Insulated areas

Either external boundaries

0

or symmetry axis

* formula extracted from [9]

Table 2. Thermo-physical parameters used in this work

In the vicinity of the surface sample, the temperature of the rarefied gas is close to the solid

one. To estimate the maximum heat loss from the surface,the gas temperature is here

voluntarily increased by 2K or 3K, depending on how far the heat source (BB) is located. For

the same reason, the screw cap temperature is also set at 2K over the solid surface one (fig.

5-b).

94

Microsensors

Owing to the plans of symmetry existing in the squared sample, the geometry of the

problem has been reduced at one eighth for the sake of finer meshing and fast computer

calculations. The whole boundaries conditions are summarized in table 2.

As shown in figure 6, the low temperature difference between the front and the back side of

the thin sample (Tsample), already obtained from 1D model is confirmed in a full 3D

modelling, whatever the thermal contact resistance value. Moreover, the temperature

difference in silicon sample is found approximately ten times higher than in copper , again

in good agreement with the 1D model..

One can also see on figure 6 the effect of Rctc on the delay to reach the steady state. As

expected, the lower is the thermal contact resistance; the faster the equilibrium regime is

reached. Note that the time expressed here could not be compared with the experiment one,

which strongly depends on the blackbody inertia. In simulations, the blackbody

temperature being immediately set at 373 K, the time evolution is only characteristic of the

thermal response of the system (cooled HFM with sample)

7,E-03

5,E-04

6,E-03

4,E-04

5,E-03

0,1

0,01

4,E-03

3,E-04

0,001

ple

ple

m

m

sa

3,E-03

sa

2,E-04

2,E-03

0,1

1,E-04

1,E-03

0,01

0,001

0,E+00

0,E+00

0

200

400

600

800

1000

0

200

400

600

800

1000

Time (s)

Time (s)

Fig. 6. Difference of front and back temperatures for Si (left) and Cu (right), at various

thermal contact resistances (in m2.K.W-1) obtained from full 3D- model

The front (TS) and the back (Tb) side temperatures of the sample presented in figure 7 are

strongly dependent on the thermal contact resistance. It is seen that the temperature of the

surface sample may be different from that of the cooling bath i.e. 278 K, even for weak thermal contact resistances.

320

315

310

310

305

305

0,1

300

) 300

0,1

(K

0,01

b

) 295

T 295

0,001

0,01

(KbT 290

0,001

290

285

285

280

280

275

275

0

200

400

600

800

1000

0

200

400

600

800

1000

Time (s)

Time (s)

Fig. 7. Simulation of the temperature time evolution at the back face of the sample for Si

(left) and Cu (right) for several thermal contact resistances, from full 3D- modelling

Simulated heat flux reaching the fluxmeter is plotted in figure 8. In the full 3D-

computations, the heat fluxes are calculated for a black body radiating at 373 K. One could

A Heat Flux Microsensor for Direct Measurements in Plasma Surface Interactions

95

easily notice that measured heat fluxes are close to the calculated ones. This result indicates

that thermal contact resistance values are in the range 10-3 to 10-1 m2.K.W-1, which is in good

agreement with values given in literature for solid-solid thermal contact resistances [6].

77

18

70

63

15

1

56

1,E-01

)

1

)

W 49

12

W

1,E-02

m

1,E-01

( 42

1,E-03

1,E-02

(m

9

flux

1,E-05

35

1,E-03

flux

eat

at

28

e

H

1,E-05

H

6

21

14

3

7

0

0

0

200

400

600

800

1000

0

200

400

600

800

1000

Time (s)

Time (s)

Fig. 8. Simulation of heat flux time evolution at the HFM surface for Si (left) and Cu (right)

samples, at various thermal contact resistances (in m2.K.W-1), from full 3D- modelling

It is interesting to compare heat fluxes deduced from experimental curves with those

calculated by 3D-simulations in similar conditions. This is summarized in table 3.

3D simulations for T

Samples T

BB = 373K

BB (°C)

Experiments

Rctc (m2.K.W-1) =

10-1 10-2 10-5

363K 12.5

mW

Copper

13 mW

17 mW

17.5 mW

393K 16

mW

363K 53

mW

Silicon

21 mW

63 mW

74 mW

393K 92

mW

Table 3. Comparisons of measured and 3D simulated heat fluxes (values given for saturation

states) for Cu and Si samples

2.3 Comparison with other heat flux probes

Since the 1960s many authors tested various techniques to measure the energy influx [10-

12]. Results provided by the literature most often come from calculations based on

temperature measurements [13, 14]. Among them, calorimetric probes, based on an original

idea of Thornton [10], were successfully applied to plasma science [15-18]. Some

sophisticated thermal probes have been developed [19-21], such as for example the one

designed in the IEAP Kiel, which consists of a thermocouple brazed to a metal plate

(substrate dummy). This probe has been used by Kersten et al to characterize many kinds of

low pressure plasmas used for powder generation, space propulsion, PECVD, etc [17, 21].

Nevertheless, with this kind of probes, the total energy flux is always estimated a posteriori

from thermograms recorded during the heating and cooling steps. Mathematical treatments

are then employed to estimate the heat flux, which introduce systematic deviations.

Moreover, with these kinds of probes, it is not possible to evidence transfer mechanisms of

different kinetics such as transfer by collision (instantaneous) or transfer involving a heating

step (IR emission). Detection of transient or small energetic contributions (several mWcm−2)

could not be reasonably achieved.

96

Microsensors

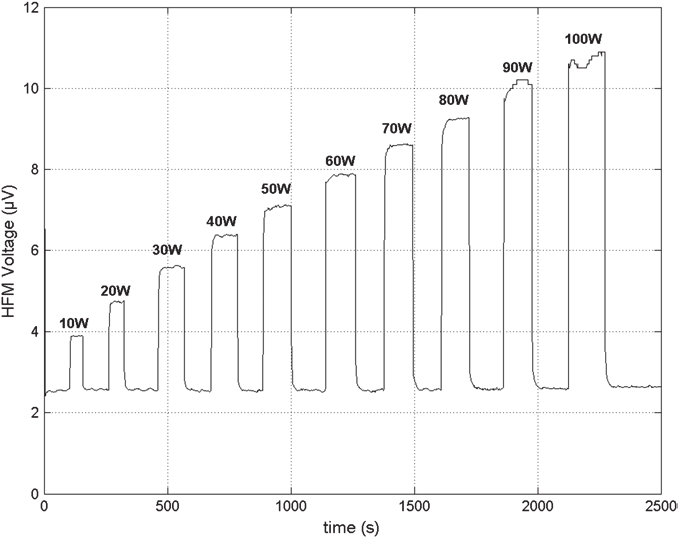

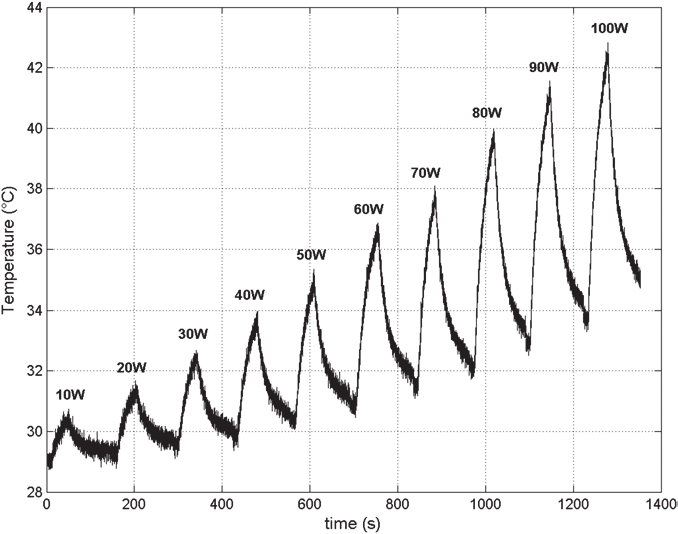

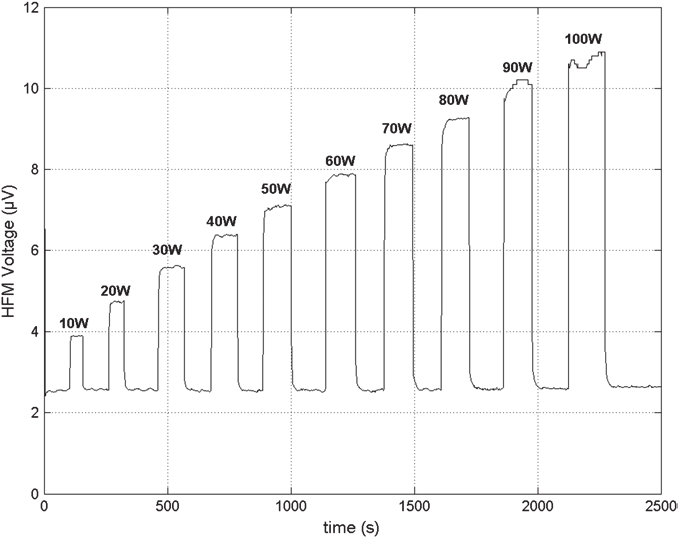

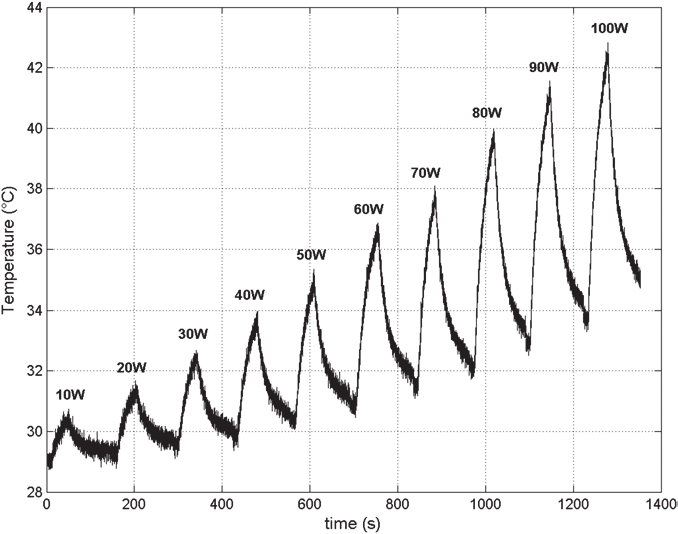

To illustrate results that can be obtained by calorimetric probes and by the HFM, typical

signals recorded in an RF argon discharge are presented in Fig. 9. Even if HFM

measurements last about 100s, it is seen on the graph that a stabiliz