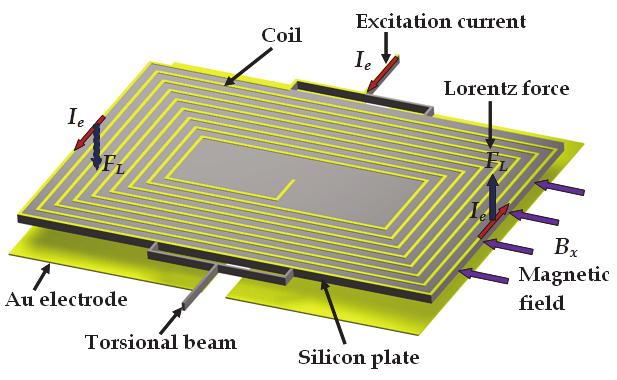

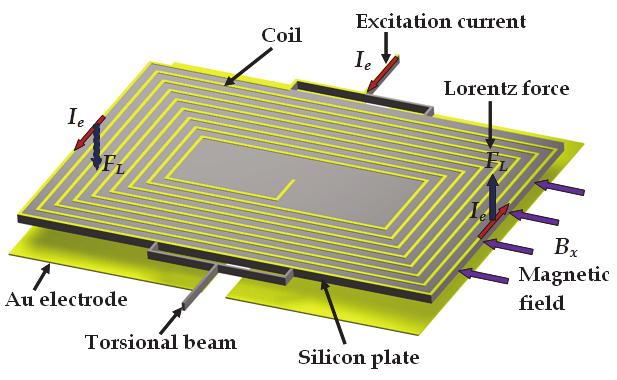

Lorentz force is generated when a sinusoidal current flows into the excitation coil under an

external magnetic field. This force causes an oscillating motion of silicon plate around the

72

Microsensors

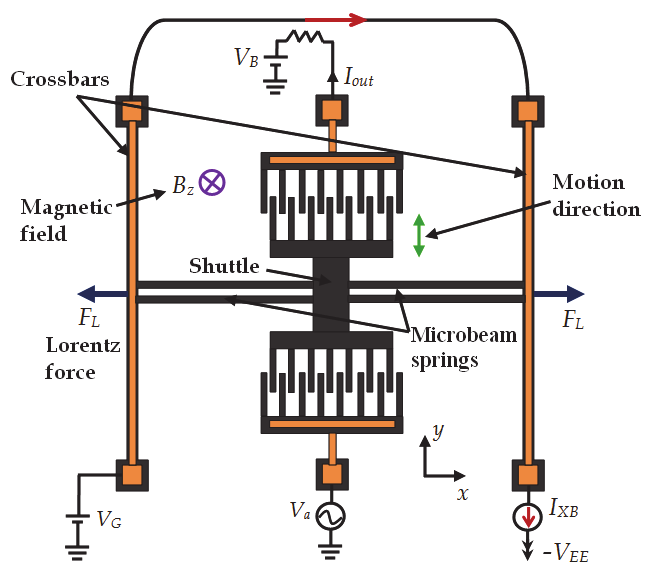

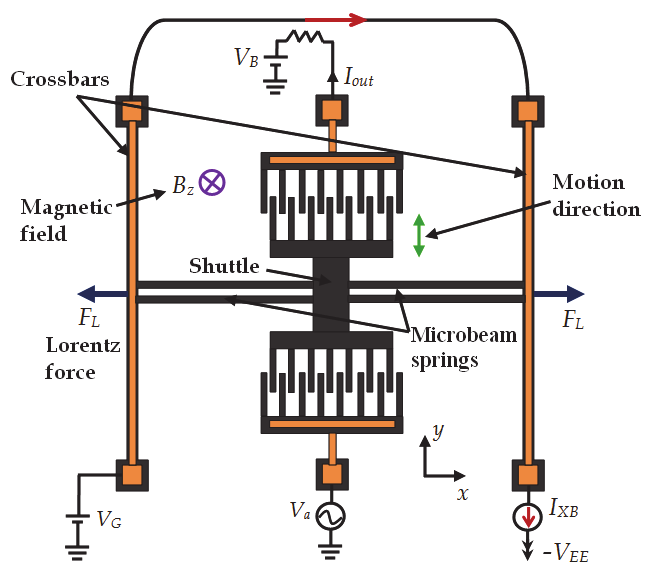

Fig. 5. Operation principle of the resonant magnetic field microsensor designed by Bahreyni

& Shafai (2007).

torsional beams. This motion produces a capacitance shift between the Au electrodes and

the silicon plate. A capacitance detection circuit measured the capacitance change that

depends of the magnitude and direction of the external magnetic field. The microsensor

needs a vacuum packaging to increase its performance. For a pressure of 10 Pa and 150 mV

driving voltage amplitude, the microsensor has a resolution of 30 nT, a sensitivity of 0.40

VT-1, a resonant frequency close to 1380 Hz, and a quality factor around 2500. Nevertheless,

it presented a non-linear response from 0 to 3 T.

Fig. 6. Operation principle of the magnetic field microsensor designed by Ren et al. (2009).

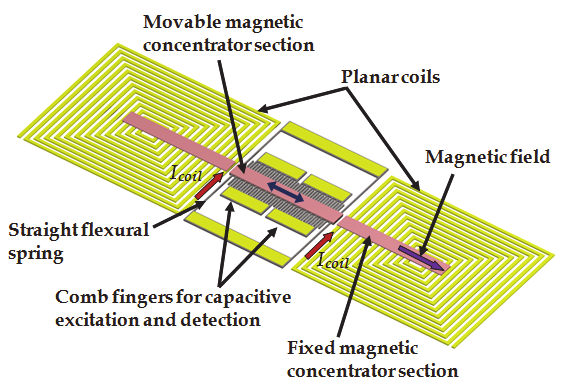

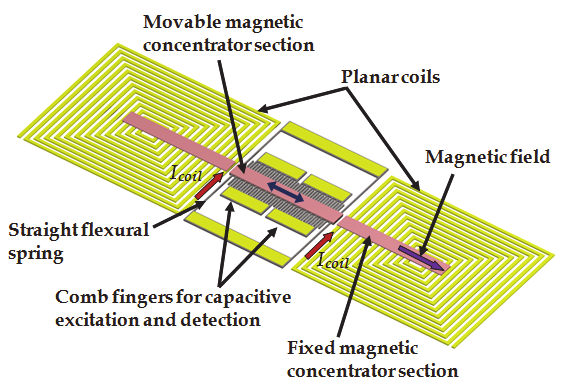

Brugger & Paul (2009) developed a novel magnetic field microsensor (dimensions of 7.5

3.2 mm) integrated by an electrostatically driven silicon resonator, an amorphous magnetic

concentrator, and a pair of planar coils. Interdigitated combs (200 14 25 m) are

employed for the electrostatic excitation of the resonator and the capacitive detection of its

resonance (see Fig. 7). The silicon resonator is suspended by four straight flexural springs

(1000 14 25 m). The magnetic concentrator (5000 250 18 m) is constructed using a

Development of Resonant Magnetic Field Microsensors:

Challenges and Future Applications

73

Metglas 2714A ribbon and is cut into three segments separated by two narrow gaps. The

inner segment is attached to the resonator surface and both outer segments are fixed. The

magnetic concentrator saturates to magnetic field above of 713 T. An auxiliary magnetic

field parallel to the magnetic concentrator is generated with the planar coils. Each coil

comprises 12 windings with a linewidth of 55 m and a line-to-line spacing of 15 m. The

resonator is excited at its resonant frequency applying a dc voltage ( Vdc) to it and ac voltage ( Vac) to the half of the interdigitated combs. Its oscillating motion is monitoring using the other half of the interdigitated combs. A magnetic force acts on the resonator when an external

magnetic field parallel to the magnetic-concentrator axis is applied. This force counteracts the

restoring force exerted on the resonator by its four flexural springs, which decrease both the

total spring constant and resonant frequency of the resonator. Then, a quadratic relationship

between the resonant frequency and a magnetic field is obtained. In order to achieve a linear

output signal of the microsensor, the external magnetic field is combined with an auxiliary

magnetic field generated by the planar coils. For a coil current of 80 mA, Vdc = 20V, Vac = 404

mV and a pressure of 10-5 mbar, this microsensor presents a sensitivity of 1.0 MHzT-1, a

resolution of 400 nT, and a quality factor around 2400. It does not need a complex feedback

and modulation electronics; however, it requires a vacuum packaging and a complex

fabrication process. This process combines the following: 1) MEMS technology based on a

silicon-on-insulator (SOI) substrate for the MEM structure; 2) the epoxy-resin-based

attachment of a thin amorphous magnetic ribbon subsequently structured using wet chemical

etching; and 3) micropatterning of the magnetic concentrator by UV-laser.

Fig. 7. Operation principle of a magnetic field microsensor based on a magnetic concentrator

developed by Brugger & Paul (2009).

Generally, a resonant magnetic field microsensor with capacitive detection needs a vacuum

packaging in order to increase its sensitivity and resolution. It suffers from parasitic

capacitances, which can be reduced through the monolithic integration of the

micromachined resonators with electronic circuits.

2.3 Optical sensing

This section includes the resonant magnetic field microsensors based on MEMS that use

optical sensing.

74

Microsensors

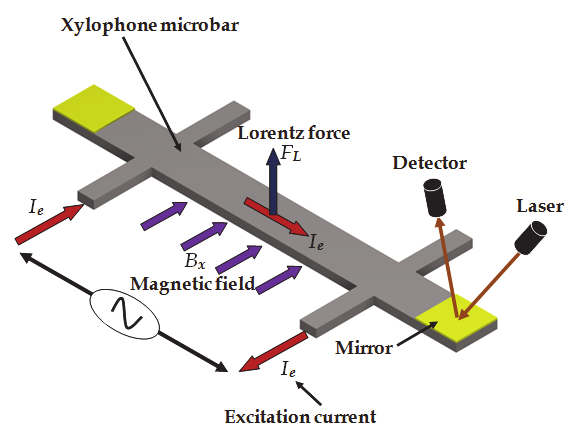

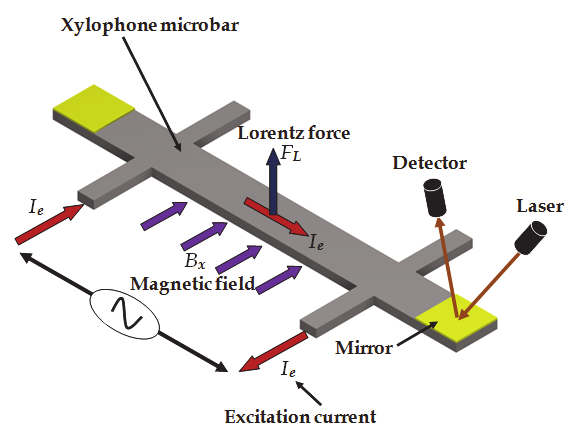

Zanetti et al. (1998) fabricated a magnetic field microsensor formed by a xylophone

microbar, which is supported (at the nodes of its fundamental vibration mode) by four

microbeams. The microsensor uses optical detection for measuring the deflections of the

xylophone microbar under an external magnetic field parallel to its length, as shown in Fig.

8. The interaction of this field with ac excitation current ( I) flowing into the microbar

produces a Lorentz force that deflects the microbar. If the ac excitation current is supplied

with one frequency equal to the bending resonant frequency of the microbar, then, its

deflection is increased. This deflection depends of the magnitude of the external magnetic

field and is measured using a miniature laser and a position sensitive detector. Thus, the

magnetic signal is proportional to the deflections of the xylophone microbar. The

microsensor has dimensions of 5000 500 250 m, a quality factor close to 700, a resolution

around 1 nT and a power consumption of few milliwatts.

Fig. 8. Operation principle of a magnetic field microsensor with optical detection based on a

xylophone microbar designed by Zanetti et al. (1998).

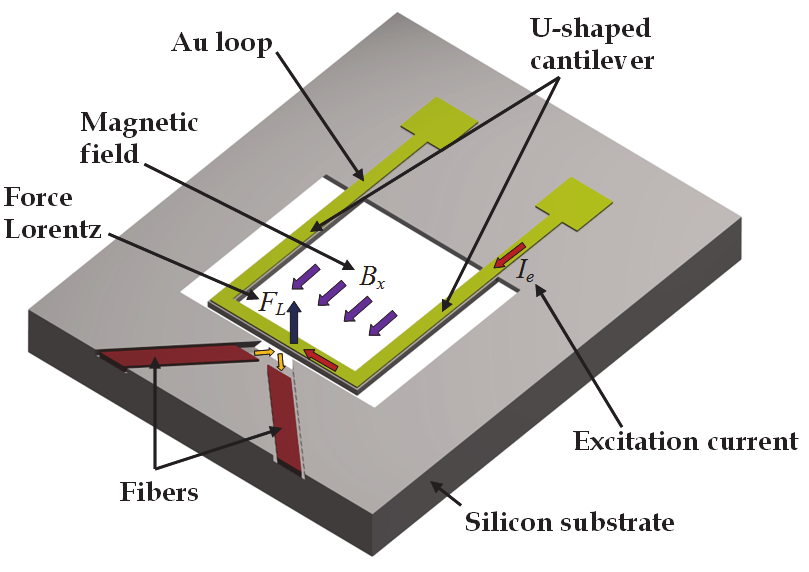

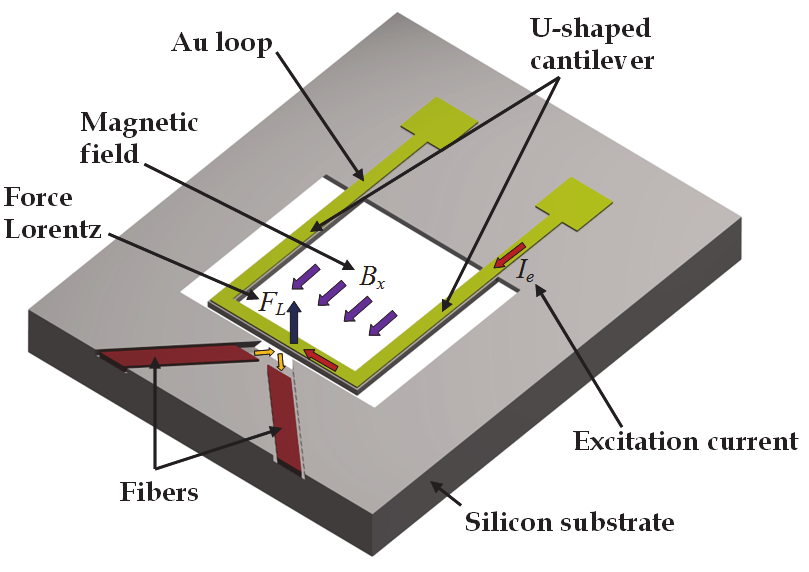

Keplinger et al. (2003, 2004) proposed a resonant magnetic field microsensor based on a

micromachined U-shaped silicon cantilever and an optical sensing system. The cantilever

(1100 100 10 m) contains on its surface a 0.5-m-thick Au layer, which flows an ac

excitation current. A Lorentz force is generated due to the interaction of the current with a

magnetic field parallel to the length of the U-shaped cantilever. This force causes a bending

motion of the cantilever that is measured through optical fibers. Thus, the magnetic input

signal is converted into a movement of the cantilever, which is increased when the

cantilever operates at its resonant frequency. The optical sensing uses two-fiber

arrangements for avoiding the problem of the interfering reflected light. In the first design

the emitted light beam is reflected only once at the cantilever front side, as shown in Fig. 9.

Nevertheless, it requires a large lateral space for the chip and microsensor. The second

design considers a cracked cantilever to allow a parallel alignment of the fibers (see Fig. 10),

which requires a perfect vertical front side of the cantilevers. This optical detection system

allows the efficient transmission of the microsensor signal in an electromagnetically noisy

environment. This microsensor detects magnetic fields from 10 mT to 50 T and has a

resonant frequency close to 5 kHz, a quality factor of 200 at atmospheric pressure, a

resolution of 10 mT, and a power consumption of a few milliwatts.

Development of Resonant Magnetic Field Microsensors:

Challenges and Future Applications

75

Fig. 9. Operation principle of a resonant magnetic field microsensor integrated by a U-

shaped silicon cantilever and two fibers placed in curved channels, which was developed by

Keplinger et al. (2003, 2004).

Fig. 10. Operation principle of a resonant magnetic field microsensor integrated by a U-

shaped cracked cantilever and two parallel fibers, which was developed by Keplinger et al.

(2003, 2004).

Wickenden et al. (2003) reported a resonant magnetic field microsensor formed by a

polysilicon xylophone microbar (500 50 2 m), which has a similar performance to

microsensor designed by Zanetti et al. (1998). A magnetic input signal is converted into an

oscillating motion of the xylophone microbar. This motion is detected by an optical readout

system based on a laser diode beam and a position sensitive detector. This microsensor has a

resonant frequency of 78.15 kHz, a quality factor around 7000 at 4.7 Pa, ac current of 22 A,

a thermal noise of 100 pTAHz-1/2, and a resolution on the order of nanoteslas. However, it

presents a linear response up to 150 T and its performance is affected by variations of

pressure and temperature. The optical readout system used in resonant magnetic field

microsensors allows a reduction in their electronic circuitry and weight. Furthermore, the

microsensors with optical sensing have immunity to EMI.

76

Microsensors

2.4 Piezoresistive sensing

This section includes the description of several resonant magnetic field microsensors with

piezoresistive sensing.

Beroulle et al. (2003) reported a magnetic field microsensor integrated by a resonant U-

shaped cantilever (520 m length and 80 m thick), a planar aluminium coil of 8 turns, and a

Wheatstone bridge of polysilicon strain gauges. This microsensor exploits the Lorentz force

principle in order to measure an external magnetic field, converting it into an electrical

output signal through Wheatstone bridge. The microsensor was fabricated using an

industrial CMOS processes with a post-processing etch step to release its resonant structure.

It has a sensitivity of 0.53 VT-1, a theoretical resolution of 2 T, a thermal noise of 5.3 nVHz-

1/2, a resonant frequency of 8.97 kHz, a quality factor of 59, and a mass of 750 ng.

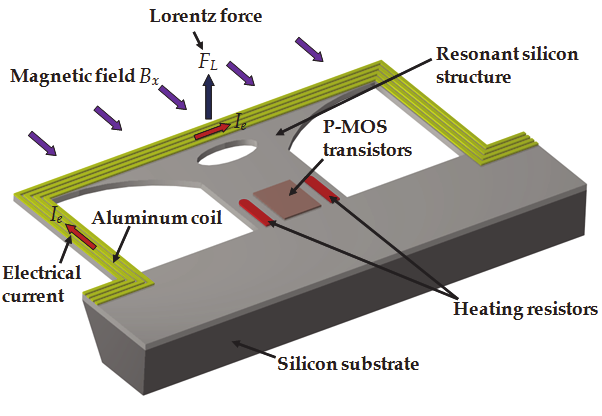

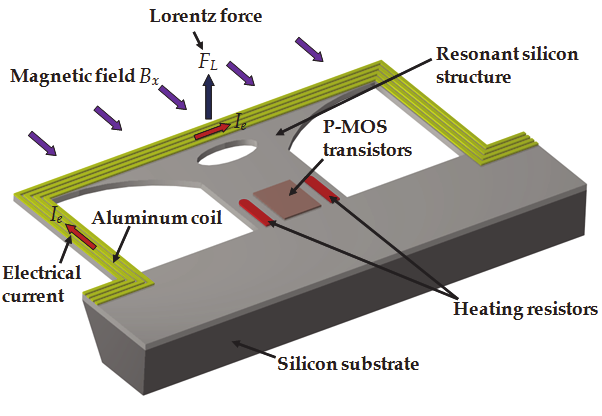

Sunier et al. (2006) developed a magnetic field microsensor using a resonant silicon structure, a

planar aluminium coil, two heating resistors, and P-channel Metal Oxide Semiconductor

(PMOS) transistors (see Fig. 11). This microsensor operates based on Lorentz force principle

and provides a frequency output signal. The silicon structure vibrates at its resonant frequency

because of the thermal actuation of two heating resistors. The oscillating motion of the silicon

structure is detected using PMOS transistors connected in a Wheatstone bridge. A Lorentz

force (generated by the interaction between an electrical current flowing through coil and an

external magnetic field) changes the total spring constant of the resonant structure. This

modifies the resonant frequency value of the silicon structure. Thus, the resonant frequency

shift is related to the magnitude of the external magnetic field. This microsensor has an

efficient continuous offset cancelation, high robustness, and low cross sensitivity. In addition,

it presents a sensitivity of 60 HzT-1, a resolution of 1 T, a resonant frequency of 175 kHz, a

quality factor of 600, and a power consumption close to 5 mW.

Fig. 11. Operation principle of a resonant magnetic field microsensor with frequency output

designed by Sunier et al. (2006).

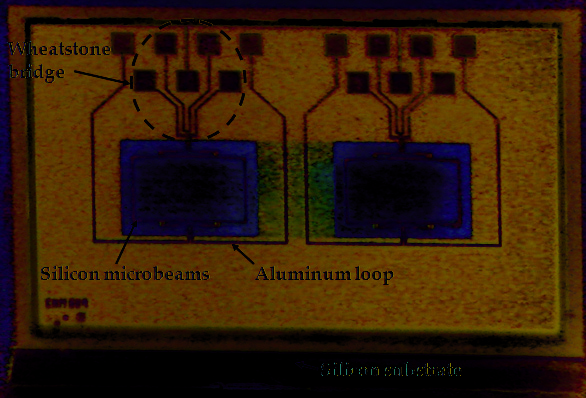

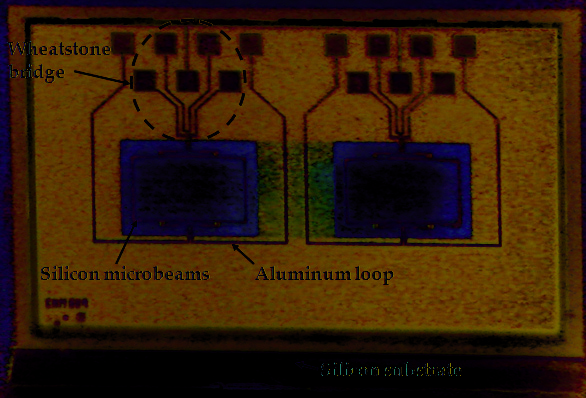

Herrera-May et al. (2009b) developed a resonant magnetic field microsensor with

piezoresistive sensing, which contains a resonant silicon microplate (400 150 15 m)

supported by four bending microbeams, an aluminium loop, and a Wheatstone bridge of

four p-type piezoresistors (see Fig. 12). It exploits the Lorentz force for monitoring external

magnetic fields. This force causes an oscillating motion of the microplate and microbeams

that strains two piezoresistors. This changes the piezoresistors resistance, modifying the

Development of Resonant Magnetic Field Microsensors:

Challenges and Future Applications

77

output voltage of the Wheatstone bridge. Then, the magnetic input signal is converted into an

electrical signal. This microsensor was designed for Tenaris TAMSA Corporation for

measuring residual magnetic fields in welded steel tubes. It was fabricated using the bulk

micromachining technology of the Microelectronics Institute of Barcelona (IMB-CNM, CSIC).

Its characteristics are: sensitivity of 0.403 VT-1, resolution of 143 nT, resonant frequency of

136.52 kHz, quality factor of 842, and a power consumption below 10 mW. However, this

microsensor presents a offset and a nonlinear response for low magnetic fields.

Fig. 12. SEM image of a die with two resonant magnetic field microsensors with

piezoresistive sensing designed by Herrera-May et al. (2009b).

The MEMS group (Herrera-May et al., 2011) from MICRONA-UV into collaboration with

IMB-CNM developed a resonant magnetic field microsensor integrated by a rectangular

loop (700 450 5 m) of silicon beams suspended with four bending beams (130 12 5

m), an aluminium loop (1 m thick), and four p-type piezoresistors connected into a

Wheatstone bridge (see Fig. 13). This microsensor operates based on Lorentz force and has a

linear response under weak magnetic fields from 40 to 2000 T. In addition, it has sensitivity

4.8 times larger than the microsensor reported by Herrera-May et al. (2009b). This

microsensor presents a resolution close to 43 nT, a resonant frequency of 22.99 kHz, a

quality factor of 96.6 at atmospheric pressure, and a low power consumption of 16 mW.

Later, researchers of MICRONA-UV designed other resonant magnetic field microsensor

with piezoresistive sensing (see Fig. 14). It was used for monitoring magnetic fields generate

by an electronic neuron developed by researchers from Institute of Physiology-BUAP (Tapia

et al., 2011). This microsensor exploits the Lorentz force and is formed by an arrangement of

silicon microbeams (700 450 5 m) suspended by four bending microbeams, an

aluminium loop (1 m thick), and a Wheatstone bridge with four p-type piezoresistors. It

has a compact structure, a response linear to low magnetic fields, a sensitivity of 1.2 VT-1, a

resolution of 80 nT, a resonant frequency of 13.87 kHz, a quality factor of 93 at atmospheric

pressure, a power consumption of 2.05 mW, and a simple signal processing.

78

Microsensors

Fig. 13. Microphotograph of a die with two resonant magnetic field microsensors designed

by the MEMS group of MICRONA-UV.

Fig. 14. SEM image of a die with two resonant magnetic field microsensors with

piezoresistive detection used for neural applications (Tapia et al., 2011).

A piezoresistive sensing system used into magnetic field microsensors can allow them a

simple signal processing, high sensitivity, and low-cost fabrication. Nevertheless, it is

affected by temperature variations, which can be reduced through compensation circuits.

2.5 Comparison of resonant magnetic field microsensors

Most the resonant magnetic field microsensors have a compact structure, small size, and

high sensitivity, wide dynamic range, and easy signal processing. Several of them can

Development of Resonant Magnetic Field Microsensors:

Challenges and Future Applications

79

measure low magnetic fields around nanoteslas with low consumption power. Their

dynamic range can be adjusted changing the magnitude of the excitation current, allowing

them to measure lower or higher magnetic fields. A comparison of the main characteristics

of these microsensors are indicates in Table 1. They could compete with conventional

magnetic sensors for monitoring magnetic fields with resolution on the order of nanoteslas.

Size of

Sensing

Resolution Resonant

Quality

resonant

Microsensor

technique

(nT)

frequency

factor

structure

(kHz)

(m × m)

Kádár et al. (1998)

Capacitive

1

2.40

700 @ 5 Pa

2,800 × 1,400

Emmerich &

Capacitive

Schöfthaler (2000)

200

1.30

30 @ 101 Pa

1,300 × 500

Tucker et al. (2002)

Capacitive <103 100

1000 @ 1 Patm <1,000 × 1,000

Bahreyni et al. (2007)

Capacitive 217 27

15000 @ 2 Pa

520 × 400

Ren et al. (2009)

Capacitive

30

1.38

2500 @ 10 Pa

3000 × 2000

Brugger & Paul (2009) Capacitive

400

2.5

2400 @ 10-5 Pa 7500 × 3200

Zanetti et al. (1998)

Optical 1 --- *

7000 @ Patm

5,000 × 500

Keplinger et al. (2003,

Optical 107

5

200 @ P

2004)

atm

1,100 × 1,000

Wickenden et al. (2003)

Optical

<103

78.15

7000 @ 4.7 Pa

500 × 50

Beroulle et al. (2003) Piezoresistive

2 × 103

8.97

59 @ Patm

520 × 520

Sunier et al. (2006) Piezoresistive

103

175

600 @ Patm

400 × 185

Herrera-May et al. Piezoresistive

143

136.52

842 @ P

(2009b)

atm

400 × 150

Herrera-May et al. Piezoresistive

43

22.99

96.6 @ P

(2011)

atm

700 × 450

* Data not available in the literature

Table 1. Main characteristics of resonant magnetic field microsensors.

3. Challenges and future applications

This section considers some challenges and potential applications of the resonant magnetic

field microsensors.

Future commercial markets will require the development of multifunctional sensors on a

single chip for monitoring several input signals such as magnetic field, pressure,

acceleration, and temperature. These sensors will be integrated by several microstructures,

transducers, and electronic circuits on a same substrate using monolithic fabrication. They

will have important advantages such as small size, compact structure, low power

consumption, and high functionality. Therefore, the integration on a single chip of the

resonant magnetic field microsensors with other type of sensors is an important challenge.

Another challenge is the suppression of any background noise in order to increase the

magnetic resolution. The performance of the future magnetic field microsensors will be limited

by the variations in Earth’s magnetic field because of geological effects. In addition, the

reduction of the output response offset and the temperature dependence of future

microsensors are needed. Potential applications into the automotive industry,

telecommunications, and consumer electronics products demand magnetic field microsensors

80

Microsensors

of low cost and high reliability. Also, a challenge is the optimization of their performance and

the decrease of the design-phase time. Investigations on new materials with better electrical

and mechanical properties than silicon could be used into the future microsensors.

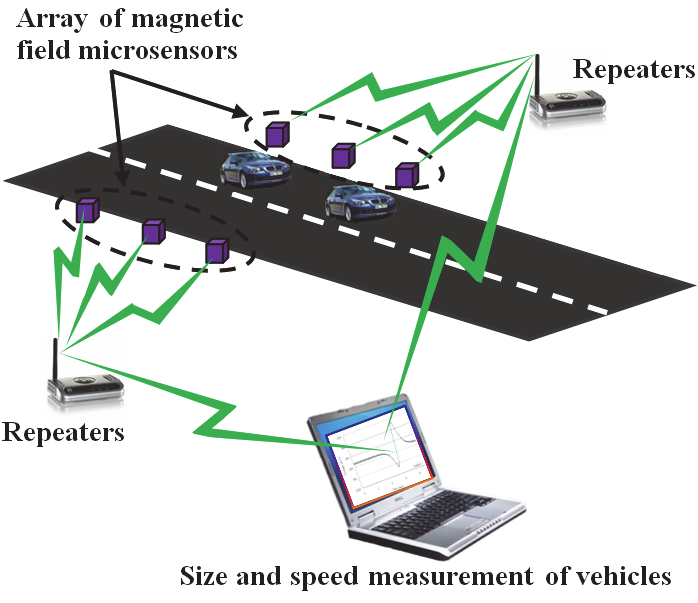

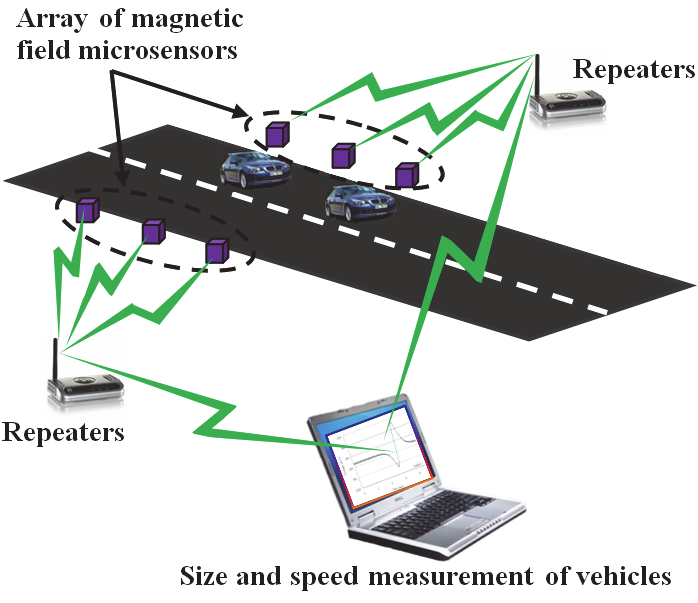

Automotive industry could be a future market of the magnetic field microsensors in order to

detect the speed and size of vehicles (see Fig. 15). A traffic’s detection system may be formed

by two microsensors (separated by 1 meter distance from each other) placed in parallel

beside the road. The microsensors will measure the change of the Earth’s magnetic field due

to the vehicle motion, which will be proceeded to A/D converter and digital data processing

system. The magnetic variation will depend of the vehicle’s size and speed, and it will be

detected by the microsensors in different times ( t1 and t2). Then, the vehicle’s speed will be determined through the ratio of the separation distance between the two microsensors to the

time difference t1- t2. This system could be applied with an intelligent signal control to decrease traffic congestion on roads.

Fig. 15. Schematic diagram of a traffic’s detection system based on magnetic field

microsensors.

Also, magnetic field microsensors could be employed at the electronic stability program

(EPS), which keeps the vehicle dynamically stable in critical situations such as hard braking

and slippery surfaces. ESP systems needs data about steering-wheel angle, lateral

accelerations, yaw rate, and wheel speed. These parameters could be measured through

accelerations, gyroscopes, pressure sensors, and magnetic field microsensors.

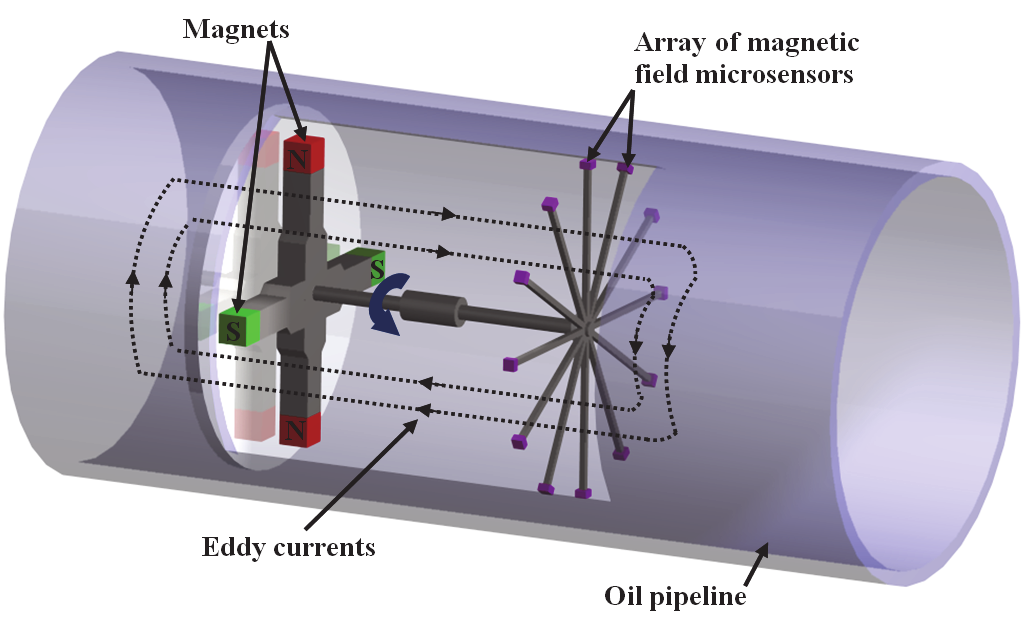

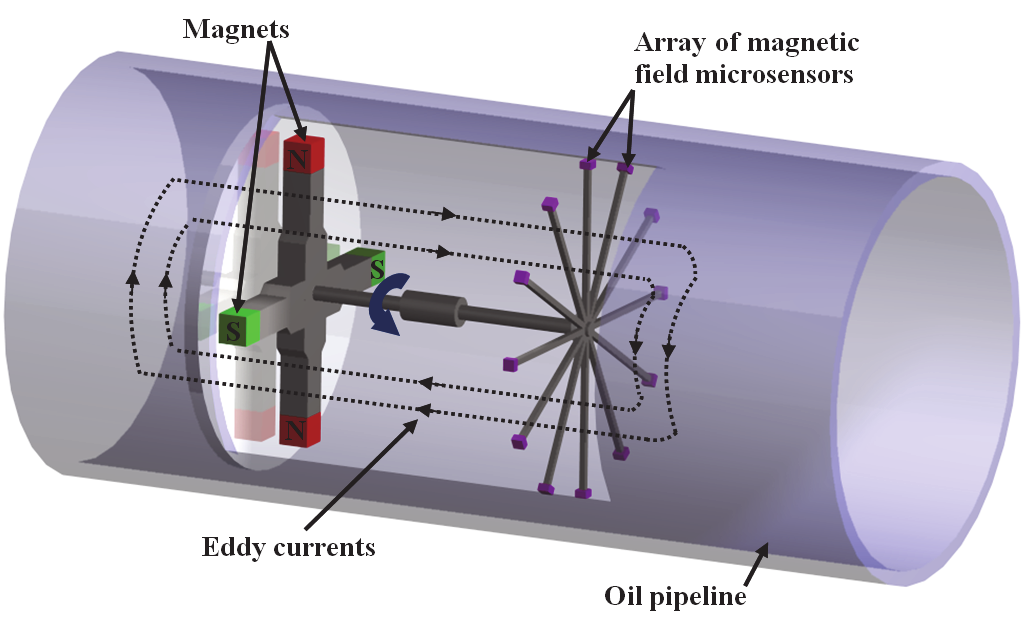

Another potential application of the magnetic field microsensors is the monitoring of the

corrosion and geometrical defects in ferromagnetic pipeline. Fig. 16 depicts an inspection

platform for oil pipeline walls reported by Nestleroth & Davis (2007). It is integrated by a

rotating permanent magnetic exciter, which may induce uniform eddy currents in the pipe

wall. The eddy currents are deflected pipeline defects such as corrosion and axially sligned

cracks. The variation of the current densities (that causes a magnetic flux leakage in the pipe

wall) could be measured by magnetic field microsensors. Therefore, the defects location

could be reached with these microsensors.

Development of Resonant Magnetic Field Microsensors:

Challenges and Future Applications

81

Fig. 16. Schematic view of an inspection platform of oil pipeline walls that consists of a

rotating permanent magnetic exciter and an array of magnetic field microsensors.

Magnetic field microsensors could detect cracks, geometrical defects or stress concentration

zones in ferromagnetic structures using passive magnetic techniques such as Metal

Magnetic Memory (MMM). This technique relies on the self magnetization of ferromagnetic

structures by ambient magnetic fields such as the Earth’s field (Wilson et al., 2007). It

measures changes in the self magnetic leakage field of the ferromagnetic structures due to

geometrical discontinuities and high density dislocations.

New cell phones could use resonant magnetic field microsensors, accelerometers, and

gyroscopes integrated on a single chip for their global positioning system (GPS). This could

reduce the size, cost, and power consumption of the cell phones.

The important advantages of resonant magnetic field microsensors will allow their

incorporation in future commercial markets, principally into the automotive sector,

telecommunications, and consumer electronics products.

4. Conclusion

The development of resonant magnetic field microsensors based on MEMS has been

presented. These microsensors exploit the Lorentz force for measuring magnetic fields and

can use different sensing types such as: capacitive, optical, or piezoresistive. Their main

advantages are small size, com