(6.6)

K

cr − o

where С – specific heat capacity of concrete kJ/kg⋅K; t – maximal

cr

(critical) temperature (Celsius) of hardened concrete; К – factor

depending on conditions of concrete cooling (K≤1); t – temperature

о

(Celsius) of the fresh concrete after its finishing; ρ – concrete density,

kg/m3.

116

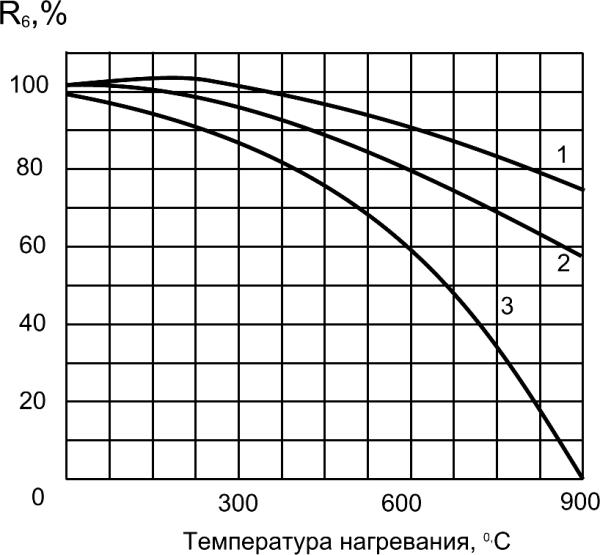

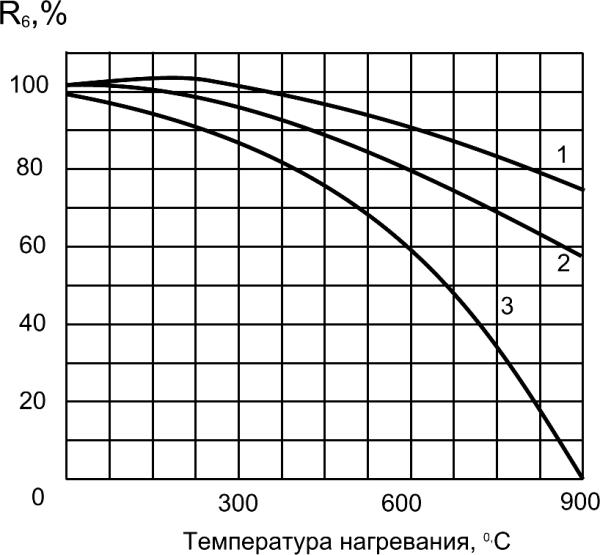

Strength, %

Intensive destructive processes

begin at heating concrete to

temperature more than 200°C.

For heat resistance increase,

finely divided mineral

admixtures can be added into

cement or concrete mixes, that

chemically react with calcium

oxide, resist to heats and

reduce shrinkage of cement

Temperature of heating, 0C

stone at heating.

Fig.6.5. Effect of temperature on strength of

concrete:

1 – Portland cement 70% + Trepel 30%;

2 – Portland cement 70% + Pumice 30%;

3 – Portland cement

117

6.3. Permeability

Permeability of concrete characterizes its ability to conduct gases and liquids at

a certain pressure difference. Permeability of concrete is defined by a factor of

permeability - the quantity of a liquid getting through unit of the area of the

specimen in unit of time at a gradient of a pressure equal 1.

In concrete there are capillaries of the various size, therefore various

mechanisms of moving of gas and liquids can simultaneously operate.

Watertightness

Two normative characteristics of watertightness are possible to use:

1. Maximal pressure of water (W, MPa) which standard specimens with height

and diameter 150 mm can sustain without water infiltration.

2. Coefficient of water filtration through a concrete defines the quantity of water

getting through unit of the area for a time unit, at a gradient of water pressure

equal 1.

The coefficient of water filtration through concrete can be used for

determination of permeability for other liquids:

(К /К) = (η/η ), (6.7)

f

w

where К and η - coefficient of permeability and viscosity of liquid different from

water; К and η - coefficient of filtration and water viscosity.

f

w

118

/sec

/sec

, cm1

, cm

-1

-12

⋅10

⋅10

K f

K f

on

on

ltrati fi

filtrati

t of

t ofenci

oefficienC

oeffiC

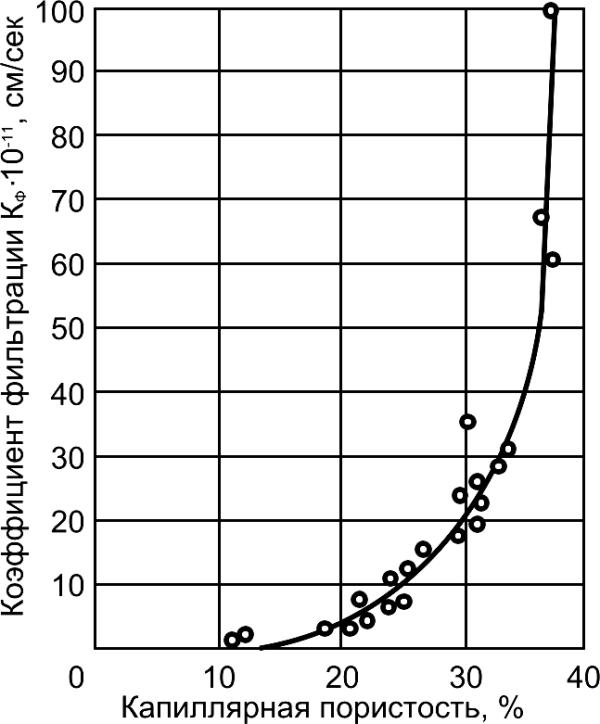

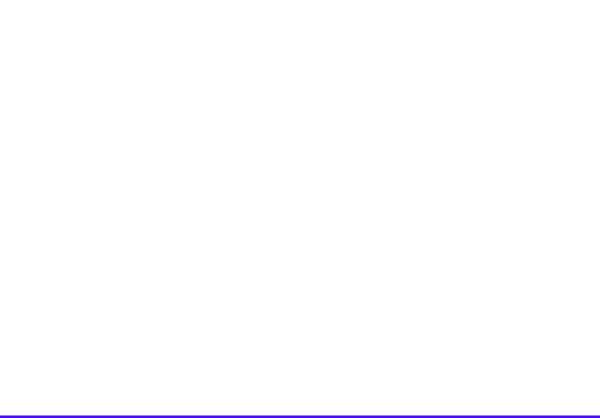

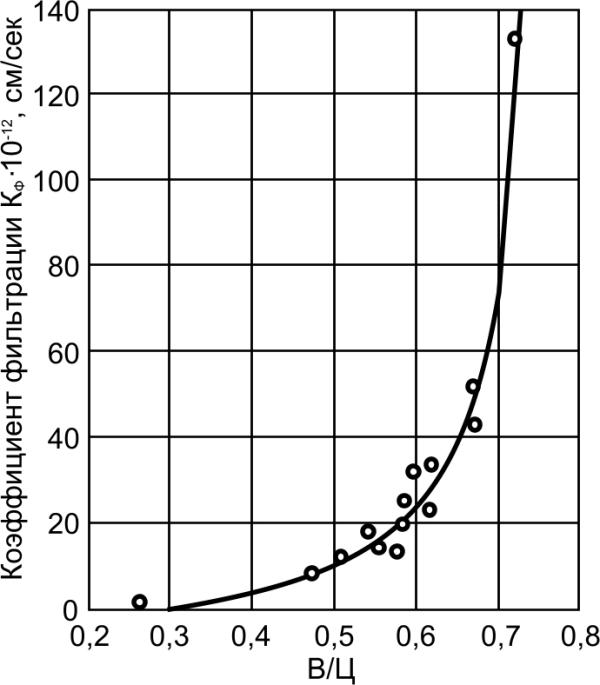

Capillary porosity, %

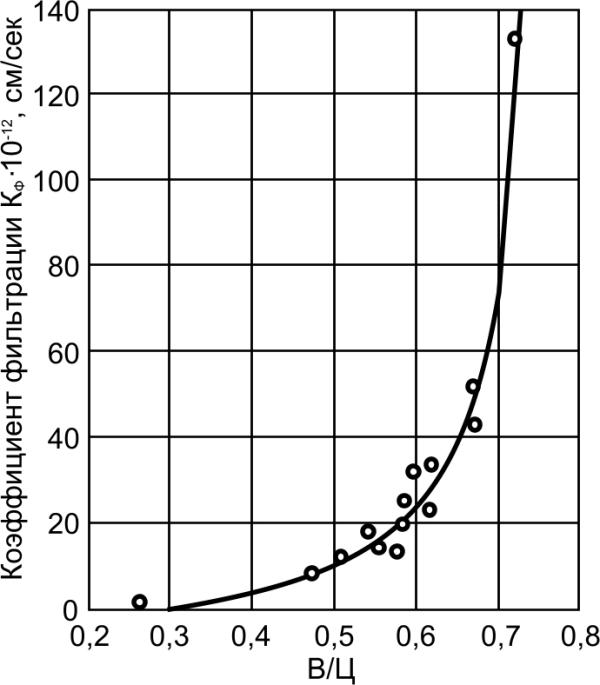

Water-cement ratio

Fig.6.6. Relationship between

Fig.6.7. Relationship between

permeability and capillary porosity of

permeability and water-cement ratio of

the cement stone

the cement stone

119

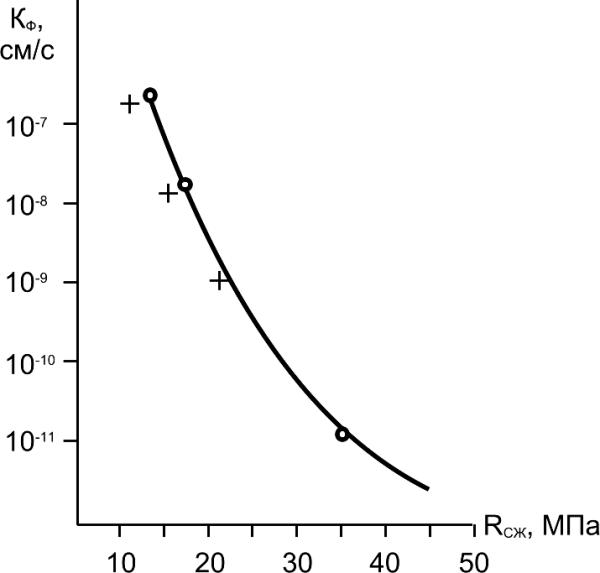

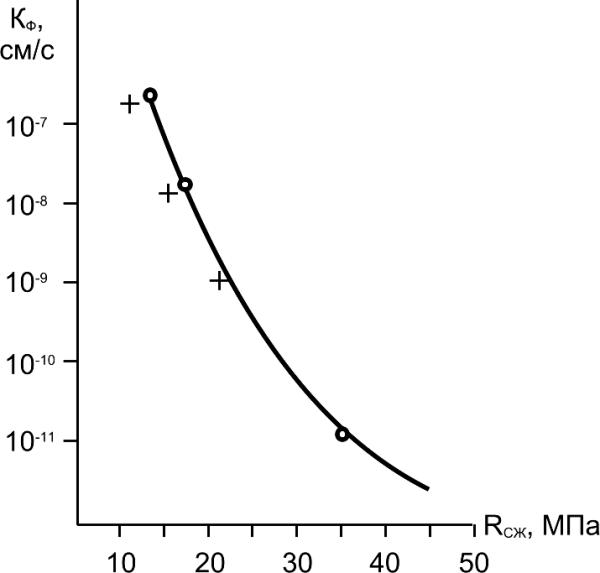

As it is experimentally shown, relationship between coefficient of concrete

filtration (K ) and its compressive strength (R

) is defined as:

f

cmp

К

К

R m

, (6.8)

f =

w

cmp

Kf,

cm/sec

where К and m - factors which values

w

are determined by features of concrete

mixtures, conditions and duration of

hardening, etc.

Effective way of decreasing of concrete

permeability is adding organic or

inorganic admixtures into concrete mix.

R

As organic materials apply surfacecmp, MPa

active and polymeric admixtures .

Fig. 6.8. Relationship between coefficient

Inorganic materials for decrease of

of filtration of concrete (Kf) and

permeability are presented by various

compressive strength (Rcmp):

"+" – From Elbakidze,

salts, clays and active mineral

"ο"–Our experimental data

admixtures (pozzolans).

)

120

After producing concrete's constructions, decrease in its permeability can be

reached by processing of concrete surface by waterproof substances and the

substances chemically reacting with minerals of cement stone with formation of

insoluble compounds or covering surface by protective materials.

6.4. Corrosion resistance

Degree of aggressive effect of an environment is defined by its chemical

composition and a complex of the factors describing conditions of contact of

environment and concrete.

Cement stone consists of alkaline chemical compounds, therefore the most

intensive corrosion of concrete occurs at influence of the environment

containing water solutions of acids on it. Salts, inorganic and organic

substances can be also aggressive to concrete.

The degree of aggressive influence of liquids depends on concentration of

hydrogen ions (pH), amount of carbonic acid (CO ), salts, caustic alkalis,

2

sulfates. Oils and solvents also are aggressive liquids.

121

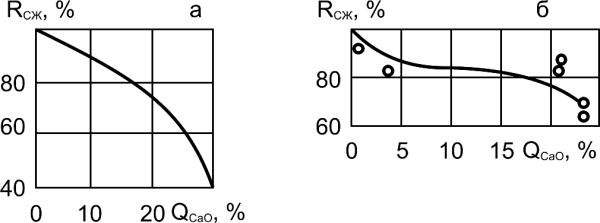

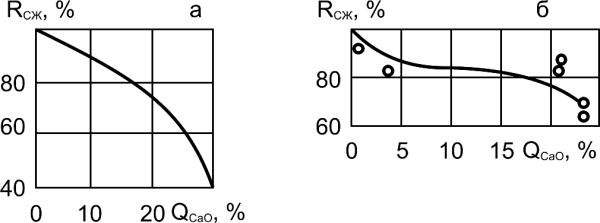

Rcmp, %

A

Rcmp, %

B

QCaO, %

QCaO, %

Рис. 6.10. Effect of dissolution of calcium hydroxide on

compressive strength of cement stone (A) and concrete (B):

QCaO - Amount of dissolved calcium hydroxide, %;

Rcmp – Compressive strength of cement stone and concrete, %

From Moskvin classification, dissolution processes of lime and its washing

away from concrete concern to corrosion of first type.

122

Corrosion of the second type is caused by chemical reactions between the

products of hydration of cement and acids or salts which affect concrete.

Calcium salts of usually well water-soluble appear as a result of action of acids.

Corrosion of the second type is also caused by magnesium salts, often

presents in large amount in underground and sea water (15.5...18% from total

salts content). At magnesia corrosion appears amorphous mass of Mg(OH)2

decreasing strength of concrete along with soluble salts.

Corrosion of the third type develops in concrete from internal stress due to

accumulation of insoluble salts in the capillaries of concrete.

The most widespread corrosion of this type is sulfate corrosion which takes

place in cement stone under action of ions.

2−

SO 4

123

Ettringite appears in the cement stone under the action of sulfate water:

СаО

3

⋅ Al O ⋅ 6Н О

2

3

2

+ (

3 СаSO ⋅ 2H O

4

2 ) + 19H О

2

=

СаО

3

⋅ Al O ⋅ Са

3 SO ⋅ H

31

O

2

3

4

2

Volume expansion and concrete destruction are often caused by

ettringite formation.

Active mineral admixtures (pozzolans) essentially increase sulfate

resistance due to chemical reaction with calcium hydroxide.

2−

Water containing more than 1000 mg/Litre ions SO4

cause mainly gypsum corrosion due to accumulation of gypsum in

capillaries of the cement stone.

Destructions of concrete under influence of vegetative and animal

organisms are called biological damages.

124

Durability of concrete in the terms of influence of aggressive environment is

provided by application of concrete with a high density, by use initial components

with the proper chemical composition and application at a necessity the special

measures of concrete's defense (application of isolating materials, admixtures

etc.).

Special kind of the aggressive environment for concrete is ionizing radiation.

Structures of nuclear reactors are exposed to the greatest degree ionizing

radiation. Ability of concrete to keep their properties after radiation action is

called radiating resistance.

125