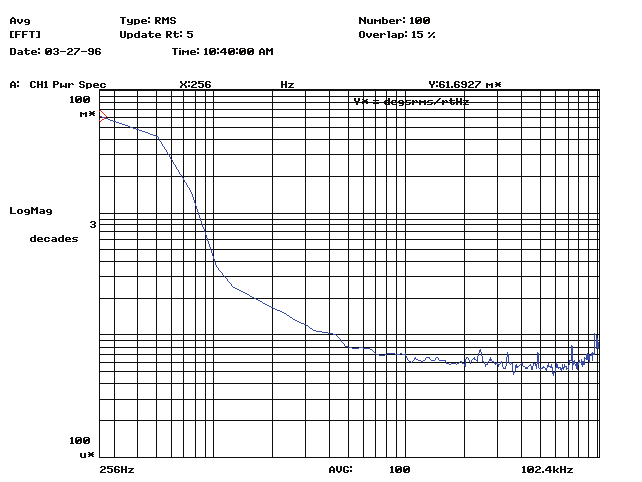

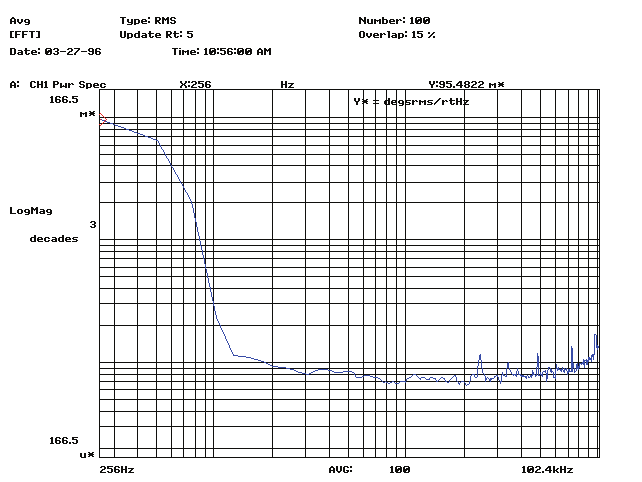

5.3.5 Noise power spectral density

The output noise Power Spectral Density (PSD) has been measured by using a Digital Signal

Analyzer (DSA). For a fair comparison, the full-scales of the two sensors have been selected

to be as matched as possible: therefore, the STM sensor FS has been set to 300 ◦/ s (scale factor

= 3.33 mV/ ◦/ s), while the IS sensor (IDG-500) FS has been selected as 500 ◦/ s (scale factor =

2 mV/ ◦/ s). With such configuration, the measured output noise floors of the two sensors are

√

√

almost identical, e.g. Sn = 0.035 ◦/ s/ Hz for the STM LPR530AL and Sn = 0.030 ◦/ s/ Hz for the IS IDG-500 (see also Fig. 16).

Fig. 16. Output noise power spectral density measurements: STM (left); IS (right).

6. Conclusions

In recent years, the development and commercialization of MEMS gyroscopes have

experienced a rapid growth, as a result of performance improvements and cost reductions.

Such sensors have begun to be applied in many consumer and industrial applications, either

to replace older, bulkier and more expensive angular rate sensors, or to become essential parts

in completely new applications requirin